Fiberglass sheet samples are essential for understanding the versatility and applications of fiberglass sheets. These samples allow users to evaluate different types, including laminate and standard sheets, before making a purchase. By examining fiberglass sheet samples, you can assess properties such as strength, thickness, and finish, ensuring you select the right type for your specific project needs. Whether for construction, automotive, or marine applications, fiberglass sheet samples provide invaluable insights into how these materials perform in real-world scenarios. To ensure the highest quality and variety of fiberglass sheets, sourcing from a reputable fiberglass sheet factory is crucial, as they can offer a wide range of options and tailored solutions for different industrial needs. Epoxy fiberglass sheet is especially significant in this context, as they demonstrate superior properties such as higher heat resistance, enhanced durability, and excellent chemical resistance. Choosing the appropriate fiberglass sheet samples can significantly impact the durability and functionality of your projects, making it crucial to explore all available options. GangLong Fiberglass offers fiberglass sheet samples for construction and marine use, letting you assess the material before ordering in bulk.

What are Fiberglass Sheet Samples?

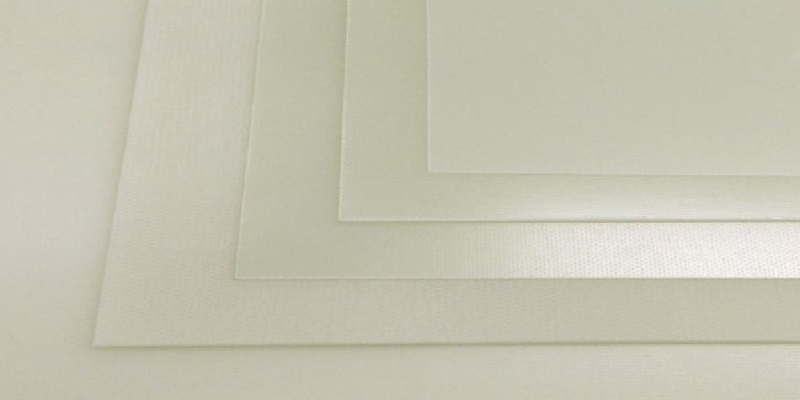

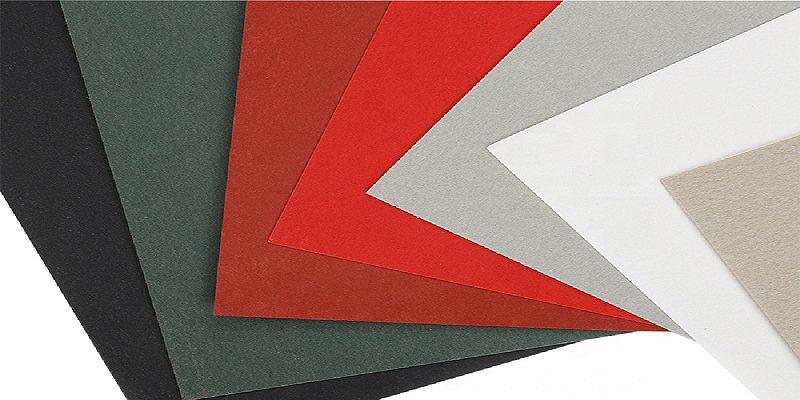

Fiberglass sheet samples serve as tangible representations of the different types of fiberglass available on the market. They provide an opportunity to physically assess the material’s texture, finish, and overall quality. When you handle fiberglass sheet samples, you can gauge how the sheets will perform in your specific applications. This firsthand experience is invaluable, especially for industries where material performance is critical.

Fiberglass sheet samples are critical for those exploring the various applications of fiberglass sheets. These samples allow users to examine the unique properties and benefits of different fiberglass sheets, helping them make informed decisions for their projects. When considering fiberglass sheets, it is essential to evaluate factors such as thickness, strength, and durability. Understanding these aspects through fiberglass sheet samples can lead to better outcomes in construction, automotive, and marine industries.

Applications of Fiberglass Sheets

Fiberglass sheets are versatile materials widely utilized in various industries, including construction and marine applications. The unique properties of fiberglass, such as its strength, lightweight nature, and resistance to environmental factors, make it an excellent choice for many projects. This section explores the common uses of fiberglass sheets, particularly in the construction and marine sectors.

Construction Industry Uses

In the construction industry, fiberglass sheets are employed for a variety of applications, thanks to their durability and adaptability. One prominent use is in the creation of cladding systems. These sheets provide an attractive finish and can be molded into various shapes, enhancing architectural design while also offering insulation properties. A fiberglass sheet with holes can be particularly useful in these applications, as the perforations allow for ventilation or light filtration, adding both functional and aesthetic value. Additionally, fiberglass sheets are resistant to rot and corrosion, which are critical factors in prolonging the lifespan of structures exposed to harsh weather conditions. When comparing acrylic vs fiberglass sheets, fiberglass is often chosen for its cost-effectiveness in such applications, whereas acrylic sheets might be preferred for projects prioritizing enhanced durability and aesthetics.

Fiberglass sheet samples are often utilized in roofing systems. Their lightweight nature reduces the overall weight burden on a building, making them an ideal option for modern architectural designs. The sheets can be manufactured in various thicknesses and sizes, allowing for flexibility in design. Their resistance to UV light also helps maintain structural integrity, reducing the need for frequent replacements.

Another significant application in construction is in the fabrication of partitions and walls. Fiberglass sheets can be used to create strong, lightweight walls that offer both privacy and sound insulation. This is particularly beneficial in commercial spaces where noise reduction is essential. Furthermore, these sheets can be treated to improve fire resistance, making them suitable for use in areas requiring stringent safety standards.

Marine Industry Uses

The marine industry heavily relies on fiberglass sheets due to their exceptional performance in challenging environments. Fiberglass is well-known for its durability and resistance to water damage, making it a preferred material for boat manufacturing and repairs. Fiberglass sheets for boats provide not only strength but also a lightweight alternative to traditional materials, improving fuel efficiency and handling.

One of the key benefits of fiberglass sheets in marine applications is their waterproof characteristics. Boats constructed with fiberglass are less prone to leaks and water-related damage. The material’s ability to resist saltwater corrosion also extends the lifespan of marine vessels. These properties make fiberglass an ideal choice for hulls and other structural components that must withstand the rigors of marine environments.

In addition to boat construction, fiberglass sheets are often used for various marine accessories, such as decking and storage compartments. These sheets can be easily molded to fit specific shapes and sizes, providing custom solutions for boaters. Their non-slip surfaces are particularly advantageous, enhancing safety for users while also allowing for aesthetic customization.

Additional Applications

Beyond construction and marine uses, fiberglass sheets find applications in many other fields. In the automotive industry, fiberglass sheets are used to manufacture body panels, helping to reduce vehicle weight while maintaining strength. This contributes to better fuel efficiency and improved handling characteristics in modern vehicles.

Another area where fiberglass sheet samples excel is in the realm of electrical insulation. These sheets are often utilized in the production of electrical enclosures and insulation barriers, providing reliable protection against electrical hazards. Their excellent dielectric properties ensure safety in various electrical applications, making them indispensable in industrial and commercial settings.

Fiberglass sheets are also increasingly being used in the renewable energy sector, particularly in the production of wind turbine blades. The strength-to-weight ratio of fiberglass allows for larger blades that can harness more wind energy, improving overall efficiency. Additionally, the durability of these materials ensures that they can withstand the elements, contributing to the longevity of wind energy installations.

GangLong Fiberglass provides specialized fiberglass sheet samples tailored to meet the needs of various industries. Understanding the specific applications can help customers make informed decisions about the products that will best suit their projects.

Benefits of Using Fiberglass Sheets

The popularity of fiberglass sheets can be attributed to their numerous advantages. One significant benefit is their lightweight nature, which makes handling and installation easier compared to heavier materials. This can lead to reduced labor costs and quicker project timelines.

Fiberglass sheets also offer excellent resistance to various environmental factors, including moisture, UV radiation, and chemical exposure. This resistance reduces the need for maintenance and replacement, ultimately leading to cost savings over the lifespan of the product.

Furthermore, fiberglass sheets are non-combustible, which enhances their appeal for use in construction and industrial applications where fire safety is a concern. This characteristic, combined with their durability, makes fiberglass sheets a reliable choice in various applications.

Lightweight and Easy to Handle

One of the primary advantages of using fiberglass sheets is their lightweight nature. Fiberglass sheets are significantly lighter than many traditional building materials such as metal or concrete, making them easier to transport, cut, and install. This ease of handling can result in faster project completion times, as less manpower is needed to move and position the material. Moreover, the reduced weight can lower shipping and handling costs, contributing to overall cost savings. For construction and marine industries, where time and labor are crucial factors, the lightweight properties of fiberglass sheets are a significant benefit, offering efficiency without compromising on durability.

Resistance to Environmental Factors

Fiberglass sheets are known for their excellent resistance to moisture, UV radiation, and chemical exposure, which makes them highly durable in various environments. In construction and marine industries, materials often face extreme weather conditions, humidity, and exposure to chemicals, which can degrade other materials over time. Fiberglass, however, resists corrosion, rot, and rust, making it an ideal choice for applications in coastal areas or places prone to harsh weather conditions. The UV resistance ensures that fiberglass sheets do not degrade or discolor under prolonged sunlight, and their resistance to chemicals makes them useful in industrial environments where exposure to corrosive substances is a concern. This durability results in reduced maintenance needs, longer product lifespans, and significant cost savings.

Non-Combustible and Fire-Resistant

Fiberglass sheets are inherently non-combustible, meaning they do not catch fire easily. This property is highly valuable in construction and industrial settings, where fire safety is a priority. In buildings, fiberglass sheets can be used in fire-resistant walls, ceilings, and other structural elements to prevent the spread of flames. Their fire-resistant nature not only enhances safety but also complies with building codes that require fireproofing materials. Additionally, fiberglass sheets maintain their integrity at high temperatures, providing an added layer of protection in industrial environments where fire risks may be elevated. This fire-resistant characteristic, coupled with their durability, makes fiberglass sheets a trusted material for both residential and commercial applications.

Reduced Maintenance and Long Lifespan

Fiberglass sheets are known for their low maintenance requirements due to their resistance to environmental damage, such as rot, corrosion, and UV degradation. Unlike wood, metal, or plastic, fiberglass does not require regular painting or treatment to maintain its appearance or functionality. This makes fiberglass sheets a highly cost-effective choice in the long run, as they don’t need frequent replacements or repairs. Their resilience also reduces the likelihood of damage, ensuring that fiberglass installations continue to perform efficiently for many years. This long lifespan, combined with reduced maintenance needs, makes fiberglass sheets an economical investment for both residential and industrial applications.

Versatile and Flexible Applications

Fiberglass sheets are incredibly versatile and can be adapted for use in a variety of applications. Whether in construction, marine, automotive, or industrial settings, fiberglass sheets can be customized in terms of size, thickness, and design to suit the specific needs of a project. Their ability to be molded into different shapes and sizes also allows for creative and functional uses in various industries. For example, in construction, fiberglass sheets can be used for wall cladding, roofing, and insulation, while in the marine industry, they are commonly used in boat hulls and other components. This flexibility makes fiberglass sheets a go-to solution for a wide range of projects, from small DIY repairs to large-scale industrial applications.

Cost-Effective

Although fiberglass sheets may have a higher upfront cost than some materials, their long-term cost-effectiveness is undeniable. Due to their durability, resistance to environmental factors, and minimal maintenance needs, fiberglass sheets reduce the need for frequent replacements and repairs. This lowers the total cost of ownership over time. Additionally, the lightweight nature of fiberglass reduces shipping and labor costs, contributing to overall savings. Their fire resistance and environmental durability mean that they can be used in applications where other materials might not last as long, further reducing replacement costs. Ultimately, fiberglass sheets offer a reliable, low-maintenance, and cost-efficient solution for a wide range of industries.

Selecting the Right Fiberglass Sheet Samples

When considering fiberglass sheet samples for a project, it’s essential to evaluate the specific requirements and conditions they will face. Factors such as thickness, size, and the intended application should guide the selection process.

GangLong Fiberglass offers a range of fiberglass sheet options tailored to meet diverse needs. Whether for construction, marine, automotive, or electrical applications, understanding the unique characteristics of each fiberglass sheet sample is crucial.

Additionally, considering the environmental impact of the materials is becoming increasingly important. GangLong Fiberglass is committed to sustainable practices, ensuring that their fiberglass sheets are produced with minimal environmental footprint.

Thickness in Fiberglass Sheet Samples

Thickness is one of the most important aspects to consider when selecting fiberglass sheets. Fiberglass sheet samples can come in various thicknesses, with options typically starting from as thin as 2mm. Thicker sheets are often used in applications requiring greater structural integrity, while thinner sheets may be suitable for less demanding environments. Evaluating fiberglass sheet samples allows you to determine the appropriate thickness needed for your project, ensuring optimal performance.

Properties of Fiberglass Sheet Samples

When examining fiberglass sheet samples, it is essential to consider their inherent properties. Fiberglass sheets are known for their high mechanical strength, making them suitable for demanding applications. They exhibit excellent temperature resistance, often tolerating heat up to 180°C, which is particularly beneficial in environments exposed to high temperatures. Additionally, fiberglass sheets have outstanding dielectric properties, making them ideal for electrical insulation purposes. Evaluating these properties through fiberglass sheet samples ensures you select the most appropriate product for your specific requirements.

Availability of Fiberglass Sheet Samples

The availability of fiberglass sheet samples is another crucial aspect for potential users. Depending on the region, various suppliers may offer a range of fiberglass sheets. GangLong Fiberglass is a reliable source for obtaining quality fiberglass sheet samples, showcasing different types and specifications. By visiting local suppliers or online platforms, you can access a variety of samples that meet your project needs. Understanding the availability helps you streamline your selection process.

Cost of Fiberglass Sheet Samples

Cost is always a consideration when sourcing fiberglass sheet samples. Prices can vary based on factors such as thickness, type, and supplier. GangLong Fiberglass offers competitive pricing for their fiberglass sheet samples, making it easier for businesses and individuals to access quality materials without breaking the bank. When budgeting for your projects, keep in mind that investing in high-quality fiberglass sheet samples can lead to better long-term performance and durability.

Environmental Considerations with Fiberglass Sheet Samples

As sustainability becomes increasingly important, understanding the environmental impact of fiberglass sheet samples is vital. While fiberglass is known for its durability, it is essential to consider how these materials are produced and disposed of. Choosing suppliers like GangLong Fiberglass that prioritize sustainable practices can help mitigate environmental concerns. Additionally, using fiberglass sheets in applications designed for longevity can reduce waste over time, contributing to a more sustainable approach.

Pricing and Budgeting

Pricing for fiberglass sheet samples in Australia can vary widely based on factors such as thickness, size, and supplier. Understanding the cost implications is crucial for effective budgeting. While it may be tempting to choose the cheapest option available, it is essential to consider the long-term value and performance of the materials.

GangLong Fiberglass offers a range of products at various price points, allowing customers to find options that fit within their budgets while still meeting quality standards. When budgeting for a project, it is advisable to account for additional costs such as shipping or installation, which can impact the overall expenditure.

Essential Specifications for FRP Cable Threading Pipe Use

Installation and Maintenance Requirements for Fiberglass Sheet Samples

Maintenance is an often-overlooked aspect of using fiberglass sheets. While they are known for their durability, proper care is still necessary to ensure their longevity. Regular inspections of fiberglass sheet samples are recommended to identify any signs of wear or damage. Cleaning should be performed with mild detergents and soft brushes to avoid scratching the surface. Understanding the maintenance needs of fiberglass sheets through samples can help users maintain their integrity over time.

Installation Tips

Installing fiberglass sheet samples requires careful attention to detail to ensure optimal performance and longevity. Proper installation techniques can prevent issues such as warping or delamination. It is advisable to follow manufacturer guidelines provided by suppliers like GangLong Fiberglass to achieve the best results.

Using appropriate adhesives and fasteners is crucial for securing fiberglass sheets effectively. Additionally, ensuring that the surface is clean and properly prepared can enhance adhesion and overall performance.

Maintenance and Care

Maintaining fiberglass sheets is relatively straightforward, making them an attractive option for many applications. Regular cleaning with mild soap and water can help preserve their appearance and functionality. For areas exposed to harsh conditions, periodic inspections are advisable to identify any signs of wear or damage early on.

GangLong Fiberglass often provides maintenance guidelines to assist customers in caring for their products. By following these recommendations, users can ensure the longevity and effectiveness of their fiberglass sheets.

How about Customization Options for Fiberglass Sheet Samples?

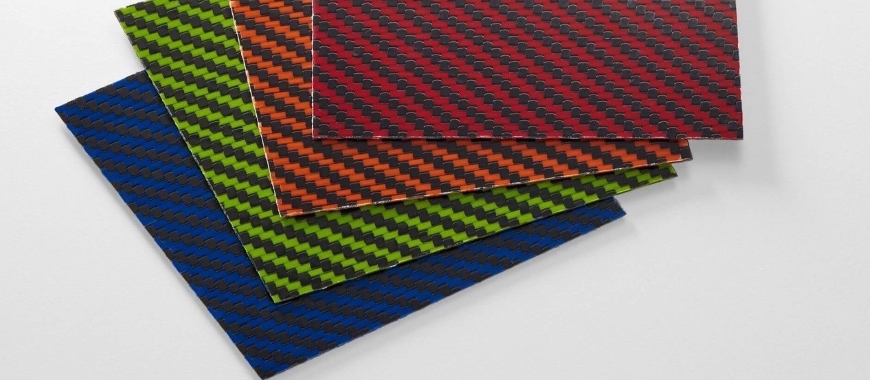

Customization is another essential feature when dealing with fiberglass sheet samples. Many suppliers, including GangLong Fiberglass, offer customization options to cater to specific project requirements. This can include tailoring the thickness, size, and even the color of the fiberglass sheets. By exploring fiberglass sheet samples, you can assess available customization options and determine what best fits your project needs. Customizable fiberglass sheets ensure that you can achieve the desired functionality and aesthetics.

Customization Options

One of the advantages of purchasing fiberglass sheet samples from local suppliers is the ability to explore customization options. Many companies, including GangLong Fiberglass, provide tailored solutions to meet specific project requirements. This may include custom sizes, thicknesses, or finishes that align with particular design preferences.

Customization can be particularly beneficial for specialized applications, such as in the marine industry where specific dimensions may be necessary for optimal performance. Suppliers often work closely with clients to understand their needs and provide solutions that enhance the overall functionality and aesthetic appeal of the final product.

Why Are Fiberglass Rods Shorter Than Other Fishing Rods

Shop Fiberglass Sheet Samples

Local Suppliers

In Australia, numerous suppliers specialize in fiberglass products, providing options that cater to both commercial and residential projects. Notable suppliers include hardware stores and specialized fiberglass distributors. One of the most recognized names in the market is GangLong Fiberglass, known for its comprehensive selection of fiberglass sheet samples. They offer sheets in various thicknesses and sizes, ensuring customers can find the right product for their specific applications.

Another option for sourcing fiberglass sheets is through large retail chains, which often stock a range of building materials. These suppliers provide a convenient way for consumers and contractors to access fiberglass sheets for their projects. Whether one is looking for standard sheets or customized sizes, local retailers are typically well-equipped to meet diverse requirements.

Sourcing Quality Products

When sourcing fiberglass sheet samples in Australia, quality should be a priority. It is important to consider factors such as the material’s durability, resistance to environmental elements, and ease of installation. Choosing reputable suppliers, such as GangLong Fiberglass, can help ensure that the products meet industry standards and are suitable for their intended applications.

Additionally, it is advisable to check for certifications or specifications provided by suppliers. These details can give insights into the performance characteristics of the fiberglass sheets. For instance, certain products may be designed to withstand higher temperatures or offer enhanced UV resistance, making them more suitable for specific environments.

Online Shopping Trends

The rise of e-commerce has significantly impacted the availability of fiberglass sheet samples in Australia. Many suppliers now offer online shopping options, allowing customers to browse products from the comfort of their homes. This trend provides convenience and often results in competitive pricing. Online platforms often feature comprehensive product descriptions and customer reviews, enabling buyers to make informed decisions.

GangLong Fiberglass also has a strong online presence, offering a wide array of fiberglass sheets with detailed fiberglass sheet specifications. This accessibility allows both individual consumers and contractors to order materials that meet their project needs without the hassle of visiting physical stores. By providing comprehensive specifications, GangLong Fiberglass ensures that customers can easily select the right sheets based on their requirements, whether it’s for strength, thickness, or finish.

Market Trends and Innovations

The Australian market for fiberglass sheets is continuously evolving, driven by innovations in materials and manufacturing processes. New technologies are being developed to enhance the performance and durability of fiberglass products. For example, advancements in resin formulations can result in fiberglass sheets that offer improved chemical resistance or lighter weight without compromising strength.

Keeping abreast of these trends is essential for contractors and consumers looking to make informed choices. Suppliers like GangLong Fiberglass often stay updated on the latest advancements, ensuring that they provide cutting-edge products to their customers.

Why the Best Fiberglass Rods Are Essential for Anglers

FAQs about Fiberglass Sheet Samples

Yes, fiberglass is commonly available in sheet form, typically used in construction, manufacturing, and for insulation purposes. Fiberglass sheets are often sold in various sizes and thicknesses, depending on the intended use. These sheets are made by weaving glass fibers into a fabric-like form, which is then coated with resin for reinforcement. You can purchase fiberglass sheets from hardware stores, specialized supply shops, and online retailers. The sheets are often used for applications such as creating custom moldings, reinforcing materials in construction, or producing lightweight, durable surfaces for boats and cars. Always handle fiberglass sheets with care, as the glass fibers can be harmful to the skin and lungs if disturbed during cutting or handling.

Fiberglass is found in a wide range of household items. Common household products that contain fiberglass include insulation materials (batts or rolls), air filters, and certain types of shower stalls and tubs. It’s also used in flooring tiles, some furniture, and even in the construction of windows or doors, especially in energy-efficient models. Some fabrics, particularly those used for curtains or upholstery, may be made with fiberglass to improve fire resistance. Additionally, products like boats, coolers, and even some outdoor furniture are often reinforced with fiberglass. Fiberglass is used because it provides durability, lightweight properties, and resistance to heat and water, which is ideal for many household applications.

Yes, fiberglass sheets can be cut, but it requires the proper tools and safety precautions. To cut fiberglass sheets, you typically use a circular saw or a utility knife, depending on the thickness of the material. When cutting fiberglass, it is essential to wear protective gear such as gloves, a dust mask, goggles, and long sleeves to avoid irritation from the fine glass fibers. Cutting fiberglass releases small particles into the air, which can be harmful if inhaled. If you’re using a saw, make sure to use a blade designed for fiberglass or a carbide-tipped blade for best results. You may also want to wear a respirator to protect against inhaling the dust. After cutting, clean up thoroughly to prevent any fiberglass dust from lingering in your environment.

Fiberglass is found in many discarded items that are considered junk, especially in older or broken household and industrial products. Examples include broken insulation materials, old fiberglass-reinforced plastics (such as parts of cars, boats, and outdoor furniture), and discarded fiberglass panels or tiles. Older, worn-out items like broken bathtubs, shower stalls, and swimming pools may also contain fiberglass. Additionally, fiberglass is commonly found in scrap from construction and renovation projects, including insulation or leftover sheets of fiberglass used in walls and roofs. When handling fiberglass waste, it’s important to follow proper disposal guidelines, as the material can be hazardous if its fibers become airborne and are inhaled or come into contact with the skin.

If you touch fiberglass, it is important to remove the fibers from your skin as quickly as possible to avoid irritation. First, try to brush off the fibers gently using a soft cloth or by tapping your skin to dislodge the particles. Do not rub the skin, as this can push the fiberglass deeper. After brushing off as much as possible, wash the area with soap and water, using a mild scrubbing motion to remove any remaining particles. If the irritation persists, you can apply a cold compress or take a shower to soothe the skin. If you experience significant itching, redness, or swelling, you may want to consult a healthcare professional. Avoid scratching the affected area, as this can lead to infection or further irritation.

To determine if an object is made of fiberglass, you can inspect its texture and weight. Fiberglass is typically lightweight but durable and can have a smooth, slightly shiny finish. You may also notice a woven pattern, as fiberglass sheets are made from interlacing glass fibers. The surface of fiberglass can often feel rough or textured, especially if it’s unfinished. Another method is to tap on the item; fiberglass often produces a dull sound, unlike metal or plastic. Additionally, you can check the manufacturer’s label or specifications for the material. If you’re still uncertain, you can test the object by exposing it to heat or chemicals. Fiberglass is known for its resistance to fire and chemical degradation, making it a good candidate for outdoor use or high-temperature environments.

Fiberglass does not “go away” on its own. Once it is in the environment or on your skin, it remains until it is physically removed. Fiberglass particles, such as those from insulation or broken sheets, can linger in the air or on surfaces for long periods, posing a potential health hazard. Fiberglass dust and particles can be inhaled or settle on fabrics and other materials, requiring cleaning and proper disposal. If fiberglass particles are on your skin, they will not dissipate without being washed off. Therefore, it’s crucial to take appropriate measures to clean and protect yourself from fiberglass exposure, especially in work environments where fiberglass products are frequently handled.

No, fiberglass is not found in all mattresses, but it is commonly used in some mattress brands, particularly those that are fire-resistant. Fiberglass is often used in the fire barriers of mattresses, as it is an effective material for preventing fires. It acts as a flame retardant by creating a barrier between the outer cover and the inner components of the mattress. However, not all mattresses use fiberglass; some may use other materials like wool or cotton to achieve the same fire-resistant effect. If you’re concerned about the presence of fiberglass, it’s always a good idea to check the manufacturer’s information or ask directly before purchasing a mattress, especially if you have sensitivities to the material.

“Poor man’s fiberglass” is a term used to describe alternative materials or methods that mimic the qualities of fiberglass without the cost. A common example is using cloth combined with polyester resin to create a lightweight, strong, and water-resistant surface, much like fiberglass. While it doesn’t have the same durability as traditional fiberglass, it can be used for DIY projects or temporary repairs where strength and waterproofing are required. This method is often employed by hobbyists and makers who need to reinforce materials or create custom molds but don’t have access to high-quality fiberglass materials. The term “poor man’s fiberglass” can also refer to low-cost, lesser-quality fiberglass products that may not meet the standards of commercial-grade materials.

Fiberglass is found in a wide variety of products, ranging from everyday household items to specialized industrial equipment. Common products containing fiberglass include insulation materials (batts, rolls, and loose-fill), reinforced plastic parts for cars, boats, and appliances, and various construction materials like roofing panels, wallboards, and siding. Fiberglass is also used in sporting goods like tennis rackets, surfboards, and bicycles, as well as in medical equipment such as casts. Other items like window frames, certain types of swimming pools, and water tanks may contain fiberglass for durability and resistance to corrosion. Additionally, some fabrics and textiles, especially those designed for fire resistance, are made from fiberglass fibers. The versatility of fiberglass makes it an essential component in products requiring strength, heat resistance, and lightweight properties.

Fiberglass is commonly used in mattresses as a flame retardant. However, there have been concerns about its safety in bedding products, particularly when the fiberglass is exposed. If the fiberglass is contained within a protective layer, such as a fire-resistant barrier, it is generally considered safe. However, if the mattress cover is damaged or the fiberglass is exposed, it can be a health hazard. Fiberglass particles can irritate the skin, eyes, and respiratory system. Consumers who purchase mattresses with fiberglass should take precautions, such as ensuring the mattress is not punctured or torn, and checking whether the fire barrier is intact. Some people may choose to avoid fiberglass-containing mattresses altogether or opt for alternatives made with non-toxic materials.

Fiberglass is primarily produced by companies that specialize in manufacturing composite materials and construction supplies. You can find fiberglass sheets, insulation, and other fiberglass products at home improvement stores, hardware stores, and specialized suppliers. Large retailers like Home Depot, Lowe’s, and Walmart may stock fiberglass products, especially for home insulation, repairs, or DIY projects. Online marketplaces like Amazon, eBay, and manufacturer websites are also reliable sources for fiberglass materials. For more specific needs, such as fiberglass for automotive or marine applications, specialized distributors or fabricators can provide high-quality materials. Depending on your needs (insulation, molding, or reinforcement), you may choose from a variety of forms, including rolls, sheets, and mats, available both in-store and online.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.