Fiberglass tubing is widely used across many industries due to its lightweight, durable, and corrosion-resistant properties. It can be found in applications ranging from structural supports to electrical insulation. This versatility makes fiberglass tubing a popular choice for industrial, commercial, and recreational projects. When looking for fiberglass pipe near me , it’s important to find a reliable supplier to ensure you get high-quality materials. Local sources can provide faster delivery, reduce shipping costs, and offer the convenience of on-site inspection. Whether for construction, plumbing, or custom fabrication, having fiberglass tubing near me ensures quick access to the right products for your project needs. Fiberglass tubing near me provides lightweight, durable, corrosion-resistant options like square and round FRP tubes, ideal for strength and cost balance.

Simplifying Your Life: Key Functionalities

| Attributes | Details |

|---|---|

| Place of Origin | Hebei, China |

| Brand Name | GangLong Fiberglass |

| Product Name | Fiberglass Tubing |

| Company Type | Manufacturer |

| Technology | Pultrusion, Pultruded, Extrusion |

| Material | Fiberglass Reinforced Plastic |

| Processing Services | Punching, Bending, Forming, Cutting |

| Surface Treatment | Smooth, UV Protection or Polyester Veil |

| Features | High Strength, Corrosion Resistance, No Rust, Snow and Ice Resistance, Insulation Performance |

| Advantages | Light Weight |

| Color | Customized |

| Size | Customized |

| Length | Customized |

| Diameter | Customized |

| Straightness | Less than 0.005mm |

| Certificate | ISO9001 |

| OEM | Accept |

| Service | Support Online Technical Service |

| Package | Customized According to Your Needs |

| Sales Unit | Single Item |

| Port | According to Customer Requirements |

| Supply Capacity | 200,000 Pieces Per Month |

Fiberglass Tubing Near Me for Sale

Finding fiberglass tubing near me is crucial for accessing reliable materials for industrial and structural applications. Local suppliers typically offer a variety of high-quality fiberglass tubing in different sizes and specifications to meet your project needs.

When searching for fiberglass pipe near me, consider key factors like material quality, price, and suitability for your application. High-quality fiberglass ensures durability, especially in environments like chemical processing or structural supports. Local suppliers can offer competitive pricing and fast delivery, saving on shipping costs. It’s also important to choose tubing that can withstand specific conditions like corrosion or extreme temperatures.

Local fiberglass tubing near me serves a wide range of industries. Whether in water treatment, chemical processing, or construction, fiberglass tubing’s lightweight and durable nature makes it ideal for structural supports. It’s also a popular choice for electrical insulation due to its non-conductive properties. Local suppliers often offer customized solutions tailored to your project requirements.

Thick Wall Fiberglass Tube: A Comprehensive Applications

Fiberglass Tubing Near Me: Large Diameter Fiberglass Tube

Corrosion Resistance in Harsh Environments

When searching for fiberglass tubing near me, large diameter fiberglass tubes are often required for projects demanding strength and durability. These tubes offer excellent corrosion resistance, making them ideal for harsh environments like marine construction or chemical processing plants. Fiberglass is non-corrosive, meaning it can withstand long-term exposure to saltwater, chemicals, and other corrosive substances without degrading. This ensures a longer lifespan for projects and minimizes the need for frequent replacements.

Lightweight and High Strength-to-Weight Ratio

Large diameter fiberglass tubes are lightweight yet strong. Their high strength-to-weight ratio makes them easier to transport and install compared to traditional materials like steel. This not only reduces labor costs but also improves efficiency in large-scale projects.

Industrial Applications of Large Diameter Fiberglass Tubes

Industries such as marine construction, large-scale plumbing, and industrial fluid systems often rely on fiberglass pipe near me for these very reasons. In marine environments, these tubes serve as structural supports for docks, piers, and offshore platforms. In plumbing and fluid systems, their corrosion-resistant properties ensure smooth operation over time, handling large volumes of water or chemicals effectively.

Local Suppliers for Large-Diameter Fiberglass Tubes

For those looking for fiberglass pipe near me, local suppliers often carry large-diameter options to suit various industrial and structural needs. These tubes are essential for ensuring longevity and performance in demanding environments.

Key Benefits of Using Petroleum FRP Pipe in Oil Industry

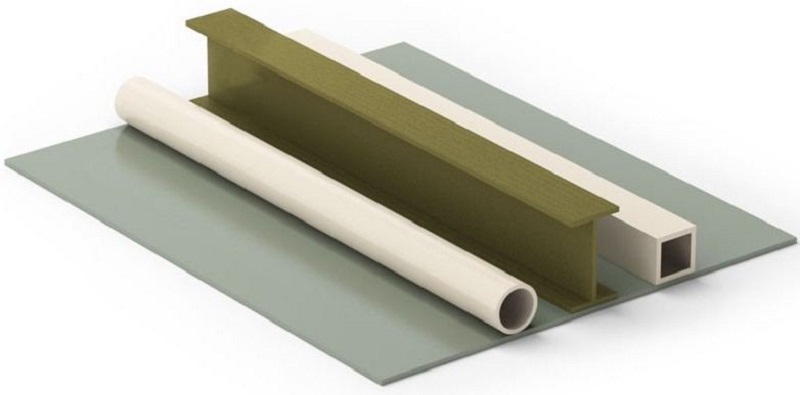

Fiberglass Pipe and Square Tubing

Fiberglass pipe and fiberglass square tubing are widely used in both industrial and residential applications due to their strength, durability, and versatility. These materials are popular choices for projects where traditional materials, like steel or aluminum, might fail due to corrosion or excessive weight, making fiberglass tubing near me a preferred option for many builders.

Key Applications of Fiberglass Square Tubing

Fiberglass square tubing is often used in structural supports and frames, especially in environments that require lightweight yet strong materials. The non-conductive and corrosion-resistant properties of fiberglass make it suitable for applications like:

Industrial Frames

Ideal for assembling lightweight, durable structures in chemical plants or factories.

Construction Supports

Used in building frameworks that require non-conductive materials, such as electrical rooms or corrosive environments.

Residential Fencing

Fiberglass square tubing is resistant to moisture and UV rays, making it a long-lasting option for outdoor fencing.

Overview of the Advantages of Fiberglass Pipe

Fiberglass pipe is highly valued for its unique combination of corrosion resistance, strength, and flexibility. This makes it ideal for handling fluids or gases in industries where traditional metal pipes would degrade quickly. Some key advantages include:

Corrosion Resistance

Fiberglass pipes are resistant to various chemicals and corrosive elements, making them ideal for use in harsh environments such as wastewater treatment plants or chemical factories.

Strength and Flexibility

Despite being lightweight, fiberglass pipes are strong enough to handle high pressure, making them suitable for high-pressure fiberglass pipe applications, such as oil and gas transportation. Additionally, fiberglass tubes are known for their remarkable flexibility, allowing them to bend without breaking. This flexibility makes them particularly useful in dynamic environments, like marine applications or plumbing systems. The strength and flexibility of fiberglass pipes also makes installation easier, as they can be shaped or routed around obstacles without the risk of fracture or damage.

Low Maintenance:

Once installed, fiberglass pipes require little maintenance compared to metal alternatives, saving time and costs over the lifespan of the project.

Where to Find High-Quality Epoxy Fiberglass Tube for Sale Online

The Importance of Choosing and Buying Fiberglass Tubing near Me

When looking for fiberglass pipe near me, it’s crucial to evaluate the specific requirements of your project. Whether you need tubing that can handle chemical exposure or lightweight materials for easier installation, the right choice can improve efficiency, reduce maintenance costs, and enhance the overall longevity of the system.

Advantages of Local Suppliers

Exploring local suppliers for fiberglass tubing near me offers additional benefits, including cost savings on shipping, faster delivery, and the ability to inspect products firsthand. Many local suppliers provide customization options, ensuring you get exactly what you need for your project.

Maximize Value with Expert Guidance

For the best results, it’s recommended to consult local experts who can assist in selecting the ideal fiberglass tubing for your specific application. With the right guidance, you’ll find high-quality materials that fit both your technical requirements and budget.

Advantages of GangLong Fiberglass as a Fiberglass Tubing Manufacturer

GangLong Fiberglass excels as a fiberglass tubing manufacturer, offering superior product quality and reliable service. Here’s why they stand out:

- Exceptional Product Quality

GangLong Fiberglass tubing is renowned for its high mechanical strength, combining rigidity and flexibility to suit a wide range of applications. The tubing features excellent corrosion resistance, ensuring durability in challenging environments, and anti-aging properties for long-term reliability. - Advanced Manufacturing Capabilities

The company leverages cutting-edge technology and processes to produce fiberglass tubing that meets the highest standards. Their ability to customize tubing according to specific requirements ensures solutions tailored to every project. - Innovative Approach

GangLong is dedicated to innovation, continuously introducing and refining new technologies in fiberglass manufacturing. This ensures their products remain competitive and capable of meeting modern engineering demands. - Strong Focus on Customer Needs

With a customer-centric philosophy, GangLong provides personalized service and technical support, ensuring every fiberglass tubing solution aligns with the client’s specifications and project scope. Their experienced team is ready to assist with any customization or technical challenge. - Durability and Cost-Effectiveness

GangLong fiberglass tubing offers an excellent balance of strength, weight, and cost, making it a preferred choice over traditional materials like steel or aluminum. Its long service life translates to reduced maintenance costs, making it an economical and reliable option. - Global Trust and Recognition

GangLong has earned the trust of domestic and international clients by delivering consistently high-quality products and maintaining strong partnerships. Their reputation as a reliable fiberglass tubing manufacturer is reinforced by their commitment to excellence.

Choose GangLong Fiberglass for robust, customizable, and efficient fiberglass tubing solutions, backed by a dedicated team ready to meet your needs. Contact them at [email protected] to start your project today.

Key Factors to Consider When Purchase Fiberglass Tubing Near Me

When purchasing fiberglass tubing, it’s essential to evaluate several factors to ensure the product meets your specific application requirements.

Here’s a detailed breakdown of the critical factors and their impact on your choice:

Strength-to-Weight Ratio

- Importance: Fiberglass tubing is popular for its lightweight yet strong structure. Choosing tubing with the right strength-to-weight ratio ensures it can handle the load and stress without adding unnecessary bulk.

- Impact: A higher strength-to-weight ratio is ideal for applications requiring portability or structural efficiency, such as in construction or transportation industries.

Corrosion Resistance

- Importance: One of the standout features of fiberglass tubing is its resistance to corrosion from chemicals, moisture, and harsh environmental conditions.

- Impact: For industries like marine, chemical, or outdoor installations, selecting tubing with superior corrosion resistance ensures durability and reduces maintenance costs over time.

Shape and Dimensions

- Importance: Fiberglass tubing is available in various shapes, including round, square, and rectangular, each suited to different applications. The dimensions also affect load distribution and fit within a design.

- Impact: Choosing the right shape ensures optimal structural performance. For instance, round tubing works well for evenly distributed loads, while square and rectangular shapes are better for stable frameworks.

Temperature Resistance

- Importance: Fiberglass tubing is known for its thermal stability, but the degree of resistance can vary. Applications in high-temperature environments require tubing capable of withstanding heat without deforming or losing strength.

- Impact: Using tubing with inadequate temperature resistance can lead to premature failure in environments such as industrial plants or power stations.

Customization Options

- Importance: Many manufacturers offer customizable solutions for fiberglass tubing, allowing you to specify length, diameter, wall thickness, and resin type.

- Impact: Customization ensures the tubing fits seamlessly into your project, saving time and resources during installation and improving overall efficiency.

UV Resistance

- Importance: Prolonged exposure to sunlight can degrade some materials, but UV-resistant fiberglass tubing maintains its structural integrity and appearance over time.

- Impact: For outdoor applications, choosing UV-resistant tubing minimizes wear and discoloration, prolonging its service life.

Manufacturer Reputation and Support

- Importance: A trusted local supplier of fiberglass tubing ensures consistent quality, quick delivery, and reliable customer support.

- Impact: Opting for a reputable manufacturer near you reduces the risk of delays or defective products and provides access to technical assistance if needed.

Cost and Value

- Importance: While fiberglass tubing is generally cost-effective, balancing price with quality is vital to ensure long-term value.

- Impact: Choosing a cheaper, low-quality product may result in higher maintenance or replacement costs in the future. Prioritizing value ensures a better return on investment.

By thoroughly considering these factors, you can confidently select fiberglass tubing near you that meets your specific project needs while ensuring durability, efficiency, and cost-effectiveness.

Factors Affecting the Manufacturer’s Pricing of Fiberglass Tubing Near Me

When purchasing fiberglass tubing near me, understanding the pricing structure is essential to make an informed decision. Manufacturers consider various factors when determining the cost of fiberglass tubing, which can significantly impact the final price. These factors include material quality, manufacturing process, customization options, and market conditions, among others. Knowing how each factor contributes to the pricing can help you evaluate options and choose the best product for your budget.

Below is a table summarizing the key factors influencing the pricing of fiberglass tubing and how they affect the manufacturer’s costs:

| Factor | Description | Impact on Pricing |

|---|---|---|

| Material Quality | The type and grade of fiberglass and resin used in production, including additives for specific properties. | High-quality materials increase costs but improve durability, strength, and resistance to corrosion. |

| Manufacturing Process | Techniques like pultrusion or custom molding require varying levels of expertise and resources. | Advanced methods like pultrusion are costlier but ensure precision and consistency in tubing. |

| Customization | Tubing tailored to specific dimensions, colors, or performance requirements. | Customization adds to costs due to additional labor, material usage, and specialized production. |

| Shape and Size | The shape (round, square, rectangular) and size (diameter, wall thickness) of the tubing. | Larger and more complex designs require more material and labor, increasing the price. |

| Quantity Ordered | The volume of tubing ordered in a single purchase. | Bulk orders often reduce per-unit costs due to economies of scale, while small batches are pricier. |

| Durability Features | Additional properties like UV resistance, chemical resistance, or fire retardancy. | Enhanced features increase the cost due to the need for specialized materials and treatments. |

| Shipping and Logistics | Transportation costs from the manufacturer to the buyer's location. | Proximity to the manufacturer can reduce shipping costs, making "fiberglass tubing near me" more economical. |

| Market Demand | Fluctuations in demand for fiberglass products within the local and global markets. | High demand can lead to increased prices, while low demand might result in discounts or promotions. |

| Labor Costs | The cost of skilled labor involved in the production and finishing of the tubing. | Regions with higher labor costs typically result in more expensive products. |

By analyzing these factors, you can better understand how manufacturers price fiberglass tubing and make cost-effective purchasing decisions that align with your project requirements.

FAQs about Fiberglass Tubing near Me

Cutting fiberglass tubing requires the right tools and precautions to ensure clean cuts and minimize damage to the material. A common method involves using a saw with a diamond or carbide-coated blade, as these are designed to cut through fiberglass without causing excessive splintering. Before cutting, it’s recommended to wrap the area where you

’ll make the cut with masking tape. This helps reduce the likelihood of splintering along the cut edges. Additionally, it’s important to use a stable surface and secure the tube firmly to prevent movement during the cutting process.

Always wear protective gear, including gloves, safety goggles, and a mask, as fiberglass particles can be harmful if inhaled or if they come into contact with the skin. For smaller diameter tubes, handheld rotary tools can also be used, while for larger diameter fiberglass tubing, a tile saw with a toothless carbide blade can ensure precision and minimize dust.

Fiberglass tubing is known for its impressive strength-to-weight ratio. Although lightweight, it is capable of withstanding substantial force, making it a preferred material in various industrial and structural applications. Fiberglass tubes are much lighter than steel yet provide similar strength in many cases. This makes them ideal for situations where weight needs to be minimized but strength is still essential.

In terms of tensile strength, fiberglass tubing can outperform certain metals, offering a high degree of flexibility without breaking under pressure. This strength is largely due to the way fiberglass is made, with filaments of glass woven together and coated in resin, creating a material that is resistant to stretching and bending. Additionally, fiberglass tubing is non-corrosive and resistant to environmental factors like moisture and chemicals, making it durable and long-lasting even in harsh conditions.

Fiberglass tubes are used in a wide range of applications due to their combination of strength, flexibility, and corrosion resistance. In the construction industry, they are often employed as structural supports, especially in environments where traditional materials like steel might corrode over time. For example, fiberglass tubing is frequently used in marine construction for docks, piers, and offshore platforms because of its ability to withstand exposure to saltwater and other corrosive elements.

Fiberglass tubes are widely used in telecommunications, where their non-conductive properties make them ideal for supporting antennas and other equipment. In recreational industries, they are commonly found in tent poles, fishing rods, and sports equipment due to their lightweight yet strong nature. Their versatility allows them to be used across various industries, providing a long-lasting and low-maintenance solution in numerous applications.

Fiberglass tubing offers several advantages, making it a preferred material in many fields. One of its key benefits is its corrosion resistance, which makes it suitable for use in environments exposed to moisture, chemicals, or extreme temperatures. Unlike metals, fiberglass doesn’t rust, corrode, or degrade over time, ensuring longevity and reducing the need for frequent replacements.

Fiberglass tubing is also lightweight but exceptionally strong. Its high strength-to-weight ratio means it can support heavy loads without adding significant weight, making it ideal for construction, aerospace, and marine applications. Additionally, fiberglass is non-conductive, which makes it an excellent choice for electrical insulation and in situations where avoiding electrical interference is crucial.Fiberglass tubing is customizable in terms of size, thickness, and finish, allowing it to meet specific project needs across various industries.

FRP (Fiberglass Reinforced Plastic) square tubes are structural components made from a composite of fiberglass reinforcements and resin. These tubes are lightweight yet exceptionally strong, offering corrosion resistance and durability. They are widely used in industries like construction, transportation, and marine applications due to their ability to withstand harsh environments, including moisture, chemicals, and UV exposure.

Compared to traditional materials like steel or aluminum, FRP square tubes offer a lower weight-to-strength ratio, making them easier to transport and install. Additionally, they are non-conductive and thermally stable, which enhances safety in electrical or high-temperature applications.

If you’re searching for “fiberglass tubing near me,” FRP square tubes might be the solution for your structural or industrial needs. Many local suppliers offer customizable sizes and colors, allowing you to find the perfect match for your project. Always compare specifications to ensure compatibility with your application.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.