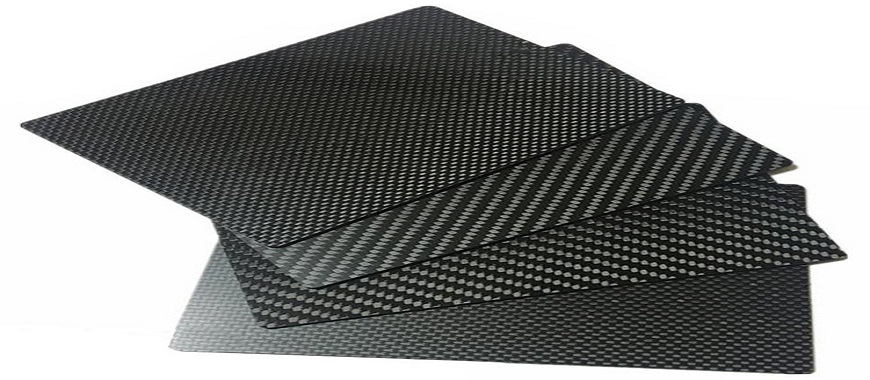

The carbon fiber industry has seen remarkable growth in recent years, becoming a key player in various global markets. Known for its lightweight, high-strength, and durable properties, carbon fiber is increasingly sought after across multiple sectors. Key industries such as aerospace, automotive, wind energy, and sports equipment rely heavily on carbon fiber to enhance performance, reduce weight, and improve energy efficiency. Additionally, the versatility of carbon fiber is expanding into new areas, with carbon fiber household products gaining traction due to their strength and durability. The growing demand for carbon fiber is driven by its superior performance characteristics, making it essential for applications that require precision, strength, and durability. As industries continue to innovate and seek more sustainable solutions, the carbon fiber industry is expected to remain at the forefront of technological advancements and material development.

Global Carbon Fiber Market Size and the Carbon Fiber Industry: Trends, Drivers, and Growth Projections

Market Value and Growth Projections

The carbon fiber industry continues to experience significant growth, with the market size in 2023 valued at approximately USD 17.4 billion. Projections indicate that the global carbon fiber market is expected to reach USD 23.2 billion by 2033, growing at a robust pace over the next decade. This growth is driven by the increasing demand for lightweight, high-strength materials across several high-performance industries, as well as technological advancements that are making carbon fiber more accessible and cost-effective.

The Compound Annual Growth Rate (CAGR) of the carbon fiber industry is estimated at around 6.8% from 2023 to 2033, reflecting a steady expansion in both demand and production. This growth trend is largely fueled by ongoing innovations in carbon fiber manufacturing processes, such as the development of more efficient and scalable methods for producing carbon fiber at lower costs. As industries continue to invest in sustainability, the carbon fiber market is expected to grow in tandem with the increasing need for advanced, high-performance materials.

Market Drivers

Several key factors are contributing to the rapid expansion of the carbon fiber industry, including:

- Increasing demand in aerospace: Carbon fiber is widely used in aerospace applications due to its lightweight nature, which improves fuel efficiency and reduces emissions. As the global aerospace industry continues to grow, especially with the rise in air travel and demand for fuel-efficient aircraft, the need for carbon fiber is expected to increase significantly.

- Automotive industry advancements: With the push towards electric vehicles (EVs) and lightweight components to enhance battery efficiency, the automotive sector is increasingly adopting carbon fiber for manufacturing vehicle parts. This adoption is driven by carbon fiber’s strength and durability, which helps improve vehicle performance and reduce energy consumption.

- Renewable energy growth: Carbon fiber’s role in wind turbines is becoming more prominent as the renewable energy sector expands. Carbon fiber’s strength-to-weight ratio is perfect for making large, durable turbine blades, which are critical for the efficiency of wind energy production.

- Technological innovations and material advancements: The development of new carbon fiber manufacturing techniques, such as automated carbon fiber placement and continuous fiber production, is significantly lowering production costs. These innovations make carbon fiber more accessible to a broader range of industries, including those with high-volume, cost-sensitive applications.

These drivers collectively position the carbon fiber industry for sustained growth in the coming years, with increasing adoption across multiple sectors pushing the market toward new heights.

Master Skills at Carbon Fiber and Fiberglass School

Carbon Fiber Industry and Carbon Fiber Stock Market: Trends, Insights, and Investment Opportunities

Stock Market Trends

The carbon fiber industry has garnered significant attention in the stock market, with several companies listed on global exchanges seeing substantial interest from investors. As the demand for carbon fiber continues to rise across various industries, the performance of carbon fiber manufacturers’ stocks has become a key area of focus. Key companies within the sector, such as Toray Industries, Hexcel Corporation, and SGL Carbon, are actively traded on major stock exchanges like the Tokyo Stock Exchange, New York Stock Exchange, and Frankfurt Stock Exchange.

The market performance of these companies is closely tied to the overall growth of the carbon fiber industry. As industries like aerospace, automotive, and renewable energy demand more advanced materials, these companies have seen their stock prices fluctuate in response to production capabilities, innovation, and global market conditions. For example, during periods of heightened demand, such as during advancements in electric vehicles or new aerospace projects, stocks in carbon fiber companies have demonstrated significant upward momentum.

However, market fluctuations also impact carbon fiber manufacturers. The volatility of raw material prices, such as petroleum-based precursors for carbon fiber production, and fluctuations in global supply chains can affect these companies’ profitability. In addition, macroeconomic factors, including interest rates, geopolitical issues, and trade regulations, can influence the stock performance of companies in the carbon fiber industry. As the industry is still evolving, stock market investors must keep an eye on trends in manufacturing technology and global demand to predict potential growth and risks.

Investment Insights

For stakeholders and potential investors, the carbon fiber industry presents a range of opportunities, though with some challenges. The sector’s rapid growth and increasing global demand for lightweight, high-strength materials make it an appealing market for investment. As industries such as aerospace, automotive, and renewable energy continue to integrate carbon fiber into their designs and production processes, there is an increasing opportunity for investors to gain exposure to companies within the supply chain.

Key investment opportunities in the carbon fiber industry include:

- Research and Development (R&D) Companies: Companies focusing on the development of new carbon fiber production techniques or more sustainable methods of manufacturing carbon fiber offer long-term growth potential. These firms are often seen as high-risk, high-reward investments due to the capital-intensive nature of their work and the potential for significant breakthroughs in material science.

- Raw Material Suppliers: Companies that supply the precursor materials for carbon fiber production, such as polyacrylonitrile (PAN) or pitch, represent a strategic investment opportunity, especially as global demand for carbon fiber grows. Investors may also look into companies focused on improving the efficiency of precursor material production.

- Manufacturers and End-Users: Major manufacturers that produce carbon fiber for industries like automotive, aerospace, and renewable energy are expected to experience consistent demand for their products. These companies are generally considered more stable investments, as their growth is tied to the expansion of carbon fiber use across these industries.

Notable stock market trends in the carbon fiber industry indicate that demand will continue to rise, especially with advancements in electric vehicle production and the transition toward more sustainable technologies in aerospace and construction. As the cost of carbon fiber production decreases with innovations in manufacturing, such as automated fiber placement and continuous fiber production, investors may expect increased profitability in the sector. However, the industry remains subject to external market pressures, so investors should be aware of potential volatility and the longer-term prospects of individual companies.

Carbon Fiber Aluminum and Fiberglass Alloy

Carbon Fiber Industry and Carbon Fiber Price Trends: A Comprehensive Overview

Historical Price Trends

Over the past decade, the carbon fiber industry has witnessed significant fluctuations in pricing, driven by various factors, including raw material costs, production methods, and technological advancements. In the early 2010s, the price of carbon fiber was relatively high, with prices for standard carbon fiber hovering around USD 30 to 40 per kilogram. However, the increasing demand from sectors like aerospace, automotive, and renewable energy, combined with advancements in manufacturing technologies, led to gradual price reductions by the mid-2010s.

A key factor influencing carbon fiber pricing has been the cost of raw materials used in its production. Carbon fiber can be produced from PAN-based (Polyacrylonitrile) or pitch-based precursors. The price of these raw materials fluctuates depending on global supply and demand, and any change in the price of these inputs directly impacts the overall cost of carbon fiber. For example, fluctuations in the cost of petroleum, which is the base material for PAN, have historically caused carbon fiber prices to rise during periods of oil price volatility.

Moreover, while technological improvements, such as automated manufacturing and better processing techniques, have helped reduce production costs, the high initial investment in carbon fiber plants and infrastructure has kept prices relatively high, especially in niche markets that require premium-grade carbon fiber.

Current Price Trends

As of the current market, carbon fiber prices have become more competitive, though they still vary depending on the specific application and material grade. For instance, standard carbon fiber prices in the automotive industry can range between USD 10 to 15 per kilogram, while high-performance aerospace-grade carbon fiber can cost upwards of USD 50 per kilogram.

Several factors contribute to the price fluctuations in the carbon fiber industry today:

- Demand Surge in Electric Vehicles (EVs): The automotive sector, particularly the electric vehicle market, has seen a significant increase in carbon fiber usage. This rise in demand for lightweight materials to improve fuel efficiency and battery performance has led to a steady increase in prices, particularly in the EV sector.

- Wind Energy and Aerospace Demand: The renewable energy sector, especially wind turbines, continues to drive demand for larger and stronger carbon fiber blades. In aerospace, the use of carbon fiber in aircraft components also remains high, contributing to price pressures due to the demand for high-quality, lightweight materials.

- Supply Chain Issues: The carbon fiber industry has faced disruptions in global supply chains due to geopolitical factors, natural disasters, and the ongoing effects of the COVID-19 pandemic. These supply chain constraints have led to increased prices for carbon fiber in some regions, particularly where production is concentrated.

- Technological Advancements: On the positive side, innovations in manufacturing methods, such as continuous carbon fiber production and automated fiber placement, have the potential to drive down the cost of carbon fiber production over the long term, leading to lower prices in the future.

Forecast

Looking ahead, carbon fiber price predictions are mixed but generally optimistic. Analysts expect prices to gradually decrease over the next 5-10 years, primarily due to the following factors:

- Increased Competition and Market Expansion: As more players enter the market and competition increases, prices may decrease, especially for standard carbon fiber used in mass-market applications like automotive and construction.

- Advancements in Production Techniques: Ongoing improvements in manufacturing processes, such as carbon fiber recycling and advanced processing technologies, are expected to make carbon fiber production more efficient and cost-effective, driving down material costs. This could particularly benefit industries with high-volume production needs.

- Supply-Demand Dynamics: Although the demand for carbon fiber will continue to grow across several industries, particularly in automotive, aerospace, and wind energy, supply shortages in raw materials or manufacturing capacity may create occasional upward price pressures in the short term.

While carbon fiber industry prices have seen some fluctuations over the past decade, future trends suggest that ongoing technological advancements, along with increased competition and improved manufacturing methods, will likely reduce costs and increase accessibility to this high-performance material. However, price stability will still be influenced by factors such as global demand, raw material costs, and supply chain conditions.

Introduction to Carbon Core Fiberglass: Key Features Explained

Carbon Fiber Industry and Carbon Fiber Cost: An In-Depth Analysis

Factors Influencing Carbon Fiber Cost

The carbon fiber industry faces a complex cost structure, driven by several factors that impact the final price of carbon fiber materials. Understanding the breakdown of these costs is essential for businesses and stakeholders looking to optimize production and purchasing decisions.

Key factors influencing the cost of carbon fiber include:

- Raw Materials: The base materials used to produce carbon fiber, particularly Polyacrylonitrile (PAN) and pitch, can account for a significant portion of the cost. These materials are petroleum-based, and fluctuations in oil prices often have a direct impact on carbon fiber prices.

- Manufacturing Processes: The production of carbon fiber involves energy-intensive processes like polymerization, spinning, and carbonization, all of which require specialized equipment and technology. As a result, these processes contribute to high operational costs. Carbon fiber made through high-temperature processing and advanced techniques tends to be more expensive due to the energy and time required.

- Labor: The skilled labor force needed to produce high-quality carbon fiber also adds to the cost. Advanced training and expertise are essential to ensure proper handling of raw materials, machinery, and quality control during production.

- Logistics: The cost of transporting raw materials to production facilities and shipping the finished carbon fiber products to end-users is another significant component. Global supply chain issues, such as increased fuel costs or transportation delays, can raise the overall cost of carbon fiber.

- Economies of Scale and Technological Advancements: The carbon fiber industry has experienced some improvements over the years in terms of economies of scale, where large-scale production leads to reduced unit costs. Moreover, technological innovations such as automated manufacturing and the development of cheaper precursor materials have been instrumental in lowering the cost of production in some cases. These advancements allow manufacturers to produce carbon fiber more efficiently, which can eventually lead to price reductions across various industries.

Cost vs. Performance

The cost of carbon fiber plays a crucial role in its adoption across different industries. While carbon fiber offers exceptional strength, durability, and light weight, its high price can often be a barrier to broader use, especially in industries where cost-effectiveness is a critical factor. However, the long-term performance benefits of carbon fiber often justify its price tag, particularly in industries where performance and material efficiency are paramount.

Some of the ways the cost of carbon fiber impacts various industries include:

- Automotive: In the automotive sector, carbon fiber is highly sought after for its ability to reduce weight and improve fuel efficiency. This is particularly relevant with the rise of electric vehicles (EVs), where the need for lightweight materials is even more crucial to enhance battery life. However, the high cost of carbon fiber can limit its use in mass-market vehicles, as automakers look for cost-effective alternatives without sacrificing safety or performance. As production methods become more efficient, it is expected that the automotive industry will be able to utilize carbon fiber more widely, especially in premium models and EVs.

- Aerospace: In the aerospace industry, carbon fiber is an essential material for reducing weight and improving fuel efficiency in aircraft. While the cost of carbon fiber is still relatively high, its use is justified due to the significant performance advantages, such as higher strength-to-weight ratios and better corrosion resistance, which ultimately lead to reduced maintenance costs and increased aircraft lifespan. As the carbon fiber industry grows and technology advances, the costs are expected to decrease, making it more accessible for broader use in both commercial and military aircraft.

- Wind Energy: The wind energy sector is another area where carbon fiber plays an important role, especially in the construction of large wind turbine blades. The high cost of carbon fiber is balanced by the material’s performance, which enables turbines to operate more efficiently and last longer. As demand for renewable energy grows, technological advancements in manufacturing and raw material sourcing could help bring down costs, making carbon fiber more widely used in wind energy applications.

Alternative Carbon Fiber Solutions

Due to the high cost of carbon fiber, industries have increasingly looked for alternative carbon fiber solutions to reduce production costs without sacrificing performance. Some of these alternatives include:

- Glass Fiber: More affordable than carbon fiber, glass fiber offers good tensile strength and durability but is heavier and less stiff. It is widely used in applications like construction, marine, and automotive industries where the highest performance is not required.

- Natural Fiber Composites: Materials like hemp, flax, and jute have been explored as alternatives to carbon fiber, especially in industries that require biodegradable and sustainable options. While these materials are cheaper, they typically don’t match carbon fiber’s strength and durability.

- Basalt Fiber: Made from volcanic rock, basalt fiber is gaining attention as a potential carbon fiber alternative. It offers excellent thermal resistance and high strength, but it is still not as widely used in comparison to carbon fiber or glass fiber due to limited manufacturing capacity.

- Hybrid Composites: By combining carbon fiber with materials like glass fiber or natural fibers, manufacturers can reduce costs while still achieving a good balance of performance. These hybrid composites are already being used in industries like automotive and sporting goods, offering a cost-effective solution without sacrificing too much in terms of weight or strength. Hybrid composites that integrate carbon fiber plastic offer an even more versatile solution by combining the advantages of both materials.

While the carbon fiber industry faces challenges related to high production costs, ongoing technological advancements and the exploration of alternative materials are making this high-performance material more accessible and affordable across various industries. By understanding the cost structure and the trade-offs between cost and performance, businesses can make informed decisions when choosing materials for their applications.

Carbon Fiber Industry and Carbon Fiber Market Allied Sectors: Exploring the Interconnected Growth

Complementary Materials

In the carbon fiber industry, carbon fiber itself is often not used in isolation. To unlock its full potential, complementary materials such as resins, composites, and coatings are frequently utilized alongside carbon fiber in various applications. These materials not only enhance the performance and durability of carbon fiber products but also help optimize cost-efficiency and manufacturing processes.

- Resins: Epoxy and polyester resins are commonly used to bond carbon fiber in composite materials. These resins provide structural integrity and protect the carbon fiber from external damage, such as impacts, environmental exposure, and chemical degradation. In the aerospace and automotive industries, resins are tailored to meet specific performance requirements like heat resistance, chemical resistance, and flexibility.

- Composites: The integration of carbon fiber with other materials like glass fiber, aramid fiber, or thermoplastic resins results in hybrid composites. These hybrid composites offer a blend of properties such as strength, stiffness, and lightweight characteristics. In some applications, fiber graphite is also combined with carbon fiber to enhance thermal conductivity and mechanical performance. This combination is particularly valuable in industries like aerospace and high-performance sports equipment, where both strength and heat dissipation are critical factors.

- Coatings: Coatings are applied to carbon fiber to improve its surface properties. These coatings can enhance corrosion resistance, provide UV protection, or improve friction properties in specific applications. For example, aerospace components may require coatings that protect against extreme temperatures and environmental conditions, while automotive parts may use coatings to reduce wear and tear.

Allied Industries

The carbon fiber industry has far-reaching impacts across a variety of allied industries, providing enhanced performance characteristics, weight savings, and durability in a wide range of applications. Some of the key industries benefiting from the use of carbon fiber include:

- Construction: Carbon fiber’s high strength-to-weight ratio makes it an excellent material for use in construction, particularly for reinforcing structures. Carbon fiber reinforced polymers (CFRP) are used in the repair and strengthening of concrete and steel structures, such as bridges, buildings, and tunnels. These materials help extend the lifespan of structures while reducing the need for extensive, costly repairs or rebuilds. In earthquake-prone regions, carbon fiber is also utilized to reinforce buildings for seismic safety.

- Defense: The defense industry has seen significant advancements through the use of carbon fiber in lightweight armor, vehicle structures, and weaponry. Carbon fiber composites provide strength and protection without adding excessive weight, making them ideal for military applications. Carbon fiber is used in everything from personal body armor to missile casings, UAVs (unmanned aerial vehicles), and military vehicles. The material’s ability to withstand high-impact forces and extreme conditions has made it an indispensable component in modern defense technologies.

- Sports and Recreation: In the sports sector, carbon fiber’s lightweight and high-performance characteristics are leveraged in products like bicycles, skis, tennis rackets, golf clubs, and kayaks. Athletes and enthusiasts benefit from carbon fiber’s ability to enhance performance by reducing the weight of equipment while maintaining durability and strength. The technology has revolutionized competitive sports, providing an edge in both professional and recreational activities.

- Renewable Energy: The renewable energy sector, particularly wind energy, has seen significant contributions from the carbon fiber industry. Carbon fiber composites are used to manufacture large wind turbine blades, which require a combination of strength, lightweight, and flexibility to withstand harsh weather conditions while maintaining performance. As the demand for renewable energy continues to grow, carbon fiber’s role in improving the efficiency and sustainability of wind energy generation becomes increasingly important.

Technological Innovations and Sustainability

Advancements in the carbon fiber industry have not only focused on improving material performance but also on promoting sustainable practices and reducing carbon footprints. As industries face growing pressure to adhere to environmental regulations and sustainability goals, carbon fiber technology has evolved to address these concerns.

- Recycling and Reusability: One of the key areas of innovation in the carbon fiber industry is the development of recycling methods for carbon fiber composites. Traditionally, carbon fiber materials are challenging to recycle due to their rigid, high-performance structure. However, new processes, such as pyrolysis and solvolysis, are being developed to break down carbon fiber composites into reusable fibers, helping to close the loop and reduce environmental impact.

- Sustainable Manufacturing Practices: Manufacturers are increasingly adopting energy-efficient processes and sourcing renewable energy to power production plants. Innovations in the carbon fiber industry include the use of sustainable precursor materials, such as plant-based fibers, and the reduction of energy-intensive steps in the manufacturing process. These improvements are making carbon fiber production more eco-friendly and less reliant on petroleum-based feedstocks.

- Carbon-Negative Alternatives: The introduction of alternative materials like Galvorn offers a promising step forward in sustainability. Galvorn, a new generation of carbon fiber alternative materials, has a carbon-negative footprint, meaning it absorbs more carbon than is emitted during its production. This development is paving the way for more sustainable solutions in industries that rely on carbon fiber for high-performance applications.

The carbon fiber industry continues to evolve in response to technological advancements and sustainability demands. Complementary materials, along with innovations in recycling and manufacturing practices, are driving progress in various allied industries. By leveraging these advancements, industries can continue to benefit from the exceptional performance of carbon fiber while contributing to global sustainability goals.

FAQs About Carbon Fiber Industry

The carbon fiber industry has proven to be a highly profitable sector, especially as demand for advanced materials continues to grow. The profitability of carbon fiber businesses is driven by its widespread use in high-performance applications across industries like aerospace, automotive, wind energy, and sports equipment. Carbon fiber’s unique properties—such as high strength-to-weight ratio, durability, and heat resistance—make it a sought-after material, particularly in sectors that prioritize performance, safety, and fuel efficiency.

However, the carbon fiber business does come with challenges that can affect profitability, such as high production costs, which are primarily due to the expensive raw materials and energy-intensive manufacturing processes. To counter these challenges, companies are increasingly focusing on scaling production, improving manufacturing technologies, and reducing costs through automation and alternative raw material sourcing. As demand for lightweight, sustainable, and high-strength materials grows, particularly in the electric vehicle (EV) and renewable energy sectors, the carbon fiber market is expected to remain profitable and expand in the coming years.

The carbon fiber industry is dominated by a few key players, with the largest producers being Toray Industries (Japan), Hexcel Corporation (USA), and SGL Carbon (Germany). Toray Industries holds a significant share of the global carbon fiber market, with its high-quality products being used in a variety of industries, from aerospace to automotive. The company has established a reputation for technological advancements in carbon fiber production and has made substantial investments in research and development to maintain its market leadership.

Hexcel Corporation is another major player in the carbon fiber market, particularly known for its high-performance composite materials. It supplies carbon fiber to industries like aerospace, automotive, and wind energy. SGL Carbon, with a focus on sustainable carbon fiber solutions, also plays a significant role in the industry. These companies, along with others, are actively investing in expanding production capacities and developing cost-effective solutions to meet the rising demand for carbon fiber materials globally.

Yes, carbon fiber is in high demand and continues to experience significant growth across multiple industries. The increasing emphasis on lightweight, durable, and high-performance materials in sectors like aerospace, automotive, sports, and renewable energy is driving this demand. In the aerospace industry, carbon fiber is crucial for reducing weight and improving fuel efficiency in aircraft, while in automotive, it is being used to make vehicles lighter, which enhances fuel efficiency and performance, particularly for electric vehicles (EVs).

The wind energy sector is also a key driver of carbon fiber demand, as manufacturers use carbon fiber composites for wind turbine blades, which need to be both light and strong to withstand extreme weather conditions. Additionally, sports equipment, such as bicycles, tennis rackets, and golf clubs, rely heavily on carbon fiber for its strength and lightweight properties. As industries increasingly focus on sustainability, carbon fiber’s role in reducing energy consumption and carbon emissions makes it even more desirable, leading to continued demand.

The forecast for carbon fiber is highly positive, with the market expected to continue expanding at a steady pace. According to industry reports, the global carbon fiber market is projected to reach a value of USD 23.2 billion by 2033, growing at a compound annual growth rate (CAGR) of 10.5% over the next decade. This growth is largely driven by the increasing adoption of carbon fiber in key industries such as aerospace, automotive, wind energy, and sports equipment.

Technological advancements in carbon fiber production are expected to reduce costs and increase accessibility, further fueling its adoption across various sectors. For example, innovations in the production of carbon fiber from sustainable sources, such as plant-based fibers, could drive the material’s popularity even higher. Additionally, the growing focus on electric vehicles and renewable energy solutions is likely to boost demand for carbon fiber, as these industries require lightweight, high-strength materials to meet performance and environmental goals.

With the continued focus on performance, sustainability, and energy efficiency, the carbon fiber market is poised for substantial growth in the coming years, with both demand and investment expected to rise significantly.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.