Threaded fiberglass rod is a durable, lightweight solution commonly used across construction and industrial applications. It offers excellent corrosion resistance, making it ideal for outdoor environments exposed to moisture and chemicals. These rods are manufactured using the pultrusion process, which ensures consistent strength and dimensional stability. Threaded fiberglass rod is valued for its ability to provide reliable tensile strength while remaining non-conductive, making it suitable for electrical installations. It also performs well under high temperatures and extreme weather, ensuring longevity. Threaded Fiberglass Rod structurally strong and reliable made of corrosion-resistant material with a wide range of styles and sizes. These rods come in various sizes to meet specific project requirements, such as the widely used 1/2 fiberglass threaded rod. The inclusion of threaded ends allows for secure fastening, enhancing versatility in structural and framing applications, similar to the use of a fiberglass rod thread spool in industrial setups for efficient storage and handling.

What Is Threaded Fiberglass Rod

Threaded fiberglass rod is a reliable material used across diverse industries, particularly in construction, electrical installations, and marine applications. Known for its corrosion resistance and non-conductive properties, it offers a strong, lightweight solution for fastening and structural needs. This section provides a detailed overview of threaded fiberglass rod manufacturing, material properties, dimensions, and specifications.

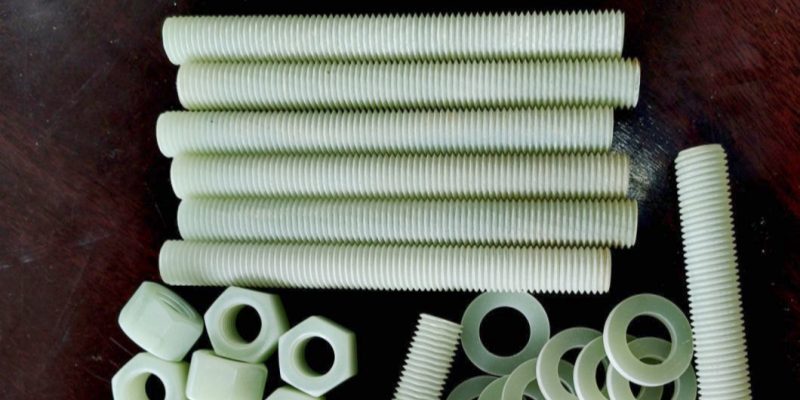

Description of Threaded Fiberglass Rods and Nuts

Threaded fiberglass rods and nuts are essential components used to secure frameworks and heavy structures. They offer distinct advantages compared to traditional metal rods. Below are key aspects related to their production and performance:

- Material Properties That Ensure Durability and Versatility

- Threaded fiberglass rod exhibits excellent corrosion resistance, even in harsh environments.

- It remains non-conductive, making it suitable for electrical installations.

- The material is lightweight, simplifying transportation and installation.

- Fiberglass rod tensile strength retain under high temperatures.

- Chemical resistance enhances their performance in industrial and marine settings.

- Practical Use Cases of Threaded Fiberglass Rods and Nuts

- Used in constructing frames for electrical cabinets and switchgear.

- Common in marine environments for corrosion-resistant fastening systems.

- Provides structural reinforcement for bridges and walkways.

- Ensures safe, non-conductive connections in substations and power plants.

- Supports ventilation systems and cable tray fittings in industrial buildings.

Threaded Fiberglass Rod Sizes and Specifications

Threaded fiberglass rod comes in various dimensions, each designed for specific applications. Selecting the right size ensures proper performance and safety. Below are details on dimensions and specifications relevant to these rods.

- Common Dimensions and Thickness Variations, Including 1/2 Fiberglass Threaded Rod

- Threaded fiberglass rods are available in standard thicknesses, such as 1/4 inch, 1/2 inch, and 1 inch.

- The 1/2 fiberglass threaded rod is widely used in structural applications.

- Thickness options allow these rods to support varying load capacities.

- Lengths typically range from 3 feet to 10 feet, depending on the application.

- Custom sizes are available for specific project needs, ensuring flexibility.

- Available Size Ranges and Lengths Suitable for Various Applications

- Smaller rods (e.g., 1/4 inch) are ideal for lightweight frameworks.

- Mid-range sizes, such as the 1/2 fiberglass threaded rod, are used for framing studs.

- Larger rods, like 1-inch diameter options, provide structural reinforcement.

- Shorter rods are often used for localized fastening in confined spaces.

- Long rods are essential for continuous frameworks, such as cable tray or bridges.

- Factors Influencing the Selection of Threaded Fiberglass Rod Sizes

- Load Requirements: Thicker rods support heavier loads with greater tensile strength.

- Environmental Conditions: Diameter and length affect stability in harsh conditions.

- Application Type: Smaller rods are used for detailed work; larger ones for structural support.

- Installation Constraints: Shorter rods are selected when space is limited.

- Maintenance Requirements: Proper sizing ensures durability and reduces repair frequency.

- Examples of Size-Based Use Cases

- 1/2 fiberglass threaded rod used in framing studs for residential construction.

- 1-inch rods applied in the reinforcement of bridges and platforms.

- Short rods supporting ventilation systems in industrial buildings.

- Long rods used to stabilize marine installations like piers and docks.

- Custom-sized rods designed for specialized electrical enclosures.

This detailed breakdown of threaded fiberglass rod sizes ensures that users can make informed decisions when selecting rods for their specific applications.

Advantages of Using Threaded Fiberglass Rod

Threaded fiberglass rods offer numerous advantages due to their unique material properties and design. Below is a detailed explanation of these benefits:

High Strength-to-Weight Ratio

Threaded fiberglass rods are known for their impressive strength while remaining lightweight. This characteristic makes them ideal for applications requiring strong structural support without adding unnecessary weight, such as in construction, transportation, and industrial equipment.

Corrosion Resistance

Fiberglass is inherently resistant to corrosion. Unlike metal rods, it does not rust or degrade when exposed to moisture, salt, or chemicals. This makes threaded fiberglass rods suitable for use in harsh environments, including marine settings and chemical processing facilities, ensuring longevity and reduced maintenance.

Electrical Insulation

Fiberglass rods are non-conductive, making them an excellent choice for electrical and telecommunications applications. Their dielectric properties provide safety and reliability, particularly in environments where electrical conductivity needs to be minimized or avoided.

Thermal Resistance

Fiberglass can withstand high temperatures without losing its structural integrity, making threaded fiberglass rods suitable for high-temperature applications. They are ideal for industrial settings or outdoor environments exposed to prolonged heat.

Customizable and Versatile

Threaded fiberglass rods are easy to cut, drill, and customize to meet specific needs. The threading allows for secure connections, enabling their use in various applications, including structural supports, machinery, and fasteners.

Lightweight and Easy to Handle

Compared to traditional materials like steel, fiberglass rods are significantly lighter. This makes them easier to transport, handle, and install, reducing labor costs and physical strain during construction or assembly projects.

Durability and Longevity

Fiberglass is highly resistant to wear and tear, UV radiation, and environmental degradation. This ensures that threaded fiberglass rods remain reliable over long periods, even in demanding conditions, reducing the need for frequent replacements.

Non-Magnetic Properties

Fiberglass rods are non-magnetic, which makes them ideal for applications where magnetic interference needs to be avoided, such as in sensitive electronic systems or scientific equipment.

Low Maintenance Requirements

Thanks to their resistance to corrosion, wear, and environmental damage, fiberglass rods require minimal maintenance, leading to significant cost savings over their lifespan.

Eco-Friendly

Fiberglass materials are often more environmentally friendly than metals. Their long lifespan reduces waste, and in some cases, they can be recycled, making them a sustainable choice for various applications.

Threaded fiberglass rods provide a reliable, efficient, and versatile solution for many structural and industrial applications. Their unique combination of strength, durability, and adaptability makes them a superior choice over traditional materials in numerous scenarios.

Essential Guide to Working with Coloured Fibreglass Products

Threaded Fiberglass Rod Material

Threaded fiberglass rods are composed of advanced composite materials designed for durability, strength, and resistance to environmental factors. Below is a detailed breakdown of the materials and their properties:

Core Material: Fiberglass (Glass-Reinforced Plastic – GRP)

Fiberglass is the primary material used in the production of these rods. It is created by reinforcing a polymer matrix with glass fibers, resulting in a composite material that offers a unique combination of strength and lightweight properties.

- Glass Fibers:

- Provide tensile strength and rigidity.

- Offer high resistance to impact and stress.

- Non-conductive and corrosion-resistant.

- Resin Matrix:

- Binds the glass fibers together to form a solid, durable structure.

- Enhances chemical resistance and thermal stability.

- Often made from thermosetting resins like epoxy, polyester, or vinyl ester, depending on the intended application.

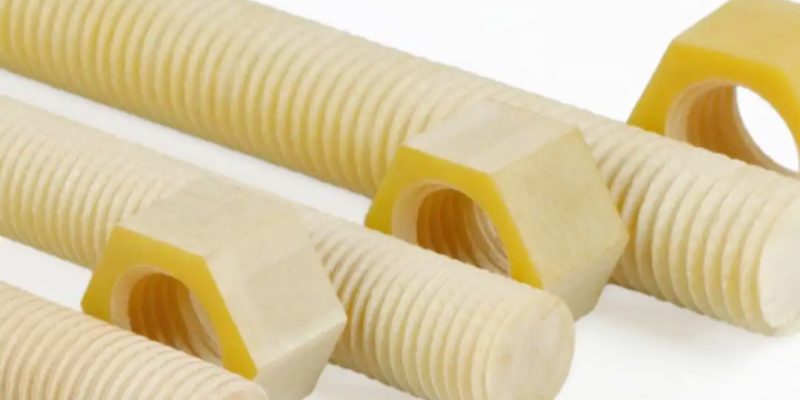

Threaded Section Material

The threaded portion of the fiberglass rod is typically integrated into the structure during the manufacturing process or created by machining.

- Integrated Threading:

- Produced during the molding process to ensure structural integrity.

- Threads are formed directly into the composite material, maintaining strength and consistency.

- Machined Threading:

- Achieved by precision cutting tools post-production.

- Ensures compatibility with specific applications while maintaining the properties of the fiberglass.

Optional Coatings and Additives

To enhance performance, manufacturers may include additional coatings or additives:

- UV Stabilizers:

- Protect against ultraviolet degradation, extending lifespan in outdoor applications.

- Fire Retardants:

- Improve resistance to high temperatures and flame exposure.

- Anti-Slip or Textured Coatings:

- Provide a better grip for specific industrial or manual handling needs.

Key Material Properties

- High Strength-to-Weight Ratio: Combines the lightweight nature of fiberglass with high tensile strength.

- Non-Conductivity: Ideal for electrical and telecommunication applications.

- Corrosion Resistance: Resistant to chemicals, moisture, and saltwater.

- Thermal Resistance: Performs well under high temperatures without deformation or loss of integrity.

- Environmental Durability: Resistant to UV rays, wear, and weathering.

Material Advantages Over Traditional Materials

- Compared to Steel:

- Lighter and corrosion-resistant.

- Non-conductive, avoiding electrical hazards.

- Compared to Aluminum:

- Superior chemical resistance.

- Higher tensile strength for certain applications.

- Compared to Plastic:

- Better structural integrity and heat resistance.

The choice of materials in threaded fiberglass rods ensures a balance of strength, durability, and adaptability for industrial, commercial, and specialized applications.

Threaded Fiberglass Rod Manufacturing Process

The production of threaded fiberglass rods involves several stages that combine fiberglass reinforcement with resin matrices to create a strong, durable, and customizable product. The following is a detailed description of the process:

Pultrusion Process

Most fiberglass rods, including threaded ones, are manufactured using the pultrusion process. This is a continuous manufacturing method that ensures uniformity and high-quality results.

- Steps in Pultrusion:

- Fiberglass Reinforcement Feeding:

- Glass fibers are unwound from spools and guided through preforming stations.

- The fibers are aligned to create the desired structure (longitudinal or crosswise layers).

- Resin Impregnation:

- The aligned fibers pass through a resin bath where they are thoroughly saturated.

- Excess resin is removed to achieve the correct resin-to-fiber ratio.

- Shaping and Curing:

- The resin-impregnated fibers are pulled through a heated die that shapes the material into a rod.

- The heat activates the curing process, solidifying the resin and locking the fibers into place.

- Cutting:

- The continuous rod is cut to the desired length using automated saws.

- Fiberglass Reinforcement Feeding:

Threading Process

The threading can be integrated into the manufacturing process or added after the rods are formed, depending on the design and application.

- Integrated Threading:

- During the pultrusion process, the die is customized to form the threads directly into the rod as it cures.

- This method ensures seamless integration and uniform threading.

- Machined Threading:

- For precise or custom threading, post-production machining is used.

- CNC machines or precision cutting tools create the threads without compromising the rod’s integrity.

Surface Treatments (Optional)

Depending on the application, additional treatments may be applied to enhance the rod’s performance:

- Coatings:

- UV-resistant or anti-corrosive coatings are applied for outdoor or harsh environments.

- Texturing:

- Anti-slip or textured finishes can be added for improved handling.

- Coloring:

- Pigments or dyes can be applied to match industry standards or aesthetic requirements.

Quality Control

To ensure that the rods meet stringent quality standards, manufacturers perform the following tests:

- Tensile Strength Testing:

- Confirms the rod can withstand specified loads.

- Thread Integrity Testing:

- Ensures proper fit and durability of the threaded sections.

- Environmental Testing:

- Verifies resistance to UV, moisture, and chemicals.

- Dimensional Accuracy:

- Checks for precise diameter and thread alignment.

Packaging and Distribution

- The finished rods are packaged to prevent damage during transport.

- They are often bundled or stored in protective sleeves, particularly for longer rods.

Advantages of the Process

- Consistency: The pultrusion process ensures uniformity in structure and strength.

- Customization: Threading and additional treatments allow the rods to be tailored for specific uses.

- Efficiency: The continuous manufacturing process reduces costs and production time.

This manufacturing process ensures a high-quality, durable product capable of performing in diverse and demanding environments.

Strength and Performance of Threaded Fiberglass Rod

Threaded fiberglass rod provides exceptional performance across a range of industrial and construction applications. Known for its high tensile strength, resistance to harsh environments, and reliable performance under stress, it is often chosen over traditional materials like steel. This section explores the tensile strength metrics of threaded fiberglass rod and its resistance to extreme temperatures and chemicals.

Fiberglass Threaded Rod Tensile Strength

Tensile strength defines how much force a material can withstand without breaking. Threaded fiberglass rod offers impressive tensile strength, ensuring reliable performance under heavy loads. Below is a detailed overview of tensile strength metrics, testing methods, and real-world performance.

- Overview of Tensile Strength Metrics and Testing

- Tensile strength is measured in pounds per square inch (PSI) or megapascals (MPa).

- Testing involves applying gradual force until the rod breaks or reaches its limit.

- A threaded fiberglass rod typically achieves tensile strength ranging from 50,000 to 100,000 PSI.

- Rods undergo testing in controlled environments to ensure consistent quality and performance.

- Standardized tensile tests guarantee each rod meets industry safety requirements.

- Performance Under Stress, Load, and Environmental Challenges

- Threaded fiberglass rod maintains structural integrity under heavy loads without bending or warping.

- It performs well in dynamic settings where vibrations or shocks are present.

- The rod’s tensile strength ensures long-term stability in framing applications.

- It supports electrical installations by holding cable trays without sagging.

- In bridges and walkways, it enhances durability by distributing load evenly.

- Benefits of High Tensile Strength in Practical Applications

- Ensures safe load-bearing capabilities in industrial environments.

- Prevents premature failure, reducing the need for repairs or replacements.

- Supports stable structures in earthquake-prone regions.

- Enhances safety in marine settings by withstanding wave impact.

- Ideal for electrical switchgear, preventing collapse under the weight of heavy cables.

- Challenges and Considerations in Testing and Application

- Overloading the rod may lead to gradual material fatigue.

- Extreme compression can impact the threaded ends, requiring maintenance.

- Uneven load distribution may affect long-term stability.

- Installation techniques can influence tensile performance.

- Consistent testing and inspection help prevent unexpected failures.

Temperature and Chemical Resistance Capabilities

Threaded fiberglass rod provides superior resistance to extreme temperatures and chemicals, making it ideal for harsh environments. This section details the rod’s heat tolerance and chemical resistance for industrial use.

- Heat Resistance and Temperature Tolerance

- Threaded fiberglass rod withstands temperatures from -40°C to 200°C without deformation.

- It remains stable during thermal cycling, reducing expansion and contraction risks.

- High-temperature performance makes it suitable for power plants and industrial facilities.

- The rod maintains structural integrity when exposed to direct sunlight or UV rays.

- It works well in hot climates, supporting outdoor structures without weakening.

- Advantages of Heat-Resistant Properties in Applications

- Ensures reliable performance in environments with fluctuating temperatures.

- Prevents warping or softening under intense heat.

- Provides durability in fire-prone environments, slowing heat transfer.

- Suitable for cooling towers and HVAC systems exposed to heat.

- Supports solar installations by maintaining shape during prolonged heat exposure.

- Chemical Resistance Properties for Industrial Use

- Threaded fiberglass rod resists degradation from chemicals, oils, and solvents.

- It performs well in corrosive environments like chemical plants and refineries.

- Saltwater exposure does not impact performance, making it ideal for marine use.

- Acid and alkali resistance ensures durability in laboratories and factories.

- It prevents rust formation, unlike metal alternatives, ensuring long-term reliability.

- Examples of Chemical-Resistant Applications

- Used in marine structures like piers, docks, and boats.

- Supports chemical storage tanks, offering corrosion-free stability.

- Reinforces wastewater treatment plants exposed to harsh chemicals.

- Ensures safe, corrosion-resistant installations in electrical substations.

- Ideal for framing structures in factories handling acids or corrosive substances.

- Limitations and Maintenance Considerations

- Extreme chemical exposure may reduce surface integrity over time.

- Rods require inspection in environments with concentrated chemical use.

- Temperature fluctuations combined with chemicals may affect performance.

- Protective coatings may enhance durability in highly corrosive environments.

- Scheduled maintenance ensures long-term reliability.

Threaded fiberglass rod delivers dependable performance through a combination of tensile strength, heat resistance, and chemical stability. Its ability to withstand challenging conditions ensures it remains a reliable choice for both industrial and structural applications.

Fiberglass Duct Rod For Efficient Cable Threading Solutions

Applications and Use Cases of Threaded Fiberglass Rod

Threaded fiberglass rod provides significant advantages across a variety of industries due to its lightweight, non-conductive, and corrosion-resistant properties. This section explores its practical use in construction, industrial settings, and specialized applications where threaded ends play a crucial role in ensuring stability and ease of installation.

Common Applications in Construction and Industry

Threaded fiberglass rod is a preferred material for both construction frameworks and industrial environments. Its versatility allows it to meet the demands of diverse sectors.

- Integration in Fiberglass Framing Studs for Building Frameworks

- Threaded fiberglass rod strengthens walls by integrating with fiberglass framing studs.

- It reinforces structures without adding unnecessary weight, improving load distribution.

- Non-corrosive properties make it suitable for coastal or humid environments.

- The rod ensures insulation in electrical installations, reducing energy transfer through walls.

- Its stability under stress enhances the safety of residential and commercial buildings.

- Utility Across Electrical, Marine, and Chemical Environments

- Threaded fiberglass rod supports electrical installations by securing cable trays and conduits.

- It prevents rust and corrosion in marine environments, ensuring long-lasting performance.

- Chemical plants use these rods for structural support where exposure to harsh chemicals is common.

- In wastewater treatment facilities, the rod resists chemical damage and moisture.

- Its non-conductive nature makes it ideal for power plants and electrical substations.

Fiberglass Rods with Threaded Ends for Specialized Use

Threaded fiberglass rods with threaded ends offer enhanced functionality for fastening and structural stability. The design allows them to integrate seamlessly into specialized applications, improving assembly and maintenance processes.

- Practical Uses in Fasteners and Reinforced Installations

- Threaded fiberglass rods with threaded ends provide a secure fastening solution in dynamic environments.

- They connect structural elements, distributing load evenly and preventing joint failure.

- These rods are used in bridge reinforcement to ensure long-term stability under heavy traffic.

- They fasten cable trays in industrial settings, preventing sagging over time.

- In marine applications, they offer corrosion-resistant fastening for boats and docks.

- Benefits of Threaded Ends for Secure Assembly and Maintenance

- Ease of Assembly: Threaded ends simplify the installation process, ensuring quick and secure fastening.

- Workers can use basic tools to assemble complex structures, reducing labor time.

- Fasteners align easily, ensuring precise connections in intricate frameworks.

- Reduced Maintenance Needs: Threaded ends maintain stability, minimizing maintenance over time.

- Connections remain secure, preventing loosening from vibrations or dynamic forces.

- The material resists wear, even in high-stress environments, reducing repair frequency.

- Versatility Across Applications: Threaded fiberglass rod is compatible with various fastener types.

- It integrates with nuts, washers, and brackets for multiple configurations.

- Adjustable connections allow for easy modifications to existing structures.

- Long-Term Durability: The rods resist corrosion, ensuring reliability in harsh environments.

- Threaded ends remain intact, even when exposed to chemicals or saltwater.

- Structures using these rods show improved longevity, reducing overall project costs.

- Enhanced Safety: Secure connections provided by threaded ends improve structural safety.

- Proper fastening prevents accidental disassembly or equipment failure.

- The non-conductive material ensures safety in electrical installations, minimizing risks.

- Ease of Assembly: Threaded ends simplify the installation process, ensuring quick and secure fastening.

Threaded fiberglass rods with threaded ends are essential in fasteners and reinforced installations due to their durability, ease of use, and resistance to environmental challenges. They remain an ideal choice for industries requiring secure assembly and long-lasting performance.

Key Benefits of Installing Fiberglass Fuse Tube Products

Threaded Fiberglass Rod Price and Availability

Threaded fiberglass rod provides reliable performance for construction and industrial applications, but understanding its pricing and availability is essential for making informed purchases. Prices vary based on several factors, such as dimensions, environmental resistance, and market demand. This section outlines the key factors influencing the cost and the size-based pricing structure for threaded fiberglass rods.

Pricing for Different Sizes of Threaded Fiberglass Rod

The cost of threaded fiberglass rod depends on its size, application requirements, and external factors affecting the market. Below is a breakdown of key pricing considerations.

- Factors Influencing the Price of Fiberglass Threaded Rods

- Rod Dimensions and Length:

- Larger diameters, such as 1-inch rods, require more material, increasing production costs.

- Longer rods also add to the cost due to the extra materials required.

- Smaller rods, like 1/2 fiberglass threaded rod, are more affordable for standard applications.

- Tensile Strength and Performance Standards:

- Higher tensile strength rods undergo more rigorous testing, impacting their final price.

- Stronger rods are designed for industrial environments, which adds to their value.

- Rods meeting specific load-bearing certifications may also carry a higher cost.

- Environmental Resistance Capabilities:

- Heat-resistant and chemical-resistant rods cost more due to specialized manufacturing.

- Corrosion-resistant materials add to the production expenses, especially for marine use.

- UV-stabilized rods for outdoor applications are priced higher to ensure long-term durability.

- Market Demand and Supply Chain Factors:

- Fluctuations in raw material availability directly impact fiberglass rod pricing.

- High demand in construction or industrial projects can temporarily raise prices.

- Seasonal demand shifts also influence pricing, especially for outdoor applications, affecting the cost of raw fiberglass rods used in these sectors.

- Customization and Special Orders:

- Custom sizes or finishes incur higher costs due to additional production steps.

- Orders requiring specific threaded ends or unique lengths may increase prices.

- Bulk orders usually offer cost savings, while small quantities may be more expensive.

- Rod Dimensions and Length:

- Overview of Available Sizes and Pricing Structures

- Standard Rod Sizes: Threaded fiberglass rods are commonly available in 1/4, 1/2, and 1-inch diameters.

- Length Options: Lengths vary from 3 feet to 10 feet, meeting different project requirements.

- Size-Based Pricing: Smaller rods are typically more affordable, while larger diameters increase in cost.

- Affordable Options for General Use: 1/2 fiberglass threaded rod is popular for residential construction due to its lower price.

- High-Performance Rods for Industry: Large-diameter and chemical-resistant rods are priced higher for specialized applications.

The factors influencing the price of threaded fiberglass rod helps buyers plan their projects efficiently. Selecting the appropriate size and performance level ensures the best balance between cost and functionality. Availability across different sizes ensures that threaded fiberglass rods meet a wide range of project demands.

FAQs about Threaded Fiberglass Rod

Yes, fiberglass rods can be threaded, but it requires specific tools and techniques. Fiberglass is a composite material made from glass fibers and resin, which can splinter or crack under improper machining. When threading fiberglass, it is best to use sharp, carbide-tipped tools and take slow, controlled passes to avoid damaging the material. It is also advisable to use a lubricant or coolant during the process to minimize heat buildup and wear. For best results, pre-drill the rod slightly smaller than the desired thread size and use a tap or die set designed for hard materials. For some applications, instead of threading directly, adding threaded inserts or adhesive-mounted fittings may provide better strength and longevity.

Yes, fiberglass fishing rods are excellent for specific applications. They are highly durable, flexible, and resistant to wear, making them ideal for anglers who prioritize toughness over lightweight design. Fiberglass rods excel in situations that require slow to moderate action, such as when targeting species like bass or panfish with live bait or soft plastic lures. Their slower action helps cushion the fight of larger fish, reducing the risk of hook pulls or line breakage. Additionally, fiberglass rods are generally more affordable than graphite alternatives, making them a great choice for beginners. However, they are heavier and less sensitive than graphite rods, which may be a drawback for some anglers who need precision and quick action.

The strongest threaded rods are typically made of high-strength materials like stainless steel, alloy steel, or titanium, with specific grades such as ASTM A193 B7 or ASTM F1554 Grade 105. Among these, alloy steel threaded rods are especially strong due to their combination of toughness, hardness, and resistance to deformation. Stainless steel rods (e.g., Grade 316) offer excellent corrosion resistance alongside considerable strength, making them ideal for outdoor or marine environments. The tensile strength of these rods can range from 70,000 PSI to over 150,000 PSI, depending on the material and grade. Always choose a threaded rod based on your specific load, environmental, and structural requirements for optimal performance.

Absolutely! Fishing tackle can be used with fiberglass rods just like any other rod material. Fiberglass rods are compatible with various tackle setups, including spinning, baitcasting, and fly fishing rigs. When attaching tackle, ensure that the rod’s action and power align with the weight of your lures and lines for optimal performance. For example, a medium-power fiberglass rod is ideal for mid-weight lures and live bait, while a heavier rod can handle larger lures or saltwater tackle. Fiberglass rods are versatile and resilient, making them suitable for both fresh and saltwater fishing when paired with the appropriate tackle.

Installing threaded inserts in fiberglass involves several careful steps to ensure a secure fit and prevent damage to the material:

Drill a Hole: Choose a drill bit size recommended for your insert and drill a pilot hole in the fiberglass.

Clean the Hole: Remove dust and debris from the hole to ensure a clean surface.

Epoxy Adhesive (Optional): Apply a high-strength epoxy adhesive to the hole for added grip and durability.

Insert the Threaded Insert: Screw or press the insert into the hole, depending on its design. Some inserts require a specific installation tool.

Allow Adhesive to Cure: If using epoxy, let it fully cure before applying load.

This process ensures a strong and reliable threaded connection in fiberglass.

Fiberglass rods offer several key benefits:

Durability: They are resistant to cracking, chipping, and general wear, making them long-lasting and suitable for rugged use.

Flexibility: Their slower action absorbs shock and provides excellent bend, making them ideal for battling hard-fighting fish.

Affordability: Fiberglass rods are generally more cost-effective compared to graphite rods.

Ease of Use: Their forgiving nature makes them a great choice for beginners and casual anglers.

Versatility: Suitable for various fishing styles, including trolling, bait fishing, and saltwater applications.

Despite being heavier and less sensitive than graphite, fiberglass rods remain a popular choice for their robustness and affordability.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.