Sourcing 4 inch fiberglass angle from local suppliers offers numerous advantages, including faster delivery times, reduced shipping costs, and the ability to inspect the product before purchase. Purchasing from nearby manufacturers or distributors ensures that you receive high-quality materials while supporting local businesses. When looking for a reliable supplier of 4 inch fiberglass angle, it’s important to verify their reputation through customer reviews and industry certifications. Companies like GangLong Fiberglass offer dependable products that meet industry standards, ensuring long-lasting performance. Additionally, local suppliers may provide personalized customer service and offer flexible options for custom orders or bulk purchases, making them an ideal choice for your project needs. The 4 inch fiberglass angle is lightweight, durable, corrosion-resistant, and ideal for structural use, surpassing steel and aluminum in harsh conditions.

Common Uses of 4 Inch Fiberglass Angle

The 4 inch fiberglass angle is a versatile and durable structural component used across many industries due to its strength, lightweight nature, and corrosion resistance. Fiberglass angles are commonly chosen for projects that require materials capable of withstanding harsh environments without degrading. Their ability to resist moisture, chemicals, and UV radiation makes them particularly valuable in marine, industrial, and infrastructure applications.

Architectural and Structural Applications for 4 Inch Fiberglass Angle

In architectural projects, 4 inch fiberglass angle serves as an essential support structure for a variety of building designs. It is frequently used for framing windows, doors, and roof structures, as well as providing support for outdoor awnings and decks. Fiberglass angles are especially popular in modern architectural projects where the materials need to be both aesthetically pleasing and functional. The angles can be easily painted or coated to match the desired design aesthetic, while still maintaining their structural integrity.

Fiberglass angles are also commonly found in structural applications where strength and lightweight characteristics are essential. These angles can support significant loads without adding unnecessary weight to the overall structure, making them ideal for use in bridges, industrial platforms, and walkways. The high strength-to-weight ratio of the 4 inch fiberglass angle allows architects and engineers to create innovative designs without compromising safety or stability.

Industrial Applications of 4 Inch Fiberglass Angle

Fiberglass angles are widely used in industrial settings due to their ability to withstand extreme conditions. Unlike traditional materials like steel or aluminum, fiberglass does not corrode when exposed to moisture, chemicals, or saltwater. This makes the 4 inch fiberglass angle an excellent choice for factories, chemical plants, and manufacturing facilities, where it may come into contact with corrosive substances.

In addition to its corrosion resistance, fiberglass is non-conductive, which makes it a safe material to use in environments where electrical hazards are a concern. The 4 inch fiberglass angle is commonly used in electrical enclosures, cable tray management systems, and support structures in areas where electricity is present. Its non-conductive nature ensures that workers are protected from potential electrical accidents, while the material itself remains intact over time.

Fiberglass angles are also resistant to heat and fire, which further increases their suitability for industrial applications. This makes them an excellent choice for areas where high temperatures are present, such as in power plants or chemical processing facilities. The 4 inch fiberglass angle can maintain its strength and shape even under intense heat, making it a reliable option for heavy-duty industrial use.

Marine Applications of 4 Inch Fiberglass Angle

Marine environments are some of the harshest conditions for construction materials due to the constant exposure to saltwater, humidity, and UV radiation. Fiberglass, however, is well-suited for marine applications because it resists corrosion, does not absorb water, and maintains its structural integrity in both fresh and saltwater environments. The 4 inch fiberglass angle is a common component in boat construction, dock installations, and marine infrastructure projects.

In boatbuilding, fiberglass angles are used to reinforce hulls, decks, and other structural components. Since fiberglass is lightweight, it does not weigh the vessel down, which is crucial for maintaining fuel efficiency and maneuverability in the water. Additionally, the 4 inch fiberglass angle offers strength and flexibility, allowing it to withstand the constant movement and stress that comes with marine applications.

On docks and piers, fiberglass angles provide a sturdy yet lightweight framework that resists the effects of water and sunlight. Whether used for handrails, walkways, or structural supports, the 4 inch fiberglass angle ensures long-term durability without the need for frequent maintenance or repairs. This reduces costs for marina operators and extends the lifespan of the infrastructure.

Infrastructure Projects Using 4 Inch Fiberglass Angle

Fiberglass angles are also becoming more popular in infrastructure projects, particularly in areas where traditional materials would quickly deteriorate. The 4 inch fiberglass angle is used in bridge construction, highway barriers, and drainage systems due to its ability to withstand environmental exposure without corroding or losing strength.

For bridges, fiberglass angles provide structural fiberglass support columns while minimizing the overall weight of the bridge. This is particularly beneficial in pedestrian bridges, where the lightweight nature of fiberglass allows for more flexibility in design without compromising safety. Additionally, the 4 inch fiberglass angle offers a level of corrosion resistance that makes it ideal for use in environments prone to heavy rainfall or flooding.

In drainage systems, fiberglass angles help direct water flow and provide structural support for water channels. Since the material is non-corrosive, it can withstand constant exposure to water without the need for frequent replacements. The longevity and durability of the 4 inch fiberglass angle make it a cost-effective option for infrastructure projects that require reliable materials over the long term.

Chemical Plants and Wastewater Treatment Facilities

In environments where exposure to harsh chemicals or corrosive substances is a concern, the 4 inch fiberglass angle is ideal for providing structural support. Its resistance to chemical degradation makes it a popular choice in these industries.

Electrical Applications

Fiberglass’s insulating properties make it a suitable material for electrical applications. The 4 inch fiberglass angle can be used in enclosures, supports, and brackets that need to maintain electrical isolation.

Fiberglass is non-conductive, making it an excellent choice for electrical and telecommunications infrastructure. The 4 inch fiberglass angle can be used to support electrical conduit, frp cable tray, and other components that must remain isolated from electrical currents. Its non-conductive properties also make it safer for use in high-voltage environments.

Choosing and Using 4 Inch Fiberglass Angle

Many successful projects have incorporated 4 inch fiberglass angle due to its reliability, strength, and versatility. One notable example is the use of fiberglass angles in the construction of a pedestrian bridge in a coastal city. The local government needed a material that could withstand the salty ocean air and high humidity, while also supporting the weight of the bridge and its users. The 4 inch fiberglass angle was chosen for its corrosion resistance and lightweight properties, making the bridge both durable and easy to maintain.

Another example involves the use of 4 inch fiberglass angle in an industrial chemical plant. The plant needed a material that could support heavy equipment and withstand exposure to various chemicals. After considering several options, the engineers selected fiberglass due to its high strength-to-weight ratio and resistance to corrosion. The plant has since experienced fewer maintenance issues and reduced downtime, thanks to the durability of the fiberglass angles.

In a marine setting, a yacht manufacturer selected 4 inch fiberglass angle for reinforcing the hulls of their luxury boats. The lightweight yet strong nature of the fiberglass angle allowed the manufacturer to create vessels that were both fuel-efficient and able to withstand the harsh marine environment. Customers reported increased satisfaction with the performance and longevity of the boats, thanks to the use of high-quality fiberglass materials.

The Key of Choosing a 4 Inch Fiberglass Angle

Selecting the right 4 inch fiberglass angle is crucial for ensuring that it meets the specific demands of your project. One of the main reasons to choose fiberglass over other materials is its resistance to environmental factors, which makes it a long-lasting solution for many structural needs.

Fiberglass is not only lightweight but also has an impressive strength-to-weight ratio, meaning it can support significant loads without adding unnecessary bulk to the structure. This is particularly useful in applications where weight reduction is essential, such as in marine or aerospace projects. Additionally, fiberglass is resistant to corrosion, making it a great choice for environments where traditional materials like steel might degrade due to moisture or chemical exposure.

Another important consideration when choosing a 4 inch fiberglass angle is its ease of customization. Fiberglass can be cut, shaped, and molded to fit specific project requirements, which makes it highly adaptable. GangLong Fiberglass offers customizable options, ensuring that the fiberglass angles are cut to your precise specifications, providing both structural integrity and flexibility.

Benefits of Using a 4 Inch Fiberglass Angle

There are several advantages to using a 4 inch fiberglass angle in various applications, each contributing to its growing popularity in multiple industries.

- Strength and Durability: Despite its lightweight nature, a 4 inch fiberglass angle offers exceptional strength and can support substantial loads. This makes it a reliable component in both structural and non-structural projects where stability is key.

- Corrosion Resistance: One of the most significant benefits of a 4 inch fiberglass angle is its ability to resist corrosion. Unlike metals such as steel and aluminum, fiberglass is impervious to moisture, chemicals, and saltwater. This makes it an excellent choice for outdoor projects or industries where exposure to corrosive substances is unavoidable.

- Low Maintenance: Once installed, a 4 inch fiberglass angle requires very little maintenance compared to traditional materials. It does not rust, rot, or degrade over time, which reduces the need for frequent inspections, repairs, or replacements.

- Thermal and Electrical Insulation: Fiberglass is a natural insulator, both thermally and electrically. This makes the 4 inch fiberglass angle ideal for use in environments where electrical conductivity or heat transfer could pose a risk. It can be used in electrical enclosures or around sensitive equipment without the risk of short circuits or overheating.

- Lightweight: A 4 inch fiberglass angle is significantly lighter than its metal counterparts, making it easier to handle, transport, and install. This can reduce labor costs and improve efficiency, particularly in large-scale construction projects.

- Flexibility and Customization: Fiberglass is easy to fabricate and mold into various shapes and sizes, offering a high degree of customization. This flexibility allows the 4 inch fiberglass angle to be tailored to fit specific project requirements.

How about Installing a 4 Inch Fiberglass Angle?

The installation process for a 4 inch fiberglass angle is relatively straightforward and requires standard tools. However, there are several key steps to follow to ensure the proper installation and performance of the angle.

- Cutting the Fiberglass Angle: Fiberglass angles can be easily cut to the desired length using standard cutting tools such as an angle grinder with a concrete angle grinder wheel cutting fiberglass or a circular saw with a carbide-tipped blade. When cutting fiberglass, it’s important to wear protective equipment such as gloves, goggles, and a dust mask, as fiberglass dust can cause irritation to the skin and respiratory system.

- Drilling and Fastening: Fiberglass angles can be drilled using carbide-tipped bits, and holes should be drilled slowly to avoid cracking the material. Fastening the 4 inch fiberglass angle to other surfaces can be done using standard bolts, screws, or adhesive, depending on the project’s needs. It is recommended to use corrosion-resistant fasteners to match the durability of the fiberglass.

- Surface Preparation: Before installation, it is important to clean and prepare the surfaces that will come into contact with the fiberglass angle. Removing dirt, dust, and grease ensures a stronger bond and a more secure installation.

- Sealing Joints: When installing a 4 inch fiberglass angle in environments where moisture or chemicals are present, sealing the joints with an appropriate sealant or adhesive is crucial. This step helps maintain the material’s integrity and prevents leaks or corrosion.

Maintenance Tips for 4 Inch Fiberglass Angle

Although fiberglass requires minimal maintenance, it’s important to conduct routine inspections and cleaning to ensure longevity and optimal performance.

- Regular Inspection: Periodically inspect the 4 inch fiberglass angle for any signs of damage, wear, or stress, particularly in high-traffic areas or environments exposed to extreme conditions. If any cracks or chips are detected, repairs should be made promptly to avoid further damage.

- Cleaning: Cleaning the fiberglass angle is easy and requires only mild soap and water. Avoid using abrasive cleaners that could scratch the surface or weaken the protective resin. If the fiberglass is exposed to chemicals or saltwater, it is recommended to rinse the angle with fresh water to prevent buildup.

- Repairing Minor Damage: Fiberglass is highly durable, but if minor damage occurs, such as surface chips or cracks, it can be repaired using fiberglass repair kits. These kits contain resin and hardener to restore the strength of the damaged area.

- Avoiding Overloading: Although fiberglass angles are strong, it’s important to avoid overloading the structure beyond its capacity. Ensure that the 4 inch fiberglass angle is used within its load-bearing limits to prevent stress or failure.

What are the Challenges of Using a 4 Inch Fiberglass Angle?

While a 4 inch fiberglass angle offers numerous advantages, there are some challenges to consider when working with this material.

- Dust and Safety Concerns: Cutting or sanding fiberglass generates dust that can be harmful if inhaled or comes into contact with the skin. Always wear proper protective gear and work in a well-ventilated area to minimize exposure.

- Initial Cost: Fiberglass can be more expensive than traditional materials like wood or metal. However, the long-term benefits, such as lower maintenance costs and a longer lifespan, often offset the initial investment.

- UV Degradation: Although fiberglass is resistant to most environmental factors, prolonged exposure to UV rays can cause some degradation over time. To mitigate this, UV-resistant coatings or paints can be applied to the 4 inch fiberglass angle to enhance its durability in outdoor applications.

GangLong Fiberglass offers a wide range of high-quality 4 inch fiberglass angles that are designed to withstand harsh environmental conditions while providing excellent structural support. Whether you’re working on a marine project, industrial construction, or electrical installation, the versatility and durability of fiberglass make it a smart choice for long-lasting performance.

How Fiberglass Tie Beams Improve Structural Stability and Safety

The Key of Fiberglass Angle Construction

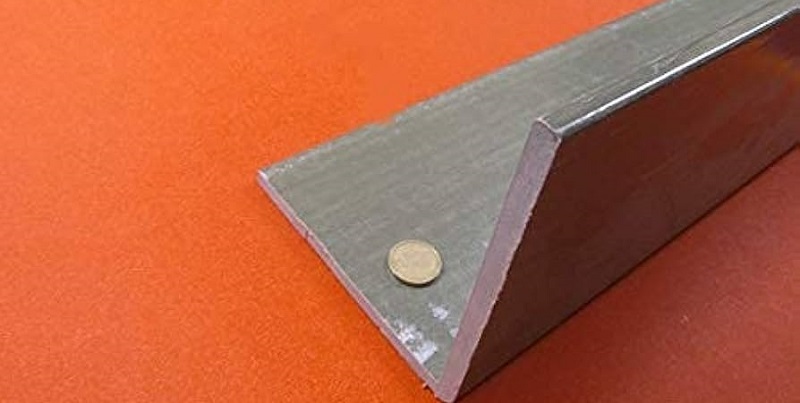

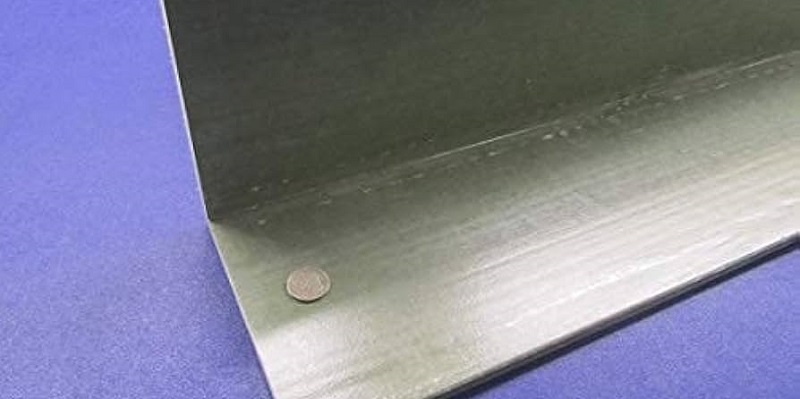

Fiberglass angles, including the 4 inch fiberglass angle, are composed of a matrix of fiberglass strands embedded in a resin. This combination of materials results in a product that is lightweight, yet incredibly strong and resilient. The resin used in fiberglass production acts as a binder, holding the hollow glass fibers together and providing a protective layer against environmental factors such as moisture, chemicals, and UV radiation. This makes fiberglass angles ideal for outdoor use, especially in environments where traditional materials would corrode or weaken over time.

The 4 inch fiberglass angle is typically produced through a process known as pultrusion. During this process, continuous strands of fiberglass are pulled through a resin bath and then shaped into the desired form. The result is a product that is uniform in thickness and dimensions, ensuring consistent strength and performance across all applications. GangLong Fiberglass uses advanced pultrusion techniques to manufacture angles that meet stringent quality standards, ensuring durability and reliability in any project.

Strength and Durability of a 4 Inch Fiberglass Angle

The strength of a 4 inch fiberglass angle is one of its key benefits, especially when compared to other materials like wood, steel, or aluminum. Fiberglass angles are designed to withstand heavy loads without bending or breaking, making them suitable for structural support in buildings, bridges, and industrial platforms. Additionally, fiberglass maintains its strength even when exposed to high temperatures, moisture, or corrosive chemicals, which can weaken traditional materials over time.

Durability is another significant advantage of the 4 inch fiberglass angle. Because fiberglass is non-conductive and resistant to rust and corrosion, it is an excellent choice for projects that require long-lasting materials. This makes it particularly well-suited for marine environments, where constant exposure to saltwater and humidity would degrade other materials. Fiberglass angles from GangLong Fiberglass are specifically designed to withstand these harsh conditions, providing years of reliable service without the need for extensive maintenance.

How about Comparing Fiberglass Angle with Aluminum Angle?

When comparing a 4 inch fiberglass angle with an aluminum angle, several key differences emerge in terms of strength, durability, and corrosion resistance. While both materials are lightweight and commonly used in construction and industrial projects, fiberglass offers distinct advantages in specific applications.

- Corrosion Resistance: Fiberglass is inherently resistant to corrosion, making it a better choice for environments where exposure to moisture, chemicals, or saltwater is common. Aluminum, while more corrosion-resistant than steel, can still corrode over time, especially in highly corrosive environments. In marine applications or chemical plants, a 4 inch fiberglass angle would outperform aluminum in terms of longevity and resistance to environmental degradation.

- Non-Conductivity: One of the most significant advantages of fiberglass over aluminum is its non-conductive nature. Fiberglass does not conduct electricity, making it a safer option for use in electrical and telecommunications applications. Aluminum, on the other hand, is highly conductive, which limits its use in environments where electrical insulation is required.

- Strength-to-Weight Ratio: Both fiberglass and aluminum are lightweight materials, but fiberglass angles tend to have a higher strength-to-weight ratio. This means that a 4 inch fiberglass angle can support more weight without adding significant bulk to the structure, making it ideal for applications where weight reduction is a priority, such as in marine or aerospace projects.

- Maintenance Requirements: Fiberglass angles require far less maintenance than aluminum, particularly in outdoor or industrial environments. Aluminum may need to be treated or coated to prevent corrosion, and it can become damaged by scratches or dents. Fiberglass, by contrast, maintains its structural integrity without the need for protective coatings or regular upkeep. This makes a 4 inch fiberglass angle a more cost-effective option over the long term, especially in environments where materials are exposed to harsh conditions.

Exploring Key Jointing Systems and Essential FRP Pipe Data

Precautions When Using the 4-Inch Fiberglass Angle

Proper handling and usage of the 4-inch fiberglass angle are essential to maximize its performance and longevity.

Below are detailed precautions to follow during its use:

Handling and Storage

- Precautions:

- Avoid dropping or applying excessive impact to the fiberglass angle, as this can cause microcracks or surface damage.

- Store in a dry, shaded area to prevent prolonged UV exposure, which may degrade the material over time.

- Use padded supports during transportation to avoid scratches or deformations.

Cutting and Drilling

- Precautions:

- Use appropriate tools, such as carbide-tipped saw blades or drill bits, designed for composite materials.

- Wear personal protective equipment (PPE), including safety goggles, gloves, and a mask, to protect against fiberglass dust.

- Secure the angle firmly during cutting or drilling to ensure precise work and prevent splintering.

Installation

- Precautions:

- Ensure proper alignment and load distribution to avoid overstressing the fiberglass angle.

- Use corrosion-resistant fasteners, such as stainless steel or composite screws, to maintain the angle’s durability in corrosive environments.

- Avoid using adhesives or sealants incompatible with fiberglass, as they may weaken the bond or damage the material.

Environmental Considerations

- Precautions:

- Protect the angle from prolonged exposure to direct sunlight by applying UV-resistant coatings if used outdoors.

- Verify the material’s compatibility with chemicals if installed in highly corrosive environments, such as industrial or marine applications.

- Monitor temperature conditions, as excessive heat can reduce the structural integrity of fiberglass.

Maintenance and Inspection

- Precautions:

- Inspect the angle periodically for cracks, delamination, or other signs of wear.

- Clean the surface using mild soap and water to prevent buildup of debris or chemicals.

- Address any damage promptly to maintain the structural performance of the angle.

By adhering to these precautions, you can ensure the 4-inch fiberglass angle maintains its strength, durability, and functionality across various applications.

Other Sizes of Fiberglass Angles and Differences from 4-Inch Fiberglass Angle

Fiberglass angles are available in various sizes and specifications to accommodate different structural and industrial needs. Understanding the options and their differences from the 4-inch fiberglass angle can help you choose the right size for your application.

Common Sizes and Specifications

- 2-Inch Fiberglass Angle: Smaller and lighter, suitable for applications with lower load requirements or limited space, such as framing or brackets.

- 3-Inch Fiberglass Angle: A mid-range size offering a balance of strength and weight, often used in moderate load-bearing structures.

- 6-Inch Fiberglass Angle: Larger and stronger, ideal for heavy-duty applications like industrial frameworks or large-scale construction.

- Custom Sizes: Many manufacturers offer custom dimensions and thicknesses to meet specific project needs.

Each size is typically available in varying thicknesses, such as 1/4-inch, 3/8-inch, or 1/2-inch, which influence the angle’s strength and rigidity.

Differences Between 4-Inch Fiberglass Angle and Other Sizes

- Load Capacity: Larger sizes, like 6-inch angles, can bear significantly higher loads compared to the 4-inch fiberglass angle, making them better suited for heavy-duty projects. Smaller sizes, like 2-inch or 3-inch angles, are less load-bearing but more versatile for lightweight structures.

- Weight: Smaller angles are lighter and easier to handle, whereas larger ones are heavier but provide increased structural support. The 4-inch angle strikes a balance between these extremes.

- Applications:

- 2- and 3-Inch Angles: Common in small-scale projects like residential structures, framing, and decorative elements.

- 4-Inch Angle: Suitable for medium-duty applications, offering a good mix of strength and versatility.

- 6-Inch Angle: Used in industrial settings, marine applications, and large-scale construction where maximum strength is required.

- Cost: Smaller angles are generally less expensive due to lower material requirements, while larger sizes like 6-inch angles are costlier due to increased material and manufacturing demands.

Choosing the Right Size

- Assess the specific load-bearing requirements and environmental conditions of your project.

- Consider the space available for installation and the ease of handling.

- Factor in the cost and determine the most efficient size and thickness for your budget and needs.

Fiberglass angles, including the 4-inch fiberglass angle, come in a variety of sizes to suit a wide range of applications. Selecting the right specification ensures optimal performance and cost-effectiveness for your project.

Fiberglass Reinforced Glue Laminated Beams in Architecture

FAQs about 4 Inch Fiberglass Angle

FRP (Fiberglass Reinforced Plastic) angles are structural components made from composite materials, designed to provide strength, support, and durability in construction projects. The term “FRP angle” refers to the L-shaped profile of these components, commonly used in frameworks, bracing, and reinforcement applications. FRP angles are preferred in many industries due to their lightweight nature, corrosion resistance, and high strength-to-weight ratio, making them suitable for environments exposed to moisture, chemicals, or extreme weather conditions.

FRP angles are commonly used in marine applications, industrial settings, and infrastructure projects where traditional materials like steel or aluminum may corrode or degrade over time. The non-conductive and non-magnetic properties of FRP make it ideal for electrical installations or environments where electromagnetic interference is a concern.

The R-value of a material measures its resistance to heat flow, which is an important factor in insulation performance. For 4-inch fiberglass insulation, the R-value typically ranges between R-13 and R-15, depending on the specific type of fiberglass used and its density. Fiberglass is one of the most commonly used insulation materials because of its effectiveness in slowing the transfer of heat, which helps keep buildings warm in winter and cool in summer.

The higher the R-value, the greater the insulation’s ability to resist heat transfer, meaning it provides better insulation. The R-value of 4-inch fiberglass insulation is ideal for use in walls, attics, and other spaces where standard insulation thickness is required. GangLong Fiberglass provides high-quality insulation products with optimal R-values to suit a variety of residential and commercial needs. It is important to choose the correct R-value for your project based on your local climate and the building’s specific insulation requirements.

By selecting the right R-value, you can improve energy efficiency and reduce heating and cooling costs, contributing to a more comfortable and energy-efficient home or building.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.