FRP pipe insulation is essential for plumbing pipes because it provides protection against temperature fluctuations, corrosion, and environmental damage. By insulating plumbing systems, FRP helps maintain consistent temperatures, reducing the risk of freezing in cold climates and minimizing heat loss in hot water systems. FRP pipe insulation also acts as a barrier against corrosion, which is particularly important for pipes exposed to moisture or chemicals. This insulation helps extend the life of plumbing systems by preventing deterioration and reducing maintenance needs. Overall, frp pipe insulation is a vital component for ensuring the long-term durability and efficiency of plumbing systems in both residential and industrial applications. FRP pipe insulation reduces heat loss, improves water heater efficiency, and extends system life for hot and cold pipes in commercial and industrial settings.

Simplifying Your Life: Key Functionalities

| Place of Origin | Hebei, China |

|---|---|

| Brand Name | GangLong Fiberglass |

| Product Name | FRP Pipe |

| Material | Fiberglass Reinforced Plastic |

| Technology | Pultrusion |

| Surface Treatment | Smooth Paint or Customer Requirement |

| Processing Services | Molding, Cutting |

| Color | Customized Color |

| Shape | Customized Shape |

| Size | Customized Size |

| Thickness | Customized Thickness |

| Length | Customized Length |

| Density | ≥2.2 g/cm3 |

| Water Absorption | <0.05% |

| Fiber Content | >80% |

| Temperature | 150℃-180℃ |

| OEM | OEM Accepted |

| Features | High Strength, Corrosion Resistance, Dielectric Properties |

| Certificate | ISO9001 |

| Type | Manufacturer |

| Port | All Major Ports |

| Packing Details | As per Customer Requirements |

| Sales Unit | Single Item |

The Key of FRP Pipe Insulation

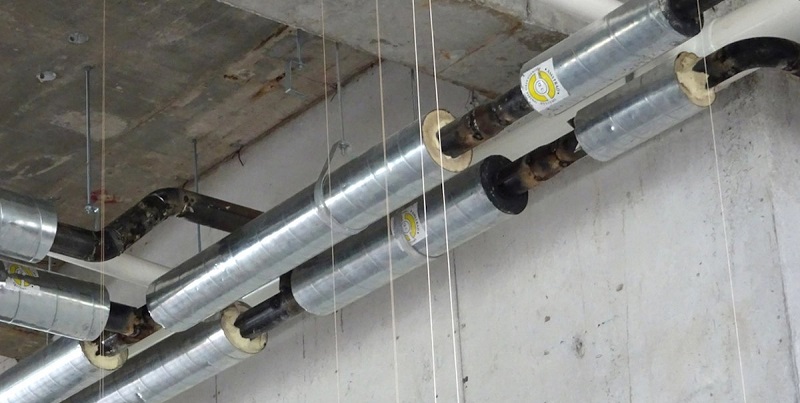

FRP (Fiberglass Reinforced Plastic) pipe insulation plays a crucial role in enhancing the performance of industrial piping systems. By insulating FRP pipes, industries can maintain the efficiency and longevity of their piping systems, preventing temperature fluctuations and ensuring consistent fluid flow. FRP pipe insulation involves applying insulating materials around the pipes to reduce thermal conductivity, making it essential in applications where temperature regulation is critical. From improving energy efficiency to protecting against external environmental factors, frp pipe insulation provides multiple advantages that benefit a variety of industries, including oil and gas, water treatment, and chemical processing.

The Benefits of FRP Pipe Insulation for Heating, Cooling & Ventilation

One of the primary reasons industries invest in frp pipe insulation is its ability to regulate temperatures in heating, cooling, and ventilation systems. By insulating pipes, industries can prevent heat loss when transporting hot fluids and minimize heat gain when transporting cold fluids. This not only ensures that the fluid maintains a stable temperature from point A to point B but also reduces the energy required to maintain that temperature. In heating systems, frp pipe insulation helps to retain heat, improving overall energy efficiency and lowering operational costs. For cooling systems, the insulation prevents the absorption of external heat, keeping fluids at their intended lower temperatures.

FRP pipe insulation also protects pipes in ventilation systems, where consistent airflow is vital to maintaining a controlled environment. Insulated FRP pipes has FRP pipe temperature limits help regulate the air temperature being distributed throughout a building or facility, whether for cooling or heating purposes, ensuring that HVAC systems operate efficiently without excessive energy use.

Enhancing Energy Efficiency with FRP Pipe Insulation

Energy conservation is one of the key benefits of frp pipe insulation, especially in large industrial settings where energy usage is a major operational expense. Uninsulated pipes allow heat to escape, which means that more energy is needed to maintain the desired temperature for transported fluids. This increased energy consumption leads to higher costs and reduced system efficiency.

By insulating FRP pipes, industries can greatly reduce energy loss, allowing systems to run at optimal performance levels while using less power. The insulation acts as a barrier, preventing heat transfer between the fluid inside the pipe and the surrounding environment. This energy efficiency is particularly beneficial in industries such as oil and gas, chemical processing, and food manufacturing, where temperature-sensitive materials are frequently transported through long pipe networks.

In addition to conserving energy, frp pipe insulation reduces the strain on heating and cooling equipment. Since less energy is required to maintain fluid temperatures, the equipment doesn’t need to work as hard, which can extend its life and reduce the need for frequent repairs or replacements. The investment in high-quality insulation materials can pay off in the long run with significant energy savings and reduced operational costs.

Protection from External Environmental Factors

FRP pipes are known for their durability and corrosion resistance, but in many environments, they are still exposed to various external factors that can affect their performance. Insulating FRP pipes provides an additional FRP pipe shields, shielding them from environmental stressors such as extreme temperatures, moisture, and UV radiation. This added protection is especially important in outdoor installations, where pipes are exposed to the elements and may degrade more quickly without insulation.

In regions with cold climates, frp pipe insulation can protect pipes from freezing, which can lead to cracks or other damage. By insulating the pipes, industries can ensure that fluids continue to flow, even in freezing temperatures, and avoid the costly repairs and downtime associated with burst pipes. Similarly, in hot climates, insulation prevents the pipe from absorbing excess heat, which could raise the temperature of the fluid and compromise system performance.

For industries that handle corrosive or hazardous chemicals, the added protection provided by frp pipe insulation helps prevent chemical reactions with external contaminants. This is particularly important in chemical plants, where the integrity of the piping system is critical to the safe and efficient transport of materials.

Durability and Extended Lifespan of Insulated FRP Pipes

Another significant benefit of frp pipe insulation is the increased durability and extended lifespan of the pipes. While FRP pipes are already known for their long-lasting performance, adding insulation can further enhance their resilience to environmental and mechanical stressors. Insulated pipes are less susceptible to wear and tear from temperature fluctuations, which can cause expansion and contraction, leading to material fatigue over time.

By reducing the exposure of FRP pipes to extreme conditions, insulation helps preserve their structural integrity, reducing the need for frequent maintenance or replacement. This makes frp pipe insulation a cost-effective solution, as it not only improves energy efficiency but also minimizes long-term repair and replacement costs. GangLong Fiberglass offers a variety of insulation options that are specifically designed to complement their FRP pipes, ensuring that the insulation materials are compatible and provide maximum protection.

Proper maintenance is essential to ensure that frp pipe insulation continues to provide the benefits of energy efficiency and protection over time. Regular inspections should be carried out to check for any damage, wear, or deterioration in the insulation material. This is especially important in environments where the insulation may be exposed to moisture, chemicals, or extreme temperatures, as these factors can degrade the material over time.

If any damage is detected, it is important to repair or replace the affected insulation promptly to prevent further damage to the pipes or systems. By maintaining the integrity of the frp pipe insulation, building owners and operators can ensure that their plumbing and HVAC systems continue to function efficiently and last longer.

Maintaining FRP insulation also involves cleaning the surfaces of the insulated pipes to prevent the buildup of dirt or contaminants, which can reduce the insulation’s effectiveness. Following best practices for maintenance and keeping a regular inspection schedule will help maximize the performance and longevity of frp pipe insulation in both residential and industrial settings.

Customization of FRP Pipe Insulation for Specific Applications

One of the strengths of frp pipe insulation is the ability to customize it based on the specific needs of the project. Different industrial applications require different insulation materials and thicknesses, depending on factors such as temperature range, fluid type, and environmental exposure. For instance, in high-temperature applications, thicker insulation with higher thermal resistance may be required to maintain fluid temperatures effectively.

GangLong Fiberglass offers tailored frp pipe insulation solutions for various industries, allowing customers to select the insulation specifications that best meet their operational requirements. Whether it’s for a chemical plant transporting corrosive fluids or a water treatment facility managing temperature-sensitive processes, the right insulation can make a significant difference in system performance and longevity.

Long-Term Cost Savings with FRP Pipe Insulation

Investing in frp pipe insulation is not only about improving system performance and energy efficiency—it also offers long-term cost savings. By minimizing heat loss and reducing energy consumption, industries can lower their utility bills and improve their overall profitability. Furthermore, by protecting pipes from environmental damage and reducing the frequency of maintenance, companies can save on repair and replacement costs.

Over time, the initial investment in insulating materials is outweighed by the financial benefits of improved system efficiency and reduced operational expenses. With proper insulation, FRP pipes can provide consistent, reliable service for years, allowing industries to focus on productivity rather than maintenance issues.

For companies looking to maximize their piping systems’ performance and longevity, frp pipe insulation is a critical step in achieving those goals.

FRP Pipe Insulation: A Critical Solution for Plumbing and Industrial Systems

FRP pipe insulation is a crucial component for ensuring the efficiency and longevity of plumbing and industrial systems. The insulation provides numerous benefits, including protection from temperature fluctuations, corrosion, and environmental damage. In addition, it helps to optimize energy use by minimizing heat loss and reducing energy consumption, making it an ideal choice for various applications, from residential plumbing to large-scale industrial systems. FRP pipe insulation can significantly extend the lifespan of pipes, while also improving the overall performance of heating and cooling systems. This detailed discussion will explore the key benefits of FRP pipe insulation and how pre insulated FRP pipe can improve system efficiency and durability.

Why FRP Pipe Insulation is Essential for Plumbing Pipes

FRP pipe insulation plays an essential role in protecting plumbing pipes from several challenges, such as temperature fluctuations, external damage, and corrosion. One of the key reasons to insulate plumbing pipes with FRP is the ability to maintain consistent internal temperatures. In cold climates, this insulation helps to prevent pipes from freezing, a common cause of pipe bursts and damage. Meanwhile, in systems that carry hot water, such as in homes or industrial settings, frp pipe insulation prevents heat loss, ensuring that water stays at the desired temperature with less energy required to reheat it.

Another critical benefit of frp pipe insulation is its resistance to corrosion. Plumbing systems, especially those exposed to moisture or harsh chemicals, are prone to corrosion, which weakens pipes over time and can lead to costly repairs. By insulating the pipes with PPR FRP, this risk is minimized, as the material creates a barrier between the pipes and their environment. This makes frp pipe insulation particularly effective for both underground installations and exposed pipes in harsh environments. Additionally, the insulation can help protect pipes from physical damage caused by impacts, further extending the life of the plumbing system.

The Role of Plumbing Tools and Sealants in FRP Pipe Installation

When installing frp pipe insulation, using the right tools and sealants is crucial to ensuring a long-lasting and effective solution. Proper installation requires specialized tools designed to work with FRP materials, such as cutting tools that can precisely trim the insulation without damaging it. Additionally, plumbing sealants used during the installation process must be compatible with FRP to ensure a tight and secure bond between pipe joints. A poor seal can lead to air gaps or water leaks, which may compromise the insulation’s effectiveness and reduce the efficiency of the plumbing system.

It’s important to use high-quality sealants to enhance the bond and create an airtight seal around the joints. These sealants also prevent moisture from penetrating the insulation, which can reduce the risk of condensation and water damage. By ensuring that all the components of the installation are properly fitted and sealed, the performance and longevity of the frp pipe insulation can be maximized. Proper use of tools and sealants during installation ensures that the insulation remains effective over the long term, reducing the need for frequent repairs or maintenance.

Maximizing Efficiency in Water Heaters with FRP Pipe Insulation

Water heaters play a vital role in both residential and industrial settings, and their efficiency can be significantly enhanced by using frp pipe insulation. One of the primary ways that insulation improves water heater efficiency is by reducing heat loss. When hot water is transported through uninsulated pipes, a significant amount of heat escapes into the surrounding environment. This heat loss means that the water heater has to work harder to maintain the desired temperature, which increases energy consumption and operational costs.

By applying frp pipe insulation to the pipes that carry hot water to and from the water heater, the system can retain more heat within the pipes. This leads to a more consistent water temperature and reduces the need for reheating, ultimately lowering energy usage. Additionally, by keeping the water at the desired temperature for longer periods, frp pipe insulation helps to reduce strain on the water heater, extending its operational life and improving overall system performance.

For industrial applications, where large volumes of water are heated and transported, frp pipe insulation can result in significant energy savings. The ability to maintain higher water temperatures over long distances means that industrial operations can operate more efficiently, while also reducing their environmental impact by cutting energy consumption. In both residential and industrial settings, frp pipe insulation is an essential solution for improving the efficiency of water heating systems and reducing operational costs.

Key to ensure successful frp pipe procurement process

Enhancing Ducting and Ventilation with FRP Pipe Insulation

Ducting and ventilation systems are critical components of HVAC systems, and frp pipe insulation offers key benefits in these applications. One of the primary advantages of using FRP insulation in ducting and ventilation systems is its ability to maintain stable temperatures within the ducts. This is particularly important for systems that transport conditioned air, whether heated or cooled. Without insulation, temperature changes can occur as the air passes through the ducts, leading to inefficiencies and increased energy consumption as the system works to correct the temperature deviations.

FRP pipe insulation also helps to reduce noise within ventilation systems. Air moving through ducts can create vibrations and noise, especially in large-scale industrial settings. The insulating properties of FRP can dampen these vibrations, resulting in quieter operations. This is especially valuable in environments where noise control is essential, such as in offices, hospitals, and residential buildings.

Another advantage of frp pipe insulation in ducting and ventilation systems is its ability to prevent condensation. When cool air passes through warm ducts or when warm air moves through cooler ducts, condensation can form inside the pipes. Over time, this moisture can lead to mold growth or water damage, reducing the effectiveness of the ventilation system. FRP insulation prevents this from happening by acting as a barrier between the temperature fluctuations inside and outside the ducts.

How FRP Pipe Insulation Improves Overall Building Insulation

FRP pipe insulation doesn’t just protect pipes and systems—it also contributes to the overall insulation of a building. By insulating pipes that carry hot water, steam, or other fluids, the insulation helps maintain consistent temperatures within the building. This reduces the load on HVAC systems and improves the energy efficiency of the entire building. Properly insulated pipes can also help reduce drafts and hot or cold spots within the building, leading to a more comfortable indoor environment for occupants.

Additionally, by preventing heat loss or gain in plumbing and HVAC systems, frp pipe insulation reduces the need for these systems to work harder to maintain temperature control. This, in turn, lowers energy consumption and decreases utility costs. Over time, these energy savings can add up, making frp pipe insulation a cost-effective investment for building owners and operators.

FRP insulation also contributes to the sustainability of a building by reducing energy use, which can help achieve environmental certifications or meet energy efficiency standards. For large commercial or industrial buildings, installing frp pipe insulation can be an important part of creating a sustainable, eco-friendly facility.

FRP pipe roughness factor table for improved flow analysis

FRP Pipe Insulation: Environment and Benefits

FRP (Fiberglass Reinforced Plastic) pipe insulation is an essential component for maintaining the efficiency and durability of piping systems in various industrial settings. For industries like oil and gas, petroleum frp pipe insulation plays a critical role in temperature regulation, energy conservation, and protection against environmental factors. This insulation is widely used in applications such as chemical processing and water treatment, where the management of fluid temperatures and the prevention of heat loss or gain are vital to operational success. By insulating petroleum frp pipes, industries can enhance the performance of their systems while reducing long-term maintenance and operational costs.

Thermal Efficiency and Energy Savings with FRP Pipe Insulation

One of the most significant benefits of frp pipe insulation is the improvement in thermal efficiency, which leads to substantial energy savings. In many industrial applications, FRP pipes are used to transport fluids at various temperatures, ranging from hot liquids in chemical plants to chilled water in cooling systems. Without proper insulation, the pipes would lose or gain heat as the fluid moves through them, requiring additional energy to maintain the desired temperature.

By insulating the pipes, industries can minimize these temperature fluctuations, ensuring that the fluid remains at a stable temperature throughout its journey. This translates into less energy being used by heating or cooling systems, resulting in lower utility bills and a more efficient operation overall. The energy savings achieved through the use of frp pipe insulation are particularly beneficial in large-scale industrial operations, where energy consumption can be a major expense.

Furthermore, frp pipe insulation reduces the strain on equipment, such as boilers, chillers, and pumps, by helping to maintain consistent temperatures. This not only extends the life of the equipment but also reduces the frequency of repairs and maintenance, providing further cost savings over time.

Protection Against External Environmental Conditions

Another critical function of frp pipe insulation is its ability to protect pipes from external environmental conditions. While FRP pipes are known for their durability and resistance to corrosion, they are still vulnerable to extreme weather conditions, UV radiation, and physical damage. Insulating the pipes adds an extra layer of defense against these potential threats, helping to extend the life of the system and ensure consistent performance.

In outdoor installations, frp pipe insulation shields the pipes from fluctuating temperatures, preventing the material from expanding and contracting due to thermal stress. This is especially important in climates where temperatures can vary drastically between day and night, as repeated expansion and contraction can weaken the structural integrity of the pipes over time.

UV radiation is another factor that can degrade the performance of FRP pipes over the years. While FRP is resistant to corrosion, prolonged exposure to sunlight can cause the material to become brittle and prone to cracking. By applying insulation, industries can protect their pipes from UV damage, preserving their strength and performance for a longer period.

Moisture is another environmental concern that frp pipe insulation helps to address. In humid or wet environments, uninsulated pipes are susceptible to condensation buildup, which can lead to corrosion or the growth of mold and mildew. Insulating the pipes prevents condensation from forming on the outside of the pipe, keeping the system dry and free from potential damage.

Durability and Long-Term Performance of FRP Pipe Insulation

Durability is one of the key factors that make frp pipe insulation a valuable investment for industries that require long-lasting piping systems. Insulating FRP pipes not only enhances their performance but also extends their lifespan by protecting them from wear and tear caused by temperature fluctuations, environmental stress, and physical impacts.

FRP pipe insulation is designed to withstand harsh industrial conditions, providing long-term protection against heat, cold, moisture, and chemicals. This durability means that insulated FRP pipes require less frequent maintenance and are less likely to experience premature failure, reducing the need for costly repairs or replacements.

In addition, the use of high-quality insulating materials further enhances the longevity of the pipes. GangLong Fiberglass offers a range of insulation options that are specifically designed to complement their FRP piping systems. By choosing the right insulation materials for the job, industries can ensure that their FRP pipes remain in peak condition for decades.

Customizing FRP Pipe Insulation for Specific Applications

The versatility of frp pipe insulation allows it to be customized for specific industrial applications. Depending on the type of fluid being transported, the temperature range, and the environmental conditions, different types of insulation materials can be used to meet the unique requirements of the system.

For example, in high-temperature applications, thicker insulation with a higher thermal resistance may be necessary to prevent heat loss. In low-temperature systems, such as refrigeration or cooling systems, the insulation must be able to prevent heat gain and protect against condensation.

GangLong Fiberglass provides tailored insulation solutions and best fiberglass insulation for a wide variety of industries, ensuring that the insulation meets the precise needs of each project. Whether the system requires insulation for extreme temperatures, protection from moisture, or resistance to chemicals, the right insulation can significantly improve the performance and efficiency of the FRP piping system.

Minimizing Noise with FRP Pipe Insulation

In addition to temperature regulation and energy efficiency, frp pipe insulation also plays a role in noise reduction. In many industrial settings, pipes can create significant noise due to the flow of fluids, vibrations, or pressure fluctuations. This noise can be disruptive to workers and can contribute to overall noise pollution within the facility.

By applying insulation to FRP pipes, industries can reduce the transmission of noise through the pipes, creating a quieter and more comfortable work environment. The insulation acts as a sound barrier, absorbing vibrations and dampening the noise generated by the movement of fluids or gases within the system.

In HVAC systems, where air is circulated through ducts and ventilation shafts, frp pipe insulation helps reduce the noise associated with air movement and the operation of fans or blowers. This noise reduction not only improves the acoustic environment within the building but also enhances the overall performance of the HVAC system by reducing energy losses and maintaining consistent airflow.

Environmental Benefits of FRP Pipe Insulation

In addition to the financial savings, frp pipe insulation also offers environmental benefits by reducing energy consumption and lowering greenhouse gas emissions. Insulating pipes helps industries operate more sustainably by minimizing heat loss and reducing the need for energy-intensive heating and cooling processes.

By conserving energy, insulated FRP pipes contribute to a reduction in the overall carbon footprint of industrial operations. This is particularly important in industries that are focused on sustainability and meeting environmental regulations. Reducing energy consumption not only lowers operating costs but also supports efforts to reduce the environmental impact of industrial activities.

Planning for Long-Term Success with FRP Pipe Insulation

Incorporating frp pipe insulation into the design and maintenance of industrial piping systems is a strategic decision that can lead to significant benefits in terms of efficiency, durability, and cost savings. Whether the goal is to improve energy efficiency, protect pipes from environmental damage, or reduce noise levels, insulation is a key factor in ensuring the long-term success of the system.

By working with experienced suppliers like GangLong Fiberglass, industries can select the best insulation materials for their specific applications and ensure that the insulation is installed correctly to maximize performance. Properly insulated FRP pipes will provide reliable, efficient service for years to come, making them an essential part of any well-designed industrial piping system.

Selecting the Right FRP Pipe Spacers for Your System

FRP Pipe Insulation: Maximizing Efficiency and Protection

FRP pipe insulation is a critical element for ensuring the efficiency, durability, and performance of plumbing and industrial systems. By offering protection against temperature fluctuations, environmental damage, and corrosion, FRP insulation helps extend the life of piping systems while optimizing energy use. It plays a vital role in reducing heat loss, lowering energy consumption, and maintaining system integrity in various applications, including residential plumbing, water heating, and HVAC systems. This in-depth look at frp pipe insulation will explore its many benefits, as well as how proper installation and maintenance can maximize its effectiveness.

How FRP Pipe Insulation Contributes to Building Sustainability

FRP pipe insulation not only protects plumbing and HVAC systems but also contributes to the overall sustainability of buildings. By reducing heat loss, preventing corrosion, and maintaining system efficiency, frp pipe insulation helps lower energy consumption and reduce the carbon footprint of a building. This is especially important in commercial and industrial buildings, where energy use is often high due to heating, cooling, and water heating demands.

By improving the energy efficiency of plumbing and HVAC systems, frp pipe insulation reduces the need for frequent system repairs or replacements, further contributing to sustainability. Buildings equipped with insulated pipes can operate more efficiently, minimizing waste and conserving resources. In many cases, the installation of frp pipe insulation can help buildings meet energy efficiency standards or achieve environmental certifications, making it an important part of any sustainability strategy.

FRP insulation also supports the long-term durability of building systems by protecting them from environmental damage and wear. This reduces the need for new materials and construction work, helping to minimize the environmental impact associated with building maintenance and renovations. In this way, frp pipe insulation is an investment not only in energy efficiency but also in the long-term sustainability of the building.

The Key of Maintenance for Long-Lasting FRP Pipe Insulation

Maintaining frp pipe insulation is essential to ensuring its long-term effectiveness and durability. Regular inspections should be conducted to check for signs of wear, damage, or degradation, especially in environments where the insulation may be exposed to extreme temperatures, moisture, or chemicals. If any damage is detected, it is important to repair or replace the insulation promptly to prevent further damage to the pipes or the system.

Proper maintenance also involves cleaning the insulated pipes to prevent the buildup of dirt or contaminants, which can reduce the insulation’s effectiveness over time. Keeping the insulation free from debris helps ensure that it continues to provide the necessary thermal and protective benefits for the system. By following a regular maintenance schedule and addressing any issues early, building owners and operators can maximize the performance and lifespan of their frp pipe insulation, ensuring that it continues to deliver energy savings and protection for many years to come.

Why Choose GangLong Fiberglass for FRP Pipe Insulation?

GangLong Fiberglass offers high-quality FRP pipe insulation with superior durability, corrosion resistance, and efficient heat retention. Unlike conventional materials, GangLong’s FRP insulation combines the rigidity of metal with the toughness of fiberglass, ensuring long-lasting performance. Their innovative manufacturing processes and dedication to product quality make GangLong Fiberglass the ideal choice for customized FRP solutions. With an experienced team ready to meet your needs, GangLong guarantees reliable, cost-effective, and tailored insulation solutions for various commercial and industrial applications.

Choosing the Right Size for FRP Pipe Insulation

FRP pipe insulation is available in two primary size categories: pipe size and insulation thickness.

- Pipe size refers to the external diameter of the pipe that the insulation is designed to fit. FRP pipe insulation is typically available in a wide range of sizes to accommodate various pipe diameters, from small residential pipes to large industrial pipelines.

- Insulation thickness refers to the wall thickness of the insulation material itself, and this is a critical factor in determining the level of thermal protection. Common thicknesses range from 1/2 inch to 3 inches, depending on the insulation requirements. Thicker insulation offers greater thermal resistance, making it suitable for high-temperature applications, while thinner insulation may be adequate for less demanding situations.

How Important Is It To Choose The Right Size For Frp Pipe Insulation?

- Thermal Efficiency: Proper insulation thickness ensures effective temperature control, reducing heat loss in hot pipes or preventing freezing in cold pipes.

- Cost-Effectiveness: Using the correct size minimizes waste and ensures you are not over- or under-insulating, which could affect both performance and cost-efficiency.

- Longevity of the System: If the insulation is too thin, it may not provide sufficient protection, leading to increased wear on the pipes or energy inefficiency. Conversely, too thick insulation may be unnecessary and impractical.

- Fit and Functionality: The insulation must fit the pipe properly to prevent air gaps, which could reduce the insulation’s effectiveness and lead to temperature fluctuations or condensation buildup.

How To Choose The Right Size For Frp Pipe Insulation

- Measure the Pipe’s External Diameter: Start by accurately measuring the outside diameter of the pipe. This will determine the pipe size required for the insulation. Ensure the measurement includes any coatings or pipe features that may affect the external dimensions.

- Determine the Thermal Needs: Based on the environment and temperature requirements, choose the appropriate insulation thickness. For pipes carrying high-temperature fluids, thicker insulation (1 inch to 3 inches) will help minimize heat loss. For lower-temperature or more moderate conditions, a thinner insulation (1/2 inch to 1 inch) may suffice.

- Consult Manufacturer Specifications: Different manufacturers may have different recommendations or size variations for their FRP pipe insulation products. It’s important to follow these guidelines for optimal performance.

By selecting the correct pipe size and insulation thickness, you can ensure that the FRP pipe insulation performs efficiently, prolonging the life of the system while maintaining energy savings.

Step-by-Step Installation Guide for FRP Pipe Insulation

This guide provides clear, easy-to-follow steps for installing FRP pipe insulation, ensuring a secure and effective thermal barrier for both hot and cold pipes. Proper installation is essential to maximize energy efficiency, prevent heat loss, and protect pipes from freezing or damage. The steps cover everything from positioning the insulation to sealing joints and using PVC fitting covers for a complete system.

- Prepare the Insulation: Start by selecting the appropriate FRP pipe insulation cover for your pipe size. Ensure that the insulation cover has a hinged portion, allowing easy installation over the pipe.

- Position the Insulation: Open the hinged part of the commercial pipe insulation and position the opening over the pipe. The cover should fit snugly around the pipe.

- Seal the Insulation: Once the fiberglass cover is securely in place, remove the release paper from the self-sealing lap. Starting from the center of the pipe, press the cover towards the edge to ensure a tight fit and a secure seal.

- Apply Butt Tape: To further secure the insulation, seal the two sections of the cover together with a piece of butt tape. Make sure to rub the tape firmly to ensure a strong bond.

- Use Additional Tape for Large Projects: For larger projects or areas with multiple cuts of insulation, it is recommended to use additional tape to ensure a complete and secure seal.

- Install PVC Fitting Covers: After the FRP pipe insulation is installed along the pipes, cover elbows, tees, joints, and other fittings with PVC fitting covers to maintain insulation continuity and prevent heat loss or freezing.

By following these simple steps, you can efficiently install FRP pipe insulation, ensuring proper thermal performance and longevity for your piping system.

FAQs about Frp Pipe Insulation

Yes, fiberglass pipe insulation is highly effective at reducing heat loss and protecting pipes from temperature fluctuations. The fiberglass material provides excellent thermal insulation, helping to maintain the desired temperature of fluids or gases flowing through the pipes. This insulation reduces energy consumption by minimizing heat transfer, making systems more energy-efficient. Additionally, fiberglass insulation can protect pipes from freezing in colder environments and prevent condensation in humid conditions. It is commonly used in both residential and industrial settings for hot water systems, steam pipes, and HVAC systems. Fiberglass pipe insulation is also resistant to fire and corrosion, making it a safe and durable option for protecting pipes over the long term. By insulating pipes with fiberglass, industries can reduce energy costs, increase system efficiency, and extend the life of their piping systems

FRP pipe and PVC pipe differ in several key aspects, including material composition, strength, and applications. FRP pipe is made from fiberglass reinforced with plastic resin, giving it a high strength-to-weight ratio and excellent resistance to corrosion, heat, and chemicals. It is commonly used in industrial settings where the pipes are exposed to aggressive chemicals or extreme temperatures. On the other hand, PVC (Polyvinyl Chloride) pipe is a type of plastic pipe that is more suited for residential or light industrial applications, such as plumbing and irrigation systems. While PVC is lightweight, cost-effective, and easy to install, it does not offer the same level of strength, chemical resistance, or heat tolerance as FRP. PVC is more prone to degradation when exposed to harsh chemicals or high temperatures, whereas FRP can maintain its integrity in more demanding environments. In summary, while both pipes are useful, FRP is preferred for more heavy-duty, industrial applications, whereas PVC is more suited to everyday, lower-stress uses.

FRP pipe stands for Fiberglass Reinforced Plastic pipe. It is a composite material made of fiberglass and a polymer resin, which creates a strong, durable, and corrosion-resistant product. FRP pipes are widely used in industries such as chemical processing, water treatment, and oil and gas due to their ability to withstand harsh environments and corrosive substances. The combination of fiberglass and plastic offers a lightweight yet robust solution, making FRP pipes suitable for both underground and above-ground installations. The unique properties of FRP pipes, including resistance to chemicals, UV radiation, and extreme temperatures, make them a reliable and long-lasting choice for various applications.

FRP (Fiberglass Reinforced Plastic) pipe material is a composite made of a polymer matrix reinforced with fiberglass. It combines the benefits of plastic, such as corrosion resistance and lightweight properties, with the added strength and durability of fiberglass. This makes FRP an ideal material for pipes in industries like water treatment, chemical processing, and oil and gas, where durability and resistance to harsh conditions are crucial. FRP pipes are typically used in situations where metal pipes would corrode or be too heavy to handle. The material is also resistant to UV degradation, making it suitable for both outdoor and underground installations. FRP pipes are known for their ability to withstand high pressure and temperatures, making them versatile in a range of industrial applications.

To effectively insulate PVC pipes, the best method involves using foam pipe insulation or fiberglass pipe wrap. Foam pipe insulation is a pre-slit, tubular material that easily fits over the pipe, providing an efficient thermal barrier that minimizes heat loss or gain. Fiberglass wrap is also a popular option, offering superior thermal insulation and higher resistance to extreme temperatures. It’s crucial to ensure that the insulation completely covers the entire length of the pipe, including joints, to prevent condensation and freezing in cold climates. In addition, securing the insulation with tape or insulation wire ensures it stays in place. For areas with higher temperatures, you may want to use an insulated jacket or reflective foil. For outdoor applications, additional weatherproofing with a vapor barrier can prevent moisture buildup and enhance the durability of the insulation.

FRP stands for Fiberglass Reinforced Plastic. It is a composite material made from a polymer resin reinforced with fiberglass filaments, which significantly enhance its strength, durability, and resistance to various environmental factors like corrosion, UV rays, and chemicals. FRP is often used in industries where traditional materials like metal or concrete would be prone to corrosion or require heavier maintenance. Common applications include pipes, tanks, and structural components, especially in industries such as chemical processing, water treatment, and marine construction. The versatility of FRP allows it to be molded into various shapes, offering a lightweight yet durable solution for many demanding applications.

Yes, FRP (Fiberglass Reinforced Plastic) is waterproof. One of the key advantages of FRP is its ability to resist moisture and water penetration. This characteristic makes it a preferred material for applications in wet or submerged environments, such as in water treatment plants, piping systems, and marine vessels. The resin used in FRP is highly resistant to water absorption, preventing degradation or weakening over time. Additionally, FRP’s resistance to corrosion and chemical damage makes it ideal for use in industries dealing with water or corrosive substances. When properly sealed and maintained, FRP materials will remain waterproof, ensuring long-lasting performance in environments where water exposure is a constant concern.

FRP (Fiberglass Reinforced Plastic) is generally not stronger than steel in terms of raw tensile strength. However, FRP offers a high strength-to-weight ratio, meaning that it can be stronger than steel in terms of its durability and performance under certain conditions when considering its weight and resistance to corrosion. FRP is significantly lighter than steel, which can be advantageous in applications where reducing weight is important. Additionally, FRP is highly resistant to corrosion, unlike steel, which can rust over time when exposed to water or chemicals. As a result, FRP is often preferred in industries where corrosion resistance and lightweight properties are more critical than sheer strength.

To prevent pipes from freezing, it’s essential to use proper insulation materials, seal all gaps, and ensure heat is applied where needed. Start by using high-quality foam pipe insulation or fiberglass pipe wrap, which are both effective at maintaining the temperature of the water within the pipes. Insulation should cover the entire pipe, including elbows and joints, where freezing is more likely to occur. In addition to insulating, you should seal any gaps or cracks in walls, floors, and windows that may allow cold air to reach the pipes. For extra protection, consider using heat tape or heat cables, which can be wrapped around the pipe to maintain a constant temperature during extremely cold conditions. Finally, ensure that the thermostat in your home is set to a minimum of 55°F (13°C) to help prevent freezing in colder weather.

While FRP (Fiberglass Reinforced Plastic) and fiberglass are related, they are not exactly the same material. Fiberglass refers to the individual strands or fibers of glass that are used as reinforcement in composite materials, while FRP is the end product—a composite material that combines fiberglass with a resin matrix to form a strong, durable material. FRP tends to be more versatile than raw fiberglass, as it is designed to have specific properties such as improved resistance to chemicals, corrosion, and UV degradation. While fiberglass by itself is strong, its full potential is realized when it is incorporated into FRP, offering enhanced strength, durability, and flexibility. Therefore, in most applications, FRP is superior to just fiberglass because of the combined benefits of the resin and the glass fibers.

The choice between foam and fiberglass pipe insulation depends on the specific needs of the application. Foam insulation is lightweight, easy to install, and provides good thermal resistance. It is often used for residential applications and offers a cost-effective solution for maintaining the temperature of pipes. It is available in pre-slit tubes that can be easily slid over the pipes, making installation quick and simple.

Fiberglass insulation, on the other hand, provides superior thermal performance and is often used in industrial or commercial settings. It offers higher resistance to extreme temperatures and is better for high-performance insulation needs. Fiberglass is also more durable, especially in outdoor or high-temperature environments. However, it can be more difficult to install and may require more protective clothing due to its irritant properties.

For residential, lightweight needs, foam is typically preferred, while fiberglass is better for industrial applications requiring higher performance insulation.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.