The debate between carbon fiber vs fiberglass speed has been a key topic of discussion across several industries, particularly in fields that prioritize speed and performance. Both materials offer unique benefits, but their impact on product efficiency and velocity is often a deciding factor. Whether it’s drones, sports equipment, or vehicles, the choice of material plays a significant role in enhancing or limiting speed capabilities. Carbon fiber is often praised for its lightweight properties, while fiberglass, with its flexibility, is commonly used in various applications where durability is critical. This article aims to explore the differences in speed performance when using carbon fiber vs fiberglass, shedding light on which material excels in delivering superior speed across various sectors.

What is the Basics: Carbon Fiber vs Fiberglass Speed

When discussing materials for high-speed applications, understanding the core differences between carbon fiber and fiberglass is crucial. Both materials are frequently compared in terms of performance, durability, and speed. In this section, we will delve into the properties of each material and how they contribute to speed, particularly focusing on carbon fiber vs fiberglass speed.

Carbon Fiber

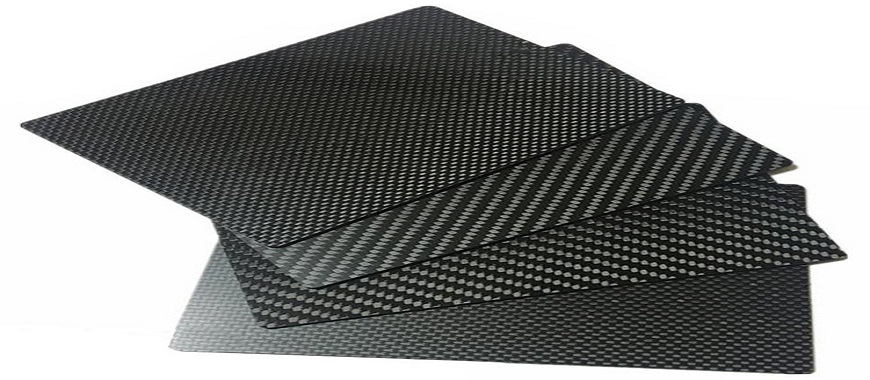

Carbon fiber is a lightweight, high-strength material that is widely celebrated for its stiffness and durability. Composed of thin, strong fibers of carbon, it offers superior strength-to-weight ratios, making it ideal for applications that demand high performance, such as racing cars, bicycles, and drones. The primary advantage of carbon fiber in speed-related applications is its ability to reduce overall weight while maintaining structural integrity. This makes carbon fiber a preferred choice in industries where every gram counts, and maximizing speed is a priority. Carbon fiber’s rigidity also contributes to its enhanced aerodynamic properties, which can result in higher speeds in racing vehicles or drones designed for competitive performance.

Fiberglass

Fiberglass, on the other hand, is a composite material made from fine strands of glass woven together to form a strong and flexible material. While not as light as carbon fiber, fiberglass offers exceptional durability and flexibility, which makes it suitable for a wide range of applications. Fiberglass is commonly used in products like boats, sporting equipment, and vehicles, where its ability to withstand impact and stress is crucial. However, in terms of speed performance, fiberglass tends to be heavier compared to carbon fiber, which can affect acceleration and overall velocity. While fiberglass has a lower strength-to-weight ratio than carbon fiber, its versatility makes it a valuable material in situations where a balance between weight, flexibility, and durability is necessary.

Understanding the differences in carbon fiber vs fiberglass speed requires an appreciation of their unique characteristics. Carbon fiber excels in high-speed applications, where every reduction in weight contributes to faster acceleration and higher top speeds. Meanwhile, fiberglass may not match the sheer speed potential of carbon fiber but offers a balanced mix of durability and flexibility.

How Lightning Protection Fiberglass Reinforced Plastic Safety

Fiberglass vs Carbon Fiber Weight Difference and Its Impact on Speed

One of the most significant factors in the ongoing debate of carbon fiber vs fiberglass speed is the weight difference between the two materials. The weight of a material can have a profound impact on the performance of products, especially in applications where speed and acceleration are crucial. In this section, we will explore how the weight of each material influences the performance and speed of various products.

Carbon Fiber

Carbon fiber is significantly lighter than fiberglass, which is one of its primary advantages in high-performance applications. This reduced weight contributes directly to faster acceleration and overall speed in products such as sports equipment, including bicycles and rowing boats. In cycling, for instance, the use of carbon fiber frames allows athletes to experience better handling and reduced effort while climbing or accelerating. The lightweight nature of carbon fiber also enhances aerodynamics, reducing drag and enabling faster speeds. In drones, a lighter frame means quicker takeoff and more agile maneuvers, which is why carbon fiber is the material of choice for high-performance racing drones. When discussing carbon fiber vs fiberglass speed, the material’s weight advantage becomes clear—carbon fiber allows for faster, more responsive motion in a variety of applications.

Fiberglass

While fiberglass is relatively lightweight compared to many other materials, it is still heavier than carbon fiber. This increased weight can negatively affect the speed and acceleration of products where every gram counts. For example, in high-speed drones, the added weight of fiberglass can reduce overall flight performance, making the drone slower to accelerate and less responsive to control inputs. Similarly, performance bikes made with fiberglass tend to be heavier than their carbon fiber counterparts, which can affect acceleration and climbing performance. Although fiberglass offers durability and flexibility, its weight disadvantage makes it less suitable for applications where speed and lightweight performance are prioritized. In carbon fiber vs fiberglass speed comparisons, fiberglass may not deliver the same speed capabilities as carbon fiber due to its greater weight.

The weight difference between carbon fiber and fiberglass plays a critical role in determining the speed and performance of products. Carbon fiber’s lighter composition contributes to faster acceleration and higher top speeds, while fiberglass, though still relatively light, tends to limit performance in speed-centric applications.

Can You Paint Fiberglass Reinforced Plastic Panels?

Speed Performance in Specific Applications: Carbon Fiber vs Fiberglass Speed

The debate of carbon fiber vs fiberglass speed becomes particularly significant when we examine their performance in specific applications. In this section, we will explore how each material affects the speed and overall performance in various products, such as pickleball paddles, fishing rods, and helmets. These applications demonstrate the tangible benefits of carbon fiber and fiberglass in real-world scenarios where speed is crucial.

Pickleball Paddles: Faster Swings and Quicker Responses

When it comes to pickleball paddles, the difference between carbon fiber and fiberglass is immediately noticeable. Carbon fiber vs fiberglass speed plays a pivotal role in competitive play, as the material choice directly influences the player’s ability to react quickly and swing faster. Carbon fiber paddles are known for their lightweight and stiff properties, which allow for rapid paddle speed, better ball control, and quicker responses. The rigid nature of carbon fiber transfers more of the player’s energy to the ball, making it ideal for those looking to maximize power and speed in their shots. On the other hand, fiberglass paddles, while still relatively light, offer more flex and forgiveness. This results in slower swings and less responsive play, which can be beneficial for casual players but less effective in competitive environments where speed is paramount.

Fishing Rods: Response Time and Speed Performance

In the world of fishing, the choice between carbon fiber and fiberglass also has significant implications for speed and responsiveness. Carbon fiber vs fiberglass speed in fishing rods affects how quickly a fisherman can react, set the hook, and recover after a catch. Carbon fiber rods are stiffer and lighter, which allows for a quicker response time and a faster hook-set. This makes carbon fiber rods ideal for fast-action fishing, where rapid movements are necessary to secure the catch. The lightness of the material reduces fatigue during prolonged fishing sessions, enabling better control and faster actions. Fiberglass rods, on the other hand, are generally more flexible and forgiving, which provides a smoother and slower action. While they are less efficient in terms of speed, fiberglass rods are often favored for their durability and versatility in various fishing environments. However, for speed-sensitive applications, carbon fiber remains the preferred choice.

Helmets: Enhancing Aerodynamics and Speed

In speed-dependent sports like motorsports and cycling, helmets play a critical role in reducing drag and improving performance. Carbon fiber vs fiberglass speed is an essential consideration in helmet design, particularly when it comes to weight reduction and aerodynamics. Carbon fiber helmets are considerably lighter than their fiberglass counterparts, which reduces the overall weight worn by the athlete. This weight reduction, combined with the material’s stiffness, allows for better aerodynamic properties, helping athletes maintain higher speeds with less effort. In cycling, for example, a lightweight carbon fiber helmet can minimize wind resistance, allowing the rider to achieve faster speeds with improved comfort. In motorsports, carbon fiber helmets offer the same benefits, contributing to better performance on the track. Fiberglass helmets, while still offering good protection and durability, tend to be heavier and less aerodynamic, which can slightly hinder speed and performance, especially in competitive settings.

From pickleball paddles to fishing rods and helmets, carbon fiber vs fiberglass speed directly impacts the performance of various products. Carbon fiber excels in applications where speed, responsiveness, and lightweight performance are crucial. Its stiffness and light weight make it the preferred choice for competitive sports and high-speed activities. Fiberglass, though heavier and slower in certain contexts, provides flexibility, durability, and cost-effectiveness, making it a solid choice for casual or endurance-focused applications. Understanding the performance differences between these materials helps users select the right option for speed-sensitive activities.

Can Fiberglass Reinforced Plastic Panels Be Painted Effectively?

Strength and Durability Impacting Speed: Carbon Fiber vs Fiberglass Speed

The strength and durability of a material are not only important for its longevity but also significantly influence its speed performance, particularly in high-demand applications. When comparing carbon fiber vs fiberglass speed, the inherent differences in strength and durability between the two materials can drastically impact performance in competitive and high-stress environments. This section explores how the strength characteristics of both materials affect speed and performance.

Carbon Fiber Strength: Superior Power Transfer for Higher Speeds

Carbon fiber is renowned for its superior strength-to-weight ratio, which plays a vital role in its speed-related performance. The material’s high tensile strength allows it to remain rigid and resist flexing under pressure. This lack of flex translates directly into better power transfer, especially in applications like race cars, bicycles, and drones, where precise energy distribution is crucial for achieving higher speeds.

In racing cars, for example, carbon fiber components like chassis and body panels help reduce overall weight while maintaining structural integrity. This allows the car to accelerate faster and achieve higher top speeds due to more efficient power delivery. Similarly, carbon fiber bicycles are not only lighter but also stiffer, meaning that more of the rider’s pedaling force is transferred to forward motion instead of being absorbed by the flexing of the frame. This results in faster acceleration and better overall speed performance on the road or track. In drones, carbon fiber’s rigidity and strength enable greater aerodynamic efficiency and faster speeds by minimizing unnecessary movement or vibrations that could hinder flight performance.

When discussing carbon fiber vs fiberglass speed, carbon fiber’s ability to handle high loads without significant flex makes it the superior choice in speed-centric, high-performance environments. The strength of carbon fiber ensures that power is efficiently translated into speed, making it ideal for competitive use.

Fiberglass Strength: Flexibility with Impact Resistance but Limited Speed Performance

Fiberglass, while not as stiff or lightweight as carbon fiber, offers a different set of advantages in terms of strength and durability. One of its key benefits is its flexibility, which gives fiberglass a high level of impact resistance. This makes fiberglass an excellent choice for applications where the material is likely to face rough handling, impacts, or stress. For example, fiberglass is often used in the construction of boat hulls and sports equipment like fishing rods, where durability and the ability to withstand bending or impact are essential.

However, when it comes to speed performance, the flexibility of fiberglass can be a disadvantage. In high-stress environments, such as racing or competitive sports, the increased flexibility of fiberglass can result in energy loss, as the material tends to flex under load rather than transferring power efficiently. This reduction in power transfer results in slower acceleration and lower top speeds compared to carbon fiber. While fiberglass is durable and impact-resistant, its increased weight and flexibility hinder its performance in speed-driven applications.

In high-performance applications where carbon fiber vs fiberglass speed is a key consideration, fiberglass’s strength offers good durability but falls short in delivering the same level of power transfer and speed performance as carbon fiber. The material is more suited to situations where flexibility and impact resistance are prioritized over maximum speed and efficiency.

The strength and durability of both carbon fiber and fiberglass have a direct impact on speed. Carbon fiber’s superior strength-to-weight ratio provides a more rigid, efficient material that enhances power transfer, leading to higher speeds in competitive environments. On the other hand, fiberglass offers flexibility and impact resistance, making it a durable choice for applications requiring resilience, but its increased weight and flexibility make it less effective for high-speed performance. In a carbon fiber vs fiberglass speed comparison, carbon fiber consistently outperforms fiberglass when it comes to speed, acceleration, and power transfer in high-stress applications.

The Cost of Speed: Carbon Fiber vs Fiberglass Speed

When considering carbon fiber vs fiberglass speed, the cost is an essential factor that often influences material selection, particularly in industries with cost constraints. While both materials offer distinct advantages in performance and durability, their price differences can significantly impact decisions, especially in areas where speed and performance are crucial. This section examines the cost implications of using carbon fiber and fiberglass, and how these materials are selected based on both performance needs and budget considerations.

Carbon Fiber: High Performance Comes with a Higher Price Tag

Carbon fiber is widely recognized for its superior strength, lightweight properties, and exceptional performance in speed-centric applications. However, these high-performance benefits come at a cost. The manufacturing process for carbon fiber is highly complex and labor-intensive, involving intricate steps such as weaving the fibers and curing the material at high temperatures. This specialized production process makes carbon fiber significantly more expensive than fiberglass.

In industries where carbon fiber vs fiberglass speed is a critical consideration, such as motorsports, aerospace, and professional cycling, the benefits of carbon fiber often justify its higher cost. The material’s lightweight and rigid nature translate into enhanced speed, responsiveness, and power transfer, making it a preferred choice for competitive use. However, in markets where budget constraints are a significant concern—such as amateur sports, recreational activities, or entry-level products—the high cost of carbon fiber can be prohibitive. For these applications, manufacturers may opt for fiberglass, even if it means sacrificing some speed and performance.

For example, in professional cycling, carbon fiber frames are standard due to their lightweight and aerodynamic properties, which contribute to higher speeds. In contrast, amateur cyclists or casual riders may be more likely to choose fiberglass bikes, which offer good performance at a much lower price. Thus, while carbon fiber excels in high-performance scenarios, its cost often limits its use to industries or users who can afford the investment in pursuit of ultimate speed.

Fiberglass: Affordability with Trade-Offs in Speed Performance

Fiberglass is generally much more affordable than carbon fiber, making it an attractive option for industries or consumers with cost constraints. The production process for fiberglass is simpler and less time-consuming than that of carbon fiber, which translates into lower manufacturing costs. This affordability makes fiberglass a common choice for entry-level products or industries that prioritize cost-effectiveness over top-tier performance.

In terms of carbon fiber vs fiberglass speed, fiberglass does not provide the same performance benefits as carbon fiber in high-speed applications. While it is still lightweight and durable, fiberglass is more flexible and less rigid than carbon fiber, which can impact speed performance. The material’s flexibility tends to absorb more of the energy that would otherwise be used for forward motion, which can lead to slower acceleration and lower overall speed. However, in many cases, fiberglass still offers sufficient performance for non-competitive or recreational applications, where cost savings are more important than achieving the highest possible speed.

For example, in recreational boating, fiberglass boats are more commonly used due to their affordability and durability, even though they may not perform as well in terms of speed and acceleration compared to carbon fiber boats. Similarly, in the sports industry, fiberglass is often used in products like fishing rods and beginner-level sporting equipment, where the need for high-speed performance is less critical. Overall, fiberglass provides a cost-effective solution for many applications but sacrifices some of the speed advantages that carbon fiber offers.

The decision between carbon fiber vs fiberglass speed is heavily influenced by the cost of the materials. Carbon fiber offers superior performance in terms of speed, strength, and weight, but comes with a higher price tag due to its complex manufacturing process. This makes it ideal for industries or applications where ultimate performance is the top priority, such as professional motorsports, high-end bicycles, and aerospace. On the other hand, fiberglass is a more affordable alternative, making it a popular choice for entry-level products or industries that prioritize cost-effectiveness over speed. While it may not match carbon fiber’s performance in speed-sensitive applications, fiberglass provides a durable and reliable option for many everyday use cases where performance needs are less demanding.

FAQs about Carbon Fiber VS Fiberglass Speed

Carbon fiber is often used in automotive applications for its lightweight and strong properties, which can indeed help make a car faster. The primary benefit of using carbon fiber in cars is its exceptional strength-to-weight ratio. By replacing heavier materials such as steel or aluminum with carbon fiber, the overall weight of the car is reduced, leading to improved acceleration, handling, and top speed. A lighter car requires less energy to move, which means the engine can work more efficiently, resulting in faster speeds. Additionally, carbon fiber components, such as body panels, hoods, and spoilers, are commonly designed to be aerodynamically optimized. This reduces drag, allowing the car to cut through the air more effectively, which also contributes to improved speed and fuel efficiency.

However, while carbon fiber can improve performance, it is not the only factor in making a car faster. The engine, tires, suspension system, and overall vehicle design also play a significant role in determining speed. Carbon fiber’s benefits are more pronounced in high-performance sports cars and racing vehicles, where weight reduction and aerodynamics are critical to speed. It’s important to note that carbon fiber is an expensive material, and its cost can make it a less viable option for everyday cars.

When comparing carbon fiber vs fiberglass, the choice between the two depends largely on the specific application and performance requirements. Carbon fiber is generally considered superior to fiberglass in terms of strength, weight, and performance. It is much lighter and stronger than fiberglass, making it the material of choice for industries where high strength-to-weight ratios are essential. For example, carbon fiber is widely used in aerospace, automotive, and sports equipment, where lightweight structures are crucial for speed, acceleration, and overall performance.

In contrast, fiberglass is heavier and less rigid than carbon fiber but is still a durable and versatile material. Fiberglass offers good impact resistance and is more flexible, which makes it ideal for applications that require durability and resistance to deformation under stress, such as in boat hulls, wind turbine blades, and some consumer goods.

One significant advantage of fiberglass is its cost; it is much more affordable than carbon fiber, which makes it a popular choice for products where extreme performance is not a primary concern. Carbon fiber, however, is more expensive due to its complex manufacturing process, and its high cost limits its use to high-performance and premium products. In summary, carbon fiber is better in performance-critical applications, while fiberglass is more cost-effective for less demanding uses.

Carbon fiber is an extremely strong and rigid material, but it is not specifically designed to stop bullets. While carbon fiber is used in bulletproof vests, armor, and other protective gear, it is typically combined with other materials like aramid fibers (e.g., Kevlar) or ceramics to provide effective ballistic protection. The primary role of carbon fiber in ballistic protection is to add strength and contribute to the material’s ability to disperse the energy of a bullet, but on its own, carbon fiber alone cannot stop a bullet.

The reason for this is that carbon fiber, despite being incredibly strong for its weight, is not thick enough to withstand the high velocity and force of a bullet. Bulletproof armor is designed with multiple layers of materials that can absorb and dissipate the energy from a bullet. These layers might include Kevlar, which is woven to create a dense, flexible fabric that can absorb the impact of a bullet, as well as ceramic plates that can shatter the bullet upon impact. In this context, carbon fiber is used to reinforce the structure and make the armor lighter, but it is not a standalone solution for stopping bullets.

Carbon fiber boats are highly regarded for their lightweight, strength, and performance, but they do come with several disadvantages that must be considered. One of the most significant downsides of carbon fiber boats is their cost. Carbon fiber is a premium material, and the manufacturing process is labor-intensive, which makes carbon fiber boats much more expensive than those made from fiberglass or aluminum. For casual boaters or those on a tight budget, the high price tag of a carbon fiber boat can be prohibitive.

Another disadvantage is the material’s susceptibility to damage from impacts. While carbon fiber is incredibly strong, it is also more brittle than fiberglass, meaning it can crack or shatter upon impact, especially if struck by a hard object or during a collision. In contrast, fiberglass has more flexibility and is more forgiving when it comes to minor impacts, making fiberglass boats less prone to structural damage.

Additionally, carbon fiber boats can be more difficult to repair than fiberglass boats. While fiberglass is relatively easy to patch up with repair kits, carbon fiber repairs often require specialized techniques and equipment, making them more complex and costly.

Finally, carbon fiber boats can be more challenging to maintain, as the material is prone to UV degradation over time. To maintain their strength and appearance, carbon fiber boats need to be carefully stored and protected from prolonged sun exposure. Overall, while carbon fiber boats offer superior performance, their high cost, fragility, and maintenance requirements can be considered significant drawbacks for many users.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.