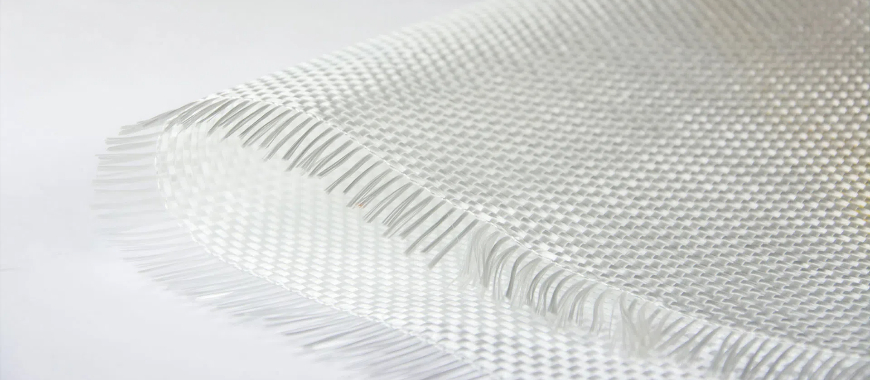

Clear fiberglass clothes is a versatile and durable material made from woven glass fibers, offering a unique combination of strength and transparency. Unlike traditional opaque fiberglass fabrics, clear fiberglass cloth allows for a higher degree of visibility, making it an ideal choice for projects where aesthetic appeal and smooth finishes are essential. It is commonly used in boat building, automotive repairs, and DIY composite projects, where both the structural integrity and visual quality of the material are important. The material’s transparent nature provides a clear view of underlying structures, making it particularly useful in applications requiring both functionality and design. Its strength and flexibility make it suitable for reinforcing surfaces while maintaining a clean, polished appearance. Whether for marine construction or creating custom composite products, clear fiberglass clothes offers the perfect balance of durability and clarity.

Types of Clear Fiberglass Cloth Available

Clear fiberglass cloth is available in a variety of weights and forms to cater to different applications. From lightweight cloth suitable for detailed projects to heavier options ideal for structural reinforcement, these fabrics provide flexibility, strength, and transparency for a wide range of uses. Below are some common types of clear fiberglass clothes, each designed to meet specific needs in boat building, automotive repair, and DIY composite applications.

75 oz Fiberglass Cloth

The .75 oz fiberglass cloth is a lightweight material perfect for intricate designs, such as model-making and fine-detail work. Its thin structure makes it ideal for small-scale applications where precision and minimal weight are critical. This type of cloth is often used for projects that require a delicate yet strong finish without adding unnecessary bulk.

Benefits of 75 oz Fiberglass Cloth

- Lightweight: Perfect for small-scale projects where weight reduction is crucial.

- Easy to handle: Its thinness makes it easier to manipulate around tight corners or curves.

- Ideal for detailed work: Suitable for applications where precision and finesse are required, such as scale models or small boat components.

4 oz Fiberglass Cloth

The 4 oz fiberglass cloth is a medium-weight option that strikes an excellent balance between strength and flexibility. It is commonly used for boat building, lightweight repairs, and composite applications where moderate durability is required. This cloth can be used on larger surfaces or for applications that demand more substantial support than the .75 oz option.

Benefits of 4 oz Fiberglass Cloth

- Versatility: Suitable for a wide range of medium-duty applications.

- Strength and flexibility: Offers a good combination of durability and ease of handling.

- Commonly used in boat building: Provides the necessary reinforcement for boat hulls, decks, and smaller repairs.

6 oz Fiberglass Cloth

The 6 oz fiberglass cloth is stronger than the 4 oz variety, making it suitable for larger, more demanding applications. This cloth is commonly used in boat hulls and other larger composite structures that require additional strength and durability. Its thicker weave ensures better resistance to wear and tear, making it ideal for more robust construction projects.

Benefits of 6 oz Fiberglass Cloth

- Enhanced strength: Provides increased durability for heavy-duty applications.

- Larger applications: Perfect for larger boat hulls, automotive repairs, or other structures requiring substantial reinforcement.

- Greater impact resistance: Offers superior protection against external stressors, providing long-lasting results.

Fiberglass Cloth Roll for Boats

Fiberglass cloth rolls come in varying widths, such as 4 oz and 6 oz, and are designed specifically for boat-building projects. These rolls are easy to handle and can be cut to the desired size, making them highly versatile for creating smooth, durable finishes. The continuous length of fiberglass cloth ensures seamless application across large surfaces, minimizing the need for joints or seams.

Benefits of Fiberglass Cloth Rolls for Boats

- Convenience: Ready-to-use rolls make it easy to cover large areas quickly.

- Durable finish: Offers smooth, high-quality results, essential for marine environments.

- Customizable size: Can be cut to fit the dimensions of the project, providing flexibility for various applications.

Clear fiberglass cloth is an essential material for a variety of applications, offering durability, transparency, and ease of use across different industries. The different weights and types of cloth cater to specific needs, making it easier to choose the right one based on the project’s requirements. Whether you’re working on a boat hull, a model, or a composite structure, clear fiberglass clothes provides the ideal balance of strength and flexibility.

Do Fabric Softeners Have Fiberglass in Their Ingredients?

Clear Fiberglass Cloth and Resin: A Perfect Combination

Clear fiberglass cloth is a versatile material widely used in various industries, including boat building, automotive repair, and DIY composite projects. When combined with the right resin system, it forms a durable, high-performance composite material that is strong, flexible, and resistant to environmental stressors. The synergy between clear fiberglass cloth and resin systems—such as epoxy, polyester, and vinyl ester—creates an ideal solution for many applications, ensuring long-lasting durability and high-quality finishes.

Interaction of Clear Fiberglass Cloth with Resin Systems

The way transparent fiberglass cloth interacts with different resin systems is crucial in determining the final strength, flexibility, and durability of the composite material. Each resin type has specific properties that work best with fiberglass cloth, allowing the combination to deliver superior results for various applications.

- Epoxy Resin: Epoxy resin is highly favored in combination with clear fiberglass cloth due to its excellent bonding properties and superior resistance to moisture, chemicals, and temperature changes. The resin penetrates the fibers of the cloth, creating a solid, durable bond that enhances the overall strength of the composite. This combination is ideal for boat building, automotive repairs, and other high-performance applications that require longevity and reliability.

- Polyester Resin: Polyester resin is more commonly used for general-purpose applications and offers a faster curing time compared to epoxy. When paired with clear fiberglass cloth, it forms a strong bond that is cost-effective for larger projects. While it may not have the same level of resistance to heat or moisture as epoxy, polyester resin is a practical option for many marine or DIY projects where durability is important but cost constraints exist.

- Vinyl Ester Resin: Vinyl ester resin is a hybrid of polyester and epoxy, offering the best of both worlds. It has superior chemical resistance compared to polyester and provides a stronger bond with clear fiberglass cloth than standard polyester resin. It is especially effective in environments where exposure to corrosive substances is a concern, such as in marine applications. The clear finish achieved with vinyl ester resin combined with clear fiberglass cloth results in a smooth, durable surface that is both aesthetically pleasing and highly resistant to wear.

Role of Fiberglass Cloth and Resin Kits

Fiberglass cloth and resin kits are designed to simplify the application process, making it easier for users—whether professionals or DIY enthusiasts—to create high-quality composite materials. These kits typically include pre-measured amounts of resin and hardener, along with clear fiberglass cloth cut to size, ensuring that the user has everything necessary to complete the project with minimal hassle.

- Convenience: The pre-measured resin and fiberglass cloth ensure consistency in the application process, eliminating the guesswork and reducing the likelihood of mistakes.

- Efficiency: Having all the materials in one kit allows for quicker and more efficient application, especially on larger projects such as boat hulls or automotive panels.

- Versatility: Many fiberglass cloth and resin kits come with a variety of resin options, including epoxy, polyester, or vinyl ester, allowing the user to select the best combination for their specific project.

How to Apply Resin to Clear Fiberglass Cloth for Optimal Strength and Finish

Proper application of resin to clear fiberglass cloth is crucial to achieving the desired strength, smooth finish, and long-lasting durability of the composite material. Follow these steps for the best results:

- Prepare the Surface: Ensure that the surface where the clear fiberglass cloth will be applied is clean, dry, and free of any contaminants, such as dust, oil, or grease. A smooth surface ensures better resin adhesion and a stronger bond.

- Cut the Clear Fiberglass Cloth: Measure and cut the clear fiberglass cloth to the required size, allowing for some overlap to ensure full coverage of the surface.

- Mix the Resin: Carefully follow the instructions on the resin container to mix the resin and hardener in the correct ratio. Proper mixing is essential for achieving the desired curing time and strength.

- Apply the Resin: Use a brush or roller to apply a thin layer of resin to the clear fiberglass cloth. Work in small sections to ensure even coverage. Once the resin is applied to the cloth, press it into the surface, ensuring no air bubbles are trapped between the cloth and the substrate.

- Saturate the Cloth: After placing the fiberglass cloth on the surface, apply more resin to fully saturate the cloth, ensuring that all fibers are completely bonded with the resin. This step is crucial to achieve the maximum strength and durability.

- Curing: Allow the resin and fiberglass cloth to cure according to the manufacturer’s instructions. Ensure the composite is kept at the recommended temperature and humidity levels during the curing process to avoid defects in the final product.

- Finish: Once cured, the surface can be sanded and smoothed to achieve a flawless finish. A final coat of resin can be applied for added protection, ensuring that the clear fiberglass cloth maintains its transparency and strength.

The combination of clear fiberglass cloth and resin provides an incredibly strong, lightweight material that is suitable for a wide range of applications. Whether used for boat construction, repairs, or custom composite projects, this pairing offers an efficient, durable, and aesthetically pleasing solution.

Building with DIY Aquarium Safe Fiberglass Fabric for Safety

Benefits of Using Clear Fiberglass Cloth in Projects

Clear fiberglass cloth is a highly versatile material, offering numerous benefits for a wide range of applications. Its unique properties make it a preferred choice for projects where both strength and aesthetics are important. Whether you’re building a boat, repairing an automotive part, or working on a DIY composite project, the advantages of clear fiberglass cloth are significant.

Transparency for Clean, Smooth Finishes

One of the standout features of clear fiberglass cloth is its transparency. This property is especially important in projects where the final product needs to showcase a smooth, flawless finish or where the underlying material needs to remain visible. The transparency allows for a clean, polished surface that does not obscure the design or structure beneath. This makes clear fiberglass cloth an ideal choice for applications such as:

- Boat building: When used for fiberglassing over wooden or carbon fiber hulls, it ensures the boat’s natural design and finish are preserved.

- Automotive repairs: The clear cloth allows for a smooth and aesthetically pleasing surface, especially in parts where visibility and finish quality are critical.

- DIY projects: Clear fiberglass cloth offers hobbyists the ability to create custom designs with a smooth, professional finish.

The transparency not only enhances the visual quality of a project but also provides a clean, neat appearance, especially in visible areas like boat decks, automotive bodies, or custom-crafted designs.

Strength and Durability

Clear fiberglass cloth offers an exceptional balance of strength and durability, making it highly effective in demanding applications. It boasts a high strength-to-weight ratio, which means it can provide significant structural reinforcement without adding excessive weight. This makes it especially useful in industries where both strength and lightweight characteristics are necessary, such as:

- Boat hulls: Clear fiberglass cloth adds significant strength to boat hulls while keeping the overall weight down, improving buoyancy and performance.

- Automotive repairs: It is used for reinforcing and repairing body panels, where strength is crucial for ensuring the vehicle’s integrity and safety.

- Structural reinforcement: Clear fiberglass cloth is also commonly used in lightweight reinforcement for other composite structures, where long-lasting durability is needed without compromising on weight.

Thanks to its exceptional durability, clear fiberglass cloth can withstand harsh environmental conditions, such as moisture, UV exposure, and temperature fluctuations. This durability makes it a long-term solution for a wide variety of applications, contributing to the longevity of the final product.

Versatility for Shaping and Molding

Clear fiberglass cloth is highly versatile, with the ability to be easily shaped and molded to fit complex contours and surfaces. This makes it ideal for use in projects with intricate designs, where other materials may struggle to maintain a tight bond or form around curved surfaces. The flexibility of clear fiberglass cloth ensures that it adheres tightly to the surface and provides a smooth, consistent finish, even in challenging applications. Key benefits of this versatility include:

- Adaptability to complex shapes: Clear fiberglass cloth can conform to tight curves, angles, and irregular surfaces, ensuring complete coverage and a seamless finish.

- Molding over multiple surfaces: Whether it’s a boat, automotive part, or composite structure, clear fiberglass cloth can be molded over various substrates like wood, metal, or plastic, providing a tight and durable bond.

- Ease of handling: Clear fiberglass cloth can be manipulated easily, making it suitable for both large-scale applications and small, intricate repairs.

By being highly flexible and moldable, clear fiberglass cloth ensures that it can be used in a wide range of projects, providing a perfect fit and finish even in the most complex designs. The ability to shape and mold this material makes it indispensable for projects that require detailed craftsmanship and high-quality results.

These benefits—transparency, strength and durability, and versatility—make clear fiberglass cloth an essential material for many different projects, from boat building to automotive repairs and beyond. Its ability to provide both aesthetic appeal and structural integrity ensures its place as a top choice for composite applications.

Best Methods to Cover Fiberglass Acoustic Panel Fabric

Pricing and Availability of Clear Fiberglass Cloth

When considering clear fiberglass cloth for your project, it’s important to understand the pricing and availability based on factors such as the cloth’s weight, roll size, and the type of application. Clear fiberglass cloth is available in various weights (e.g., 4 oz, 6 oz) and roll sizes, and the cost can vary significantly depending on the type and quantity purchased. Whether you’re completing a small DIY project or a larger-scale construction like boat-building, knowing the price range and availability can help you plan your budget effectively.

4 oz Clear Fiberglass Cloth Roll Prices

The price of clear fiberglass cloth often depends on the weight and roll size. For example, a 4 oz clear fiberglass cloth roll typically ranges from $10 to $30 per yard, depending on the supplier and material quality. This weight is ideal for medium-duty projects such as automotive repairs, smaller boat-building applications, or DIY composite projects. The price can fluctuate based on the manufacturer, but 4 oz clear fiberglass cloth offers an excellent balance of affordability and performance.

- Affordable for small projects: 4 oz clear fiberglass cloth is a cost-effective choice for DIYers and hobbyists, providing good strength and durability at a reasonable price.

- Widely available: It is easy to find in most suppliers’ inventory, making it accessible for both casual users and professional contractors.

Bulk Purchase Benefits for Larger Projects

For larger projects, such as boat-building, purchasing clear fiberglass cloth in bulk can provide significant cost savings. Bulk purchases often come with discounts and make it easier to maintain consistency in material quality across a large area. For example, larger rolls of clear fiberglass cloth (6 oz or more) are priced based on square footage rather than yards, with the price per square foot often decreasing as the order quantity increases.

- Cost savings: Buying in bulk can reduce the overall cost per yard or square foot, making it more affordable for extensive applications like boat hulls or large composite structures.

- Consistent material supply: Bulk purchases ensure that you have a continuous supply of the same material, reducing the risk of inconsistency in quality, which is especially important for projects requiring large-scale reinforcement or repairs.

- Availability for large-scale projects: Many suppliers offer clear fiberglass cloth in bulk specifically for large-scale commercial or industrial applications, such as boat-building or infrastructure repairs.

Choosing the Right Size and Weight Based on Project Needs

Choosing the right size and weight of clear fiberglass cloth is crucial to ensure that the material meets the needs of your project. For smaller repairs or intricate projects, lighter weights such as 4 oz cloth may be more suitable, while for larger, more demanding applications like boat hulls or reinforced automotive parts, heavier weights such as 6 oz or 8 oz are often preferred.

- Consider the surface area: A larger project with more surface area will likely require a bulk roll of clear fiberglass cloth to ensure there is enough material for the entire application.

- Project complexity: The weight and thickness of the cloth will also depend on the complexity of the surfaces you are working with. For instance, projects that involve curved surfaces or require molding may benefit from lighter cloth, as it can better conform to irregular shapes.

- Strength requirements: For projects requiring higher durability or strength, such as marine applications, a heavier weight of clear fiberglass cloth may be necessary to ensure long-lasting performance and structural integrity.

The pricing and availability of clear fiberglass cloth vary based on the material’s weight and size. Whether you are working on a small DIY repair or a large boat-building project, clear fiberglass cloth is available at a range of price points and can be purchased in bulk for significant savings. Understanding your project’s specific requirements will help you determine the right weight and roll size for optimal performance and cost-efficiency.

Clear Fiberglass Cloth for Boat Building

Clear fiberglass cloth is an essential material for boat building, offering a perfect combination of strength, flexibility, and aesthetic appeal. It is widely used for creating durable boat hulls and reinforcing structures while maintaining a smooth, transparent finish. The following step-by-step guide will walk you through the process of applying clear fiberglass cloth to a boat’s hull and the benefits it brings to boat-building projects.

Step-by-Step Guide on Applying Clear Fiberglass Cloth to a Boat’s Hull

- Surface Preparation: Before applying the clear fiberglass cloth, the boat’s hull must be thoroughly cleaned and prepared. This includes sanding the surface to remove any old paint, dirt, or imperfections that could affect the bonding process. It’s essential to ensure that the surface is smooth and free of contaminants to achieve optimal adhesion between the cloth and the resin.

- Cutting the Cloth: Once the surface is prepared, the next step is to cut the clear fiberglass cloth to the required size. Measure the boat hull’s dimensions carefully and cut the cloth to fit snugly. It’s important to leave a slight overlap at the edges to ensure a secure bond when applying the resin.

- Applying Resin: After cutting the cloth, the next step is to apply a layer of resin to the hull. This resin, whether epoxy, polyester, or vinyl ester, acts as the bonding agent that binds the fiberglass cloth to the boat. Using a roller or brush, apply a generous coat of resin to the hull. Place the clear fiberglass cloth over the resin, ensuring there are no wrinkles or air bubbles. Once the cloth is in place, apply another layer of resin on top, fully saturating the cloth.

- Curing and Finishing: Allow the resin to cure completely before adding additional layers, if necessary. The curing time depends on the type of resin used, but typically it takes several hours. Once the resin has fully cured, you can sand the surface to create a smooth, glass-like finish. This smooth surface not only enhances the boat’s appearance but also ensures the durability and water resistance of the hull.

Advantages of Using Clear Fiberglass Cloth in Boat-Building

Clear fiberglass cloth offers several advantages that make it ideal for boat-building projects:

- Water Resistance: Clear fiberglass cloth, when combined with the right resin, creates a highly water-resistant surface, making it perfect for marine applications. This feature is critical for boat hulls, which are constantly exposed to water and need to withstand harsh conditions.

- Aesthetic Finish: One of the main reasons boat builders use clear fiberglass cloth is its ability to provide a clean, transparent finish. This allows builders to showcase the natural design of the boat or enhance its appearance with a smooth, glossy surface. It is particularly useful when a visual appeal is important, such as in custom boat projects or when working with wood or other decorative materials.

- Strength and Durability: Fiberglass cloth offers excellent strength-to-weight ratio, which is ideal for maintaining the structural integrity of the boat while keeping the weight down. This makes it a perfect choice for building long-lasting boats that are both lightweight and durable.

Repairing Boats with Clear Fiberglass Cloth

Clear fiberglass cloth is not only beneficial for building new boats but also for repairing damaged hulls. Whether you need to fix cracks, reinforce weakened areas, or perform general maintenance, clear fiberglass cloth can provide a seamless solution that doesn’t compromise the boat’s appearance.

- Fixing Cracks: To repair cracks in the boat hull, first, clean and sand the affected area. Cut the clear fiberglass cloth to the appropriate size and apply resin to the damaged spot. Lay the cloth over the crack and saturate it with resin. The clear fiberglass cloth will bond to the surface, sealing the crack and restoring the boat’s integrity.

- Reinforcing Weak Areas: For boats with areas that have been stressed over time, such as the hull or deck, clear fiberglass cloth can be applied to reinforce these sections. This helps to distribute pressure evenly, preventing further damage and improving the boat’s overall strength.

- Maintaining Visual Appeal: One of the unique benefits of using clear fiberglass cloth for repairs is that it maintains the boat’s aesthetic appearance. Because the cloth is transparent, it allows the original finish of the boat to shine through, ensuring that repairs are almost invisible. This is particularly important for boat owners who value the visual quality of their vessel.

Clear fiberglass cloth is a versatile and powerful material for boat building and repairs. It provides strength, durability, and a smooth, aesthetic finish while maintaining the water resistance that boats require. Whether building a new boat or repairing an old one, clear fiberglass cloth is an essential component for creating long-lasting and beautiful marine vessels.

FAQs about Clear Fiberglass Cloth

Fiberglass cloth comes in a variety of types, each suitable for different applications based on their properties. The three most common types of fiberglass cloth are:

Plain Weave Fiberglass Cloth: This is the most common type of fiberglass cloth, made with a simple crisscross weave pattern. It is strong, flexible, and often used for general boat-building, automotive repairs, and various composite applications.

Satin Weave Fiberglass Cloth: This cloth has a more lustrous finish and a smoother surface compared to plain weave. It is often used in projects where a smooth, glossy finish is required, such as in automotive or marine applications.

Twill Weave Fiberglass Cloth: Known for its distinctive diagonal weave pattern, twill weave cloth is durable, flexible, and resistant to cracking. It is often used in projects that require high-strength composites, including in boat hulls and structural applications.

Each type offers unique benefits depending on the project requirements, with plain weave being the most versatile, satin weave providing aesthetic appeal, and twill weave offering extra strength for demanding applications.

If fiberglass cloth is not suitable for your project, there are several alternatives you can consider, depending on the application:

Kevlar Cloth: Known for its high tensile strength, Kevlar is often used in situations requiring additional strength, such as in aerospace, military, and high-performance vehicles. It offers greater resistance to impact and abrasion compared to fiberglass cloth.

Carbon Fiber Cloth: This material is stronger and lighter than fiberglass, making it an excellent choice for high-performance applications such as in racing boats, aircraft, and sports equipment. Carbon fiber cloth also provides excellent stiffness and rigidity.

Aramid Fiber Cloth: Similar to Kevlar, aramid fiber is strong, lightweight, and heat-resistant. It is commonly used in applications requiring durability and resistance to extreme conditions, such as in protective gear or vehicle body panels.

Fiberglass Mat: For applications where a thick, rigid structure is needed, fiberglass mat can serve as an alternative to fiberglass cloth. While it lacks the woven texture of cloth, it is often used in automotive and marine applications for added strength and durability.

Each of these materials has specific properties that may suit your project depending on the strength, flexibility, and weight requirements.

The choice between fiberglass mat and fiberglass cloth depends on the specific needs of your project. Here’s a comparison of both:

Fiberglass Cloth: Fiberglass cloth is woven and provides higher strength due to its interlaced structure. It offers better tensile strength and flexibility compared to mat. It’s ideal for applications where a smoother surface is required, such as boat-building and automotive repairs. The woven fibers give it the ability to withstand bending and stretching, making it a versatile choice for both structural and aesthetic applications.

Fiberglass Mat: Fiberglass mat, on the other hand, is made of chopped strands of fiberglass randomly oriented in a thick mat. It is stronger in terms of compressive strength but lacks the flexibility and tensile strength of cloth. It’s used in applications where thickness and rigidity are needed, such as in the construction of thick laminates and reinforcing structural components.

The number of layers of fiberglass cloth you should use depends on several factors, including the type of resin, the application, and the required strength of the finished product. In general, the more layers of fiberglass cloth you apply, the stronger and more durable the composite material will be.

For Light-Weight Applications: If you are working on a light-duty project, such as small boat repairs or crafting lightweight components, 2-3 layers of fiberglass cloth may be sufficient. This provides adequate strength while keeping the material relatively light.

For Medium-Duty Applications: For medium-duty projects, such as boat hulls or small to medium-sized composite structures, 4-6 layers of fiberglass cloth are commonly used. This ensures the material is strong enough to handle stress, pressure, and impact.

For Heavy-Duty Applications: For larger or more demanding projects, such as heavy boat-building or structural reinforcement, 7-10 layers of fiberglass cloth may be necessary. Multiple layers are added to ensure the composite material can withstand higher loads and harsh environmental conditions.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.