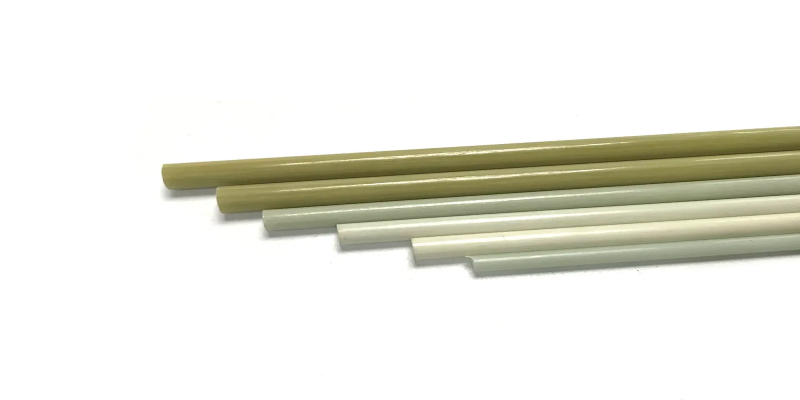

How well fiberglass rod hold thread is crucial for anglers and rod builders alike. Fiberglass rods are commonly used in various applications, including fishing and recreational uses, due to their flexibility, durability, and ease of handling. The ability of a fiberglass rod to hold thread securely is essential for attaching guides and components, which affects overall rod performance. Fiberglass is composed of woven glass fibers and hollow glass fibers embedded in a resin matrix, providing a strong yet flexible structure. This composition allows for good adhesion when threading, ensuring that guides remain securely in place during casting and retrieving. Compared to glass-filled plastics, fiberglass generally offers superior thread-holding capabilities, making it a reliable choice for rod construction. Understanding this property ensures that anglers can create effective and durable rods tailored to their specific needs. How well does fiberglass rod hold thread? It holds thread securely due to its strong, durable, and corrosion-resistant materials, with thread design influencing retention.

The Keys of How Well Does Fiberglass Rod Hold Thread

Fiberglass rods are widely used in various applications due to their unique properties. However, a common question that arises among users is how well does fiberglass rod hold thread. Understanding the factors affecting thread retention in fiberglass can help optimize its use in projects requiring threaded connections.

Properties of Fiberglass and Threading

Fiberglass is composed of long glass fibers embedded in a resin matrix, providing a lightweight yet strong material. This composition gives fiberglass rods flexibility and resilience, but it also presents challenges when it comes to threading. The structure of fiberglass may cause threads to chip or break during the machining process, affecting how well does fiberglass rod hold thread. The type of resin used can also impact the rod’s performance; for example, polyester resins tend to become brittle over time, complicating the threading process.

Threading Techniques and Their Impact

The method chosen for threading fiberglass rods significantly influences how well does fiberglass rod hold thread. Grinding is often regarded as the best method because it minimizes the risk of chipping compared to other techniques like milling or turning. Grinding creates a clean, smooth thread, which enhances the overall strength of the threaded section. Conversely, turning may lead to significant chipping, especially if not done correctly. Selecting the right tooling, such as carbide tools with TIN coatings, can further improve threading outcomes.

Challenges with Chipping

Chipping remains one of the primary challenges faced when threading fiberglass. During the machining process, especially when using traditional methods, the fibers can fracture, resulting in a weak thread. This chipping not only compromises the thread’s integrity but can also lead to potential failures in applications where strength is critical. To mitigate this issue, it is essential to adopt specialized techniques and equipment tailored for fiberglass machining.

Use of Carbide Tools

One key to successfully achieving threaded fiberglass rods lies in the tooling used. Carbide tools are highly recommended due to their durability and ability to maintain sharp edges, which is crucial when cutting through the tough fibers of fiberglass. The use of TIN-coated carbide tools can further enhance performance, as these tools provide better heat resistance and reduced friction during the machining process. Choosing the right tools is vital for achieving threads that remain strong over time.

Alternative Threading Solutions about How Well Does Fiberglass Rod Hold Thread

In cases where threading directly into fiberglass proves challenging, alternative solutions can enhance the overall effectiveness. One popular approach is to use aluminum or brass tubes. By turning down a section of the fiberglass rod and epoxying these threaded tube fiberglass inserts in place, users can create strong connections without the risk of chipping associated with direct threading. This method not only preserves the integrity of the fiberglass but also allows for more robust mechanical connections.

Epoxy and Threaded Inserts

Epoxy is a crucial component when it comes to securing threaded inserts into fiberglass rods. When considering how well does fiberglass rod hold thread, using high-quality epoxy to bond threaded inserts is essential. The combination of epoxy and inserts creates a strong bond that enhances thread retention and durability. This approach is particularly beneficial in applications where high tensile strength is required, as it can effectively distribute loads across the fiberglass.

Casting for Integrated Threads

Another innovative solution involves casting fiberglass rods with integrated threads. This method allows for a seamless connection, as the threads are formed during the casting process. Proper lubrication, mixing chopped fibers with epoxy, and vacuum degassing to eliminate air bubbles are critical steps to ensure a high-quality result. By creating threads in this manner, users can enhance how well does fiberglass rod hold thread, eliminating many of the issues associated with machining.

Maintenance of Threaded Fiberglass Rods

Proper maintenance of threaded fiberglass rods is crucial to ensuring their longevity and performance. Over time, environmental factors can affect the integrity of both the fiberglass and the threads. Regular inspections should be conducted to check for signs of wear or damage. If any issues are detected, prompt repairs or replacements can help maintain the effectiveness of the threaded connections. Additionally, cleaning the threads and ensuring they are free of debris can prevent potential failures in critical applications.

Applications in Various Industries

Fiberglass rods find applications across numerous industries, from construction to marine environments. Understanding how well does fiberglass rod hold thread is essential in these fields, where threaded connections often bear significant loads. For example, in underwater structures, avoiding corrosion is critical, and utilizing fiberglass with properly threaded connections can provide an effective solution. Users should consider the specific requirements of their application when deciding on the best approach for threading fiberglass pipe.

Essential Specifications for FRP Cable Threading Pipe Use

Challenges in How Well Does Fiberglass Rod Hold Thread

When discussing how well does fiberglass rod hold thread, it is important to address the challenges associated with threading these materials. One significant issue that often arises is chipping. Fiberglass rods are made from a composite material that consists of glass fibers embedded in a resin matrix. While this combination provides strength, it can also lead to chipping when attempting to create threads.

Chipping occurs when the cutting tool used for threading encounters the glass fibers within the composite. As the tool rotates, it may not only cut through the resin but also displace the glass fibers, leading to small fractures along the threaded surface. These fractures can weaken the integrity of the threads, resulting in a less secure connection. To mitigate this issue, users should employ appropriate tooling techniques and speeds that minimize the risk of chipping.

Common problems faced during drilling and milling processes can further complicate the threading of fiberglass rods. The unique properties of fiberglass, such as its tendency to fray or delaminate under stress, can present challenges during machining operations. For instance, when drilling, excessive heat generated from the drilling process can lead to resin softening, which can cause the fibers to separate from the matrix. This can compromise the surface quality of the hole and affect the overall strength of the threaded area.

Proper Tools and Techniques

To improve how well does fiberglass rod hold thread, selecting the right tools and techniques is essential. Specialized cutting tools designed for composite materials can greatly enhance threading efficiency. These tools are typically made from high-speed steel or carbide, featuring cutting edges specifically designed to handle the unique properties of fiberglass.

Adjusting the feed rate and rotational speed during the threading process can also help reduce chipping and improve the overall quality of the threads. A slower feed rate may allow the cutting tool to work more effectively, giving it the chance to cut cleanly through the material without causing excessive stress on the fiberglass. Additionally, using coolant or lubrication during the threading process can help dissipate heat and reduce friction, further minimizing the risk of damage to the fiberglass.

Thread Types and Their Impact

The type of thread used can also affect how well does fiberglass rod hold thread. There are various thread forms, including standard, fine, and coarse threads, each with its own advantages and disadvantages. Coarse threads tend to provide better grip in softer materials like fiberglass, as they have a larger surface area to engage with the material. Conversely, fine threads may be more prone to stripping or pulling out of the fiberglass if not properly formed.

The choice of thread form should take into account the specific application and the load that the threaded connection will be subjected to. For applications involving significant stress or dynamic loads, it may be beneficial to use coarser threads to enhance holding power.

Long Fiberglass Rods: Essential Uses For Gardening

Surface Preparation for How Well Does Fiberglass Rod Hold Thread

Before threading fiberglass rods, proper surface preparation can significantly influence how well does fiberglass rod hold thread. This process often involves cleaning and possibly roughening the surface to improve the mechanical bond of the thread. Removing any contaminants such as dust, oil, or resin residues can create a cleaner surface for threading.

In some cases, lightly sanding the area where the thread will be applied can help improve grip. By creating a slightly rougher surface, the threads have more material to engage with, which can enhance their holding capacity. However, care should be taken not to over-sand, as this could lead to unnecessary weakening of the fiberglass material.

Adhesives and Thread Lockers

In addition to mechanical methods, the use of adhesives and thread lockers can significantly improve how well does fiberglass rod hold thread. These products can provide additional bonding strength to threaded connections, helping to secure them against loosening due to vibrations or thermal expansion.

When selecting an adhesive or thread locker, it is essential to choose one that is compatible with fiberglass materials. Some adhesives are specifically formulated for composite materials, offering optimal bonding without compromising the integrity of the fiberglass. Proper application techniques and curing times should also be followed to ensure maximum effectiveness.

Inspection and Quality Control

After threading fiberglass rods, conducting thorough inspections is crucial to ensure that the threads are properly formed and capable of holding securely. This step often involves visual inspections for any signs of chipping, misalignment, or other defects. Dimensional checks may also be necessary to ensure that the threads meet the required specifications.

Quality control processes can help identify potential issues before the fiberglass rods are put into service. Regular monitoring and testing can ensure that the threading process remains consistent, ultimately leading to improved performance and reliability in applications.

Best Fiberglass Hot Rod Bodies For Custom Car Building Projects

Features of Fiberglass Rods: A Comprehensive Overview

Fiberglass rods are known for their impressive range of features that make them suitable for diverse applications across industries. These rods combine durability, versatility, and strength, making them an ideal choice for environments where materials are subjected to harsh conditions. The following sections will break down the key features of fiberglass rods, exploring their resistance properties, ease of use, and strength compared to other materials, as well as their suitability for various industries.

Corrosion-Resistant, Weather-Resistant, Moisture-Resistant, and Insect-Resistant

Fiberglass rods are highly resistant to environmental factors, making them ideal for use in various challenging outdoor environments. They are not prone to rust, rot, or corrosion, which is a significant advantage over materials like steel or wood that may degrade over time. This resistance makes fiberglass rods suitable for use in areas with high moisture

levels, such as marine environments, or regions with fluctuating weather conditions.

Fiberglass is impervious to moisture, so it won’t absorb water, which would otherwise weaken materials like wood. Additionally, fiberglass does not attract or harbor insects, which can damage organic materials. This resistance to environmental elements ensures that fiberglass rods have a longer lifespan, even when exposed to harsh conditions such as humidity, rain, and extreme temperatures. As a result, fiberglass rods are commonly used in infrastructure, construction, and marine applications.

Easy to Drill, Cut, and Install

One of the standout advantages of fiberglass rods is their ease of manipulation. Unlike many other materials that require specialized tools or extensive labor to cut and shape, fiberglass rods can be easily drilled, cut, and installed with basic tools. This makes them a cost-effective option, especially in situations where customization or on-site adjustments are needed.

Fiberglass rods can be quickly drilled to create holes for fittings or fasteners, allowing them to be integrated into existing structures or systems. The rods can also be cut to specific lengths without much effort, ensuring that they meet the requirements of different projects. Their ease of installation makes them popular in industries where quick turnaround times are essential, such as construction, engineering, and telecommunications.

Applicable to a Wide Range of Industries and Environments

Due to their versatility, fiberglass rods find applications across many industries, from construction and manufacturing to telecommunications and transportation. Their resistance to environmental stressors, along with their strength and lightweight properties, makes them a valuable resource in numerous fields. Fiberglass rods are used in everything from reinforcing structures to creating intricate parts for machinery and equipment.

For example, in the construction industry, fiberglass rods are often used for reinforcement in concrete, offering strength while reducing the overall weight of the material. In telecommunications, fiberglass rods serve as protective conduits for wiring, ensuring durability and reliability in the field. Their use extends into other sectors as well, such as transportation (for reinforcing vehicle parts) and even in the military and aerospace industries, where their unique properties are highly beneficial.

More Impact-Resistant Than Wood

Fiberglass rods outperform wood in terms of impact resistance, making them ideal for use in environments where physical stress or heavy impacts are common. While wood can crack or splinter under force, fiberglass is engineered to absorb and distribute impact forces more efficiently. This makes fiberglass rods suitable for applications that require high durability under mechanical stress.

The ability of fiberglass to withstand sudden impacts without breaking or deforming gives it an edge over traditional materials in many industrial applications. For example, fiberglass rods are often used in applications like support structures, where they are subjected to physical forces from machinery or environmental factors. Unlike wood, fiberglass maintains its integrity and performance, even under significant impact, making it a reliable choice for many industries.

Stronger Than Steel in Some Ways, Especially When Used as a Reinforcement Material

While steel is widely known for its strength, fiberglass can offer comparable, if not superior, strength in certain applications, particularly when used as a reinforcement material. Fiberglass rods are lighter than steel, making them easier to handle, install, and transport without sacrificing strength. When combined with other materials like resin, fiberglass can provide strength that rivals or even surpasses that of steel, particularly in tension and compression.

In structural applications, fiberglass rods can be used as reinforcement in concrete or composite materials, providing exceptional strength without the added weight of steel. The unique combination of lightweight properties and high strength makes fiberglass rods a desirable option in fields like civil engineering and architecture, where both strength and ease of installation are critical.

Fiberglass rods offer a combination of resistance to environmental elements, ease of manipulation, and impressive strength, making them suitable for a wide range of industries and applications. Their corrosion resistance, impact resistance, and ability to be easily cut, drilled, and installed make them an excellent choice for projects requiring durability, flexibility, and longevity. The advanced properties of fiberglass ensure that it remains a top material in various sectors, providing reliable solutions even in the most challenging conditions.

Applications of Fiberglass Rods Across Various Industries

Fiberglass rods are versatile components used in numerous industries due to their lightweight, strong, and corrosion-resistant properties. These rods are commonly employed in public utilities, construction, wind power generation, and commercial construction. Their excellent insulation properties, high strength-to-weight ratio, and durability under harsh conditions make fiberglass rods a valuable material for both structural and non-structural purposes. This section delves into the varied applications of fiberglass rods, highlighting their utility in several key sectors.

Fiberglass Rods in the Public Utility Sector

Fiberglass rods have a significant role in the public utility sector, especially in electrical and telecommunications applications. These rods are primarily used in the construction of support structures for power lines, telecommunication cables, and other infrastructure. Due to their non-conductive properties, fiberglass rods are ideal for use as insulators in environments where electrical isolation is critical. They are often used in combination with other materials to form reliable and durable support systems for overhead power lines, substations, and cable systems. Fiberglass rods are also employed as reinforcements for underground utility installations, ensuring longevity and resistance to corrosion, which is a common challenge for metal-based components. Additionally, their lightweight nature simplifies handling and installation, making them an excellent choice for utility companies.

Fiberglass Rods for Construction

In the construction industry, fiberglass rods are utilized for reinforcing concrete and other composite materials. Their high tensile strength, corrosion resistance, and non-conductivity make fiberglass rods an ideal alternative to traditional steel rebar in some applications. They are often used in projects where environmental factors—such as moisture or exposure to chemicals—accelerate the degradation of steel reinforcements. In addition to reinforcing concrete, fiberglass rods are used to create support structures, frameworks, and even as rods for lifting and anchoring in specialized applications. Their application is especially common in areas requiring high-strength, lightweight materials with excellent resistance to corrosion. These properties also make them an optimal choice in marine construction and other exposed environments.

Fiberglass for Wind Power Generation

Fiberglass rods are integral to the wind power generation industry, playing key roles in the construction of wind turbine blades, towers, and support structures. These rods are often used as part of composite materials for blades due to their combination of lightweight, flexibility, and strength, which helps to improve the efficiency and lifespan of the turbines. The non-corrosive properties of fiberglass make it highly suitable for wind turbine applications, where long-term exposure to harsh weather conditions is expected. Additionally, fiberglass rods are sometimes used in the internal framework of wind turbine towers, helping to reinforce the structure without adding excessive weight. The versatility of fiberglass materials contributes to the overall performance of wind energy infrastructure by ensuring durability and minimizing maintenance needs over time.

Fiberglass Rods for Commercial Construction

Fiberglass rods find multiple applications in commercial construction, serving as both structural reinforcements and utility supports. In the context of structural reinforcement, fiberglass rods are used to create strong, lightweight beams, frames, and supports for buildings. Their corrosion resistance is particularly valuable in environments exposed to moisture or chemicals, such as in coastal areas or industrial facilities. Moreover, fiberglass rods are often used to reinforce walls, flooring, and foundation elements in commercial buildings. They are also employed in specialized applications, such as seismic retrofitting, where they help to strengthen existing structures against earthquakes. Their non-conductivity is beneficial in certain commercial environments where electrical safety is a priority. These rods are not only cost-effective but also provide long-lasting solutions in demanding commercial construction projects.

Fiberglass rods are essential components across a variety of industries, offering unique advantages in terms of strength, lightweight design, and resistance to corrosion. From supporting public utility infrastructure to enhancing the durability of commercial buildings and wind power systems, fiberglass rods serve as a key material in modern construction and energy solutions. The diverse applications of these rods highlight their growing importance in sectors that demand high-performance, long-lasting materials.

Factors Affecting Drilling and Bonding with Fiberglass Rods

Fiberglass rods are versatile materials used in various applications, but when it comes to drilling holes or bonding them with other products, there are several important factors to consider. These factors can affect the ease and effectiveness of drilling or bonding and ensure the integrity of the fiberglass rod is maintained. The following sections break down the primary factors that influence these processes, including the type of resin used, the diameter and thickness of the rod, the rod’s flexibility and composition, and the choice of bonding agents. Understanding these factors is crucial for ensuring successful drilling and bonding operations with fiberglass rods.

Type of Resin Used in Fiberglass Rods

The type of resin used in the construction of fiberglass rods plays a critical role in how easy it is to drill holes or bond them with other materials. Resins, such as polyester, epoxy, or vinyl ester, offer varying levels of hardness and chemical resistance. For example, epoxy resin tends to create a harder, more rigid fiberglass, while polyester resins may offer more flexibility.

When drilling fiberglass rods, the hardness of the resin can affect the wear on the drill bit and the ease of creating a clean hole. Harder resins, such as epoxy, require more careful handling as they can cause more stress on tools and lead to chipping or cracking. Softer resins, on the other hand, may be easier to drill but could present bonding challenges if they do not create a durable enough surface. Selecting the appropriate resin for the specific application can greatly impact the ease of drilling and the effectiveness of bonding.

Diameter and Thickness of the Rod

The diameter and thickness of fiberglass rods significantly influence the process of drilling holes. Thicker, larger-diameter rods tend to be more difficult to drill due to the increased volume of material that needs to be penetrated. This requires more force, specialized equipment, and careful technique to avoid cracking or damaging the rod. In contrast, smaller, thinner rods are easier to drill but may lack the strength or durability required for certain applications.

The thickness of the rod also affects bonding, as thicker rods may require stronger adhesive forces or a more extensive surface area for bonding to achieve a secure attachment. For thinner rods, it’s important to ensure that the bonding agent can still create a sufficient bond without causing the material to become too brittle. Understanding the diameter and thickness helps in choosing the right tools and bonding materials to achieve successful results.

Flexibility and Composition of the Rod

Fiberglass rods come in varying degrees of flexibility, which can affect both drilling and bonding processes. Flexible fiberglass rods bend easily under pressure and are often used in applications where impact resistance or flexibility is required. However, drilling through flexible fiberglass rods can sometimes lead to uneven drilling if the rod bends during the process. This may result in an unclean hole or cause the material to crack. More rigid fiberglass rods, on the other hand, tend to hold their shape better during drilling, ensuring cleaner and more precise holes.

Additionally, the composition of the fiberglass rod—whether it is a single-layer or multi-layer composite—also plays a role in how it behaves during drilling and bonding. Multi-layer fiberglass rods may require more effort to drill through due to the various layers and materials used, while single-layer rods may be easier to drill but might not offer the same strength for bonding.

Choice of Bonding Agent

The type of bonding agent used to attach fiberglass rods to other materials has a significant impact on the success of the bond. Fiberglass typically requires strong adhesives, such as epoxy resins or polyurethane-based adhesives, to ensure a secure and durable bond. The surface of the fiberglass rod also needs to be prepared properly to enhance adhesion—this can involve sanding or cleaning the surface to remove any debris or contaminants.

The choice of bonding agent also depends on the type of material the fiberglass rod is being bonded to. For instance, bonding fiberglass to metal requires an adhesive that is designed to adhere to both materials. If the adhesive is incompatible with the fiberglass rod or the other material, the bond may not hold, leading to weak points or potential failure in the application. The curing time and environmental conditions also play a role in the bonding process, as temperature and humidity can affect the effectiveness of the bond.

Tool Selection and Drilling Technique

The tools used for drilling fiberglass rods and the technique employed are crucial to the success of the operation. Fiberglass is a tough material that requires specialized drill bits, such as carbide-tipped or diamond-coated bits, to drill effectively without causing damage. Using standard drill bits can result in jagged edges, cracking, or overheating, which can weaken the structure of the fiberglass.

In addition to the tool, the technique also matters. Drilling fiberglass should be done at low speeds to prevent excessive heat buildup, which could cause the material to melt or crack. It’s also important to apply steady pressure while drilling and to clear away dust frequently, as fiberglass dust can be abrasive and could cause damage if not removed. Taking these factors into consideration helps achieve clean holes and maintain the integrity of the fiberglass rod during the drilling process.

Drilling holes and bonding fiberglass rods depend on several critical factors, including the resin type, rod diameter and thickness, flexibility, and the choice of bonding agents. Each of these elements plays a vital role in determining the success of both processes. Selecting the appropriate tools, techniques, and materials ensures that fiberglass rods can be drilled and bonded effectively, leading to strong, durable results in various applications.

FAQs about How Well Does Fiberglass Rod Hold Thread

Fiberglass rods are known for their strength and durability. While they may not have the same stiffness as carbon rods, they offer excellent resistance to breakage and can withstand a significant amount of stress. This makes fiberglass rods a preferred choice for anglers fishing in rugged environments or targeting larger species. Their ability to absorb shocks helps in preventing damage, making them reliable tools for various fishing conditions.

The strength of a fiberglass rod can be influenced by several factors, including the quality of the materials used, the rod’s construction, and its design. Higher-quality fiberglass with reinforced layers can enhance strength, while the specific taper and action of the rod will also play a role. Proper care and maintenance, such as avoiding exposure to extreme temperatures and storing the rod correctly, can further extend its lifespan and maintain its strength.

To thread fiberglass rods, you’ll need a few essential tools, including guide feet, thread, an epoxy finish, and a thread-wrapping tool. Additionally, scissors or cutting tools for trimming the thread and a rod dryer for curing the epoxy can help ensure a professional finish. Familiarizing yourself with these tools and their uses will facilitate the threading process, allowing you to create a well-constructed rod.

Yes, a fiberglass rod can be threaded, although the process is not as straightforward as threading metal rods. Fiberglass rods are typically made from woven glass fibers bound with resin, giving them strength and flexibility. When you want to thread a fiberglass rod, you would need to use a tap to create internal threads or a die to form external threads. The key challenge lies in the fact that fiberglass is a composite material, which means it can be harder than some metals but can also chip or crack under certain conditions. Therefore, a special technique or treatment, such as pre-drilling or using inserts, might be needed to ensure that the threading holds securely. The durability and tightness of the threads largely depend on the design and size of both the rod and the threads themselves.

Graphite and fiberglass are both strong materials, but they differ in terms of strength-to-weight ratio and flexibility. Graphite is generally stronger than fiberglass in terms of tensile strength, meaning it can handle more force before breaking. It also tends to be stiffer and lighter than fiberglass, making it an ideal choice for applications where weight reduction and rigidity are important. However, fiberglass has its own strengths, particularly in flexibility and impact resistance. Fiberglass rods are less likely to crack under impact compared to graphite, which is more prone to breaking upon sudden shocks. Therefore, graphite may be stronger overall in terms of raw strength, but fiberglass rods excel in situations requiring flexibility and resilience. In terms of holding thread, both materials perform well, but fiberglass may offer better durability in environments where impact resistance is needed.

Fiberglass rods are not inherently “sensitive” in the same way that, for example, graphite rods are often described. However, they do have some sensitivity, especially in the context of fishing rods. Sensitivity in rods generally refers to how well the rod transmits vibrations from the bait or fish to the angler’s hand. Fiberglass rods tend to be less sensitive than graphite rods due to their relatively slower action and more flexible nature. They are designed to bend more, absorbing impacts and vibrations, which makes them ideal for casting lures or fishing in rough conditions. While fiberglass rods may not provide the same level of “feel” as graphite rods, they do offer durability and resilience, which can be crucial for certain fishing situations. In terms of holding thread, their sensitivity does not typically affect how well they retain or hold the thread.

Yes, fiberglass rods are flexible, which is one of their key features. The flexibility of fiberglass rods makes them ideal for applications that require bending or absorbing shock, such as fishing. Fiberglass is a composite material made of glass fibers that are woven and bound with resin, giving the rod its unique balance of flexibility and strength. The flexibility of fiberglass rods allows them to handle heavy loads or sudden shocks without breaking, which is why they are commonly used in fishing, industrial, and structural applications. In terms of holding thread, the flexibility of fiberglass rods does not usually affect their ability to retain the thread, but it can affect how the rod is used in specific applications. The threads will stay secure as long as the correct threading process and materials are used.

Yes, you can put a bobber on a fiberglass rod, as fiberglass rods are widely used for fishing. The flexibility and durability of fiberglass rods make them suitable for various fishing setups, including those that require a bobber. A bobber is typically attached to the fishing line to indicate when a fish bites, and fiberglass rods are designed to handle such setups with ease. The rod’s strength and flexibility make it ideal for casting and reeling in with a bobber, as they can withstand the force of pulling and allow for smooth, controlled action. However, the type of fiberglass rod you use might affect its performance with a bobber. For instance, longer, more flexible fiberglass rods are better suited for certain types of fishing where bobbers are commonly used. The fiberglass material will securely hold the line without affecting the bobber’s movement.

Yes, you can put fishing tackle on a fiberglass rod. Fiberglass rods are commonly used in fishing because they are durable, flexible, and strong enough to handle a variety of tackle. You can easily attach hooks, lures, weights, and other fishing tackle to the line, which is often guided through the guides on the rod. The flexibility and strength of fiberglass rods allow them to handle a wide range of tackle sizes, from light lures to heavier weights. In fact, many traditional fishing rods are made from fiberglass due to its ability to withstand long-term use and resist breaking under pressure. When considering the type of tackle, it’s important to choose the appropriate fiberglass rod for your fishing style, as some rods are designed for light tackle while others are built for heavier gear.

Yes, you can put a spinner on a fiberglass rod, as fiberglass rods are well-suited for a variety of fishing techniques, including using spinners. A spinner is a type of fishing lure that rotates or spins as it moves through the water, often imitating the movement of prey. Fiberglass rods, with their balance of strength and flexibility, are perfect for casting and retrieving spinners. These rods are able to handle the force of casting spinners and the impact of reeling in fish, all while maintaining their durability. Since fiberglass rods can be designed with different actions (fast or slow), it’s important to select the right fiberglass rod for your spinner type. For instance, a medium or slow-action fiberglass rod might work better for using spinners, as it provides more control over the lure’s movement.

Yes, you can screw into fiberglass columns, but the process requires some care. Fiberglass columns are made from a composite material that is durable and strong but not as dense or rigid as solid wood or metal. To screw into fiberglass columns effectively, it is important to pre-drill a hole to prevent cracking or damage to the material. Fiberglass columns can hold screws securely, especially if you use appropriate fasteners designed for use with composites. It’s best to use screws with a coarse thread or those designed for fiberglass to ensure a firm hold. For optimal results, you can also use a specialized insert or anchor if additional stability is required. When working with fiberglass columns, it’s important to ensure the screw is not too long or large, as that could compromise the structural integrity of the column.

Yes, fiberglass rods do have a spine, but it may not be as pronounced as in some other materials like bamboo or graphite. The spine of a rod refers to the area where the rod naturally bends and the axis around which it flexes. Fiberglass rods, being flexible and resilient, still exhibit a “spine” or bending pattern when pressure is applied. However, compared to graphite, which tends to have a more defined spine due to its stiffer nature, the spine of a fiberglass rod is less noticeable. The strength and flexibility of fiberglass rods make them reliable for applications requiring bending or shock absorption. In fishing, understanding the spine of a fiberglass rod can help determine its action and how it will perform under load. Though the spine may not be as sharply defined, fiberglass rods still offer the balance and strength needed for effective use.

Fiberglass rods are excellent insulators and do not conduct electricity, making them ideal for applications requiring electrical insulation. Fiberglass is composed of glass fibers and a resin binder, both of which have high dielectric properties. This insulating quality makes fiberglass rods suitable for environments where electrical conductivity must be minimized, such as power line tools, insulators, or components in electronic devices. If threading is introduced, the material’s integrity as an insulator remains unaffected, provided that no conductive materials are embedded in the threaded area.

Attaching objects to fiberglass involves techniques that preserve the material’s structural integrity. For threading, using threaded inserts or screws is common. First, drill a pilot hole slightly smaller than the insert or screw to avoid cracking. Then, insert the fastener gently, ensuring it aligns well. Adhesives, like epoxy or polyurethane, can also reinforce attachments, especially for high-load applications. To improve the hold, sanding the fiberglass surface around the attachment point increases adhesion. When threading, the material’s properties ensure that the thread remains secure under typical stress, provided the installation is precise.

Drilling fiberglass without cracking requires the right tools and techniques. Use a high-speed drill with a bit designed for composites or a brad-point bit. To start, place masking tape over the drilling area to minimize splintering. Drill slowly and steadily, applying light pressure to prevent overheating, which can damage the material. Always start with a small pilot hole to guide the bit and avoid excessive stress on the fiberglass. If threading is planned, ensure the drilled hole matches the fastener’s specifications for a snug fit without inducing cracks.

Installing threaded inserts in fiberglass involves precision to ensure durability. First, mark and drill a hole slightly smaller than the insert’s outer diameter. Use a countersink bit to chamfer the edges, reducing stress points that could lead to cracking. Apply an adhesive like epoxy to the insert before carefully screwing or pressing it into the hole. Allow the adhesive to cure fully before applying load. Threaded inserts significantly improve thread strength in fiberglass, distributing load evenly and preventing stripping or wear over time.

Fiberglass rods can outperform traditional rebar in specific applications. They are lighter, corrosion-resistant, and non-conductive, making them ideal for environments with high moisture or electrical risks. While fiberglass rods provide excellent tensile strength, they may not match the compressive strength of steel rebar. Regarding threading, fiberglass rods hold threads well for light attachments, but their application in concrete is typically for structural reinforcement rather than threaded connections. Consider the specific project’s demands to decide whether fiberglass rods are a better alternative.

Fiberglass rods are versatile and used in various applications due to their strength, flexibility, and non-conductive properties. Common uses include electrical insulators, structural supports, tent poles, and tool handles. In areas requiring threaded attachments, fiberglass rods can support moderate loads if reinforced with threaded inserts or adhesives. Their corrosion resistance makes them suitable for outdoor use, while their lightweight nature adds convenience in portable setups. Threading enhances their versatility, allowing secure attachments in diverse scenarios.

Fiberglass fishing rods offer durability, flexibility, and affordability. Their softer action makes them ideal for casting light lures and handling large fish without breaking. They are also resistant to wear and corrosion, suitable for freshwater and saltwater environments. However, fiberglass rods are heavier and less sensitive than graphite rods, making them less ideal for techniques requiring finesse. For threaded attachments, fiberglass fishing rods can accommodate reel seats or guides securely, provided that proper inserts or adhesives are used during installation.

To cut a fiberglass rod cleanly, use a fine-toothed saw, such as a hacksaw or diamond blade. Secure the rod firmly to prevent movement and wrap the cutting area with masking tape to minimize splintering. Cut slowly and steadily, applying light pressure to avoid fraying. Sand the edges after cutting to smooth any roughness. If threading is required, ensure the cut end is square and chamfered, facilitating precise thread installation or attachment.

“All thread” and “threaded rod” are terms often used interchangeably, but they may have subtle differences. All thread refers to a rod with threads running its entire length, while a threaded rod can refer to a rod partially threaded or fully threaded. Both are used for fastening or tensioning, but in fiberglass applications, threaded inserts are often used to achieve a durable threaded connection. Fiberglass rods can accommodate all-thread or threaded rods if properly reinforced to ensure secure holds under load.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.