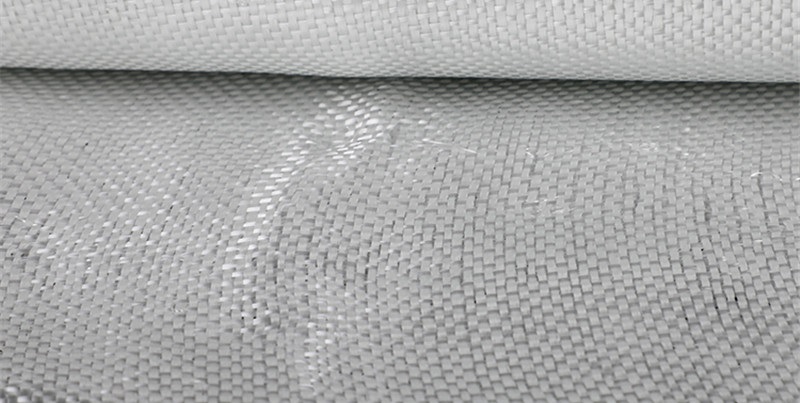

Choosing the right adhesive for fiberglass fabric is crucial for achieving strong, durable bonds in various projects. Fiberglass fabric is widely used due to its lightweight nature and high structural integrity, making it essential to select adhesives that can effectively handle these properties. Applications include construction, marine, and automotive industries, where fiberglass fabric plays a critical role in reinforcing surfaces and structures. Specialized adhesives are necessary to ensure a secure bond without compromising the material’s strength or flexibility. Using the wrong adhesive could lead to weak joints, reducing the fabric’s performance and longevity. Therefore, understanding the appropriate adhesive for fiberglass fabric is key to ensuring project success and durability. The best adhesive for fiberglass fabric includes epoxy and methyl methacrylate, offering strong bonds, waterproofing, and multi-material versatility.

What Are Adhesives for Fiberglass Fabric

Definition and Purpose of Adhesives for Fiberglass Fabric

Adhesives for fiberglass fabric are specifically designed to bond fiberglass fabric to various surfaces or other materials. Fiberglass fabric, known for its lightweight and durable properties, is commonly used in industries like construction, automotive, and marine engineering. To ensure that fiberglass fabric retains its structural integrity, specialized adhesives are required. These adhesives offer a permanent and stable bond without compromising the fabric’s strength or flexibility. Incorporating fiberglass fabric facts, such as its heat resistance and adaptability, highlights the importance of choosing the correct adhesive to ensure that the bonded material remains effective under pressure and in harsh environments, making it essential for a wide range of applications.

Importance of Using the Right Adhesive for Long-Lasting, Durable Bonds

Choosing the right adhesive for fiberglass fabric is crucial for creating long-lasting, durable bonds. Below are five reasons why selecting the right adhesive is essential:

- Resistance to Environmental Conditions

Fiberglass fabric is often exposed to extreme conditions, including high humidity, water, and temperature variations. The right adhesive ensures the bond can withstand these changes without breaking down. A high-quality adhesive will resist degradation from exposure to elements like UV rays, moisture, and chemicals, ensuring that the bond lasts over time. - Maintaining Structural Integrity

Adhesives designed for fiberglass fabric help maintain the material’s structural integrity. When bonded properly, fiberglass fabric contributes to reinforcing structures, from boats to composite panels. A strong bond prevents delamination, which could lead to material failure in high-stress applications. - Flexibility for Dynamic Loads

Fiberglass fabric is used in situations where flexibility is required, such as in parts that expand, contract, or move. Choosing the correct adhesive ensures that the bond can withstand dynamic loads and movement without cracking or losing its grip. This is especially important for applications like marine vessels or vehicles that are constantly exposed to vibrations. - Enhanced Aesthetic Finish

Mechanical fasteners like screws or bolts can create visible marks or seams that disrupt the surface of fiberglass. An adhesive creates a smooth, uniform surface without the need for external hardware. This not only enhances the aesthetic appeal of the finished product but also eliminates the potential for weak points where fasteners may loosen over time. - Time and Cost Efficiency

The right adhesive simplifies the assembly process. Mechanical fasteners often require drilling, screwing, or bolting, which increases production time and labor costs. Adhesives, on the other hand, provide a faster and more efficient method for bonding fiberglass fabric, reducing overall production time and costs in large-scale manufacturing.

The Rising Popularity of Fiberglass Tube Slides

Strongest Adhesive for Fiberglass Fabric

Explanation of What Makes an Adhesive Strong for Bonding Fiberglass Fabric

The strongest adhesive for fiberglass fabric should meet several key criteria to provide reliable and durable bonds. Fiberglass fabric is lightweight but requires an adhesive that can create a strong, long-lasting connection. The strength of the bond depends on several factors, including the adhesive’s ability to handle environmental stress, its chemical composition, and its compatibility with the material. A high-strength adhesive will maintain its hold even when exposed to temperature changes, humidity, and physical stress. Additionally, the adhesive must be able to bond with fiberglass fabric without causing damage or degradation to the material.

Key Features to Look for When Selecting a High-Strength Adhesive

- High Tensile Strength

The tensile strength of an adhesive refers to its ability to resist forces that attempt to pull it apart. For fiberglass fabric, an adhesive with high tensile strength ensures that the bond holds even when exposed to stretching, tension, or pulling forces. - Temperature Resistance

Fiberglass fabric is often used in environments where temperature fluctuates significantly. A strong adhesive must be able to maintain its bonding strength in both high and low temperatures without softening, cracking, or losing adhesion. This is particularly important in automotive and aerospace applications. - Moisture and Chemical Resistance

Fiberglass fabric is commonly used in marine or outdoor applications, where exposure to moisture, saltwater, and chemicals is frequent. The strongest adhesive for fiberglass fabric should resist water absorption and not break down or weaken when exposed to these elements. Waterproof adhesives ensure that the bond remains intact, even in damp or corrosive environments. - Flexibility and Elasticity

For projects involving fiberglass fabric, flexibility is key. The strongest adhesive must allow for some movement and expansion between bonded materials without causing cracks in the adhesive. This flexibility is crucial in applications where vibrations or dynamic forces are present, such as in boats or airplanes. - Curing Time and Open Time

A high-strength adhesive for fiberglass fabric should offer a suitable balance between curing time and open time (the period during which the adhesive remains workable). For large-scale or complex projects, longer open times can be beneficial, allowing for adjustments during assembly. However, once in place, the adhesive must cure fully to achieve its maximum bonding strength. - Compatibility with Fiberglass Fabric

Not all adhesives bond well with fiberglass fabric. The strongest adhesive must be chemically compatible with fiberglass, ensuring a smooth and effective bond. Some adhesives may not adhere properly or may cause damage to the fiberglass, leading to delamination or weakened structures. Always check the adhesive’s material compatibility to ensure optimal bonding.

Selecting the right adhesive for fiberglass fabric is essential for ensuring long-lasting, strong, and durable bonds. By considering factors such as tensile strength, temperature resistance, moisture resistance, flexibility, curing time, and material compatibility, you can choose the best adhesive for your specific project needs. Whether working on marine, automotive, or construction applications, the right adhesive will provide the necessary strength and resilience to withstand environmental and physical stress.

Waterproof Adhesive for Fiberglass Fabric

The Need for Waterproof Adhesives in Moisture and Outdoor Applications

When working with fiberglass fabric, it is essential to choose a waterproof adhesive to ensure a reliable bond in environments exposed to moisture or harsh weather conditions. Fiberglass fabric is commonly used in outdoor and marine settings, where contact with water, humidity, or chemicals is inevitable. Using a waterproof adhesive for fiberglass fabric helps prevent the bond from weakening due to exposure to these elements. Without waterproof properties, adhesives may break down over time, leading to failure and potential structural damage. Waterproof adhesives are designed to maintain their strength even when fully submerged or subjected to rain, humidity, or splashes, making them indispensable for projects involving boats, outdoor structures, and wet environments.

Outdoor exposure also involves challenges like extreme temperature fluctuations, UV radiation, and harsh chemicals. A waterproof adhesive for fiberglass fabric must withstand these conditions while preserving its bond integrity. For applications like sealing boat hulls, joining parts of outdoor panels, or reinforcing fiberglass in swimming pools, waterproofing is crucial. A reliable adhesive prevents water from seeping into the bond line, ensuring a strong, long-lasting connection that won’t degrade or fail when exposed to outdoor conditions.

Types of Waterproof Adhesives Suitable for Fiberglass Fabric Projects

- Epoxy Adhesives

Epoxy adhesives are one of the most popular choices for bonding fiberglass fabric in water-exposed environments. These adhesives offer excellent resistance to water and chemicals, making them ideal for projects involving marine applications, swimming pools, and outdoor installations. Epoxies cure to form a solid, durable bond that remains effective even in high-moisture environments. Furthermore, epoxy adhesives are highly versatile, working well in bonding fiberglass fabric to various surfaces such as wood, metal, and plastic. - Polyurethane Adhesives

Polyurethane adhesives are known for their flexibility and water resistance, making them ideal for projects that require waterproofing. This type of adhesive for fiberglass fabric is particularly useful when working with materials that expand, contract, or move in response to environmental changes. Polyurethane adhesives form strong bonds that resist water, UV radiation, and environmental wear, making them an excellent choice for outdoor applications. These adhesives are often used in construction, automotive, and marine industries where both water resistance and flexibility are required. - Silicone-Based Adhesives

Silicone-based adhesives provide excellent water resistance and are highly effective in sealing applications. Although not always the strongest adhesive, silicone works well in waterproofing situations where sealing is a primary concern. It is flexible, resistant to temperature extremes, and creates a long-lasting bond when properly applied. Silicone adhesives are often used in situations where fiberglass fabric is in contact with water, such as in aquariums or outdoor fixtures exposed to rain and moisture. - Acrylic Adhesives

Acrylic adhesives are another option for waterproof bonding, offering good water resistance and flexibility. These adhesives are often chosen for their fast curing times and strong bonding capabilities. Acrylics form a durable bond that resists water and environmental factors, making them ideal for use with acrylic fiberglass fabric. They are often used in construction and marine industries where water exposure is a concern, providing a balance between strength and water resistance for bonding fiberglass fabric to different surfaces.

Waterproof Glues That Are Ideal for Fiberglass Materials

When working with fiberglass materials, especially in environments where exposure to water is a concern, it is essential to use a waterproof glue. Waterproof adhesive for fiberglass fabric is specifically designed to withstand moisture and create a durable bond even when submerged or exposed to constant water contact. There are several types of waterproof adhesives ideal for bonding fiberglass fabric, including epoxy, polyurethane, and silicone-based adhesives. Each type of glue has its strengths, and the choice depends on the specific needs of the project.

Epoxy-based adhesives are widely regarded as one of the strongest waterproof glues available for fiberglass materials. They provide high resistance to water, chemicals, and extreme temperatures, making them suitable for use in marine and outdoor applications. Polyurethane adhesives are also excellent for waterproofing, providing flexibility along with strong adhesion, which makes them suitable for environments that experience temperature fluctuations or vibrations. Silicone-based adhesives, while not as strong as epoxy, offer excellent sealing properties and can be used in projects where water exposure is moderate.

Applications and Benefits in Environments Exposed to Water

Waterproof adhesive for fiberglass fabric plays a critical role in various industries and applications, particularly where exposure to water and moisture is a constant factor. Marine applications, such as boat hull repair, benefit from waterproof adhesives due to their ability to create strong, long-lasting bonds in wet environments. In such cases, the adhesive must resist both saltwater and freshwater without weakening over time. Additionally, waterproof adhesives are used in construction projects where fiberglass fabric reinforces structures exposed to rain, such as outdoor panels, roofs, and swimming pools.

One of the key benefits of waterproof adhesives is their ability to maintain their bonding strength even when submerged for long periods. Unlike non-waterproof adhesives, which can degrade and lose adhesion when exposed to water, these glues are designed to remain intact, ensuring the longevity of the project. Furthermore, many waterproof adhesives are resistant to chemicals, UV rays, and temperature extremes, adding an extra layer of protection to outdoor applications. This makes them versatile in projects where environmental factors could otherwise compromise the bond.

Selecting the appropriate adhesive for fiberglass fabric is essential for ensuring the success and durability of any project. For DIY enthusiasts, understanding the various options and following proper application techniques can make a significant difference in the quality of the final result. In water-exposed environments, choosing a waterproof glue that can withstand moisture and harsh conditions ensures that your bond will stand the test of time. Whether you’re working on a small DIY project or a large-scale industrial application, the right adhesive can significantly impact the strength and longevity of your fiberglass fabric bonds.

Best Adhesive for Fiberglass Fabric

At GangLong Fiberglass, we understand how crucial it is to choose the right adhesive for fiberglass fabric for your project. Whether you’re working on a large-scale industrial application or a smaller DIY task, making the right adhesive choice is key to ensuring long-lasting, durable bonds. Throughout this guide, we’ve covered various types of adhesives such as epoxies, methacrylates, and urethanes, each offering unique strengths depending on the demands of your project.

Epoxies are a strong contender when strength and environmental resistance are top priorities. They offer incredible durability, making them suitable for both structural applications and projects exposed to harsh conditions like water and extreme temperatures. Methacrylates, on the other hand, are ideal when flexibility and impact resistance are critical, as they bond with minimal surface preparation and cure quickly. Urethanes stand out for their ability to stretch and handle expansion and contraction, making them perfect for dynamic environments.

Tips on Selecting Adhesives for Both Structural and Non-Structural Applications

- For Structural Applications

When bonding fiberglass fabric for structural purposes, prioritize adhesives with high tensile strength and environmental resistance. Epoxy adhesives are often the best choice, as they provide strong bonds and are resistant to harsh conditions. Structural applications also require adhesives that can handle dynamic loads without losing strength over time. - For Non-Structural Applications

For projects where the bond will not experience significant stress or load-bearing, flexibility and ease of use may be more important than strength. In these cases, silicone-based or polyurethane adhesives may be suitable. These adhesives offer good adhesion, flexibility, and water resistance, making them appropriate for sealing, DIY, and aesthetic applications. - Consider Adhesive Temperature Tolerance

In both structural and non-structural applications, check the adhesive’s tolerance to temperature changes. Fiberglass fabric is often used in environments with fluctuating temperatures, and the adhesive must withstand these changes without becoming brittle or losing adhesion.

Encouragement to Explore Further Options Based on Project Needs

Each project is unique, and so are its adhesive requirements. That’s why we encourage you to explore further options and experiment with different adhesive for fiberglass fabric solutions based on your specific needs. Whether you need a strong bond for structural integrity or a flexible adhesive for dynamic environments, there is a perfect adhesive solution available.

At GangLong Fiberglass, we are always here to help you navigate the options and choose the best product for your project. Our range of adhesives is designed to meet a variety of industrial and DIY needs, ensuring that you get the best performance and durability from your fiberglass fabric applications. Feel free to reach out to us for personalized recommendations or additional resources to support your adhesive selection process.

DIY Adhesive for Fiberglass Fabric

Guide to Selecting Adhesives for DIY Projects Involving Fiberglass Fabric

Choosing the right adhesive for fiberglass fabric DIY projects is crucial for ensuring a strong and long-lasting bond, especially in DIY projects. Fiberglass fabric is known for its lightweight and durable properties, but it requires an adhesive that complements these characteristics. When selecting an adhesive, it’s important to consider the specific demands of your project, such as the type of surface you’re bonding the fabric to, environmental exposure, and the expected strength of the bond. Some common adhesive options for DIY projects include epoxy, polyurethane, and silicone-based adhesives. Each has distinct advantages and can be tailored to specific DIY needs.

For example, if your project requires bonding fiberglass fabric to wood, plastic, or metal, an epoxy adhesive is often the best choice due to its strong bonding properties. If flexibility is required, especially in outdoor applications, a polyurethane adhesive may be ideal as it can handle the expansion and contraction caused by environmental changes. In simpler DIY projects, where sealing and moderate bonding strength are needed, silicone-based adhesives can be effective.

Tips on Proper Application Techniques to Ensure Effective Bonding

- Surface Preparation

Before applying any adhesive for fiberglass fabric, the surfaces must be clean and dry. Any dirt, oil, or dust on the surface can compromise the bond. For best results, clean the surface with a solvent and allow it to dry completely. - Sanding for Better Adhesion

Lightly sanding both the fiberglass fabric and the surface to which it will be bonded can improve adhesion. This creates a rougher surface, allowing the adhesive to grip better. Sanding should be done with fine-grit sandpaper, ensuring you don’t damage the material. - Mixing Two-Part Adhesives Properly

Many adhesives for fiberglass fabric, such as epoxies, come in two parts: a resin and a hardener. For optimal bonding strength, it’s essential to mix these components thoroughly before applying. Incomplete mixing can result in weak bonds or incomplete curing. - Applying Adhesive Evenly

When applying adhesive, use an even, thin layer across the entire bonding surface. Applying too much adhesive can lead to excess squeezing out when pressure is applied, while too little can result in a weak bond. Use a brush or spreader to ensure even coverage. - Pressure Application During Curing

For maximum bonding strength, apply consistent pressure while the adhesive cures. Clamps or weights can be used to hold the surfaces together, ensuring the bond cures correctly and evenly. - Allowing Adequate Curing Time

Each adhesive for fiberglass fabric has a specific curing time, which can vary depending on the environment and temperature. Always allow the adhesive to fully cure before subjecting the bond to stress. Rushing the process can weaken the bond, leading to premature failure.

Affordable Plastic Fiberglass Repair Kit for Home Projects

Advantages of Using Specialized Adhesives for Fiberglass Fabric

Benefits of Using Adhesives Over Mechanical Fasteners for Fiberglass Projects

Using specialized adhesive for fiberglass fabric offers several advantages over traditional mechanical fasteners like screws, bolts, or rivets. Adhesives provide a cleaner, more effective bonding solution without adding extra weight or causing damage to the material.

- Eliminating Stress Points

Mechanical fasteners create localized stress points on the material, which can lead to cracks, delamination, or other structural failures. By using adhesives, the stress is distributed evenly across the entire bond line, reducing the risk of damage. This is especially important in projects involving dynamic loads or movement, where stress points could cause long-term issues. - Reducing Added Weight

Fasteners add unnecessary weight to the project, which can be problematic in applications like aerospace, automotive, or marine industries. Adhesives offer a lightweight alternative that maintains the structural integrity of the fiberglass without the extra bulk. Reducing the weight not only improves performance but also increases fuel efficiency in transportation-related projects. - Vibration and Noise Reduction

Adhesives create a continuous bond that helps dampen vibrations and reduce noise. This is particularly beneficial in applications like vehicles or boats, where minimizing noise and vibration is critical for comfort and performance. Unlike mechanical fasteners that can loosen over time, adhesives provide a consistent bond that remains effective even in high-vibration environments. - Seamless Aesthetic Finish

Another significant advantage of using adhesives is the smooth, seamless finish they provide. Mechanical fasteners can leave visible marks, protrusions, or uneven surfaces, detracting from the final appearance of the project. Adhesives create a clean, uniform surface that enhances the aesthetic appeal of the bonded fiberglass fabric, making them ideal for projects where appearance is important.

Improved Structural Integrity, Reduced Stress Points, and Better Aesthetics

Specialized adhesive for fiberglass fabric not only improves the overall performance of the project but also contributes to better structural integrity. By eliminating the need for fasteners, the bond maintains the original strength and durability of the fiberglass fabric. This is particularly important in projects requiring long-term stability, such as construction, marine, and aerospace applications.

Additionally, adhesives help reduce stress points, which can lead to material fatigue or failure. The even distribution of stress across the bond line ensures that the fiberglass fabric can withstand greater forces without compromising its structural integrity. As a result, the overall strength of the material is maintained, leading to longer-lasting, more reliable projects.

Finally, using adhesives provides a smoother, more attractive finish. The elimination of screws or bolts means that the surface remains undisturbed, leading to a cleaner, more polished appearance. This can be a crucial factor in projects where aesthetics matter, such as in automotive or architectural applications, where a sleek, seamless look is desired.

Choosing the best adhesive for fiberglass fabric ensures that your project remains strong, durable, and visually appealing. By considering factors like strength, flexibility, and environmental resistance, you can select an adhesive that meets your specific needs, whether for structural or non-structural applications. With the right adhesive, you can achieve improved performance, reduced stress points, and a better overall aesthetic finish.

Types of Adhesives for Fiberglass Fabric

Selecting the right adhesive for fiberglass fabric is essential to ensure strong, durable bonds that withstand environmental stress and dynamic loads. There are several types of adhesives commonly used with fiberglass fabric, each offering distinct benefits. The choice of adhesive largely depends on the specific needs of the project, including the desired bond strength, flexibility, and resistance to environmental factors. Here are the three most commonly used adhesives for fiberglass fabric: epoxies, methacrylates, and urethanes.

Epoxies

Epoxy adhesives are widely considered one of the best options for bonding fiberglass fabric due to their high strength and durability. These adhesives are typically composed of two parts: a resin and a hardener, which must be mixed together to initiate the bonding process. Epoxies form strong, permanent bonds that can handle heavy loads and environmental stress, making them suitable for both structural and non-structural applications.

One of the major advantages of using epoxies is their superior strength. They create bonds that are stronger than many of the materials they adhere to, ensuring that the fiberglass fabric remains firmly in place, even under high pressure or weight. Additionally, epoxies have excellent resistance to extreme temperatures, allowing them to perform well in both hot and cold conditions without breaking down or losing their adhesive properties.

Epoxies also offer high resistance to water, chemicals, and UV rays, which makes them ideal for outdoor applications, such as marine projects or construction involving exposure to the elements. These adhesives are versatile and can be used to bond fiberglass fabric to a wide range of materials, including wood, metal, and plastic. The long open time (the period during which the adhesive remains workable) of many epoxies also makes them suitable for projects that require careful assembly or adjustments.

Methacrylates

Methacrylates are another type of adhesive for fiberglass fabric known for their flexibility and impact resistance. These adhesives are particularly well-suited for bonding composites, making them an ideal choice for fiberglass fabric projects. One of the most significant benefits of methacrylates is their ability to bond with minimal surface preparation. While other adhesives require extensive cleaning or sanding of surfaces before application, methacrylates can bond effectively with little pretreatment, saving time and effort.

Methacrylates are also extremely resilient. They can absorb impacts and vibrations without cracking or losing their bond strength, which is critical in applications where the material is subjected to dynamic forces, such as in vehicles or boats. Furthermore, methacrylates offer fast curing times, allowing for quicker project completion while still ensuring a strong and reliable bond.

These adhesives are also resistant to water, chemicals, and environmental degradation, making them suitable for projects where the fiberglass fabric will be exposed to harsh conditions. Whether in automotive, aerospace, or industrial applications, methacrylates provide the flexibility and strength needed for durable, long-lasting bonds.

Urethanes

Urethanes are highly flexible and durable adhesives, making them an excellent choice for bonding fiberglass fabric in applications that require both flexibility and strength. Urethane adhesives are often used when the bonded material will experience expansion, contraction, or movement. This flexibility makes urethanes ideal for outdoor projects where the materials may be exposed to temperature fluctuations or physical stress.

One of the key characteristics of urethanes is their high peel and shear strength. This means they can resist forces that would otherwise cause the bonded materials to separate or slide apart. Urethanes are also known for their high elongation, which allows the bonded materials to stretch without breaking the bond.

Acrylic Adhesives

Acrylic adhesives are fast-curing and highly durable, providing a strong bond for fiberglass fabric projects. They are resistant to water and environmental factors, making them a good option for outdoor applications where the adhesive will be exposed to harsh conditions.

In addition to their flexibility, urethanes offer excellent resistance to environmental factors, such as water, UV radiation, and chemicals. They perform well in both indoor and outdoor settings, ensuring that the bond between the fiberglass fabric and the substrate remains intact even in challenging conditions. Urethane adhesives are commonly used in construction, automotive, and marine industries, where the combination of flexibility and durability is essential.

Factors to Consider When Choosing Adhesive for Fiberglass Fabric

Selecting the right adhesive for fiberglass fabric involves evaluating several important factors. The adhesive must be able to withstand the demands of the specific application while providing a strong, long-lasting bond. Here are key factors to consider when choosing the appropriate adhesive:

Temperature Resistance

When working with fiberglass fabric, it’s important to select an adhesive that can tolerate the temperatures the project will face. For outdoor applications or projects in environments with extreme heat or cold, an adhesive with high temperature resistance is essential. Epoxy adhesives are well-known for their ability to maintain bond strength in both high and low temperatures, while urethanes also offer good thermal resistance.

Impact Strength

In applications where the fiberglass fabric will be subjected to impact or vibrations, such as in vehicles or boats, the adhesive must have high impact strength. Methacrylates are excellent for these types of applications, as they can absorb shocks without cracking or losing adhesion. Urethanes also provide flexibility and resilience, making them suitable for dynamic environments.

Curing Time

Curing time is another critical factor to consider. Some adhesives, such as epoxies, have longer open times, allowing for more careful assembly. However, for projects that require quicker turnaround, methacrylates are a good option due to their fast curing times. Depending on the project’s timeline, choosing an adhesive with the appropriate curing time is crucial.

Flexibility

The flexibility of the adhesive is important, especially for applications where the bonded materials will move or expand. Urethane adhesives excel in this area, offering high flexibility without compromising bond strength. If the project involves materials that will experience significant movement or stress, urethanes are a good choice.

Environmental Resistance

Projects involving fiberglass fabric often require adhesives that can withstand exposure to environmental factors, such as water, chemicals, and UV rays. Epoxies and methacrylates are known for their resistance to environmental degradation, making them ideal for outdoor and marine applications. Ensuring the adhesive can handle the conditions of the project’s environment is essential for long-lasting results.

Surface Compatibility

Finally, it’s important to ensure that the adhesive is compatible with the materials being bonded. Not all adhesives work equally well with fiberglass fabric. Epoxies, methacrylates, and urethanes are generally suitable for bonding fiberglass to various surfaces, but always check the adhesive’s material compatibility to avoid issues with adhesion or durability.

Fiberglass Antenna Tube: Ideal Choice for Outdoor Antennas

How to Choose the Right Adhesive for Fiberglass Fabric Manufacturer

Selecting the right manufacturer for adhesive for fiberglass fabric is crucial to ensure quality and performance in your projects. Here are the key aspects to consider:

Product Quality and Specialization

Look for manufacturers that specialize in fiberglass-specific adhesives, such as epoxy or methyl methacrylate. High-quality adhesives should provide strong bonds, durability, and resistance to environmental factors like water, heat, or UV rays. Check for certifications and compliance with industry standards.

Product Range

A reputable manufacturer should offer a variety of adhesive options tailored to different applications, such as fast-curing, waterproof, and high-temperature adhesives. This ensures you can find a product suitable for your specific needs.

Technical Support and Expertise

Choose a manufacturer that provides detailed technical data sheets and application guidance. Access to expert advice can help you select the best adhesive and ensure proper usage.

Pricing and Cost-Effectiveness

Compare pricing among manufacturers, but prioritize quality and performance over cost alone. Some manufacturers offer bulk purchasing options, which can be more economical for large projects.

Customer Reviews and Reputation

Research customer reviews and testimonials to gauge the manufacturer’s reliability and product satisfaction. A well-reviewed company is likely to deliver consistent quality.

Customization and Innovation

Some manufacturers offer customized adhesive formulations to meet unique project requirements. Look for companies that invest in R&D to innovate and improve their product lines.

By considering these factors, you can confidently choose a reliable adhesive for fiberglass fabric manufacturer for your specific applications.

Precautions When Buying Adhesive for Fiberglass Fabric

When purchasing adhesive for fiberglass fabric, it’s essential to evaluate several factors to ensure optimal performance and cost-effectiveness. Below are key precautions to consider:

Compatibility with Fiberglass Fabric

Ensure the adhesive is explicitly designed for bonding fiberglass fabric. Products like epoxy resin or methyl methacrylate are ideal, as they provide superior adhesion and durability. Avoid generic adhesives that may not adhere well or could weaken over time.

Application Requirements

Consider the specific application, such as waterproofing, high-temperature resistance, or structural bonding. For outdoor or marine environments, opt for waterproof and UV-resistant adhesives. For industrial applications, high-strength or heat-resistant adhesives may be necessary.

Surface Preparation Needs

Understand the preparation requirements for the adhesive. Some adhesives require sanding, priming, or cleaning to ensure a strong bond. Ensure you have the tools and time for proper surface preparation.

Cure Time

Check the adhesive’s curing time. Fast-curing options are convenient for time-sensitive projects, while slow-curing adhesives may offer greater strength and durability.

Safety and Handling

Review the safety precautions associated with the adhesive. Many high-performance adhesives emit fumes or require protective equipment during application. Choose a product with manageable safety requirements.

6. Manufacturer Reputation

Purchase from reputable manufacturers or suppliers who specialize in fiberglass adhesives. Verify certifications, quality standards, and customer reviews to ensure reliability and consistency.

Packaging and Shelf Life

Adhesives have specific storage and shelf-life requirements. Buy only the quantity you need and ensure proper storage conditions to avoid waste or reduced performance.

Cost vs. Performance

Avoid choosing adhesives based solely on price. While cost is a factor, prioritize products that deliver the required performance, especially for critical or long-term applications.

By carefully evaluating these aspects, you can confidently select an adhesive for fiberglass fabric that meets your project’s demands and ensures lasting results.

Precautions When Using Adhesive for Fiberglass Fabric

Using adhesive for fiberglass fabric requires careful attention to detail to ensure effective bonding and long-term performance. Below are the key precautions to consider:

Surface Preparation

- Cleanliness: Ensure the surface is clean, dry, and free of dust, grease, or other contaminants. Use a degreaser or isopropyl alcohol for thorough cleaning.

- Sanding: Lightly sand both surfaces to create a rough texture for better adhesion. Remove sanding residue before applying the adhesive.

Proper Adhesive Selection

- Use an adhesive designed specifically for fiberglass fabric, such as epoxy or methyl methacrylate. Verify compatibility with the materials and the intended application.

- Avoid multipurpose adhesives unless confirmed to work with fiberglass fabric.

Mixing and Application

- Mixing: For two-part adhesives like epoxy, mix the components thoroughly in the correct ratio. Incomplete mixing can weaken the bond.

- Application Tools: Use appropriate tools such as brushes, rollers, or spreaders to apply the adhesive evenly. Ensure complete saturation of the fiberglass fabric without excessive pooling.

Environmental Conditions

- Temperature: Follow the recommended temperature range for applying and curing the adhesive. Extreme cold or heat can affect bonding strength.

- Humidity: Avoid high-humidity environments as they can interfere with curing, especially for epoxy adhesives.

Curing Process

- Allow sufficient curing time as specified by the manufacturer. Do not disturb or load the bond before it fully cures.

- For high-strength applications, consider post-curing by applying heat, if recommended.

Safety Measures

- Wear protective gloves, goggles, and a mask to protect against fumes and skin contact.

- Work in a well-ventilated area to avoid inhaling hazardous vapors.

Disposal and Cleanup

- Dispose of unused adhesive and materials responsibly, following local regulations.

- Clean tools immediately after use with solvents recommended by the adhesive manufacturer.

Testing and Inspection

- Test the bond on a small sample or inconspicuous area to ensure adhesion before proceeding with the full application.

- Inspect the bond for uniformity and address any air bubbles or gaps before the adhesive cures.

By adhering to these precautions, you can achieve a strong and durable bond when using adhesive for fiberglass fabric, ensuring the success of your project.

FAQs About Adhesive for Fiberglass Fabric

The best adhesive for fiberglass depends on the specific application and project needs. Epoxy adhesives are often the top choice because of their strong bonding capabilities. They create durable, long-lasting bonds that can handle heavy loads and extreme conditions. Epoxies are also resistant to water, chemicals, and UV radiation, making them ideal for outdoor or marine applications. Polyurethane adhesives are another excellent option due to their flexibility and resistance to temperature changes. These adhesives are great for projects that involve movement or expansion, as they can stretch without breaking the bond. Methacrylates work well in situations where minimal surface preparation is desired, as they bond quickly and strongly with little effort. Ultimately, selecting the best adhesive involves considering the environment, flexibility, and bonding strength required for the project.

To get fabric to stick to fiberglass, it’s essential to use the right adhesive and follow proper preparation techniques. Begin by thoroughly cleaning the fiberglass surface to remove any dirt, oils, or debris. A clean surface ensures better adhesion. Lightly sanding the fiberglass will also help improve the bond, as it creates a rougher texture for the adhesive to grip. Epoxy or polyurethane adhesives are commonly used to bond fabric to fiberglass because of their strength and flexibility. Apply the adhesive evenly across the surface, and press the fabric firmly onto the fiberglass, ensuring there are no air bubbles or gaps. Clamping or weighting down the fabric while the adhesive cures can help ensure a tight, strong bond. Allow the adhesive to fully cure before handling the bonded fabric to prevent weakening the bond.

The best adhesive for GRP (Glass Reinforced Plastic) depends on the project’s requirements. Epoxy adhesives are often the most effective, as they create incredibly strong bonds and are resistant to environmental stress. GRP is used in a variety of industries, including construction, marine, and automotive, and it requires an adhesive that can withstand high loads, extreme weather conditions, and constant exposure to moisture. Epoxies provide the chemical and water resistance needed in harsh environments, while also offering high tensile strength. Polyurethane adhesives are another strong option for bonding GRP, as they provide excellent flexibility and durability in applications where movement and expansion are expected. Methacrylates can also be used when a faster cure time and minimal surface preparation are necessary. Ultimately, the choice of adhesive depends on the specific needs of the GRP project.

To stick fiber, such as fiberglass fabric or other composite materials, various adhesives can be used depending on the application. Epoxy is one of the most popular adhesives for bonding fiber because it forms a strong, rigid bond that can endure high stresses. This type of glue is suitable for applications where strength and resistance to environmental factors are crucial. Polyurethane adhesives, on the other hand, are excellent for projects that require flexibility, as they can absorb movement and expansion without breaking the bond. They also provide resistance to moisture and chemicals, making them ideal for outdoor applications. In cases where fast bonding is required, methacrylate adhesives are useful due to their quick curing time and ability to bond without extensive surface preparation. Choosing the right adhesive depends on whether the project needs a flexible bond, a quick application, or maximum strength.

To get fiberglass cloth to stick effectively, you need to use a compatible resin or adhesive. Epoxy resin is the most commonly used bonding agent for fiberglass cloth due to its strong adhesion and durability. Begin by cleaning the surface thoroughly to remove dirt, grease, and dust. Sand the area lightly to create a rough texture, which helps the adhesive bond better. Apply the resin evenly using a brush or roller, then lay the fiberglass cloth on top. Smooth out any air bubbles with a squeegee or roller and ensure the cloth is saturated with resin. Once it cures, the fiberglass will adhere firmly. Avoid using incompatible adhesives, as they may weaken over time or fail to bond. Proper preparation, including surface cleaning and sanding, is key to achieving a strong bond.

The best adhesives for fiberglass include epoxy resin, polyester resin, and specialty adhesives like marine-grade epoxy. Epoxy resin is particularly favored for its strength, water resistance, and ability to bond well with various materials. Polyurethane-based adhesives can also work well for bonding fiberglass to metals, wood, or other surfaces. When choosing an adhesive, consider the specific application, such as whether it will be exposed to water, heat, or heavy loads. Clean and sand the surface before applying the adhesive to ensure a strong bond. Avoid using standard glues like PVA or cyanoacrylate, as they lack the durability and flexibility required for fiberglass applications. Selecting the correct adhesive ensures a reliable and long-lasting bond for your fiberglass project.

Gorilla Glue can bond to fiberglass, but it is not the most effective adhesive for this purpose. Gorilla Glue’s polyurethane formula expands as it cures, which can create gaps or uneven bonding with fiberglass cloth. For projects requiring high strength or durability, epoxy resin or marine-grade epoxy is a better choice. If you decide to use Gorilla Glue, ensure the fiberglass surface is clean, sanded, and slightly damp, as moisture activates the glue. However, Gorilla Glue may not provide the long-term durability or resistance to environmental factors, such as water or UV exposure, that epoxy resins offer. For critical applications or projects involving heavy loads, it’s better to opt for a specialized adhesive designed for fiberglass.

To adhere fiberglass to fiberglass, epoxy resin is the most effective choice. Start by cleaning and sanding both surfaces to remove dirt, grease, and any glossy finishes. Use a coarse sandpaper to create a textured surface, which improves adhesion. Mix the epoxy resin according to the manufacturer’s instructions and apply it evenly to one or both surfaces. Lay the fiberglass cloth in place and ensure it is saturated with resin. Use a squeegee or roller to remove air bubbles and press the layers together. Allow the resin to cure fully for a strong bond. Polyester resin can also be used, but epoxy resin provides a stronger and more durable bond. Proper surface preparation and curing time are essential for achieving a reliable adhesion.

Yes, JB Weld works on fiberglass and is a popular choice for repairs. It is a two-part epoxy adhesive known for its strength and durability. To use JB Weld on fiberglass, clean and sand the surface to ensure proper adhesion. Mix the two components of JB Weld and apply it to the surface. Press the fiberglass cloth or patch into place and smooth out any bubbles. Allow it to cure for the specified time, which can vary depending on the product. While JB Weld is effective for small repairs and bonding fiberglass to other materials, it may not be ideal for large-scale fiberglass laminating projects. For such applications, traditional epoxy or polyester resin is a better choice.

Fiberglass does not stick to materials like polyethylene, polypropylene, Teflon (PTFE), or waxy surfaces. These materials are chemically resistant and do not provide the rough texture required for resin adhesion. Silicone-based surfaces and oily or greasy areas also prevent proper bonding. If you need to prevent fiberglass from sticking to a specific area, you can use mold-release agents, plastic sheeting, or wax paper as a barrier. Ensuring that the surface is free of contaminants like oil or grease is crucial when bonding fiberglass. For non-stick applications, proper preparation and release agents are key to ensuring fiberglass does not adhere unintentionally.

The best adhesive for fiberglass depends on the application. Epoxy resin is widely regarded as the best choice for bonding fiberglass due to its strength, water resistance, and versatility. Marine-grade epoxy is especially effective for projects exposed to water or harsh conditions. Polyester resin is another option, particularly for laminating or repairs, but it may not be as strong or durable as epoxy. Polyurethane-based adhesives work well for bonding fiberglass to other materials like wood or metal. When selecting an adhesive, consider factors such as load-bearing requirements, environmental exposure, and curing time. Proper surface preparation ensures the best performance from any adhesive.

Loctite offers several adhesive products that can work on fiberglass, but their suitability depends on the specific type. Loctite epoxy adhesives are a good choice for bonding fiberglass, as they provide strong and durable bonds. For repairs, products like Loctite Marine Epoxy or Plastic Bonder can adhere well to fiberglass surfaces. Ensure the surface is clean and sanded before applying the adhesive. While Loctite superglues and general-purpose adhesives may stick to fiberglass temporarily, they lack the flexibility and strength needed for long-term use in demanding conditions. Always choose a product specifically designed for fiberglass or similar materials.

PVC glue is not designed to bond to fiberglass effectively. PVC glue is formulated for bonding PVC materials by chemically welding them, and it lacks the necessary strength and flexibility for fiberglass applications. For a reliable bond, use epoxy resin or marine-grade adhesive. These products are specifically formulated to work with fiberglass and provide strong, durable bonds. If you need to bond PVC to fiberglass, epoxy resin can be used as an intermediary adhesive. Ensure both surfaces are clean and properly prepared for the best results.

Liquid Nails can stick to fiberglass, but it is not the most reliable adhesive for high-stress or demanding applications. Liquid Nails is a construction adhesive designed for general use, and while it can bond fiberglass to other materials like wood or metal, it may not provide the strength and durability needed for heavy loads or outdoor conditions. For better results, use epoxy resin or a fiberglass-specific adhesive. If you decide to use Liquid Nails, ensure the surface is clean and sanded for optimal adhesion. For long-term durability, especially in marine or outdoor environments, epoxy or polyurethane-based adhesives are preferred.

Liquid Nails can bond to fiberglass under certain conditions, but its adhesion strength and durability may not match that of epoxy or marine-grade adhesives. It is best suited for low-stress applications or temporary fixes. If you need a stronger, more permanent bond, choose epoxy resin or polyurethane-based adhesives, which are designed to work specifically with fiberglass and other composite materials. Proper surface preparation, including cleaning and sanding, is essential to ensure Liquid Nails bonds effectively. For projects requiring long-term strength or exposure to water, Liquid Nails is not recommended as the primary adhesive.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.