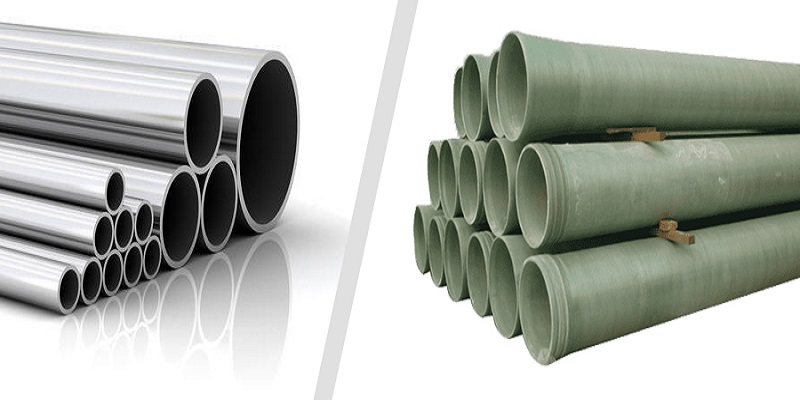

About the differences between FRP (Fiberglass Reinforced Plastic) and steel pipes is essential for selecting the appropriate material for various applications. FRP pipes are made from a polymer matrix reinforced with glass fibers, providing excellent corrosion resistance and a lightweight structure. They are commonly used in chemical processing, wastewater treatment, and marine applications. In contrast, steel pipes are known for their strength and durability, making them suitable for high-pressure and high-temperature applications. They are often used in oil and gas industries, construction, and infrastructure projects. When considering a cost comparison between FRP vs steel pipe, factors such as material costs, installation expenses, and long-term maintenance requirements play a significant role in determining the best choice for specific projects. FRP vs Steel Pipe: FRP is lighter, less brittle, and easier to install, offering enhanced durability and reduced installation burden.

Evaluating Strength: FRP vs Steel Pipe

What is FRP Pipe

FRP (Fiberglass Reinforced Plastic) pipes are composite materials made of a polymer matrix reinforced with glass fibers. Known for their lightweight nature, corrosion resistance, and high strength-to-weight ratio, FRP pipes are commonly used in industries like chemical processing, wastewater treatment, and oil and gas, where durability and resistance to harsh environments are critical.

Properties of FRP Piping

Fiberglass Reinforced Plastic (FRP) piping systems are highly valued for their combination of durability, strength, and cost-effectiveness. These pipes are used across numerous industries due to their superior properties that make them ideal for challenging environments. Below are the key properties that make FRP pipes a preferred choice in many applications worldwide:

Excellent Corrosion Resistance

One of the standout properties of FRP pipes is their exceptional resistance to corrosion. Unlike traditional materials such as steel and iron, FRP pipes do not rust or degrade when exposed to harsh environments, including seawater, chemicals, and acidic or basic substances. This makes them ideal for industries such as chemical processing, water treatment, and oil and gas, where exposure to corrosive elements is common.

Excellent Strength-to-Weight Ratio

FRP pipes possess a higher strength-to-weight ratio compared to steel and other metallic pipes. Despite being significantly lighter, they maintain excellent structural strength, which allows them to handle high pressure and tough operational conditions. This strength-to-weight advantage makes FRP pipes an ideal solution for applications where both durability and ease of handling are essential.

Lightweight for Easy Handling and Transport

One of the key advantages of FRP pipes is their lightweight nature, which simplifies both transportation and installation. The reduced weight lowers the need for heavy lifting equipment and reduces the overall labor costs during installation. This property is especially beneficial in industries such as construction, offshore applications, and shipbuilding, where ease of transport is essential.

Dimensional Stability

FRP pipes offer excellent dimensional stability, meaning they are less likely to expand or contract under temperature fluctuations. This ensures that the pipes maintain their structural integrity and performance over time, even when exposed to extreme environmental conditions. This property is particularly valuable in systems that require precise measurements and reliability.

Non-Toxicity

FRP pipes are non-toxic, making them safe for transporting potable water and other liquids that come in direct contact with food or human consumption. The non-toxic nature of FRP ensures that no harmful chemicals leach into the transported fluids, making it an ideal choice for industries that require clean, contaminant-free systems, such as water treatment and food processing.

Low Coefficient of Friction

FRP pipes have a low coefficient of friction, which is more than 25% better than steel. This property ensures excellent flow characteristics, as fluids can pass through the pipes with minimal resistance. The reduced friction also contributes to energy savings by reducing the need for excessive pumping power, making FRP pipes a cost-efficient choice for fluid transportation.

Good Abrasion Resistance

Another critical property of FRP pipes is their good abrasion resistance. They are highly durable when exposed to abrasive materials, such as those found in slurry pipelines and mining operations. The pipes maintain their integrity and functionality over time, even when handling harsh substances, making them ideal for use in industries that require the transport of solid-laden fluids.

Suitability for Both Aboveground and Buried Piping

FRP pipes can be used effectively in both aboveground and buried applications. Their resistance to corrosion, combined with their strength, makes them suitable for installation in various environments. Whether laid underground or mounted aboveground, FRP pipes are reliable and durable, making them versatile for use in water distribution, irrigation systems, and industrial installations.

Resistance to Biological Attacks

FRP pipes are resistant to biological attacks, including bacteria, fungi, and algae. This resistance is particularly valuable in environments where water or wastewater systems may be exposed to microbial growth. Unlike metal pipes, which can be corroded by biological organisms, FRP pipes remain unaffected by these issues, ensuring the long-term reliability and cleanliness of the transported fluids.

Non-Conductive to Electricity

FRP pipes are non-conductive, making them ideal for use in electrical conduit systems or environments where electrical conductivity is a concern. Their non-conductive properties help to prevent electrical hazards and ensure the safety of personnel working around these pipes, especially in areas with high electromagnetic interference or sensitive electronic equipment.

Low Maintenance Cost

Due to their corrosion resistance, durability, and long lifespan, FRP pipes have lower maintenance costs compared to traditional materials like steel or iron. The lack of rust, corrosion, and minimal wear and tear reduce the need for frequent inspections, repairs, and replacements. This makes FRP pipes a cost-effective solution over the long term, reducing operational downtime and maintenance expenses.

What is Steel Pipe

Steel pipes are made from alloys of iron and carbon, offering high tensile strength, rigidity, and suitability for high-pressure and structural applications. Steel pipes are widely used in construction, infrastructure, and transportation of fluids, though they are prone to corrosion unless treated with coatings or protective measures. While FRP excels in flexibility and resistance to corrosive environments, steel is valued for its mechanical strength and isotropic properties, making both materials suitable for different industrial needs.

FRP vs Steel Pipe

Tensile Strength of FRP and Steel

When discussing the tensile strength of FRP vs steel pipe, steel is traditionally known for its high tensile strength, making it a preferred choice in scenarios requiring the handling of substantial pressure and load. However, FRP pipe tensile strength has improved significantly, offering a competitive strength-to-weight ratio that can make it suitable for various applications while providing additional benefits like corrosion resistance and reduced weight. Steel pipes can withstand considerable stress without deformation, which is crucial in industrial applications where pipes must endure heavy operational forces.

FRP pipe, such as those produced by GangLong Fiberglass, have a distinct structure. They consist of fibers embedded in a polymer matrix, giving them a unique combination of strength and flexibility. While FRP might not match steel’s sheer tensile strength, it compensates by offering high strength-to-weight ratios. This characteristic allows FRP pipes to be lighter while maintaining sufficient strength for many applications, making them easier to transport and install. In environments where moderate tensile strength is acceptable, FRP becomes a competitive alternative to steel.

Corrosion Resistance in Various Environments

One of the most significant differences in evaluating FRP vs steel pipe is their behavior in corrosive environments. Steel, particularly when exposed to moisture, chemicals, or harsh environmental conditions, is prone to corrosion. Over time, this corrosion can lead to the degradation of steel pipes, resulting in leaks, bursts, or structural failures. While stainless steel can resist corrosion better than regular steel, it can still corrode under extreme conditions, especially when exposed to chlorides or acids.

FRP pipes, including uv resistant frp pipe, manufactured by GangLong Fiberglass inherently possess corrosion resistance due to their composite nature. The polymer matrix acts as a barrier, protecting the embedded fibers from direct exposure to corrosive elements. As a result, FRP pipes maintain their structural integrity longer in environments where steel would rapidly degrade. This makes them particularly suited for use in chemical plants, wastewater treatment facilities, and areas with high salt concentrations, where corrosion resistance is a top priority.

Performance Under High Pressure

Steel pipes are renowned for their ability to withstand high pressures, making them a popular choice for industries like oil and gas, where transporting fluids under high pressure is common. The rigidity and ductility of steel provide a robust framework that can handle extreme pressure fluctuations without compromising structural integrity. This performance attribute makes steel a go-to material for high-pressure applications.

FRP pipes, like those from GangLong Fiberglass, can also handle considerable pressure, but their performance under high-pressure conditions is generally lower compared to steel. However, advancements in FRP technology have allowed the development of high-pressure FRP pipes. These pipes can now endure moderate to high pressures in various industrial settings. Their composite structure allows for customization, adjusting the fiber orientation and matrix composition to enhance pressure resistance, providing a tailored solution for specific needs.

Weight-to-Strength Ratio Advantages

In evaluating the strength of FRP vs steel pipe, it’s essential to consider the weight-to-strength ratio. Steel pipes, though strong, are heavy, which can present challenges during transportation, handling, and installation. This weight factor often requires the use of heavy machinery and additional labor, increasing overall project costs.

FRP pipes, such as those from GangLong Fiberglass, offer a superior weight-to-strength ratio. They are significantly lighter than steel while still providing adequate strength for many applications. This reduced weight simplifies the handling and installation process, potentially eliminating the need for heavy lifting equipment. The lighter weight of FRP pipes can also lead to cost savings in transportation and reduce the overall carbon footprint of a project, aligning with more sustainable construction practices.

Comparison of technical performance between FRP pipe and steel pipe

| Factor | FRP Pipe | Steel Pipe |

|---|---|---|

| Design Flexibility | Highly flexible in design, can be customized for various technical parameters to meet customer needs. | Less design flexibility, typically limited to certain standard features and applications. |

| Strength Properties | Maximum allowable working pressure: 6.4 MPa, design safety factor: more than 6 times. | Maximum allowable working pressure is lower than FRP pipe, with lower safety factor. |

| Tensile Strength | Tensile strength ranges from 140-520 MPa (apparent), axial tensile strength ranges from 70-320 MPa. | Tensile strength varies, generally lower than FRP pipes. |

| Bending Strength | Circumferential bending strength: 154-340 MPa depending on fiber arrangement. | Bending strength is less than FRP pipes, can be prone to damage under certain conditions. |

| Impact Strength | Good impact strength: 300 kgf•cm/cm² or more, tested to withstand free fall from 1.8m without damage. | Impact strength is lower than FRP pipes, prone to damage when exposed to impacts. |

| Stiffness Performance | Can meet any stiffness requirement by increasing stiffness of middle pipe layer for bending stress. | Steel pipes are rigid and less flexible compared to FRP pipes, not as adaptable to bending stresses. |

| Service Life | Designed for 50-year service life with a breaking pressure 6 times the working pressure. | Typically has a shorter service life compared to FRP pipes, especially under corrosive conditions. |

Flexibility and Impact Resistance about Frp Vs Steel Pipe

Steel pipes are known for their rigidity, which provides structural stability but can also be a drawback in applications where flexibility is required. Steel’s lack of flexibility can make it susceptible to cracking or breaking under certain impact forces or in situations where the pipeline is subjected to ground movements, such as seismic activity or soil shifting.

FRP pipes, due to their composite nature, offer a higher degree of flexibility. This flexibility allows FRP pipes to absorb impact forces and accommodate ground movements better than steel. The flexibility of FRP, particularly in products from GangLong Fiberglass, can be advantageous in scenarios where pipelines need to navigate complex terrains or in areas prone to seismic activity. This characteristic enhances the resilience of the piping system, reducing the likelihood of damage during unforeseen events.

Thermal Stability and Expansion

Thermal expansion is a critical factor when considering the strength of FRP vs steel pipe, especially in applications involving temperature variations. Steel pipes have a high thermal conductivity and expand when exposed to heat. This expansion can lead to stress on the pipe joints and supports, potentially causing leaks or structural damage if not adequately managed. Steel’s high thermal expansion also requires careful consideration during the design and installation phases, including the inclusion of expansion joints and supports.

FRP pipes have a lower coefficient of thermal expansion compared to steel, meaning they expand less when subjected to temperature changes, which is a significant advantage of FRP pipe thermal expansion properties. This characteristic can be particularly beneficial in applications with fluctuating temperatures, reducing the risk of thermal stress. The thermal stability of FRP pipes, like those from GangLong Fiberglass, allows for more straightforward design and installation procedures without the need for extensive thermal compensation measures. This is especially beneficial when using pre insulated FRP pipes, which provide an added layer of thermal protection, further enhancing energy efficiency and reducing the need for additional insulation during installation.

Abrasion Resistance and Longevity

In applications where pipes are subjected to abrasive materials or high-velocity fluids, abrasion resistance becomes a crucial factor. Steel pipes can experience wear and tear over time due to the abrasive action of fluids or particulates, leading to thinning of the pipe walls and eventual failure. While steel can be treated or lined to enhance its abrasion resistance, this adds to the overall cost and complexity of maintenance.

FRP pipes exhibit excellent abrasion resistance, particularly when reinforced with specific fibers and resins. The composite of FRP can be engineered to withstand abrasive forces, making them a durable option for transporting slurries, chemicals, or other abrasive substances. The longevity of FRP pipes, such as those by GangLong Fiberglass, in harsh environments can surpass that of steel, offering a more sustainable and cost-effective solution in the long term.

Ease of Repair and Maintenance

When a steel pipe system requires repair, the process can be labor-intensive and costly. Steel repairs often involve cutting, welding, or replacing sections of the pipeline, necessitating specialized equipment and skilled labor. Additionally, ongoing maintenance, such as corrosion protection or repainting, is essential to extend the life of steel pipes, adding to operational expenses.

FRP pipes offer a simpler repair process due to their composite nature. Damaged sections can be repaired using adhesives, wraps, or patch kits without the need for welding or heavy equipment. The maintenance requirements for FRP pipes, like those from GangLong Fiberglass, are generally lower than steel, as they do not rust or corrode. This ease of repair and reduced maintenance can lead to cost savings and increased operational efficiency.

HDPE vs FRP Pipe: Which is Best for Your Project

Frp Vs Steel Pipe: A Detailed Cost Analysis

Material Costs and Initial Investment

When considering the initial investment for FRP vs steel pipe, material costs play a crucial role. Stainless steel is known for its strength, durability, and resistance to corrosion, making it a premium choice for various industrial applications. However, these qualities come with a high price tag. Stainless steel is considerably more expensive than regular steel due to its composition, which includes elements like chromium and nickel that enhance its corrosion-resistant properties. This cost can be prohibitive for large-scale projects requiring extensive piping systems.

FRP (Fiberglass Reinforced Plastic), such as the solutions offered by GangLong Fiberglass, provides a more cost-effective alternative. The materials used in FRP manufacturing, primarily fiberglass and resins, are generally less expensive than stainless steel. Although the cost of FRP pipes can vary depending on the specific resins and reinforcements used, the overall material cost is typically lower than that of stainless steel. This lower material cost makes FRP a viable option for projects where budget constraints are a significant concern without compromising on essential performance characteristics.

Lifecycle Expenses and Maintenance Costs

The long-term cost implications of FRP vs steel pipe become apparent when considering lifecycle expenses and maintenance requirements. Stainless steel pipes are highly durable and resistant to many forms of corrosion. However, in aggressive environments—such as those involving chloride exposure, high salinity, or chemical attack—even stainless steel may require periodic maintenance to prevent localized corrosion, stress corrosion cracking, or pitting. Maintenance activities for stainless steel pipes can include surface treatments, protective coatings, and regular inspections, all of which add to the overall lifecycle cost.

FRP pipes, like those manufactured by GangLong Fiberglass, offer a different cost profile over their operational life. Due to their inherent resistance to corrosion and chemical attack, FRP pipes require minimal maintenance compared to stainless steel. They do not rust, corrode, or degrade when exposed to harsh chemicals or extreme environmental conditions. This reduced need for maintenance translates into lower lifecycle expenses, as it minimizes the frequency and costs associated with repairs, replacements, and system downtime. Over time, the cost savings associated with the lower maintenance requirements of FRP pipes can make them a more economical choice, particularly in corrosive or demanding environments.

Installation Costs and Complexity

The cost analysis of FRP vs steel pipe must also take into account installation costs and the complexity of the installation process. Stainless steel pipes, due to their weight and rigidity, often require specialized equipment and skilled labor for installation. The welding and joining of stainless steel pipes involve specific techniques, such as TIG welding, which require trained personnel and can be time-consuming. Additionally, the need for precise alignment and support structures during installation can further increase labor costs and extend project timelines.

FRP pipes, such as those offered by GangLong Fiberglass, are lighter and easier to handle, which simplifies the installation process. Their lightweight nature reduces the need for heavy lifting equipment, making it possible to transport and install FRP pipes with less effort and at a lower cost. The joining methods for FRP pipes, including FRP pipe adhesive bonding, flanges, and mechanical couplings, are typically more straightforward and faster to execute than welding stainless steel. This ease of installation can result in significant cost savings in terms of labor, equipment, and project duration.

Potential Savings from Corrosion Resistance

The corrosion resistance of FRP vs steel pipe has a direct impact on long-term cost savings. Stainless steel is generally resistant to corrosion, but its performance can vary depending on the environment. In highly corrosive environments, such as chemical processing plants, offshore oil and gas facilities, or desalination plants, even stainless steel may succumb to corrosion over time. The costs associated with mitigating corrosion, such as applying protective coatings, cathodic protection, or using more expensive grades of stainless steel, can be substantial.

FRP pipes, especially those from GangLong Fiberglass, inherently resist corrosion due to their composite construction. The resins used in FRP pipes create a barrier that prevents corrosive substances from reaching the reinforcing fibers, ensuring long-term durability in harsh environments. This corrosion resistance eliminates the need for additional protective measures and the costs associated with them. By maintaining structural integrity over an extended period without requiring costly anti-corrosion treatments, FRP pipes offer significant potential savings for industries where corrosion is a primary concern.

Consider When Determining FRP Pipe Pressure Rating

Operating Costs and Energy Efficiency about Frp Vs Steel Pipe

Operating costs are another factor to consider when comparing FRP vs steel pipe. Stainless steel pipes, due to their high density, contribute to the overall weight of the piping system. This increased weight can result in higher operational costs, especially in applications where fluids need to be pumped through long pipe networks. The energy required to move fluids through heavier and more rigid stainless steel pipes can lead to increased energy consumption and higher utility expenses.

FRP pipes, like those provided by GangLong Fiberglass, offer a lighter alternative. Their lower weight reduces the energy required for fluid transport, enhancing the efficiency of the pumping systems. The smoother internal surface of FRP pipes can also minimize friction losses, further improving energy efficiency. By reducing energy consumption and operating costs, FRP pipes can contribute to the long-term economic and environmental sustainability of a piping system.

Customization and Material Optimization

The ability to customize and optimize materials is an important aspect of the cost analysis for FRP vs steel pipe. Stainless steel pipes are manufactured to standard specifications, offering limited opportunities for customization. While stainless steel can be fabricated to specific dimensions and configurations, this often involves additional costs for machining, welding, or bending.

FRP pipes, such as those from GangLong Fiberglass, can be tailored to meet specific application requirements. The manufacturing process allows for adjustments in fiber orientation, resin type, and pipe dimensions to optimize performance for particular conditions. This customization capability can result in material and cost optimization, ensuring that the piping system meets the required performance criteria without incurring unnecessary expenses. By using the right combination of materials and design, FRP pipes can offer a cost-effective solution that is precisely aligned with the operational needs of the project.

Environmental and Regulatory Compliance Costs

The environmental impact and regulatory compliance costs associated with FRP vs steel pipe are increasingly important in modern industries. Stainless steel production involves energy-intensive processes that result in a higher carbon footprint compared to the manufacturing of FRP pipes. Additionally, in environments where corrosion products from stainless steel could pose environmental risks, measures must be taken to prevent contamination, leading to additional costs for compliance with environmental regulations.

FRP pipes, including those manufactured by GangLong Fiberglass, have a lower environmental impact during production. The manufacturing process of FRP pipes generates fewer emissions, and the long service life of these pipes contributes to a reduced need for replacements, minimizing waste. In industries where sustainability and regulatory compliance are key considerations, the use of FRP pipes can result in cost savings related to environmental management and adherence to regulatory standards.

Long-Term Investment and Return on Investment (ROI)

The total cost of ownership and ROI are critical factors in the decision-making process for FRP vs steel pipe. Stainless steel pipes, with their high initial cost and potential maintenance expenses, require a substantial upfront investment. However, in applications where their properties are indispensable, this investment can be justified by the extended service life and performance benefits.

FRP pipes, such as those from GangLong Fiberglass, present a different financial profile. While the initial cost of FRP pipes can be lower than that of stainless steel, the true value lies in their low maintenance requirements and long-term durability. The reduced need for repairs, replacements, and maintenance activities over the lifespan of the FRP piping system can result in a favorable ROI. By lowering total ownership costs, FRP pipes can provide a more attractive investment option, particularly for projects with budget constraints or where long-term cost efficiency is a priority.

Insurance and Risk Management Costs

Risk management and insurance costs also factor into the cost analysis of FRP vs steel pipe. Stainless steel pipes, while robust, are not immune to the risks associated with corrosion, mechanical damage, or environmental factors. In industries where pipe failure can lead to significant financial losses, such as chemical processing or oil and gas, the cost of insurance and risk mitigation strategies for stainless steel piping systems can be substantial.

FRP pipes, FRP pipes, due to their resistance to corrosion and environmental stressors, offer a more reliable and safer alternative. The reduced risk of failure, particularly when considering enhanced longevity of FRP pipes, like those provided by GangLong Fiberglass, can result in lower insurance premiums and risk management expenses. By minimizing the likelihood of incidents that could disrupt operations or result in costly damages, FRP pipes contribute to a more predictable and manageable financial outlook for the piping system.

Considerations for Retrofitting and Upgrading

In situations where existing piping systems require retrofitting or upgrading, the cost implications of FRP vs steel pipe become particularly relevant. Stainless steel retrofitting can involve significant costs, especially if the existing infrastructure needs extensive modifications to accommodate the new piping. The need for welding, cutting, and other fabrication processes can increase labor costs and extend the project timeline.

FRP pipes, like those from GangLong Fiberglass, offer flexibility in retrofitting applications. Their lightweight nature and ease of installation make them suitable for upgrading existing systems without requiring major structural modifications. The ability to integrate FRP pipes into existing infrastructures with minimal disruption can lead to cost savings and a more efficient upgrade process.

Disposal and End-of-Life Costs

The disposal and end-of-life costs associated with FRP vs steel pipe are often overlooked but are essential components of the overall cost analysis. Stainless steel can be recycled, which can offset some of the disposal costs. However, the recycling process is energy-intensive and may involve transportation, sorting, and processing expenses.

FRP pipes, while not as easily recyclable as metals, have a long service life, contributing to a reduced frequency of replacements and the associated disposal costs. With their extended FRP pipe life expectancy, these pipes can remain in service for many years, and when they do reach the end of their useful life, they can often be repurposed or used in applications where structural integrity is less critical. The extended lifespan and potential for repurposing can mitigate the disposal costs.

Maintenance Costs

Maintenance is an ongoing expense that directly impacts the total cost of ownership for both FRP and steel pipes. Stainless steel pipes, while durable, still require regular inspections, cleaning, and maintenance to prevent corrosion and mechanical damage. The maintenance process, including the need for protective coatings, corrosion inhibitors, and repairs, can incur significant costs, especially in industries with aggressive environments like oil and gas or chemical processing.

FRP pipes, on the other hand, are far more maintenance-friendly. Their corrosion resistance and durability significantly reduce the need for frequent inspections or repairs. FRP pipes require less attention over their service life, leading to lower maintenance costs and less operational downtime. This makes FRP pipes a more cost-effective option in the long run, especially in sectors that require constant operational reliability.

Energy Efficiency

Energy efficiency is an often-overlooked aspect when comparing FRP and steel pipes. The internal surface of FRP pipes typically has lower friction than steel, which allows for smoother fluid flow. This reduction in friction can result in significant energy savings, as less pumping power is required to move fluids through the system. The low coefficient of friction in FRP pipes leads to more efficient fluid transportation, making them a better choice for energy-conscious operations.

In contrast, steel pipes, due to their higher friction, may require more energy to maintain the same flow rate. The increased energy costs associated with steel pipes can be a considerable long-term expense, especially in large-scale operations that involve the transportation of large volumes of fluids.

Operational Downtime and Disruptions

Both FRP and steel piping systems face the risk of operational downtime due to maintenance, repairs, or failures. However, the frequency and severity of these disruptions vary. Steel pipes, with their susceptibility to corrosion, mechanical damage, and wear, are more prone to unplanned downtime, especially in aggressive environments such as offshore platforms or chemical plants. These disruptions often require extensive repairs or even full pipe replacements, leading to costly operational downtime.

FRP pipes, with their resistance to corrosion and mechanical stresses, offer more stability in this regard. Their extended lifespan and low-maintenance nature mean that they are less likely to cause unexpected operational interruptions. In industries where uptime is critical, FRP pipes contribute to more predictable operations and reduced costs associated with system outages.

Key Factors Determining FRP Pipe Temperature Limits in Industry

Applications and Differences: FRP vs Steel Pipe

FRP vs steel pipe serve different purposes based on their distinct properties. FRP pipes are ideal for corrosive environments and lightweight applications, while steel pipes are better suited for high-pressure and structural needs. In some cases, both materials can be used for similar purposes, such as fluid transport, but the final choice depends on the specific requirements of the application. This section explores their respective applications, common uses, and key differences in detail.

Applications of FRP Pipe

Fiberglass Reinforced Plastic (FRP) pipes have gained significant popularity in various industries due to their exceptional durability, corrosion resistance, and ease of installation. These pipes excel in environments where traditional materials such as steel or PVC might fail due to exposure to harsh chemicals, high pressure, or extreme temperatures. FRP pipes are increasingly being used in industries where reliability and low maintenance are crucial. Below are some of the key applications of FRP pipes:

Chemical, Petrochemical, Oil & Gas Industries

FRP pipes are highly resistant to the aggressive chemicals and corrosive substances commonly found in the chemical, petrochemical, and oil & gas industries. Their ability to handle a wide range of acids, solvents, and hydrocarbons makes them ideal for transporting chemicals, oils, and gases. They are often used for handling corrosive by-products, waste streams, and in fluid transport systems where traditional materials would rapidly degrade.

Potable Water and Desalination Industries

In the potable water and desalination sectors, FRP pipes offer an excellent solution for transporting fresh water and seawater. Their corrosion resistance and ability to withstand the high salinity levels found in seawater make them ideal for use in desalination plants. Additionally, FRP’s non-reactive nature ensures that there are no contaminants released into the water, making it safe for use in drinking water systems.

Ducting and Vent Piping

FRP pipes are used extensively in ducting and venting applications. Their resistance to corrosion from both acidic and basic airflows makes them a preferred choice for exhaust systems, ventilation, and fume extraction units. FRP’s lightweight design also allows for easier handling and installation in complex systems, further reducing costs.

Irrigation and Sanitary Services

In irrigation systems, FRP pipes are used to transport water over long distances due to their lightweight and durable properties. FRP pipes do not corrode from soil or water, ensuring a longer lifespan in agriculture and landscape irrigation projects. In sanitary services, they provide reliable systems for waste management, ensuring efficient transportation of sewage and wastewater without the issues of corrosion.

Water Distribution and Transmission

The water distribution industry benefits greatly from the use of FRP pipes. These pipes are increasingly used in municipal water supply systems, both for fresh water distribution and sewage systems. Their superior strength-to-weight ratio allows for easier transportation and installation, reducing both installation time and labor costs. Additionally, FRP pipes’ resistance to corrosion extends their life in harsh environments, reducing maintenance and replacement costs.

Slurry Piping

FRP pipes are highly effective in transporting abrasive and corrosive slurry in industries such as mining and construction. Their ability to handle high-pressure systems while resisting erosion from abrasive materials like sand and gravel makes them ideal for slurry pipelines. The long-lasting durability of FRP ensures that slurry transport systems remain operational for extended periods without significant wear.

Power Plants

In power plants, FRP pipes are utilized for both cooling and chemical transport. These pipes are used to transport cooling water to and from heat exchangers and boilers, and they are also effective in handling chemical treatments necessary for plant maintenance. Their resistance to temperature extremes and corrosive substances makes them a crucial part of many power generation systems, ensuring efficient and safe operations.

Electrical Conduit Systems

FRP pipes are non-conductive, which makes them ideal for use in electrical conduit systems. In environments where high electromagnetic interference is present, FRP pipes offer a reliable and safe solution for housing electrical cables, protecting them from external damage and ensuring system reliability.

Customized Applications

The flexibility of FRP allows for customization in terms of size, shape, and design. This makes it an ideal material for industries that require bespoke piping solutions. FRP pipes can be fabricated to meet specific operational needs, whether that be for unique fluid handling, pipe length, diameter, or resistance to particular chemicals or environmental factors.

Applications of Steel Pipe

Steel pipes are ideal for high-pressure and load-bearing applications due to their high tensile strength and rigidity. They are extensively used in construction for structural supports, in oil and gas pipelines for transporting hydrocarbons under pressure, and in water supply systems. Steel pipes are also essential in industrial processes where durability and resistance to mechanical wear are necessary. Their isotropic properties ensure uniform strength, making them a reliable choice for critical infrastructure projects like bridges and power plants. Steel is often used in systems where temperature fluctuations and pressure variations are common, as it performs well under such conditions with proper coatings.

Common Applications of FRP and Steel Pipe

In some cases, FRP and steel pipes can be applied to the same purpose, such as fluid transport. For example, both are used in water distribution systems, oil pipelines, and industrial fluid handling. However, the choice between them depends on environmental factors and system requirements. In corrosive environments or where lightweight materials are advantageous, FRP is preferred. In contrast, for high-pressure systems or environments requiring structural strength, steel is the better option.

While FRP pipes dominate in corrosive and lightweight-critical applications, steel pipes are indispensable in high-pressure and structural scenarios. The overlap in their applications highlights the importance of understanding specific project requirements to choose the most suitable material.

Weight Differences: FRP vs Steel Pipe

The weight difference between FRP vs steel pipe significantly impacts their applications and practicality. FRP pipes are much lighter, offering advantages in transportation, installation, and load-sensitive environments. Steel pipes, while heavier, provide stability and strength for high-pressure and structural uses.

| Factor | FRP Pipe | Steel Pipe |

|---|---|---|

| Weight of FRP Pipe | 75-83% lighter than steel, making them easy to handle, transport, and install. | Heavier, providing stability and strength for high-pressure and structural applications. |

| Weight of Steel Pipe | Lightweight due to composite materials, reducing labor and transportation costs. | Heavier, requiring cranes or forklifts for installation and increasing project costs. |

| Practical Implications | Reduces transportation and installation costs, ideal for load-sensitive environments. | Increases transportation and installation costs but offers structural integrity. |

| Use Cases Based on Weight | Ideal for applications requiring weight reduction, such as marine, aerospace, and platforms. | Preferred in industrial and high-pressure systems where load-bearing is crucial. |

Specification Differences: FRP vs Steel Pipe

FRP vs steel pipe differs significantly in terms of specifications, influencing their design flexibility, standardization, and suitability for various applications. FRP pipes offer extensive customization options to meet unique project needs, while steel pipes follow strict industry standards for uniformity and compatibility. This section details the specifications of each type, their practical differences, and the use cases that benefit from these characteristics.

Specifications of FRP Pipe

FRP (Fiberglass Reinforced Plastic) pipes are highly customizable and can be fabricated to meet specific project requirements. They are manufactured using various resins, such as epoxy, vinyl ester, or polyester, and can be designed with different layers to enhance specific properties like corrosion resistance, impact strength, or thermal insulation. FRP pipes are available in a wide range of diameters, from small-diameter pipes used in plumbing to large-diameter pipes used in industrial or marine applications. Wall thicknesses can also be adjusted to meet pressure and load requirements. FRP pipes are typically produced in standard lengths but can be custom-made to reduce the need for joints or connections in long runs.

Specifications of Steel Pipe

Steel pipes follow standardized specifications set by industry codes, such as ASTM, API, and ASME, to ensure uniformity and reliability in applications. They are available in various grades of steel, such as carbon steel, stainless steel, or alloy steel, each tailored for specific applications. Steel pipes come in fixed sizes with standard diameters, wall thicknesses, and lengths, defined by industry norms. They are often manufactured in seamless or welded forms, with seamless pipes preferred for high-pressure and critical systems. Steel pipes can also be treated with coatings or linings to enhance their performance, such as corrosion-resistant coatings for offshore pipelines.

Practical Differences in Specifications

The key difference between FRP and steel pipes in terms of specifications lies in their customization and standardization. FRP pipes offer greater flexibility in design, allowing them to be tailored to unique project needs, such as specific chemical resistance, lightweight structures, or thermal insulation properties. Steel pipes, however, provide the advantage of uniformity and standardization, which ensures compatibility with existing systems and adherence to industry regulations. This makes steel pipes more predictable in applications requiring strict adherence to standard dimensions and performance criteria.

Use Cases Based on Specifications

FRP pipes are often chosen for specialized applications requiring tailored properties, such as in chemical plants, marine systems, or wastewater facilities. Steel pipes, with their standardized specifications, are preferred in industries requiring uniformity, such as oil and gas pipelines, structural supports, or high-pressure fluid systems. Understanding the differences in specifications helps ensure the selection of the right pipe for the intended application.

Future Development Trends: FRP vs Steel Pipe

The future of FRP vs steel pipe lies in innovation and sustainability, with each material evolving to meet changing industry demands. FRP pipes are expected to advance through improvements in materials, automation, and environmental sustainability, expanding their use in lightweight and corrosion-resistant applications. Steel pipes will focus on enhancing performance through metallurgical innovations, improved coatings, and greener production methods. This section explores the distinct development trajectories of both materials, potential synergies, and their roles in future infrastructure and industrial applications.

Future Development of FRP Pipe

FRP pipes are poised for significant growth due to advancements in composite materials and manufacturing processes. Innovations in resin formulations and reinforcement materials are improving the strength, durability, and chemical resistance of FRP pipes, making them suitable for a broader range of applications. Future developments are likely to focus on enhancing environmental sustainability, such as using bio-based resins or recyclable composites to reduce the carbon footprint of FRP production. Automation and additive manufacturing technologies, like 3D printing, are also expected to streamline production and lower costs, enabling more widespread adoption. Additionally, the increasing demand for corrosion-resistant and lightweight solutions in industries such as renewable energy, water desalination, and smart infrastructure will drive further advancements in FRP pipe technology.

Future Development of Steel Pipe

The future development of steel pipes centers on improving performance and addressing environmental challenges. Innovations in metallurgy, such as the development of high-strength, low-alloy steels, aim to increase durability and reduce material usage. Coating technologies are evolving to provide superior corrosion resistance and extend the lifespan of steel pipes in harsh environments. Additionally, steel production is becoming more sustainable with advancements in green steel technologies, such as hydrogen-based steelmaking and carbon capture systems, which aim to reduce greenhouse gas emissions. Steel pipes will continue to play a vital role in heavy industries, infrastructure development, and energy sectors, particularly in applications requiring structural stability and high-pressure resistance.

Comparative Trends and Synergies

While both FRP and steel pipes have distinct development trajectories, there are areas of convergence where the two materials complement each other. Hybrid systems that combine steel’s strength with FRP’s corrosion resistance are being explored for specialized applications. Both industries are focusing on sustainability, with FRP exploring recyclable materials and steel adopting greener production methods. As global infrastructure evolves, the choice between FRP and steel pipes will increasingly depend on balancing cost, performance, and environmental considerations.

FRP pipes are expected to expand into new markets driven by their adaptability and lightweight nature, while steel pipes will remain indispensable in traditional heavy industries, supported by advancements in strength and sustainability. The future of both materials is marked by innovation, with each evolving to meet the demands of a changing world.

FAQs about Frp Vs Steel Pipe

FRP (Fiberglass Reinforced Plastic) and steel each have their advantages and disadvantages, making one material better suited than the other depending on the application. FRP is known for its excellent corrosion resistance, making it ideal for environments where moisture and chemicals are present. Unlike steel, which can rust and degrade over time, FRP maintains its integrity, leading to lower maintenance costs and a longer lifespan in corrosive conditions. Additionally, FRP is lightweight, which simplifies installation and reduces transportation costs. However, steel generally has superior mechanical strength and can withstand higher temperatures and pressures. Therefore, in applications requiring high structural strength, steel may be the better choice. The decision between FRP and steel ultimately depends on the specific requirements of the project, including environmental conditions, weight restrictions, and budget considerations.

In general, FRP can be more expensive than steel upfront, primarily due to its manufacturing processes and raw material costs. However, the total cost of ownership may differ when considering factors like installation, maintenance, and lifecycle costs. FRP is lighter than steel, which can reduce transportation and installation expenses. Moreover, FRP’s resistance to corrosion can lead to lower maintenance costs over time, as it requires less frequent replacements and repairs compared to steel. In environments where corrosion is a significant concern, the long-term savings associated with using FRP may offset its initial higher price. Ultimately, while FRP may have a higher initial cost, its durability and low maintenance requirements can make it a cost-effective option in the long run.

The primary difference between FRP and stainless steel lies in their material properties and applications. FRP is a composite material made of a polymer matrix reinforced with glass fibers, giving it excellent corrosion resistance and a lightweight structure. It is ideal for applications in chemical processing, wastewater treatment, and environments prone to corrosion. In contrast, stainless steel is a metal alloy known for its strength and resistance to corrosion. While stainless steel is robust and can withstand high temperatures and pressures, it is heavier and may require protective coatings in highly corrosive environments. The choice between FRP and stainless steel depends on the specific application requirements, such as weight constraints, environmental conditions, and the need for structural integrity.

FRP (Fiberglass Reinforced Plastic) piping is a composite material made of a polymer matrix reinforced with fibers, usually glass fibers. It is widely used in industrial applications due to its corrosion resistance, lightweight nature, and durability. The polymer matrix can be made of epoxy, vinyl ester, or polyester resin, depending on the specific requirements of the application. FRP piping is especially valued in industries where corrosive fluids, high temperatures, or harsh environmental conditions are involved, such as chemical processing, wastewater treatment, and oil and gas operations. Unlike traditional materials like steel, FRP does not rust, making it ideal for environments where moisture or chemicals are present. Its modular design and ease of fabrication further enhance its appeal, enabling faster installation and lower maintenance costs compared to metal alternatives.

FRP is considered more sustainable than steel in specific applications, primarily due to its resistance to corrosion and longer service life. Unlike steel, which can degrade due to rust or chemical exposure, FRP requires minimal maintenance and does not need protective coatings or frequent replacements. This reduces the environmental impact over its lifecycle. Furthermore, FRP is significantly lighter than steel, reducing energy consumption during transportation and installation. However, sustainability is context-dependent. FRP is not biodegradable and is produced using synthetic resins, which are derived from petrochemicals. Steel, on the other hand, is highly recyclable and can be repurposed without significant quality loss. The sustainability advantage of FRP lies in applications where durability and resistance to harsh conditions lead to fewer replacements and lower resource consumption, making it a more eco-friendly choice in those scenarios.

FRP piping generally has a higher upfront cost compared to steel. Depending on the resin and fiber used, FRP can be 2 to 4 times more expensive than standard steel pipes. However, this cost difference is often offset by FRP’s lower maintenance requirements, longer service life, and resistance to corrosion. Steel pipes may require coatings, cathodic protection, or periodic replacements in corrosive environments, which can significantly increase their total cost over time. Additionally, FRP’s lightweight nature reduces transportation and installation costs. In applications involving highly corrosive substances or demanding environmental conditions, FRP may be more cost-effective in the long run despite its higher initial price. The choice between FRP and steel should consider not just material costs but also lifecycle costs, operational requirements, and environmental factors to determine the most economical solution.

While FRP is not inherently stronger than steel in terms of tensile strength, it exhibits superior strength-to-weight and specific properties in certain applications. Steel typically has higher tensile strength and is better suited for high-pressure applications requiring structural rigidity. However, FRP’s composite structure offers exceptional flexibility, impact resistance, and corrosion resistance, making it a stronger choice in environments involving chemical exposure or moisture. FRP’s lightweight nature (about one-fourth the weight of steel) allows for easier handling and reduced structural support requirements. Moreover, its non-conductive properties and resistance to thermal and electrical conductivity provide advantages over steel in specialized applications. The “strength” of FRP compared to steel is highly context-dependent. For structural applications under pure mechanical load, steel is often stronger. For environments requiring resistance to corrosion, fatigue, or low maintenance, FRP proves to be the superior option.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.