FRP centrifugal fans, constructed from Fiberglass Reinforced Plastic, are highly valued in industries requiring reliable air movement in corrosive environments. Unlike traditional metal fans, FRP centrifugal fans offer exceptional resistance to chemicals, humidity, and other harsh conditions, ensuring long-lasting durability and minimal maintenance. Fiberglass fan blades are particularly advantageous in settings with constant exposure to corrosive substances, as they withstand deterioration that commonly affects metal components. These fans find applications across industrial and commercial settings, such as chemical plants, wastewater treatment facilities, and laboratories, where resilience and efficiency are essential. By combining robustness with efficient air movement, FRP centrifugal fans offer a dependable solution for maintaining air quality and ventilation in environments prone to chemical exposure and high moisture levels.

What is an FRP Centrifugal Fan?

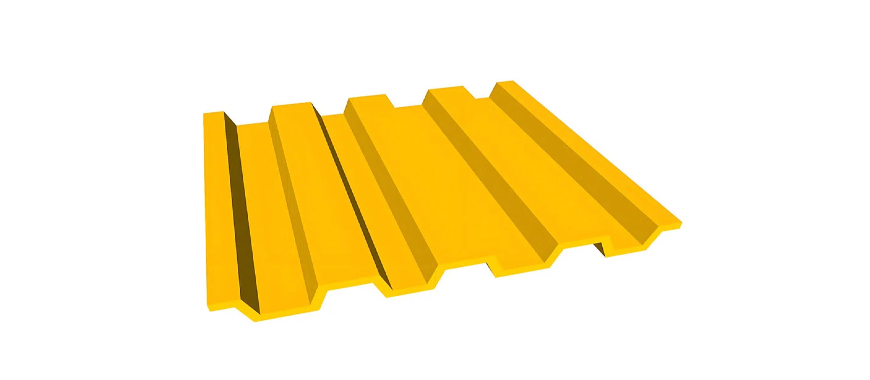

An FRP centrifugal fan, made from Fiberglass Reinforced Plastic, is a powerful tool for applications needing efficient air movement in challenging, corrosive environments. Built to resist harsh conditions, these fans serve as a dependable solution in industries like chemical processing, wastewater management, and various commercial settings. FRP centrifugal fans incorporate fiberglass materials that enhance their durability, making them essential in spaces prone to chemical exposure, moisture, and extreme temperatures. This unique material choice ensures the fan maintains consistent performance, reducing the need for frequent replacements or maintenance.

The FRP centrifugal fan is often chosen for environments where metal components may erode due to exposure to chemicals and humidity. Because of its resistance to corrosion, this fan type is ideal for facilities handling volatile substances or requiring high resistance to airborne contaminants. The fiberglass structure is lightweight, making the FRP centrifugal fan easier to install and operate across various industrial settings.

The Key of FRP Fans and Their Benefits

The FRP centrifugal fan offers significant advantages in terms of durability, efficiency, and adaptability. The fan blades, constructed from high-quality fiberglass, are resistant to corrosive damage, offering protection in environments where chemical exposure or high humidity levels are common. Unlike metal blades, which might weaken over time, fiberglass blades hold up against extreme conditions, helping maintain consistent air quality.

The unique properties of the FRP centrifugal fan make it a reliable solution for industrial and commercial sectors. It is highly effective in environments like factories, laboratories, and treatment plants, where strong, corrosion-resistant equipment is essential for safe, efficient operations. By using an FRP centrifugal fan, industries can ensure that they meet regulatory standards for air quality without the risks associated with metal corrosion.

Exploring the CFrp Centrifugal Fan Product Range

The product range of Frp Centrifugal Fan includes a variety of models, each tailored to specific airflow and pressure requirements. Each fan is designed to meet various needs across industrial settings while focusing on efficiency and durability.

SWSI Centrifugal Fan GIF Series

The SWSI Centrifugal Fan GIF series from GangLong Fiberglass is built for medium to high-volume airflow needs. Constructed to endure demanding conditions, this model is suitable for industrial facilities requiring consistent, strong ventilation. Its advanced design helps it efficiently handle the volume demands of large spaces without compromising structural integrity.

The SWSI Centrifugal Fan GIF series is particularly suited to chemical plants and production facilities where air volume and durability are critical for maintaining safe and stable operations. The fan’s structure ensures continuous airflow with minimal maintenance, thanks to the resilient FRP composition, which withstands environmental stressors.

BCMPA Series for Low to Medium Volume Needs

The BCMPA series from GangLong Fiberglass is designed to fulfill low to medium airflow requirements. It is ideal for settings where air volume demands are moderate but still require a fan that can resist environmental degradation. The BCMPA series provides reliable ventilation for industrial spaces with lower airflow needs, such as laboratories or small processing facilities. This FRP centrifugal fan model is versatile, fitting well into setups that benefit from a corrosion-resistant structure without needing high volume.

Due to its fiberglass construction, the BCMPA series ensures durability and efficiency, allowing companies to minimize maintenance concerns while keeping energy costs in check. Industries like food processing or smaller manufacturing units benefit from this model’s balanced design, as it provides the right amount of airflow without being excessive for the space’s needs.

High Pressure Solutions with the Frp Centrifugal Fan

Frp Centrifugal Fan series by GangLong Fiberglass is built for environments that require high-pressure airflow. This FRP centrifugal fan is essential for settings needing robust airflow to maintain optimal air quality. It serves as an ideal solution for facilities that deal with dense air contaminants or particulate matter. Thanks to its high-pressure capabilities, the HPB series can handle intensive airflow demands while maintaining a low maintenance requirement.

Designed with a focus on high resistance, the HPB series works well in various industrial environments, ensuring longevity and reliability. The high-pressure feature allows it to operate effectively even in areas with heavy particulate presence, safeguarding air quality standards and employee health.

Corrosion-Resistant Mini Series for Exhaust Needs

For smaller spaces or specific exhaust applications, GangLong Fiberglass offers the Mini Series, a compact and corrosion-resistant solution. This FRP centrifugal fan model is perfect for targeted ventilation requirements in confined spaces where corrosion resistance is crucial. Laboratories, controlled environments, or small workshops benefit from the Mini Series’ precise airflow capabilities and robust structure.

This fan’s compact design ensures it can be installed in tighter spaces without sacrificing performance or durability. The FRP construction adds an extra layer of protection, extending its operational life and minimizing the need for repairs. The Mini Series is designed to provide efficient, localized exhaust ventilation, keeping small spaces clear of contaminants or fumes.

Self-Cleaning MPA Series for Radial Applications

The MPA series from GangLong Fiberglass stands out for its self-cleaning design, making it suitable for radial applications in environments prone to dirt and debris. The MPA series is a unique FRP centrifugal fan that reduces maintenance needs by actively minimizing debris buildup. In industrial settings where contaminants can quickly accumulate, this fan ensures consistent airflow without frequent cleaning.

This self-cleaning feature is particularly useful in industries where downtime is costly. By choosing the MPA series, facilities can reduce maintenance intervals, enabling continuous operations. Its radial design and FRP construction also provide enhanced durability, ensuring the fan remains effective even in challenging environments.

Advantages of Choosing GangLong Fiberglass for FRP Centrifugal Fans

GangLong Fiberglass is a trusted manufacturer in the FRP centrifugal fan industry, known for producing high-quality, durable fans for a range of applications. Their products, including the SWSI, BCMPA, HPB, Mini, and MPA series, are all crafted with industrial requirements in mind.

GangLong Fiberglass offers exceptional customer support and ensures that each FRP centrifugal fan meets the highest standards for performance and reliability. Their fans are built to last, with a focus on providing solutions that cater to specific airflow and environmental needs. By investing in GangLong Fiberglass’s FRP centrifugal fans, industries can maintain safe, efficient, and environmentally compliant operations.

How about Selecting the Right FRP Centrifugal Fan for Your Application

Choosing the appropriate FRP centrifugal fan depends on the specific requirements of your environment, including airflow volume, pressure, and exposure to corrosive substances. With models ranging from high-volume to compact exhaust solutions, GangLong Fiberglass offers fans for any setting.

The right fan choice can enhance air quality, reduce maintenance costs, and increase operational efficiency. Understanding the demands of your industrial space is essential for selecting the most effective fan model. Whether the need is for high-pressure airflow, self-cleaning capabilities, or corrosion-resistant exhaust, GangLong Fiberglass has a suitable FRP centrifugal fan model to meet those needs.

What is FRP Centrifugal Fan

The FRP centrifugal fan is a specialized type of industrial fan crafted from fiber-reinforced plastic (FRP). These fans are highly valued in various industries for their exceptional resistance to corrosion, durability, and efficiency. Fiber-reinforced plastic, as a material, offers an outstanding solution for environments that expose equipment to aggressive chemicals or corrosive elements. FRP centrifugal fans are designed to handle these harsh conditions with minimal wear, thus maintaining reliable performance over extended periods. At GangLong Fiberglass, we produce a range of FRP centrifugal fans that meet different industrial needs, with models tailored for unique airflow requirements and specialized applications.

GangLong Fiberglass designs FRP centrifugal fans to support applications that demand clean air circulation, control of fumes, or handling of gases and vapors. These fans find their place in industries like chemical processing, waste treatment, laboratories, and more. Not only are they built to function efficiently in corrosive settings, but their design also supports safe and continuous operation under challenging environmental conditions.

Key Benefits of Using an FRP Centrifugal Fan

Durability and Corrosion Resistance

One of the leading features of an FRP centrifugal fan is its ability to withstand corrosive chemicals and environments. Unlike traditional fans made from metals, which can rust or corrode over time, FRP centrifugal fans are crafted from fiber-reinforced plastic, a material known for its resistance to acids, alkalis, and other chemical agents. This feature extends the lifespan of the fan and ensures its steady performance in harsh conditions.

The FRP material used in these fans has high resistance to UV light, water, and humidity, making it ideal for outdoor and chemically aggressive environments. In industries such as chemical processing, water treatment, and waste management, where equipment is frequently exposed to corrosive elements, FRP centrifugal fans offer a reliable solution that minimizes maintenance costs and ensures long-term performance.

High Efficiency and Performance

FRP centrifugal fans are designed to operate with high efficiency. Their advanced design minimizes energy consumption while delivering optimal airflow and pressure. These fans are engineered to move air effectively even in environments with high static pressure, making them suitable for demanding applications.

The internal structure of the fan, including the blades and housing, is meticulously designed to reduce turbulence and maximize airflow. This allows the fan to operate more efficiently, reducing energy costs and ensuring smoother operations. The lightweight nature of FRP also contributes to the fan’s performance, as it reduces the overall weight and allows for easier handling during installation.

Lightweight and Easy Installation

Compared to traditional metal fans, FRP centrifugal fans are significantly lighter, making them easier to handle, transport, and install. Their lightweight nature does not compromise their strength or durability, as FRP is a robust material capable of withstanding heavy-duty operations. The ease of installation also means that the fan can be quickly integrated into existing systems without the need for extensive modifications.

At GangLong Fiberglass, we ensure that our FRP centrifugal fans come with user-friendly designs that simplify the installation process. Whether the fan is being installed in a new system or replacing an older, less efficient unit, the lightweight and modular design of FRP centrifugal fans allows for a quick and smooth setup.

Customizable Designs for Specific Needs

Another significant advantage of FRP centrifugal fans is their customizable design. Depending on the specific requirements of the application, these fans can be tailored to fit particular sizes, capacities, and airflow characteristics. Whether the need is for high-pressure or high-volume airflow, GangLong Fiberglass offers a wide range of customizable options to meet various industrial needs.

For example, in a chemical processing plant where precise air movement is essential, an FRP centrifugal fan can be designed to deliver a specific airflow rate while maintaining optimal pressure levels. Similarly, for applications requiring high resistance to corrosive gases, our FRP centrifugal fans can be designed with enhanced protective coatings or internal linings to prevent any damage to the fan components.

Top FRP Distributors for Quality Fiberglass Products

How FRP Centrifugal Fans Enhance Industrial Applications

Ventilation in Chemical Processing

In industries like chemical processing, where harmful fumes and gases are a common byproduct, FRP centrifugal fans play a critical role in ensuring proper ventilation. These fans help in removing dangerous vapors, maintaining air quality, and reducing the risk of hazardous exposure to workers. The high resistance of FRP to corrosion from chemicals like acids or solvents makes it an ideal material for fans used in these industries.

The FRP centrifugal fan’s ability to move large volumes of air ensures that air is continuously exchanged within the processing facility, preventing the build-up of harmful gases. By using GangLong Fiberglass fans, industrial plants can ensure that their ventilation systems are both effective and long-lasting, reducing the need for frequent replacements.

Wastewater Treatment and Air Handling

FRP centrifugal fans are also widely used in wastewater treatment plants where air handling is crucial. These fans help in providing the necessary airflow for processes like aeration, where oxygen is introduced into the wastewater to promote the growth of bacteria that break down organic matter. The resistance to rust and corrosion provided by FRP materials ensures that the fans continue to operate even in the presence of damp and corrosive conditions typical of such plants.

The robust construction of FRP centrifugal fans also allows them to handle the high humidity and chemical exposure found in wastewater treatment facilities. As wastewater treatment plants often deal with various types of volatile organic compounds (VOCs), the ability of these fans to safely and efficiently circulate air while withstanding harsh environmental factors makes them an essential component in these applications.

Energy Efficiency in Industrial Ventilation Systems

In modern industrial environments, energy efficiency is a major concern. As energy costs continue to rise, manufacturers are looking for ways to optimize their operations to reduce consumption. FRP centrifugal fans contribute to energy savings by offering efficient airflow with lower power consumption compared to traditional fans.

The aerodynamic design of the fan blades, combined with the lightweight nature of the FRP material, ensures that these fans operate with minimal energy input. This makes them ideal for industries looking to reduce their overall energy expenditure while maintaining high levels of performance and air movement.

Basalt FRP: A Sustainable Solution for Modern Infrastructure

What to Consider When Choosing an FRP Centrifugal Fan

Performance Requirements

When selecting an FRP centrifugal fan, it’s essential to first evaluate the performance requirements of the system. Consider the volume of air that needs to be moved, the required static pressure, and the operating environment. Different models of FRP centrifugal fans are designed to meet various airflow and pressure needs, so choosing the right one ensures optimal performance.

At GangLong Fiberglass, we offer a wide range of FRP centrifugal fans, from low to high volume and pressure applications, ensuring that we have a solution for every requirement. Our expert team can assist in selecting the best model based on your specific operational needs.

Environmental Considerations

Environmental factors play a significant role in the lifespan and performance of an FRP centrifugal fan. When choosing a fan, it’s important to consider the external conditions it will face, such as temperature extremes, humidity, exposure to chemicals, and the likelihood of corrosive agents. FRP centrifugal fans excel in these harsh conditions, thanks to their superior corrosion resistance, making them the perfect choice for demanding environments.

Customization for Special Applications

In some cases, specific industrial applications require custom modifications to a standard FRP centrifugal fan. Whether it’s modifying the fan’s size, adding specific coatings, or adjusting the airflow characteristics, GangLong Fiberglass provides customizable options that ensure the fan meets the unique needs of the application.

By offering tailored solutions, GangLong Fiberglass ensures that our FRP centrifugal fans deliver optimal performance, enhancing both operational efficiency and the longevity of your equipment.

Future Trends in Advanced FRP: Shaping Tomorrow’s

FAQs about Frp Centrifugal Fan

An FRP fan is an industrial fan made of Fiberglass Reinforced Plastic, known for its high resistance to corrosion. It’s ideal for environments with corrosive gases or chemicals, commonly used in places like chemical plants, laboratories, and wastewater treatment facilities, where metal fans would corrode.

The three main types of centrifugal fans are:Radial fans: These have blades that extend straight out from the hub. They work well for high-pressure and medium-flow applications and can handle gases with particulates or sticky substances.

Forward curved fans: These have blades that curve in the direction of rotation, suitable for low-pressure, high-flow applications. They operate quietly but are generally less efficient than other types.

Backward curved fans: These have blades that curve away from the direction of rotation, providing higher efficiency. They are ideal for higher-pressure applications and offer better energy efficiency.

The full form of FRP blower is Fiberglass Reinforced Plastic blower. This refers to blowers made from FRP material, designed to withstand harsh and corrosive environments.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.