Carbon fiber products are revolutionizing industries with their unique properties. Carbon fiber, composed of thin, strong crystalline filaments of carbon, is known for being both lightweight and incredibly strong. Its stiffness and strength-to-weight ratio make it ideal for applications that require durability without adding bulk. This has led to its widespread adoption across various sectors, including aerospace, automotive, sporting goods, and consumer products. In aerospace, carbon fiber is used to reduce aircraft weight, enhancing fuel efficiency. The automotive industry relies on carbon fiber products to improve vehicle performance while keeping weight low. Additionally, carbon fiber products are used in high-performance sports equipment, offering superior strength and flexibility for athletes. As demand grows, carbon fiber is also finding its way into carbon fiber household items, offering sleek, durable solutions for furniture, kitchenware, and other everyday products. These household items benefit from the material’s lightweight yet strong properties, making them more functional and long-lasting in the home.

Types of Carbon Fiber Products

Carbon fiber products come in a variety of forms, each suited for specific applications. These products are designed to take advantage of carbon fiber’s unique properties—lightweight, strength, and stiffness. Among the most widely used forms are carbon fiber fabric, prepreg, and molded components, each playing a crucial role in different industries. Below, we will explore some of the most common types of carbon fiber items and their significance.

Carbon Fiber Fabric: The Backbone of Composites

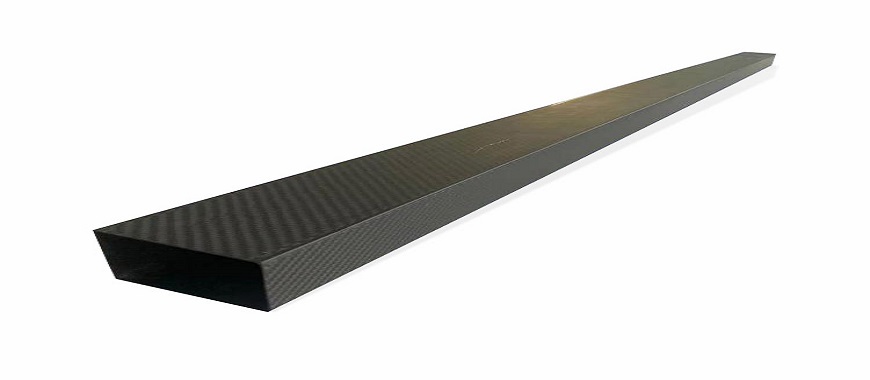

One of the foundational components of carbon fiber products is carbon fiber fabric. This fabric is made by weaving individual carbon filaments into different patterns, such as plain weave, twill, or satin. The weaving process determines the fabric’s strength, flexibility, and how it interacts with resins during the composite manufacturing process.

The primary benefit of carbon fiber fabric is its ability to be molded into lightweight yet strong components for a wide range of industries. Its versatility makes it ideal for creating durable products that require both strength and weight savings. In automotive manufacturing, carbon fiber fabric is used to produce lightweight panels, body parts, and structural components that improve vehicle performance without compromising safety. In aerospace, carbon fiber fabric is used for crafting components like fuselage panels and wing structures that reduce overall weight while maintaining structural integrity. Sports equipment such as tennis rackets, bicycle frames, and hockey sticks also benefit from the application of carbon fiber fabric, where the material’s stiffness and lightness provide enhanced performance.

The weaving patterns of the fabric—plain weave being the most basic and twill or satin offering more flexibility and strength—further influence the product’s suitability for specific uses. Each weave pattern is selected based on the desired final properties of the carbon fiber product. The high strength-to-weight ratio of carbon fiber fabric plays a crucial role in reducing the weight of these products while maintaining or even increasing their strength, making them indispensable in industries that demand both durability and lightness.

Introduction to Carbon Core Fiberglass: Key Features Explained

Carbon Fiber Products: Carbon Fiber Composites: Combining Strength with Versatility

Carbon fiber products are often combined with other materials to create carbon fiber composites, which bring out the best of both worlds: the lightweight nature of carbon fiber and the versatility of other materials like resins or metals. These composites are designed to be exceptionally strong and durable, making them highly sought after in industries where performance and weight are critical factors. By combining carbon fiber with resins, metals, or plastics, manufacturers can produce materials that are not only lightweight but also possess enhanced mechanical properties, such as high tensile strength and flexibility.

What Are Carbon Fiber Composites?

Carbon fiber composites are created by embedding carbon fiber strands into a matrix material, typically resins or thermoplastics. The carbon fiber acts as a reinforcement material, providing strength and stiffness, while the resin serves as a binder that holds everything together. The resulting composite is lighter and stronger than many metals and can be tailored to specific requirements by adjusting the resin type, fiber orientation, and processing techniques. These composites are particularly valuable in industries that require materials that are both lightweight and durable.

The versatility of carbon fiber composites makes them ideal for applications across a wide range of sectors, from automotive manufacturing to marine engineering and aerospace. In automotive applications, carbon fiber composites are used for producing lightweight car body panels, structural components, and interior parts, which significantly enhance fuel efficiency and performance. In the aerospace industry, carbon fiber composites are essential in reducing the weight of aircraft while maintaining their structural integrity. Additionally, these composites are being widely used in the marine industry for making boats and yachts that are both lightweight and highly resistant to corrosion.

Advantages of Carbon Fiber Composites

Carbon fiber composites offer numerous advantages that make them an ideal material choice for a variety of applications:

- High Strength-to-Weight Ratio: Carbon fiber composites are incredibly strong while being significantly lighter than traditional metals like steel and aluminum.

- Durability: These composites are resistant to corrosion, fatigue, and wear, making them long-lasting even in harsh environments.

- Design Flexibility: The combination of carbon fiber and resin allows for the creation of complex shapes and structures without compromising strength.

- Thermal Resistance: Carbon fiber composites can withstand extreme temperatures, making them ideal for high-performance environments such as aerospace or motorsports.

- Improved Fuel Efficiency: The lightweight nature of carbon fiber composites contributes to better fuel efficiency in transportation applications, such as in cars and airplanes.

The wide range of benefits offered by carbon fiber composites has made them a go-to material for high-performance products. These composites are used in everything from sports equipment to industrial machinery, demonstrating their versatility and high value in both consumer and commercial applications.

Carbon Fiber Luggage: Stylish, Durable, and Lightweight

One of the more recent trends in the travel industry is the rise of carbon fiber luggage. As travelers demand stronger, more durable, and lightweight products, carbon fiber has emerged as the material of choice. Carbon fiber luggage combines the material’s premium properties with stylish design, offering consumers both functionality and aesthetics.

Carbon fiber luggage products are incredibly strong, resisting damage from impact and rough handling. They are also lightweight, making them ideal for air travel where baggage weight restrictions are an issue. Additionally, the sleek and modern look of carbon fiber provides a high-end aesthetic, appealing to those who want durable luggage that stands out in a crowd.

Examples of carbon fiber luggage on the market include hard-shell suitcases, travel bags, and carry-ons. Leading brands have started incorporating carbon fiber into their product lines, offering durable and premium products that cater to luxury travelers who prioritize both style and practicality.

Carbon Fiber Gear: Premium Accessories for Performance Enthusiasts

Beyond traditional applications, carbon fiber is increasingly being used to produce high-end accessories and everyday gear. From keychains to wallets and pens, carbon fiber gear combines the material’s durability and lightness with luxury and functionality. These accessories cater to performance enthusiasts who appreciate high-quality craftsmanship and unique design.

Carbon fiber key holders, money clips, sunglasses, and phone cases are some examples of popular carbon fiber gear. These products are lightweight, resilient, and have a sleek, modern appearance. For many consumers, carbon fiber gear offers an opportunity to carry a piece of cutting-edge technology in everyday items, combining aesthetics with practical functionality. Whether for personal use or as part of a gift set, carbon fiber gear is quickly becoming a symbol of high-end performance and style.

By integrating carbon fiber into these accessories, manufacturers are able to create products that meet the needs of discerning customers who value both quality and innovation. Whether used for style or performance, these carbon fiber products reflect the growing trend of incorporating advanced materials into everyday life.

Bullet Resistant Carbon Fiber Fiberglass Composite for Protection

Benefits of Using Carbon Fiber Products

Carbon fiber products offer a range of benefits that make them highly valued across various industries. From aerospace and automotive applications to everyday consumer goods, the unique characteristics of carbon fiber are leveraged to create products that stand out in terms of performance, durability, and design. Below, we explore some of the most important advantages of using carbon fiber products.

Strength and Durability

One of the primary reasons carbon fiber products are so sought after is their remarkable strength and durability. Carbon fiber is renowned for its high strength-to-weight ratio, which makes it significantly stronger than traditional materials like steel, yet much lighter. This combination is essential in industries where weight reduction is crucial without sacrificing strength, such as in aerospace, automotive, and sporting goods.

The durability of carbon fiber stuff is another significant benefit. The material is resistant to corrosion, fatigue, and wear, ensuring that components last longer, even in harsh environments. This resilience makes carbon fiber a top choice for products subjected to heavy stress, extreme temperatures, or exposure to the elements. Whether in a racing car, an aircraft, or a boat, carbon fiber’s longevity and resistance to damage make it a smart investment for high-performance applications.

Lightweight Design

The lightweight nature of carbon fiber products is one of its most appealing aspects. Carbon fiber is exceptionally light compared to metals like steel and aluminum, making it an ideal material for applications where reducing weight is a key objective. In industries such as automotive manufacturing, carbon fiber products help reduce the overall weight of vehicles, which in turn improves fuel efficiency and performance. Similarly, carbon fiber luggage is lighter, making it easier for travelers to manage their bags while adhering to airline weight restrictions.

In sporting goods, carbon fiber’s lightweight properties contribute to better performance. For instance, carbon fiber tennis rackets or bicycle frames are favored by athletes because they allow for faster movements and more efficient use of energy. The material’s lightweight nature also extends to accessories like keychains, wallets, and sunglasses, offering users a comfortable and practical experience without the burden of heavy items.

Aesthetic Appeal

Another significant benefit of carbon fiber products is their aesthetic appeal. Carbon fiber has a sleek, modern appearance that adds a touch of sophistication and style to any product. Its distinct woven texture and glossy finish give it a unique, high-tech look, which is often associated with luxury and premium quality.

This visual appeal makes carbon fiber popular not only in industrial applications but also in consumer products. Carbon fiber accessories like phone cases, key holders, and wallets stand out with their futuristic look, attracting consumers who value design as much as functionality. In the automotive and aerospace industries, the use of carbon fiber not only improves performance but also contributes to the overall aesthetic of the vehicle or aircraft, offering a sleek and polished appearance that is both functional and visually striking.

Environmental Impact

While carbon fiber is primarily known for its performance attributes, its environmental impact is also an important consideration. As industries continue to focus on sustainability, carbon fiber products offer a way to reduce the overall carbon footprint in various applications. The lightweight nature of carbon fiber products contributes to energy efficiency, particularly in the transportation sector. For example, using carbon fiber in automobiles and aircraft helps reduce fuel consumption, which leads to lower greenhouse gas emissions over time.

Furthermore, the durability and longevity of carbon fiber products mean that they need to be replaced less frequently, reducing the amount of waste generated from product disposal. In addition, researchers are working to make the production of carbon fiber more sustainable by developing methods to recycle carbon fiber materials and use renewable resources in their manufacture. As carbon fiber production becomes more eco-friendly, its use in industries focused on reducing environmental impact is expected to increase, making it a more sustainable option for high-performance products.

Additional Benefits of Carbon Fiber Products

- Corrosion Resistance: Unlike metals that can rust over time, carbon fiber products do not corrode, which makes them perfect for use in harsh environments such as marine applications or areas with high humidity.

- Flexibility in Design: Carbon fiber can be molded into various shapes and sizes, offering designers the flexibility to create complex, intricate components without sacrificing strength or durability.

- High Temperature Resistance: Carbon fiber products can withstand high temperatures without losing their structural integrity, making them ideal for use in industries like aerospace and motorsports, where components are exposed to extreme conditions.

The combination of strength, lightweight design, aesthetic appeal, and environmental benefits makes carbon fiber products a powerful choice for industries looking to improve both performance and sustainability. As technology advances, the potential for even more innovative uses of carbon fiber continues to grow.

Is Fiberglass Carbon Fiber Fire Suppression Effective in Safety?

How Carbon Fiber Products are Revolutionizing Industries

Carbon fiber products are transforming industries across the globe by providing solutions that improve performance, reduce weight, and enhance efficiency. The unique properties of carbon fiber, including its strength, lightness, and durability, are revolutionizing sectors such as automotive manufacturing, aerospace, and consumer goods. Below, we explore how carbon fiber products are making an impact in these industries and changing the way products are designed and produced.

Automotive Industry

In the automotive industry, carbon fiber products have become a game-changer in the production of lighter, more fuel-efficient vehicles. Traditional steel and aluminum components, while strong and durable, add significant weight to vehicles. This excess weight negatively impacts fuel efficiency and overall performance. By incorporating carbon fiber things into vehicle design, automakers can significantly reduce the weight of vehicles while maintaining or even enhancing their strength and safety.

The use of carbon fiber in automotive manufacturing is particularly advantageous for performance vehicles and electric cars, where weight reduction is essential for improving acceleration, handling, and fuel efficiency. Lightweight carbon fiber body panels, chassis components, and interior elements help reduce energy consumption, extend battery life in electric vehicles, and provide better overall performance. For example, sports cars like the BMW i8 and supercars from manufacturers such as Ferrari and McLaren feature carbon fiber components in their construction, showcasing the material’s potential to improve both aesthetics and function.

Additionally, carbon fiber’s durability and resistance to corrosion make it an ideal choice for automotive parts that need to withstand long-term wear and exposure to the elements. This innovation is not limited to high-end vehicles; the use of carbon fiber is gradually making its way into more mainstream automotive models, which could lead to a broader shift toward more sustainable, fuel-efficient vehicles in the future.

Aerospace Industry

In aerospace, carbon fiber products have completely transformed the design and construction of aircraft. The aerospace industry requires materials that are not only strong but also lightweight, as reducing the weight of an aircraft can significantly improve fuel efficiency and overall performance. Carbon fiber’s exceptional strength-to-weight ratio makes it ideal for use in aerospace applications, where both strength and lightness are critical factors.

Carbon fiber composites are used in the production of various aircraft components, including fuselages, wings, tail sections, and interior parts. For example, the Boeing 787 Dreamliner is known for its extensive use of carbon fiber composites, which contribute to a reduction in the plane’s weight by approximately 20%. This weight reduction leads to significant fuel savings and reduced emissions, making air travel more environmentally friendly and cost-effective.

In addition to enhancing performance, carbon fiber products also offer increased durability. These materials are resistant to corrosion and fatigue, which are common problems in the aerospace industry, especially in aircraft exposed to harsh environmental conditions. The ability of carbon fiber to withstand these challenges while maintaining its strength makes it a crucial material for the next generation of aircraft.

Consumer Goods

Carbon fiber products are also making their way into everyday consumer goods, from luggage to personal accessories. As carbon fiber becomes more affordable and accessible, manufacturers are incorporating it into products where its strength, lightweight properties, and aesthetic appeal can add value to the consumer experience.

In the luggage industry, carbon fiber is used to produce durable, lightweight suitcases and carry-ons. Travelers are drawn to carbon fiber luggage not only for its strength and resistance to damage but also for its sleek, modern design. This trend has led to the creation of premium luggage brands that highlight carbon fiber as a key feature, offering products that stand out for both their function and style.

Similarly, carbon fiber is being used in personal accessories such as wallets, keychains, phone cases, and sunglasses. These items benefit from carbon fiber’s durability and light weight, while also providing a contemporary, high-tech appearance. Consumers are increasingly interested in these luxury items because of their unique blend of functionality, elegance, and cutting-edge technology. The growing demand for carbon fiber gear reflects a shift toward materials that combine performance with aesthetics.

Furthermore, carbon fiber’s increasing use in everyday products is an indication of its broader appeal as a premium material that enhances the user experience. Whether in sports equipment, home decor, or fashion accessories, carbon fiber products are becoming synonymous with quality, durability, and advanced technology.

Carbon fiber products are revolutionizing industries by offering solutions that address the demands for lightweight, strong, and durable materials. In the automotive industry, they are helping create fuel-efficient, high-performance vehicles. In aerospace, carbon fiber composites are making air travel more efficient and environmentally friendly. In the consumer goods sector, carbon fiber is gaining popularity in luxury accessories and everyday products due to its aesthetic appeal and functionality. As technology advances and production costs decrease, carbon fiber products will continue to shape the future of multiple industries, driving innovation and sustainability.

Carbon Fiber Products: Trends and Future Outlook

As carbon fiber products continue to shape industries across the globe, new trends and innovations are driving their growth and increasing their accessibility. From advancements in manufacturing technologies to a growing focus on sustainability, the future of carbon fiber products looks promising. In this section, we explore the key trends influencing the carbon fiber market and the exciting developments that will likely expand its applications in the coming years.

Technological Advancements

Recent technological advancements are playing a crucial role in making carbon fiber products more accessible and cost-effective. Traditionally, carbon fiber production has been expensive due to the complexity of the manufacturing process, which involved high temperatures and specialized equipment. However, as research and innovation in materials science continue, new techniques are emerging that lower production costs and reduce the energy required for manufacturing.

One such advancement is the development of more efficient carbon fiber production methods, such as the use of automated fiber placement (AFP) and automated tape laying (ATL) technologies. These methods streamline the manufacturing process, making it faster and more cost-effective while ensuring high precision and quality in the final products. Additionally, the rise of continuous carbon fiber processing, where fibers are produced in long, continuous strands, further reduces material waste and cuts costs.

Another significant breakthrough is the introduction of 3D printing technologies in the production of carbon fiber composites. 3D printing allows for the creation of complex, customized carbon fiber components with greater flexibility, speed, and lower costs. This advancement is especially important for industries such as aerospace and automotive, where the need for lightweight yet strong parts is critical.

These technological advancements are helping to make carbon fiber products more affordable and viable for a broader range of industries, driving their adoption in both high-end applications and more mainstream markets.

Sustainability in Carbon Fiber Manufacturing

Sustainability has become a key concern for many industries, and carbon fiber production is no exception. Traditionally, carbon fiber manufacturing has been energy-intensive and produced a significant carbon footprint, primarily due to the high temperatures needed during the production process. However, the industry is making strides toward more environmentally friendly production methods that will reduce the environmental impact of carbon fiber products.

One of the most promising developments in sustainable carbon fiber manufacturing is the use of renewable resources in the production of carbon fiber precursors. Companies are working on developing bio-based precursors made from renewable sources, such as plant-based fibers or even algae, which could significantly reduce the carbon footprint of carbon fiber products. Additionally, researchers are exploring ways to recycle carbon fiber materials, making it possible to reuse carbon fiber in new applications. This recycling process would help minimize waste and reduce the need for raw materials, contributing to a circular economy.

Another approach to enhancing sustainability is improving the energy efficiency of the carbon fiber production process. New, more energy-efficient technologies are being developed to lower the carbon emissions associated with carbon fiber manufacturing. These innovations are crucial in making carbon fiber products more sustainable and will likely become a major driving force in the industry’s future growth.

As sustainability becomes a more significant factor in purchasing decisions, manufacturers who prioritize eco-friendly practices will have a competitive advantage in the growing market for carbon fiber products.

The Expanding Market for Carbon Fiber Products

The market for carbon fiber products is expected to experience continued growth across various industries. As manufacturing processes become more affordable and accessible, the range of applications for carbon fiber is expanding beyond traditional sectors like aerospace and automotive into consumer goods, sports equipment, and even construction.

In the automotive industry, the push for more fuel-efficient, lightweight vehicles continues to drive the adoption of carbon fiber products. With electric vehicles (EVs) on the rise, carbon fiber’s ability to reduce weight and increase energy efficiency is increasingly valuable. Carbon fiber is already used in high-performance EV models, and as the demand for electric cars grows, the use of carbon fiber products in mainstream vehicles is expected to increase significantly.

In aerospace, carbon fiber products are becoming essential for producing lighter, more fuel-efficient aircraft. The continued expansion of the global aerospace industry, coupled with advancements in carbon fiber manufacturing, will likely lead to even greater use of this material in both commercial and military aviation. As air travel becomes more environmentally conscious, carbon fiber’s ability to reduce fuel consumption and emissions will make it an indispensable material in the development of future aircraft.

Consumer goods, including luggage, clothing, and personal accessories, are also experiencing a surge in carbon fiber applications. As consumers increasingly value lightweight, durable, and stylish products, the demand for carbon fiber items such as suitcases, phone cases, and wallets is expected to continue rising. In the sports and leisure market, carbon fiber’s strength and lightweight properties make it ideal for high-performance gear such as bicycles, golf clubs, and tennis rackets, and its popularity in these sectors is likely to increase.

Additionally, the construction industry is beginning to explore the potential of carbon fiber products for reinforcing concrete and creating stronger, lighter structures. With its ability to resist corrosion and provide long-lasting durability, carbon fiber could become a key material in the construction of infrastructure projects, such as bridges and buildings.

Predictions for the Future of Carbon Fiber Products

The future outlook for carbon fiber products is optimistic, with the market expected to grow rapidly across various industries. As technological advancements continue to lower production costs and improve the sustainability of carbon fiber manufacturing, the material is poised to become more widely adopted in both high-performance and everyday applications. With its lightweight, strong, and durable properties, carbon fiber is set to revolutionize industries from transportation to consumer goods, making it one of the most important materials of the 21st century.

In the coming years, we can expect carbon fiber to be more integrated into products used by consumers daily, such as more affordable electric vehicles, advanced consumer electronics, and sustainable fashion. As the material becomes increasingly mainstream, its potential to enhance performance, reduce environmental impact, and create new opportunities for innovation will only continue to grow.

The expanding market for carbon fiber products reflects a shift toward more sustainable, high-performance materials across industries, and this trend is expected to continue as the world moves toward greener, more efficient technologies.

FAQs about Carbon Fiber Products

Carbon fiber is a high-strength material made from thin, crystalline filaments of carbon atoms bonded together. It is known for its exceptional strength-to-weight ratio, making it one of the strongest materials used in manufacturing products across various industries. Carbon fiber is lightweight yet incredibly strong, which makes it ideal for applications where strength and weight reduction are essential. This combination of properties allows carbon fiber to be used in everything from aerospace components and automotive parts to sports equipment and consumer goods. It’s often chosen for its ability to withstand extreme conditions while remaining lightweight, durable, and resistant to corrosion. Industries such as aerospace, automotive, and sports benefit greatly from carbon fiber because it improves the performance, efficiency, and safety of the products in which it’s used. Its use in products like bicycles, vehicles, and aircraft parts enables better fuel efficiency, faster performance, and more durable structures.

Carbon fiber fabrics are made through a process that begins with the creation of carbon fiber filaments. These filaments are typically made by heating precursor materials, often polyacrylonitrile (PAN), at extremely high temperatures in an oxygen-deprived environment, causing the material to decompose and leave behind pure carbon. The resulting fibers are then woven into carbon fiber fabric, which can be made using various techniques like plain weave, twill, and satin weave. The weaving process involves interlacing the carbon fibers in different patterns, which affects the fabric’s flexibility, strength, and appearance. These fabrics are used as a reinforcement material in carbon fiber composites, where they are combined with resins or other binding agents to create rigid, strong, and lightweight components. The versatility in the type of weave and the ability to customize the fabrics for specific applications make carbon fiber fabrics crucial for manufacturing products that require both strength and flexibility, such as in aerospace, automotive, and sports gear.

Carbon fiber composites are materials made by combining carbon fiber fabrics with a resin matrix, typically epoxy or polyester. The carbon fibers provide strength and stiffness, while the resin holds the fibers together and provides shape and structure. The resulting composite material is incredibly lightweight yet strong and durable, making it an ideal choice for applications where performance and weight are critical. Carbon fiber composites are commonly used in automotive, aerospace, marine, and sports industries due to their superior strength-to-weight ratio. In the automotive industry, carbon fiber composites are used in lightweight body panels and structural components, enhancing fuel efficiency and performance. In aerospace, they are used for airplane fuselages and wings, where weight reduction is key to fuel efficiency. Additionally, carbon fiber composites are found in high-performance sporting goods like bicycles, tennis rackets, and golf clubs, where they improve durability and reduce weight, contributing to better performance. These composites are also increasingly being used in industrial applications, such as construction materials and military equipment, due to their durability and resistance to environmental stress.

Carbon fiber luggage stands out from traditional luggage due to its combination of strength, lightweight design, and durability. Unlike standard luggage, which is often made from plastic or aluminum, carbon fiber luggage is made from a material that is not only strong but also significantly lighter, allowing travelers to pack more without exceeding weight limits. The inherent strength of carbon fiber makes the luggage highly resistant to impact and scratches, providing better protection for the contents inside. This durability ensures that carbon fiber luggage can withstand rough handling at airports or during travel, maintaining its structural integrity and appearance over time. Another key advantage is its sleek, modern look; carbon fiber’s unique woven texture gives it a premium, high-tech appearance. Additionally, carbon fiber luggage is often designed with a more robust exterior, which can better absorb shocks, reducing the risk of damage to delicate items. Overall, carbon fiber luggage is a practical and stylish choice for travelers looking for both aesthetic appeal and long-lasting durability in their travel gear.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.