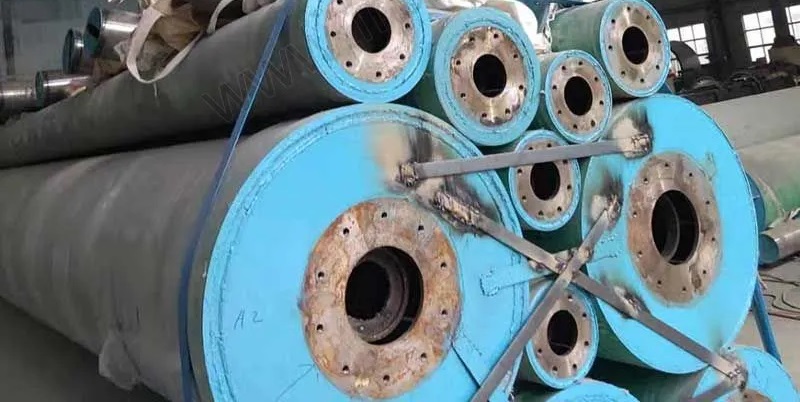

Contact molded FRP pipe is a type of fiberglass-reinforced plastic pipe manufactured through the contact molding process. This method involves manually layering fiberglass reinforcements, such as chopped strand mats, with resin over a mold, allowing for greater customization in shapes and sizes. Unlike filament winding, contact molding offers flexibility in producing complex pipe designs and fittings. Contact molded FRP pipe is known for its high strength, corrosion resistance, and adaptability, making it ideal for applications in chemical processing, water treatment, and industrial ducting. Its ability to withstand harsh environmental conditions and chemical exposure ensures long-term performance and reliability in demanding industrial environments. Contact molded FRP pipe, made with fiberglass reinforced plastic, offers high strength, corrosion resistance, and versatility for diverse uses.

The Key of Contact Molded FRP Pipe

Contact molded FRP pipe is a type of fiberglass-reinforced plastic pipe manufactured using the contact molding process, also known as fiberglass hand lay-up or open molding. This method involves manually applying layers of resin and fiberglass reinforcement to a mold, creating a composite structure with excellent mechanical properties and corrosion resistance. Contact molded FRP pipe is valued for its versatility, allowing for the production of custom shapes and sizes to meet specific application requirements. GangLong Fiberglass specializes in manufacturing high-quality contact molded FRP pipes, providing solutions that cater to various industries, including chemical processing, water treatment, and wastewater management.

What is the Contact Molding Process

The contact molding process is a manual technique used to produce FRP pipes and other composite structures. This method allows for precise control over the laminate structure, fiber orientation, and resin distribution, resulting in pipes with superior mechanical properties and corrosion resistance. Here is a detailed look at the contact molding process:

- Mold Preparation: The process begins with the preparation of a mold that defines the shape and size of the final FRP pipe. The mold is typically coated with a release agent to ensure that the finished pipe can be easily removed after curing. The mold may be designed to create straight pipes, elbows, tees, or other custom shapes, depending on the application requirements.

- Application of Gel Coat: A gel coat is often applied to the mold’s surface before the reinforcement and resin are added. This gel coat provides a smooth, high-quality finish and enhances the pipe’s resistance to environmental factors, UV radiation, and chemical attack. It also acts as a barrier layer, protecting the structural laminate from potential damage.

- Layering of Reinforcement and Resin: Fiberglass reinforcement, such as chopped strand mat, woven roving, or continuous strand mat, is manually laid onto the mold. Resin is then applied to the reinforcement layers using brushes, rollers, or spray equipment. The resin saturates the fibers, bonding them together to form a composite structure. Multiple layers of reinforcement and resin are applied to achieve the desired wall thickness and mechanical properties. The layering process can be adjusted to meet specific requirements, such as increasing the number of layers for added strength or using different fiber orientations for enhanced performance.

- Curing: Once the layers have been applied, the composite structure is allowed to cure. Curing is the process by which the resin hardens and bonds the fibers together, creating a rigid and durable FRP pipe. The curing process may be accelerated using heat or chemical catalysts, depending on the type of resin used. Proper curing is essential for achieving the desired mechanical properties and chemical resistance of the contact molded FRP pipe, as outlined in the FRP Pipe Code to ensure compliance with industry standards.

- Demolding and Finishing: After curing, the pipe is carefully removed from the mold. It may undergo additional finishing processes, such as trimming, sanding, and surface polishing, to ensure it meets the required specifications. Quality control inspections are performed to verify the pipe’s dimensions, surface quality, and mechanical properties.

The contact molding process offers several advantages, including the ability to produce custom shapes, control over the laminate structure, and the ability to manufacture pipes with complex geometries.

Resins Used in Contact Molded FRP Pipe

Resins used in the contact molding process at a wholesale FRP anticorrosion pipe factory significantly affect the properties and performance of the resulting FRP pipe. The choice of resin determines varying levels of chemical resistance, mechanical strength, and thermal stability, making it essential to select the appropriate resin for the intended application. This careful selection ensures that the factory produces high-quality anticorrosion pipes that meet the demands of diverse industrial environments. The most commonly used resins in contact molded FRP pipe include polyester, vinyl ester, and epoxy resins:

Polyester Resins

Polyester resins are widely used in the contact molding process due to their cost-effectiveness, ease of use, and good mechanical properties. They provide a strong bond with fiberglass reinforcement, resulting in a composite material with satisfactory strength and durability. Polyester resins are suitable for applications where moderate chemical resistance and mechanical strength are required.

- Chemical Resistance: Polyester resins offer good resistance to water, acids, and salts, making them suitable for applications such as water treatment and non-aggressive chemical transport. However, they may not be the best choice for highly corrosive environments involving strong acids or alkalis.

- Thermal Properties: Polyester resins have moderate thermal stability, allowing them to operate effectively in a range of temperatures. They are typically used in applications with temperature requirements below 80°C.

- Applications: Contact molded FRP pipes made with polyester resins are commonly used in water treatment facilities, irrigation systems, and light-duty chemical transport. They provide an economical solution for applications where extreme chemical resistance is not a primary concern.

Vinyl Ester Resins

Vinyl ester resins are known for their superior chemical resistance and mechanical properties compared to polyester resins. They offer a higher level of durability and resistance to aggressive chemicals, making them a preferred choice for contact molded FRP pipes used in more demanding environments.

- Chemical Resistance: Vinyl ester resins provide excellent resistance to a wide range of chemicals, including acids, alkalis, solvents, and oxidizing agents. This makes them suitable for applications in chemical processing, wastewater treatment, and other environments where exposure to corrosive substances is a concern.

- Mechanical Strength: The mechanical properties of vinyl ester resins are superior to those of polyester resins, offering higher tensile strength and impact resistance. This enhanced strength ensures that contact molded FRP pipes can withstand internal pressures and mechanical loads without compromising their integrity.

- Thermal Properties: Vinyl ester resins have better thermal stability than polyester resins, allowing them to operate effectively at higher temperatures, typically up to 120°C. This thermal stability makes them suitable for applications involving hot fluids or processes that generate heat.

- Applications: Contact molded FRP pipes made with vinyl ester resins are commonly used in chemical processing plants, wastewater treatment facilities, and industrial applications where high chemical resistance and mechanical strength are required.

Epoxy Resins

Epoxy resins are known for their exceptional mechanical properties, chemical resistance, and thermal stability. They form a strong bond with fiberglass reinforcement, resulting in a composite material with high strength and durability. Epoxy resins are often used in contact molded FRP pipes that require superior performance and long service life.

- Chemical Resistance: Epoxy resins provide excellent resistance to a wide range of chemicals, including acids, bases, solvents, and hydrocarbons. They are particularly well-suited for applications involving highly corrosive substances or environments where long-term chemical exposure is a concern.

- Mechanical Strength: The mechanical properties of epoxy resins are superior to both polyester and vinyl ester resins, offering high tensile, compressive, and flexural strength. This makes epoxy-based contact molded FRP pipes capable of withstanding high internal pressures and external mechanical loads.

- Thermal Properties: Epoxy resins have excellent thermal stability, allowing them to operate at temperatures up to 150°C or higher, depending on the specific formulation. This thermal resistance makes them suitable for high-temperature applications, such as transporting hot chemicals or fluids.

- Applications: Contact molded FRP pipes made with epoxy resins are used in highly demanding applications, including chemical processing, oil and gas transport, and high-temperature fluid handling. Their superior properties make them ideal for environments where maximum performance and durability are required.

Advantages of Contact Molded FRP Pipe

Contact molded FRP pipe offers several advantages, making it a versatile and reliable solution for various industrial applications:

- Customizable Design: The contact molding process allows for the production of custom shapes and sizes, enabling manufacturers to create pipes tailored to specific application requirements. This flexibility makes it possible to produce pipes with complex geometries, such as elbows, tees, and reducers, without the need for additional fittings.

- Enhanced Mechanical Properties: Contact molded FRP pipes exhibit excellent mechanical properties, including high tensile strength, compressive strength, and impact resistance. These properties ensure that the pipes can withstand internal pressures, mechanical loads, and external forces, providing a durable and long-lasting solution.

- Superior Corrosion Resistance: Depending on the type of resin used, contact molded FRP pipes offer exceptional resistance to a wide range of corrosive substances, including acids, alkalis, solvents, and seawater. This corrosion resistance makes them suitable for applications in harsh environments where traditional materials may fail.

- Thermal Stability: Contact molded FRP pipes can be designed to operate effectively across a broad temperature range, making them suitable for applications involving hot or cold fluids. Their thermal stability ensures that they maintain their structural integrity even under temperature fluctuations.

- High Strength and Durability: Contact molded FRP pipe is known for its high strength and durability. The manual layering of fiberglass reinforcements and resin results in a composite material that can withstand significant internal and external pressures. The strength of contact molded FRP pipes makes them suitable for applications involving high-pressure fluids, such as chemical processing or industrial wastewater transport. Additionally, the durability of these pipes ensures a long service life, even in harsh environments where exposure to chemicals, UV radiation, or mechanical stress is common. This durability reduces the need for frequent maintenance or replacement, contributing to the overall cost-effectiveness of the piping system.

- Corrosion Resistance: The corrosion resistance of contact molded FRP pipe is one of its most valuable attributes. By selecting the appropriate resin, manufacturers can produce pipes that resist a wide range of corrosive substances, including acids, alkalis, solvents, and seawater. This makes contact molded FRP pipes an ideal solution for industries like chemical processing, water treatment, and marine applications, where traditional materials such as metal or concrete would quickly deteriorate. The corrosion-resistant properties of FRP pipes ensure that they maintain their structural integrity and performance over time, even when exposed to aggressive chemicals or environmental conditions.

Applications of Contact Molded FRP Pipe

Contact molded FRP pipes are used in a wide range of industries due to their versatility, durability, and resistance to harsh conditions. Some key applications include:

- Chemical Processing: In chemical processing plants, contact molded FRP pipes are used to transport aggressive chemicals, acids, and solvents. Their corrosion resistance and ability to handle high temperatures make them an ideal choice for these demanding environments.

- Water Treatment: Contact molded FRP pipes are widely used in water treatment facilities for transporting potable water, wastewater, and process fluids. Their resistance to corrosion and smooth interior surface ensure consistent flow and prevent contamination.

- Oil and Gas: In the oil and gas industry, contact molded FRP pipes are used for transporting crude oil, natural gas, and produced water. Their resistance to corrosion and chemical attack ensures long-term performance in harsh offshore and onshore environments.

- Marine Applications: Contact molded FRP pipes are used in marine environments for seawater intake, desalination, and marine infrastructure. Their resistance to saltwater corrosion and marine growth makes them a reliable choice for coastal and offshore applications.

Layering Fiberglass Reinforcements

The contact molding process begins with the careful layering of fiberglass reinforcements onto a mold. These reinforcements can include chopped strand mat, woven roving, and surface veil, each chosen for its specific properties and contribution to the pipe’s overall performance. Chopped strand mat provides a balanced strength in multiple directions, while woven roving offers enhanced tensile strength, making the pipe resistant to internal and external pressures. Surface veil is often added to improve the pipe’s surface finish and resistance to chemical attack. During the layering process, these materials are placed in multiple layers to build up the pipe’s wall thickness, ensuring the desired structural integrity and mechanical properties.

Applying Resin

Once the fiberglass reinforcements are in place, the next step in the contact molding process involves applying the resin. The choice of resin, such as polyester, vinyl ester, or epoxy, depends on the specific requirements of the application. For instance, vinyl ester resin is commonly used for its superior chemical resistance, making it suitable for environments where the pipe will be exposed to aggressive chemicals. The resin is applied manually, saturating the fiberglass layers to ensure a complete bond between the fibers. This saturation process is crucial, as it determines the pipe’s overall strength, chemical resistance, and durability. Proper resin application ensures that the fiberglass is fully embedded within the resin matrix, creating a homogenous composite structure.

Curing the Composite

After the resin has been applied, the composite is allowed to cure. Curing is the process by which the resin hardens, transforming from a liquid state into a solid structure. This phase can be accelerated by applying heat or using catalysts that trigger the chemical reaction within the resin. During curing, the resin cross-links with the fiberglass, forming a rigid and durable pipe. The curing process must be carefully controlled to prevent defects such as voids, delamination, or warping, which could compromise the pipe’s integrity. Once cured, the pipe is demolded and subjected to further finishing processes, such as trimming and sanding, to ensure it meets the required dimensions and specifications.

Customization of Pipe Shapes and Sizes

One of the key advantages of the contact molding process is its ability to produce custom pipe shapes and sizes. Unlike automated manufacturing methods that are often limited to standard pipe dimensions, contact molding allows for the creation of complex geometries and unique fittings. This flexibility is particularly beneficial in industries like chemical processing, water treatment, and industrial ducting, where standard piping solutions may not suffice. By using contact molding, manufacturers like GangLong Fiberglass can produce pipes with varying diameters, wall thicknesses, and lengths, tailored to the specific needs of each project. This level of customization ensures that the piping system is optimally designed to handle the unique conditions of the application, whether it involves transporting corrosive fluids, operating under high pressure, or accommodating irregular installation spaces.

Applications of Contact Molded FRP Pipe

Contact molded FRP pipes are used in a variety of industries and applications, thanks to their versatility, strength, and resistance to corrosion. These pipes are commonly employed in settings where reliable and durable piping systems are essential.

Chemical Processing

In chemical processing facilities, contact molded FRP pipes are used to transport corrosive chemicals, acids, and other reactive substances. The corrosion-resistant properties of these pipes ensure safe and efficient fluid transport without the risk of leaks or pipe degradation. The ability to customize pipe shapes and sizes through contact molding allows for the creation of complex piping networks tailored to the specific needs of the chemical process.

Water and Wastewater Treatment

Water and wastewater treatment plants utilize contact molded FRP pipes for various applications, including transporting treated water, handling wastewater, and managing chemical dosing systems. The corrosion UV resistance of FRP pipes makes them suitable for environments where exposure to chemicals and varying pH levels is common. Contact molded FRP pipes’ durability and low maintenance requirements contribute to the efficient and cost-effective operation of water treatment facilities.

Industrial Ducting and Ventilation

Contact molded FRP pipes are also widely used in industrial ducting and ventilation systems. These systems often require pipes with unique shapes and configurations to navigate complex pathways and connect with equipment. The customization capabilities of the contact molding process make it possible to produce ducts and vents that fit seamlessly into the industrial environment. Additionally, the chemical resistance and durability of FRP pipes ensure that they can handle the demands of industrial exhaust and ventilation systems, even when exposed to corrosive gases or high temperatures.

FRP Pipe Fire Rating: What Every Industry Needs to Know

Joining Techniques for Contact Molded FRP Pipe

Proper joining techniques are crucial to ensuring the integrity and performance of contact molded FRP piping systems. Various methods are used to join these pipes, each suited to different applications and requirements.

Adhesive Bonding

Adhesive bonding is a common method for joining contact molded FRP pipes. This technique involves applying a special resin-based adhesive to the pipe ends and fittings, creating a strong, leak-proof joint. Adhesive bonding is ideal for permanent installations where a secure connection is required. The bonded joints provide high resistance to internal pressure and mechanical stress, ensuring the piping system’s long-term reliability.

Flanged Joints

Flanged joints involve attaching flanges to the ends of the FRP pipes, which are then bolted together with gaskets in between to ensure a tight seal. Flanged connections are suitable for applications where pipes may need to be disassembled for maintenance, inspection, or modification. They provide a robust and secure joint that can withstand various pressures and environmental conditions.

Mechanical Couplings

Mechanical couplings offer a quick and reliable way to join contact molded FRP pipes. These couplings, such as threaded or grooved fittings, provide flexibility and ease of installation, making them an ideal choice for piping systems that require frequent adjustments or modifications. Mechanical couplings allow for rapid assembly.

Advantages of Contact Molded FRP Pipe Difference Between Other

Contact molded FRP pipe offers numerous advantages over traditional piping materials and other FRP manufacturing methods. These benefits make it an ideal choice for various industrial applications:

Advantages Over Traditional Piping Materials

Contact molded FRP pipes offer several advantages over traditional piping materials such as steel, concrete, and PVC:

- Weight: Contact molded FRP pipes are significantly lighter than traditional materials like steel and concrete. This lightweight nature makes them easier to handle, transport, and install, reducing labor costs and installation time. Despite their lightweight design, they provide comparable or superior strength and durability.

- Corrosion-Free: Unlike steel pipes, which are prone to rust and corrosion, contact molded FRP pipes are inherently resistant to corrosion. They do not require protective coatings, liners, or cathodic protection to prevent corrosion, resulting in lower maintenance costs and longer service life.

- Low Maintenance: Contact molded FRP pipes require minimal maintenance due to their resistance to corrosion, scaling, and fouling. Their smooth interior surface reduces friction loss, ensuring consistent fluid flow and reducing the need for frequent cleaning. This low maintenance requirement contributes to the overall cost-effectiveness of the piping system.

Advantages Over Other FRP Manufacturing Methods

Contact molded FRP pipes offer unique benefits compared to other FRP manufacturing methods, such as filament winding and pultrusion:

- Versatility: The contact molding process is versatile, allowing for the creation of custom shapes, complex geometries, and specialized components. This flexibility makes it suitable for producing FRP anticorrosion pipes that cannot be easily manufactured using automated processes.

- Low Volume Production: Contact molding is an ideal method for low-volume or prototype production, as it does not require expensive tooling or machinery. This makes it a cost-effective option for producing custom FRP pipes or small batches for specialized applications.

How to calculate frp pipe friction factor for efficient flow

Design Methods of Contact Molded FRP Pipe

The design of contact molded FRP pipe involves advanced engineering techniques to ensure structural integrity, durability, and efficiency. The following methods are commonly applied:

Laminate Structure Design

The laminate structure of a contact molded FRP pipe is crafted by layering resin-saturated fiberglass. The thickness and orientation of these layers are carefully designed to withstand internal pressures, environmental stresses, and chemical exposure. Engineers use computational modeling to optimize the laminate for strength and cost-effectiveness.

Resin and Fiber Selection

The choice of resin and fiberglass reinforcement significantly affects the pipe’s performance. Epoxy, vinyl ester, or polyester resins are paired with specific fiberglass grades based on the pipe’s intended chemical and thermal environment. Contact molding allows precise customization of these materials.

Stress Analysis

Stress analysis tools calculate the pipe’s load-bearing capacity under various conditions, including pressure, temperature, and external loads. These calculations guide the reinforcement placement within the pipe walls to ensure maximum strength.

Joint and Fitting Design

Special attention is given to the design of joints and fittings, as they are critical points in the piping system. Laminated or adhesive-bonded joints are commonly used for seamless and robust connections. Flanged ends are included when modular assembly or disassembly is required.

Corrosion and Abrasion Resistance

Engineers incorporate design features such as corrosion-resistant inner linings or abrasion-resistant layers in contact molded FRP pipes to handle aggressive media and extend their service life.

Compliance with Standards

The design adheres to industry standards like ASME RTP-1, ensuring safety and reliability. These codes guide the material selection, wall thickness, and overall pipe configuration to meet project-specific requirements.

By combining these design methodologies, contact molded FRP pipes achieve their characteristic high strength, corrosion resistance, and versatility, making them a preferred choice for demanding industrial applications.

Standard Specifications of Contact Molded FRP Pipe

Contact molded FRP pipes are designed and manufactured according to stringent standards to ensure their reliability, safety, and performance in various industrial applications.

Below are the key standard specifications associated with contact molded FRP pipe:

Dimensional Standards

- Pipe Diameters: Contact molded FRP pipes are available in diameters ranging from small (1 inch) to large (over 144 inches), depending on the application.

- Wall Thickness: The wall thickness varies with pressure ratings and is calculated to meet mechanical and corrosion resistance requirements.

- Length: Typically produced in custom lengths to minimize joints and ensure seamless installation.

Material Standards

- Resin: Standards such as ASTM D2996 specify the type and quality of resin, including epoxy, vinyl ester, or polyester, to match the chemical and thermal environment.

- Reinforcement: Fiberglass grades and specifications, as outlined in standards like ASTM D578, ensure structural integrity and compatibility with the resin.

Mechanical Properties

- Contact molded FRP pipes comply with standards such as ASTM D1599 and ASTM D2992 for pressure testing and long-term strength validation. These tests evaluate:

- Burst pressure

- Tensile strength

- Modulus of elasticity

Corrosion Resistance

- Liners made from high-performance resins are specified to meet ASTM C581 standards, ensuring resistance to acids, alkalis, and solvents for prolonged service life.

Jointing Specifications

- Joints follow standards like ASTM D4161, which define the fabrication of flanged, laminated, or adhesive-bonded connections, ensuring leak-proof and durable assemblies.

Quality Assurance

- Standards such as ASME RTP-1 mandate the inspection, testing, and documentation of contact molded FRP pipes. Tests include visual inspections, hydrostatic pressure tests, and non-destructive evaluations.

Fire Resistance

- Optional fire-retardant grades adhere to standards like ASTM E84 for applications requiring flame resistance.

These specifications ensure that contact molded FRP pipes meet the diverse needs of industries such as chemical processing, water treatment, and power generation. Compliance with these standards guarantees the pipes’ performance, safety, and longevity.

Benefits of using frp pipe insulation in heating and cooling systems

FAQs about Contact Molded Frp Pipe

Yes, FRP can be molded into various shapes and configurations using different molding techniques, such as contact molding (hand lay-up), compression molding, and resin transfer molding (RTM). Contact molding is one of the most common methods for creating custom FRP shapes, including pipes, tanks, and fittings. In this process, layers of resin-impregnated fiberglass mats are manually placed onto a mold that defines the desired shape. The layers are built up to the required thickness, and the resin is allowed to cure, resulting in a strong, durable FRP component. Compression molding involves placing a mixture of resin and reinforcement fibers into a heated mold, which is then closed and pressurized to shape and cure the material. This method is typically used for producing smaller, high-strength FRP parts. Resin transfer molding (RTM) is a more advanced technique that involves injecting resin into a closed mold containing dry fiberglass reinforcements. This process allows for precise control over fiber placement and resin distribution, producing high-quality FRP components with complex shapes and fine details. The versatility of FRP molding techniques enables the production of a wide range of components, from standard pipes and fittings to custom-designed structures.

There are several types of FRP pipes, each designed to meet specific application requirements and performance criteria. The primary types include filament wound FRP pipes, centrifugal cast FRP pipes, and contact molded FRP pipes. Filament wound FRP pipes are manufactured by winding continuous glass fibers soaked in resin around a rotating mandrel, allowing precise control over the pipe’s wall thickness and fiber orientation. This method produces pipes with high strength and the ability to withstand high internal pressures, making them suitable for industrial applications. Centrifugal cast FRP pipes are created by spinning a mold filled with resin and reinforcement materials at high speeds. The centrifugal force distributes the resin and fibers uniformly, resulting in a dense, void-free pipe wall with excellent mechanical properties. Contact molded FRP pipes, also known as hand lay-up pipes, are made by manually layering resin-saturated fiberglass mats onto a mold. This method allows for greater customization and is often used for producing pipes with complex shapes or large diameters. Each type of FRP pipe offers unique advantages, making them suitable for a wide range of applications, from chemical transport to water distribution.

FRP pipes can be connected using several methods, depending on the specific application, pressure requirements, and installation environment. Common connection methods include adhesive bonding, flanged joints, and mechanical couplings. Adhesive bonding involves using a special resin-based adhesive to join the ends of FRP pipes and fittings, creating a strong, leak-proof joint. This method is often used for permanent installations where a secure and durable connection is required. Flanged joints involve attaching flanges to the ends of the FRP pipes, which are then bolted together with gaskets in between to ensure a tight seal. Flanged connections are suitable for applications where pipes may need to be disassembled for maintenance or inspection. Mechanical couplings, such as threaded or grooved couplings, provide a quick and reliable way to connect FRP pipes, especially in systems where flexibility and ease of installation are important. Each method has its advantages, and the choice depends on factors like system pressure, chemical exposure, and ease of maintenance.

For contact molded FRP pipes, joining methods are typically tailored to their application and include adhesive bonding, mechanical joints, flanged connections, and laminated joints. Adhesive bonding uses epoxy or resin-based adhesives for a strong, leak-proof connection. Mechanical joints employ threaded or gasket-sealed connections, often for temporary installations. Flanged connections are common in industrial applications, providing ease of assembly and disassembly during maintenance. Laminated joints involve using resin-saturated fiberglass layers to ensure a seamless, strong bond, ideal for contact molded FRP pipes due to their customized shapes. These methods leverage FRP’s corrosion resistance and strength, ensuring durability even in harsh environments.

In piping, FRP stands for Fiberglass Reinforced Plastic, a composite material made from reinforced fiberglass and resin. For contact molded FRP pipes, this combination provides high strength, corrosion resistance, and chemical durability. The fiberglass reinforcement ensures structural integrity, while the plastic resin protects against environmental factors. This makes FRP a preferred choice for industries handling corrosive fluids, such as chemical processing and wastewater treatment.

The ASME (American Society of Mechanical Engineers) code for FRP piping is ASME RTP-1, which governs the design, fabrication, inspection, and testing of reinforced thermoset plastic (RTP) vessels and pipes. For contact molded FRP pipes, this code ensures compliance with safety and quality standards. RTP-1 addresses critical parameters such as resin selection, reinforcement placement, and pressure ratings, making it essential for manufacturers and engineers working with FRP piping in demanding industrial applications.

Contact molded FRP pipes can last 25-50 years or more, depending on the application and environmental conditions. Their longevity is attributed to their superior corrosion resistance, mechanical strength, and ability to withstand harsh chemicals and UV exposure. Proper installation, regular maintenance, and adherence to design specifications further enhance their lifespan. These pipes outperform traditional materials like steel or concrete, making them a cost-effective solution for long-term use in industrial and municipal projects.

FRP stands for Fiberglass Reinforced Plastic, a composite material made of glass fibers embedded in a polymer resin. In contact molded FRP pipes, this construction offers high strength, lightweight properties, and exceptional resistance to corrosion, making them ideal for handling aggressive chemicals, sewage, and industrial waste.

Contact molded FRP pipes are widely used in industries such as chemical processing, wastewater treatment, desalination plants, and power generation. Their resistance to corrosion, lightweight structure, and versatility make them suitable for transporting acids, alkalis, and saline solutions. Additionally, FRP is used in structural applications, including storage tanks and duct systems, where durability and chemical resistance are critical.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.