Custom fiberglass columns are highly versatile architectural elements used in both residential and commercial projects. These columns offer the flexibility to tailor designs to specific aesthetic preferences, whether for traditional or modern styles. Custom fiberglass columns are lightweight yet durable, making them ideal for both indoor and outdoor use. They resist weather, rot, and insects, ensuring long-term structural integrity and minimal maintenance. Additionally, their load-bearing capabilities allow for functional applications, while their customizable designs can enhance the visual appeal of any project. Custom fiberglass columns are a popular choice for architects and builders seeking a balance between strength, aesthetics, and versatility. Discover the beauty of custom fiberglass columns from GangLong Fiberglass, offering elegant designs, custom sizes, and durable options for any space.

What is Custom Fiberglass Columns?

Custom fiberglass columns have gained widespread popularity due to their versatility and ability to meet both structural and aesthetic needs. Fiberglass as a material is lightweight, durable, and resistant to environmental elements, making it an ideal choice for architectural projects that require both form and function. Custom fiberglass columns are manufactured to fit specific design preferences, which allows architects and builders to select from a wide range of styles, including round, square, fluted, and smooth. By offering various customization options, custom fiberglass columns provide solutions for residential, commercial, and even industrial applications, while ensuring long-lasting durability and minimal maintenance.

Material Composition of Custom Fiberglass Columns

The material composition of custom fiberglass columns is what makes them so unique and adaptable to a variety of architectural designs. These columns are typically made from a blend of high-quality polyester resin, fiberglass strands, and fillers that enhance strength and rigidity. Custom fiberglass columns can be manufactured to resemble traditional materials such as wood, stone, or marble, giving them a classic aesthetic without the drawbacks of natural materials like rot, decay, or heavy maintenance.

Manufacturers like GangLong Fiberglass prioritize the strength and longevity of their columns by ensuring they meet industry standards for durability. The fiberglass strands used in the manufacturing process are strategically placed to reinforce the columns, giving them the ability to support substantial weight. This makes custom fiberglass columns an excellent choice for both decorative and load-bearing applications.

Versatility in Design for Custom Fiberglass Columns

One of the major advantages of custom fiberglass columns is their versatility in design. Fiberglass can be molded into various shapes and sizes, offering architects and builders the flexibility to create unique architectural features that complement different styles. Whether the project calls for sleek, modern columns or intricate, classical designs, custom fiberglass columns can be crafted to meet those specifications.

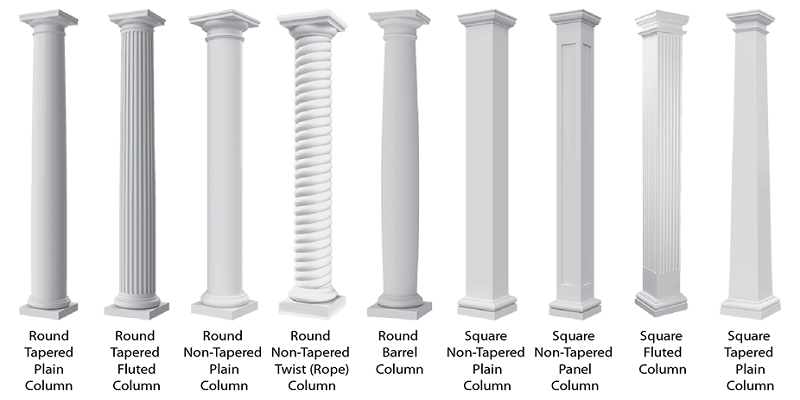

Design options include round or square columns, with additional choices in surface texture, such as smooth, fluted, or paneled. Architects working with custom fiberglass columns can also select from a range of capitals and bases to complete the look. These design elements can be customized to match the overall architectural theme of the building, whether it’s a residential home, a commercial property, or a public space.

Fiberglass columns also offer superior strength, making them suitable for load-bearing purposes. GangLong Fiberglass produces fiberglass columns that support significant weights with robust engineering, whether they are used for porches, entryways, or other architectural elements. These columns have a high strength-to-weight ratio, meaning they can support heavy loads while remaining lightweight and easy to install.

GangLong Fiberglass offers custom fiberglass columns in a variety of sizes, including 8″, 10″, and 12″ diameters, which can be tailored to the specific needs of each project. The flexibility of these custom designs ensures that builders and architects are not limited by standard column sizes or shapes, allowing for greater creativity in their architectural vision.

The Key of Customization Options for Custom Fiberglass Columns

Customization is a key element when it comes to selecting custom fiberglass columns. Architects and builders often have specific design requirements that need to be met, and fiberglass provides the perfect medium for achieving those goals. With custom fiberglass columns, the possibilities are virtually endless in terms of size, shape, and style.

Whether you’re looking for large, imposing columns to support the entrance of a commercial building or smaller, decorative columns for a residential porch, custom fiberglass columns can be tailored to fit those needs. GangLong Fiberglass specializes in providing custom solutions, offering a wide range of column designs, finishes, and structural capabilities. This ensures that each column is built to the exact specifications of the project, providing both aesthetic value and structural integrity.

Additionally, custom fiberglass columns can be produced in a variety of colors, either by applying paint during the manufacturing process or by leaving them in a paintable finish for on-site customization. This allows the columns to seamlessly blend with the rest of the building’s design, making them an integral part of the overall aesthetic.

The price of fiberglass columns varies depending on size, style, and manufacturer. On average, they range from $100 to $1,000 per column, with custom or decorative designs potentially costing more.

Load-Bearing Custom Fiberglass Columns

Custom fiberglass columns are not only designed for aesthetic purposes but also serve important structural roles. Like the fiberglass tubes, they are hollow fiberglass structures. Load-bearing fiberglass columns, in particular, are engineered to support significant weight, making them an ideal choice for porches, entryways, and large open spaces that require both style and functionality.

Fiberglass, by nature, is a strong material, and when reinforced with additional fibers, it becomes capable of bearing substantial loads without the risk of cracking, warping, or weakening over time. GangLong Fiberglass offers a range of load-bearing custom fiberglass columns that are perfect for supporting structures such as roofs, balconies, and elevated decks. These columns are designed to provide the necessary support while enhancing the architectural beauty of the building.

Load-bearing custom fiberglass columns are often used in residential settings, such as porches or verandas, where both form and function are required. The ability to customize the size, shape, and design of these columns allows them to fit seamlessly into the architectural style of the home, whether it’s a modern, minimalist design or a traditional, classical look.

Durability and Maintenance of Custom Fiberglass Columns

One of the standout features of custom fiberglass columns is their durability. Unlike wood, which is susceptible to rot, decay, and insect damage, or stone, which can crack or erode over time, fiberglass is incredibly resistant to the elements. Custom fiberglass columns are engineered to withstand harsh weather conditions, including extreme heat, cold, moisture, and UV exposure, without losing their structural integrity or aesthetic appeal.

This resistance to environmental damage makes custom fiberglass columns an ideal choice for outdoor applications, where they will be exposed to the elements year-round. Additionally, fiberglass columns require very little maintenance compared to other materials. A simple cleaning every few years is usually all that is needed to keep them looking as good as new.

Because of their durability, custom fiberglass columns offer long-term cost savings. Homeowners and commercial property owners alike can benefit from the reduced maintenance and repair costs associated with these columns, making them a smart investment for any architectural project.

Custom Fiberglass Column Wraps

Another popular application of custom fiberglass columns is the use of column wraps. These wraps are designed to fit around existing structural elements, such as wooden or metal posts, to enhance the appearance of the building. Custom fiberglass column wraps provide a quick and easy way to upgrade the look of a structure without having to replace the original supports.

Custom fiberglass column wraps are available in a variety of styles, including round, square, and fluted designs, allowing builders to select the wrap that best complements the architectural style of the building. These wraps can also be customized in terms of color and finish, ensuring that they blend seamlessly with the rest of the structure.

GangLong Fiberglass offers a range of custom fiberglass column wraps that are both lightweight and durable, making them easy to install and resistant to environmental damage. These wraps are an excellent choice for homeowners or builders looking to improve the aesthetic appeal of a building without the time and expense of a full structural renovation.

Square Custom Fiberglass Columns

While round columns are often the first thing that comes to mind when thinking of classical architecture, square custom fiberglass columns are becoming increasingly popular in modern designs. These columns offer a sleek, contemporary look that complements minimalist architectural styles.

Square custom fiberglass columns are ideal for both decorative and load-bearing applications. These columns, such as fiberglass square porch columns, can be used in a variety of settings, from modern homes to commercial office buildings, providing both aesthetic appeal and structural support. The clean lines and geometric shapes of square fiberglass columns make them a versatile option for architects and builders looking to create a modern, sophisticated look.

GangLong Fiberglass specializes in creating custom square fiberglass columns that can be tailored to the specific needs of each project. Whether you need a small, decorative column for an interior space or a large, load-bearing column for a commercial building, square custom fiberglass columns provide the perfect combination of style and function.

Applications of Custom Fiberglass Columns in Commercial Projects

Custom fiberglass columns are not limited to residential applications. They are also widely used in commercial projects, where their durability, strength, and customization options make them an ideal choice for large-scale architectural designs.

Commercial buildings often require columns that can support significant weight while maintaining an aesthetically pleasing appearance. Custom fiberglass columns provide the perfect solution, offering the necessary structural support without compromising on design. These columns can be customized to fit the specific requirements of the project, ensuring that they blend seamlessly with the overall architectural vision.

From hotels and office buildings to shopping centers and public spaces, custom fiberglass columns are used in a variety of commercial settings to enhance the visual appeal of the building while providing essential structural support.

Why Choose Custom Fiberglass Columns?

There are many reasons why architects and builders choose custom fiberglass columns for their projects. First and foremost, fiberglass is a highly durable material that can withstand the test of time. Unlike traditional materials like wood or stone, fiberglass does not rot, crack, or erode, making it a low-maintenance option for both indoor and outdoor applications.

In addition to their durability, custom fiberglass columns offer unparalleled versatility in terms of design. Whether you’re looking for classical, modern, or minimalist designs, custom fiberglass columns can be tailored to fit your specific needs. The ability to customize the size, shape, and finish of the columns ensures that they complement the overall aesthetic of the building.

Finally, custom fiberglass columns are a cost-effective solution for both residential and commercial projects. Their long-lasting durability and low maintenance requirements translate to significant cost savings over time, making them a smart investment for any architectural project.

Custom Fiberglass Columns from GangLong Fiberglass

When it comes to custom fiberglass columns, GangLong Fiberglass is a trusted manufacturer known for producing high-quality, durable products. Whether you’re looking for load-bearing columns, decorative columns, or column wraps, GangLong Fiberglass offers a wide range of customizable options to meet your specific project needs.

GangLong Fiberglass uses the latest manufacturing techniques to ensure that each column is built to the highest standards of quality and durability. Their custom fiberglass columns are designed to withstand the elements, making them an excellent choice for both indoor and outdoor applications.

By choosing GangLong Fiberglass for your custom fiberglass columns, you can rest assured that you are getting a product that combines strength, beauty, and longevity.

The Key of Custom Fiberglass Columns

Custom fiberglass columns are a popular architectural feature that adds both aesthetic appeal and structural functionality to various types of buildings. Whether for residential homes or commercial projects, custom fiberglass columns offer a unique combination of design flexibility, durability, and low maintenance requirements. Fiberglass is an ideal material for columns due to its resistance to rot, insects, and weather, making it a long-lasting option for exterior and interior applications.

By opting for custom fiberglass columns, architects, designers, and homeowners can create bespoke designs tailored to the specific requirements of a building project. Customization includes selecting unique shapes, sizes, finishes, and decorative elements to ensure the columns blend seamlessly into the architectural style of the property. Fiberglass column manufacturers like GangLong Fiberglass offer a wide range of customization options, allowing for both classical and modern designs.

The Advantages of Custom Fiberglass Columns

Custom fiberglass columns offer several benefits that make them an attractive choice for architects, builders, and property owners. These advantages go beyond the aesthetic appeal, as fiberglass columns are also known for their strength, versatility, and longevity. Understanding these benefits can help guide the decision to choose custom fiberglass columns for a project.

Fiberglass is a strong yet lightweight material, which means it provides excellent structural support while being easy to handle and install. This makes it an ideal choice for projects that require load-bearing columns, as well as decorative elements. In addition, fiberglass is resistant to moisture, pests, and extreme weather conditions, ensuring that the columns maintain their appearance and functionality over time.

Custom fiberglass columns also offer unparalleled design flexibility. Whether the goal is to replicate traditional architectural styles or create a more modern, minimalist look, fiberglass can be molded into a variety of shapes and sizes. This level of customization allows homeowners and architects to bring their unique design visions to life.

Round Fiberglass Columns

Round fiberglass columns are one of the most popular choices for custom projects due to their timeless appeal and versatility. These columns are often used in classical architectural designs, where they serve as both decorative and structural elements. However, round columns can also be incorporated into modern projects, where their smooth, clean lines add a touch of elegance.

The structural advantages of round fiberglass columns lie in their ability to evenly distribute weight, making them ideal for load-bearing applications. Round columns can support large amounts of weight, such as fiberglass porch roofs or balconies, without compromising their design. In custom fiberglass column projects, round columns can be tailored to the specific dimensions of the project, ensuring they meet both aesthetic and structural requirements.

Round fiberglass columns also offer design flexibility, as they can be finished in various textures and colors. GangLong Fiberglass provides options such as smooth finishes for a sleek, contemporary look, or fluted designs for a more traditional appearance. Additionally, decorative capitals and bases can be added to enhance the overall aesthetic of the column.

Decorative Elements for Custom Fiberglass Columns

One of the key advantages of custom fiberglass columns is the ability to add decorative elements that enhance the overall design. These elements include capitals, bases, and various surface textures, which allow homeowners and architects to create unique and personalized designs.

Decorative capitals are placed at the top of the column and can range from simple, understated designs to more elaborate, ornate styles. For example, a classical Greek or Roman column design might feature a Corinthian or Ionic capital, adding a sense of grandeur to the structure. GangLong Fiberglass offers a variety of capital styles that can be customized to match the architectural theme of the project.

Bases are another important decorative element that can be customized in fiberglass columns. Bases are placed at the bottom of the column and provide a stable foundation while adding to the visual appeal. Whether the goal is a simple, modern base or a more decorative, traditional design, fiberglass column bases can be tailored to fit the specific aesthetic of the building.

In addition to capitals and bases, custom fiberglass columns can feature a variety of surface textures. For example, fluted columns have vertical grooves running along their length, adding texture and depth to the design. Smooth columns, on the other hand, offer a sleek, minimalist appearance that is ideal for contemporary projects.

The Benefits of FRP Truss Bridges for Infrastructure and Durability

Load-Bearing Capabilities of Custom Fiberglass Columns

Custom fiberglass columns are not only decorative but can also serve as load-bearing structural elements in construction projects. Load-bearing columns are designed to support significant weight, such as the weight of a porch roof, balcony, or other architectural features. Fiberglass is an excellent material for load-bearing columns due to its strength and durability.

Manufacturers like GangLong Fiberglass design load-bearing columns that meet or exceed local building codes, ensuring they provide adequate support for the structure. The columns are reinforced to handle the weight of the overhead structure, and they are tested to ensure they can withstand various environmental conditions. This makes custom fiberglass columns a reliable choice for both residential and commercial projects.

When using custom fiberglass columns for load-bearing purposes, it is important to work with a manufacturer who can provide columns that meet the specific weight-bearing requirements of the project. GangLong Fiberglass offers a range of load-bearing columns in various sizes and designs, allowing architects and builders to choose the right column for their needs.

Installation of Custom Fiberglass Columns

The installation process for custom fiberglass columns is straightforward, but it requires careful planning and precision to ensure the columns are properly aligned and secured. Fiberglass columns are lightweight, which makes them easier to handle and install compared to materials like stone or concrete. However, it is important to ensure that the columns are installed level and securely anchored to the foundation to provide the necessary support.

Custom fiberglass columns from GangLong Fiberglass come with detailed installation instructions, and many contractors are familiar with the process of installing fiberglass columns. Whether the columns are being used for decorative or load-bearing purposes, proper installation is key to ensuring the longevity and performance of the columns.

It is also important to consider the installation site when planning for custom fiberglass columns. For example, exterior columns may require additional preparation to ensure they are protected from moisture or other environmental factors during installation. Once installed, fiberglass columns require little maintenance, but regular inspections can help ensure they remain in good condition over time.

Cost Considerations for Custom Fiberglass Columns

The cost of custom fiberglass columns can vary depending on several factors, including the size of the columns, the level of customization, and the materials used. Customization options such as decorative capitals, bases, and surface textures can add to the overall cost of the columns, but they also provide a unique and personalized design that enhances the architectural appeal of the building.

While custom fiberglass columns may have a higher initial cost compared to standard columns made from wood or other materials, the long-term benefits of durability and low maintenance make them a cost-effective choice. Fiberglass columns have a longer lifespan and require fewer repairs or replacements, resulting in long-term savings for homeowners and property managers.

Custom fiberglass columns are available at a range of price points, allowing for flexibility in budgeting. Working with a reputable manufacturer like GangLong Fiberglass ensures that you are investing in high-quality columns that provide both beauty and functionality at a competitive price.

Exploring Key Features of the Sirio 3 Element Beam CB

How About Customization Options for Fiberglass Columns?

Custom fiberglass columns come in various forms, allowing architects and builders to choose from multiple design elements. The ability to customize these columns means that the final product can be tailored to fit the exact specifications of the building project.

Size and Shape

When selecting custom fiberglass columns, one of the first considerations is the size and shape of the columns. Fiberglass can be molded into a variety of shapes, from round to square and even tapered designs. GangLong Fiberglass offers columns in standard sizes, but they also provide custom dimensions to suit specific project needs. Whether a building requires tall, slender columns or wide, robust columns, the manufacturer can adjust the dimensions to meet these requirements.

Decorative Details

Another significant customization option involves the decorative details of the columns. Clients can choose from various fluted or smooth designs, adding ornamentation such as capitals and bases. The addition of decorative capitals, for example, can transform a simple column into an ornate architectural feature. GangLong Fiberglass offers a range of decorative capitals and bases that complement different architectural styles, such as Tuscan, Ionic, or Corinthian. These details can elevate the overall look of the building, creating a cohesive and aesthetically pleasing design.

Surface Finish

Custom fiberglass columns can also be tailored in terms of their surface finish. While many fiberglass columns are left with a smooth, sleek finish, others may opt for a textured surface to mimic natural materials like stone or wood. The columns can also be painted in various colors to match the design scheme of the building. The paint adheres well to fiberglass, ensuring that the finish remains durable and resistant to peeling or fading.

The Key of Fiberglass Fluted Columns

Fiberglass fluted columns offer a classical architectural element that enhances the visual appeal of buildings. Fluting refers to the vertical grooves carved into the shaft of a column, a design element that has been used in classical architecture for centuries. Custom fiberglass fluted columns allow builders to incorporate this timeless design while enjoying the benefits of modern fiberglass technology.

Architectural Appeal

The use of fluted columns creates a sense of elegance and grandeur, making them a popular choice for entryways, porches, and other prominent areas of a building. Custom fiberglass columns with fluting can be designed to fit both traditional and modern architectural styles. The vertical grooves provide a subtle decorative detail that enhances the overall look of the building without overwhelming other design elements.

Fiberglass fluted columns from GangLong Fiberglass can be customized to match the exact specifications of the project, including the number and depth of the flutes. This ensures that the columns blend seamlessly with the overall architectural design.

Durability and Low Maintenance

Like all fiberglass columns, fluted fiberglass columns are highly durable and resistant to environmental factors such as moisture, heat, and UV rays. This makes them an excellent choice for exterior applications, where they are exposed to the elements. Unlike traditional materials such as wood or stone, fiberglass does not require frequent maintenance or repairs. The fluted design adds a decorative touch without compromising the strength or functionality of the column.

Maintenance for custom fiberglass fluted columns is minimal, requiring only occasional cleaning to remove dirt or debris. The smooth surface of fiberglass also resists staining, ensuring that the columns retain their appearance over time. This low-maintenance feature makes them a practical and cost-effective choice for both residential and commercial buildings.

Custom Fiberglass Columns for Load-Bearing Applications

In addition to their decorative appeal, custom fiberglass columns are frequently used in load-bearing applications. Whether supporting porches, pergolas, or other architectural structures, these columns are designed to provide both strength and stability. Custom fiberglass columns from GangLong Fiberglass are engineered to meet strict industry standards, ensuring that they can handle the weight and stress placed upon them.

High Strength-to-Weight Ratio

One of the most significant advantages of fiberglass columns is their high strength-to-weight ratio. Fiberglass is much lighter than traditional materials like stone or concrete, making it easier to transport and install. Despite being lightweight, fiberglass is incredibly strong, capable of supporting heavy loads without buckling or deforming. This makes custom fiberglass columns ideal for load-bearing applications, where both strength and ease of installation are critical factors.

GangLong Fiberglass offers custom columns that are specifically designed for load-bearing purposes. These columns are reinforced with additional layers of fiberglass and resins, ensuring that they meet the necessary structural requirements for the project.

Compliance with Building Codes

Custom fiberglass columns used for load-bearing applications must comply with local building codes and regulations. GangLong Fiberglass ensures that all of their load-bearing columns are tested and certified to meet the relevant standards. This guarantees that the columns will perform as expected and provide the necessary support for the structure.

Building codes often specify the load capacity, height, and material requirements for load-bearing columns. By offering customizable options, GangLong Fiberglass ensures that their columns can be tailored to meet these regulations while still fitting the aesthetic vision of the project.

What Are Fiberglass Column Wraps?

Fiberglass column wraps are another popular option for those looking to enhance the appearance of existing structural elements. These wraps are designed to fit around existing columns, posts, or supports, giving them the appearance of a full fiberglass column without the need for complete replacement.

Aesthetic Enhancement

Custom fiberglass column wraps are commonly used to cover steel, wood, or concrete posts, providing a seamless and polished appearance. The wraps can be customized to match the architectural style of the building, whether it’s a smooth, fluted, or paneled design. Fiberglass wraps are a cost-effective way to improve the look of a structure without the expense of removing and replacing existing columns.

GangLong Fiberglass offers a wide range of custom wraps that can be tailored to fit any design preference. These wraps are available in various finishes and styles, ensuring that they complement the overall aesthetic of the building.

Easy Installation

One of the main advantages of fiberglass column wraps is their ease of installation. The wraps are designed in sections that can be easily fitted around existing posts. Once installed, they create a seamless look that mimics the appearance of a full custom fiberglass column. This makes them an ideal choice for retrofit projects or for enhancing the look of existing structures without the need for significant renovations.

Add rustic charm with fiberglass ceiling beams in any room

Differences Between Custom Fiberglass Columns for Indoor and Outdoor Use

Custom fiberglass columns are versatile and suitable for both indoor and outdoor applications, but there are significant differences in their finishing, design considerations, and durability based on where they are installed. Here is a detailed breakdown:

Finishing and Coating

Outdoor Use:

Outdoor custom fiberglass columns are exposed to environmental elements such as UV rays, rain, snow, humidity, and temperature fluctuations. To withstand these challenges, they require:

- UV-Resistant Coatings: Protect the surface from fading, chalking, or discoloration caused by prolonged sun exposure.

- Waterproof Sealants: These prevent moisture infiltration, which can otherwise cause cracks or surface damage.

- Exterior-Grade Paints: Durable, weather-resistant acrylic latex or polyurethane paints are essential to maintain appearance and longevity.

Indoor Use:

Indoor fiberglass columns are not subjected to weather or direct UV exposure. As a result:

- Standard Interior Paints: Decorative or interior-grade coatings are sufficient for aesthetics.

- Minimal Sealant Requirements: Since moisture is not a concern indoors, waterproof finishes are unnecessary.

Structural Durability

Outdoor Use:

Outdoor columns must be structurally reinforced to endure wind loads, heavy rain, and temperature extremes. Manufacturers may incorporate additional resin layers, higher density materials, or specific reinforcements to ensure they remain stable and crack-resistant.

Indoor Use:

Indoor columns do not require the same level of reinforcement. Since they face fewer physical stresses, the material can focus more on visual appeal rather than added durability against environmental forces.

Design and Aesthetics

Outdoor Use:

Columns for outdoor spaces, such as porches, patios, or garden pergolas, often feature simpler, weather-tolerant designs with smooth or tapered finishes. Decorative elements must also be robust enough to withstand wear and exposure.

Indoor Use:

Indoor fiberglass columns allow for more intricate and delicate designs, such as fluted details, ornate capitals, and custom shapes. Without environmental constraints, they can prioritize aesthetic complexity without durability concerns.

Maintenance Needs

Outdoor Use:

Outdoor custom fiberglass columns require periodic maintenance to extend their lifespan, such as repainting every few years and inspecting for cracks or coating wear caused by weather exposure.

Indoor Use:

Indoor columns require minimal maintenance beyond occasional dusting and cleaning, as they are not exposed to weather or UV damage.

While custom fiberglass columns share the same material strength, outdoor versions require specialized coatings, reinforcements, and simpler, durable designs to endure environmental stress, whereas indoor columns focus more on aesthetics with fewer durability demands.

Can Custom Fiberglass Columns Be Painted?

Yes, custom fiberglass columns can be painted, and doing so can enhance their appearance, durability, and ability to blend seamlessly into any design theme. However, there are important factors to consider to ensure a successful and long-lasting finish.

Surface Preparation

Fiberglass has a smooth, non-porous surface, which can make it challenging for paint to adhere directly. To address this:

- Clean the Surface: Remove any dirt, dust, or grease with a mild detergent and water. Let it dry completely.

- Light Sanding: Gently sand the surface using fine-grit sandpaper to create a slightly rough texture, which helps the paint bond effectively.

- Priming: Use a high-quality bonding primer designed for fiberglass. This step is essential as it ensures a smooth, uniform base for the paint.

Choosing the Right Paint

The type of paint used depends on where the custom fiberglass columns are installed:

- Outdoor Applications: Use exterior-grade acrylic latex or polyurethane paint. These paints are durable, UV-resistant, and waterproof, providing protection from sun exposure, moisture, and weathering.

- Indoor Applications: Interior-grade acrylic latex paint is sufficient, as the columns are not exposed to environmental stress like UV rays or moisture.

Painting Process

Once primed, the columns can be painted using a brush, roller, or spray equipment:

- First Coat: Apply a thin, even coat of paint, allowing it to dry as per the manufacturer’s instructions.

- Second Coat: For best results, apply a second coat to achieve an even, durable finish.

Maintenance After Painting

Painted custom fiberglass columns are low-maintenance, but occasional cleaning and touch-ups may be required, especially for outdoor columns exposed to the elements. Regular inspections will ensure the paint remains in good condition.

Custom fiberglass columns can absolutely be painted, provided the proper preparation, primers, and paint types are used. This process ensures not only a beautiful finish but also added protection for years of durability and performance.

What Is the Best Caulk for Custom Fiberglass Columns?

When sealing gaps, joints, or seams on custom fiberglass columns, selecting the right caulk is crucial to ensure durability, flexibility, and a long-lasting finish. The ideal caulk must adhere well to fiberglass, provide weather resistance, and accommodate structural movement without cracking or shrinking over time.

Types of Caulk Suitable for Fiberglass Columns

Polyurethane Caulk:

- Why it’s the best: Polyurethane caulk is highly flexible, durable, and adheres exceptionally well to fiberglass surfaces. It is resistant to moisture, UV rays, and temperature changes, making it perfect for outdoor custom fiberglass columns.

- Best for: Exterior applications where flexibility and weather resistance are essential.

Silicone Caulk:

- Why it’s useful: 100% silicone caulk provides excellent water resistance, flexibility, and adhesion to smooth surfaces like fiberglass. It is mold- and mildew-resistant, making it ideal for both indoor and outdoor columns exposed to moisture.

- Limitations: Paint does not adhere well to pure silicone caulk.

Hybrid Caulk (Silicone-Polyurethane):

- Why it’s versatile: Hybrid caulks combine the benefits of silicone and polyurethane, offering excellent adhesion, flexibility, and paintability. They provide a durable seal and are suitable for interior and exterior use.

- Best for: Applications requiring both strength and a paintable finish.

Key Factors to Consider

- Adhesion: The caulk must bond effectively with fiberglass surfaces to prevent peeling or detachment.

- Flexibility: Fiberglass columns may experience slight movement due to temperature changes or structural shifts; flexible caulk ensures the seal remains intact.

- Weather Resistance: For outdoor applications, UV resistance and waterproofing are essential to prevent cracking, shrinkage, or breakdown over time.

- Paintability: If you plan to paint over the caulk, choose a paintable product like polyurethane or hybrid caulks, as silicone caulk does not hold paint well.

Recommended Products

- For Exterior Use: SikaFlex Polyurethane Sealant, Loctite PL Polyurethane, or DAP Dynaflex Ultra (hybrid caulk).

- For Interior Use: GE Silicone II or any high-quality hybrid caulk designed for smooth surfaces.

The best caulk for custom fiberglass columns is polyurethane caulk for its superior flexibility and durability, followed by hybrid caulks for their balance of performance and paintability. Always choose a product suited for your specific application to ensure long-term performance and protection.

How to Split Custom Fiberglass Columns

Splitting custom fiberglass columns is a common requirement for projects where the columns need to wrap around an existing structural element, such as a support beam, post, or pipe. This process requires precision and the right tools to ensure clean, even cuts without damaging the column’s structural integrity or aesthetic appeal. Here is a step-by-step guide to splitting fiberglass columns properly:

Tools and Safety Preparation

Before starting, gather the necessary tools and safety gear:

- Tools: A circular saw with a fine-tooth blade, measuring tape, straight edge, clamps, and sandpaper.

- Safety Gear: Safety goggles, dust mask, gloves, and long sleeves to protect against fiberglass dust.

Measuring and Marking the Column

- Determine the Split Line: Measure and mark the exact line where the column will be split. A straight edge or chalk line will help ensure precision.

- Double-Check Measurements: Accuracy is critical, as an uneven cut will affect how well the column halves fit together after splitting.

Cutting the Column

- Secure the Column: Use clamps or a stable surface to hold the column in place during cutting. This prevents movement that could cause errors or uneven cuts.

- Make the Cut: Use a circular saw with a fine-tooth blade to carefully follow the marked line. Cut slowly and steadily to avoid chipping or splintering the fiberglass material.

- For Hollow Columns: Begin the cut on one side and rotate the column as needed until the split is complete.

- For Larger Columns: If the column is too wide to cut through in one pass, carefully finish the cut from the opposite side.

Sanding and Smoothing the Edges

- After splitting, use fine-grit sandpaper to smooth the cut edges. This step removes any rough or sharp areas and prepares the column for installation.

- For a cleaner finish, you can seal the edges with a resin-based filler or primer.

Installation Around the Structural Element

- Position the two halves of the split custom fiberglass column around the support structure.

- Use construction adhesive, screws, or brackets to reassemble the halves securely. For outdoor use, apply a waterproof caulk along the seam to prevent moisture infiltration.

- If desired, the seam can be further smoothed and painted to create a seamless look.

Splitting custom fiberglass columns requires careful planning, accurate cutting, and proper finishing to maintain their functionality and aesthetic appeal. By following these steps, the columns can effectively wrap around structural elements while preserving their durability and design integrity.

Are Custom Fiberglass Columns Structural?

Yes, custom fiberglass columns can be structural, but this depends on their design, manufacturing specifications, and intended use. Fiberglass columns are widely known for their durability, strength, and versatility, making them capable of functioning as both load-bearing (structural) and decorative elements.

Here is a detailed explanation to help you understand their structural capabilities:

Load-Bearing Fiberglass Columns

- Engineered for Strength: Custom fiberglass columns designed for structural purposes are reinforced to bear significant axial loads. They are typically made with a dense fiberglass composite material or include additional reinforcements to meet strict structural standards.

- Applications: Load-bearing fiberglass columns are commonly used to support porch roofs, pergolas, balconies, and other architectural structures. They undergo rigorous testing to ensure they comply with local building codes.

- Advantages: Fiberglass columns are stronger than wood and more resistant to rot, moisture, insects, and warping, making them an ideal choice for long-term load-bearing solutions.

Decorative Fiberglass Columns

- Non-Structural Use: Some custom fiberglass columns are designed purely for decorative purposes and do not provide structural support. These hollow columns are often installed around existing load-bearing elements, such as steel, wood, or concrete posts.

- Flexibility in Design: Decorative columns offer more freedom in shape, style, and detailing, allowing for intricate designs without needing to meet structural load requirements.

How to Identify Structural Fiberglass Columns

- Manufacturer Specifications: Structural fiberglass columns will include load-bearing ratings (e.g., pounds per square inch or total weight capacity). Always consult with the manufacturer or supplier for documentation verifying their structural capabilities.

- Testing and Certification: Columns intended for structural use often meet specific standards set by building codes and engineering requirements. This information is crucial for construction projects where safety is a priority.

Combining Decorative and Structural Features

Custom fiberglass columns can serve a dual purpose: they can be both load-bearing and aesthetically pleasing. By combining structural reinforcements with elegant finishes, they provide strength while enhancing the overall architectural design.

Custom fiberglass columns can be structural if designed and manufactured for load-bearing purposes. However, it’s essential to verify their load capacity with the supplier and ensure they meet engineering requirements for your project. For purely decorative applications, hollow fiberglass columns provide flexibility without structural capabilities.

Can Railings Be Mounted to Custom Fiberglass Columns?

Yes, railings can be mounted to custom fiberglass columns, but the process requires careful planning to ensure both structural integrity and aesthetic appeal. Fiberglass columns are highly durable and versatile, making them a popular choice for supporting railings in various applications such as porches, balconies, and staircases. Here is a detailed explanation addressing key considerations, methods, and best practices when mounting railings to custom fiberglass columns:

Structural vs. Decorative Columns

- Structural Columns: If the custom fiberglass columns are load-bearing, railings can be mounted directly to them because they are designed to withstand stress and pressure. These columns have solid cores or reinforcements that can securely anchor railing brackets.

- Decorative Columns: For non-structural or hollow fiberglass columns, additional support must be added internally. This often involves installing a wood or steel post inside the column to create a solid anchor point for the railings.

Tools and Mounting Hardware

- Specialized Fasteners: Use stainless steel or corrosion-resistant screws and brackets to prevent rusting, especially for outdoor installations. These fasteners ensure the railing stays securely in place for years.

- Mounting Brackets: Railing brackets are typically used to attach railings to the column surface. Ensure the brackets are designed to distribute load evenly without cracking or damaging the fiberglass.

- Pilot Holes: Always drill pilot holes to prevent cracking or splintering the fiberglass surface when inserting screws or bolts.

Interior Reinforcement for Hollow Columns

For hollow custom fiberglass columns, adding reinforcement is often necessary:

- Wood Blocking: Insert a wooden post or block into the column at the points where railings will be attached. This provides a solid base for screws or bolts.

- Steel Posts: For more robust support, especially for heavy railings, steel posts can be installed inside the column. The railings are then mounted to the steel post through the fiberglass shell.

- Adhesive Reinforcement: In some cases, construction adhesive can be used to secure the wooden or steel reinforcement inside the column, ensuring stability.

Load and Stress Considerations

When mounting railings to custom fiberglass columns, it’s critical to ensure the columns can handle the additional stress. Factors to consider include:

- Weight of the Railing: Heavier railings, such as wrought iron, will require stronger reinforcement inside the column.

- Usage and Force: Railings in high-traffic areas or staircases must be firmly anchored to handle pushing, pulling, and other forces.

- Local Building Codes: Ensure compliance with local building codes for railing installations, particularly for height, weight support, and safety requirements.

Aesthetic Integration

Mounting railings to custom fiberglass columns can be done in a way that preserves their visual appeal:

- Hidden Brackets: Use brackets or fasteners that can be concealed for a cleaner, seamless look.

- Color Matching: Paint or coat the hardware to match the column and railing for a cohesive design.

Railings can indeed be mounted to custom fiberglass columns, whether they are structural or decorative. For load-bearing columns, the process is straightforward, while hollow columns may require internal reinforcements for added strength. Proper tools, mounting techniques, and attention to building codes will ensure a secure and visually appealing installation.

Can Screws Be Screwed Into Custom Fiberglass Columns?

Yes, screws can be screwed into custom fiberglass columns, but the process requires careful planning and proper techniques to ensure a secure and damage-free installation. Fiberglass is a durable material, but it has unique characteristics that must be considered when fastening screws. Below is a detailed explanation of how and when screws can be used, along with important considerations for successful results.

Type of Custom Fiberglass Column

- Solid Columns (Load-Bearing):

Solid custom fiberglass columns provide a denser surface that can hold screws more effectively. Screws can be directly inserted into the material without much concern for reinforcement, as these columns are designed to support weight and stress. - Hollow Columns (Decorative):

Hollow fiberglass columns are lightweight and have thin walls, which limits their ability to hold screws securely on their own. In such cases:

- Reinforcements such as wooden or steel inserts inside the column are required to provide a solid anchor point.

- Without reinforcement, screws may strip out, loosen, or fail to hold heavier objects over time.

Best Practices for Screwing into Fiberglass

- Drill Pilot Holes:

Before inserting screws, always drill pilot holes slightly smaller than the screw diameter. This prevents cracking, splintering, or damaging the fiberglass material. - Use the Right Screws:

- Stainless Steel Screws: These are ideal for fiberglass because they resist rust and corrosion, particularly in outdoor or moisture-prone areas.

- Self-Tapping Screws: These screws are designed to cut threads into the fiberglass as they are inserted, creating a stronger hold.

- Avoid regular wood screws, as they may not grip the fiberglass effectively.

- Tighten Screws Carefully:

Do not overtighten screws, as this can cause the fiberglass to crack or deform around the hole. Use controlled torque to ensure a secure fit without stressing the material.

Reinforcements for Heavier Loads

When mounting heavy objects, such as railings, brackets, or fixtures, additional reinforcement is necessary for hollow custom fiberglass columns:

- Wooden Blocking: Install a wood insert inside the column to provide a strong backing for the screws. Screws can then pass through the fiberglass and grip the wood for added stability.

- Metal Plates or Posts: For high-stress installations, steel posts or plates can be inserted inside the column, creating a solid base to support the load.

- Adhesives and Fillers: In some cases, epoxy adhesives can be used alongside screws to strengthen the bond and improve load-bearing capacity.

Surface Protection and Aesthetics

- After screwing into the fiberglass column, consider sealing the area with caulk or paint to protect against moisture infiltration and to maintain a clean finish.

- If screws are visible, use screw caps or matching paint to integrate them seamlessly into the column’s design.

Load and Safety Considerations

While screws can be securely fastened to custom fiberglass columns, the weight and force applied to the screws must be considered:

- Light Attachments: Lightweight objects, such as trim or decorative elements, can often be directly screwed into fiberglass without additional reinforcement.

- Heavy Attachments: For railings, handrails, or other weight-bearing fixtures, always reinforce the column and ensure compliance with safety standards and local building codes.

Screws can be screwed into custom fiberglass columns, but the process depends on whether the column is solid or hollow. While solid columns allow direct screwing, hollow columns require internal reinforcements like wood or steel for secure fastening, especially for heavier loads. Proper preparation, such as drilling pilot holes and using stainless steel or self-tapping screws, ensures a strong and lasting installation without damaging the fiberglass.

Are Custom Fiberglass Columns Hollow?

Yes, custom fiberglass columns can be hollow, but whether they are hollow or solid depends on their design, intended purpose, and manufacturing process. Understanding this distinction is essential when considering their applications, such as structural support, decorative use, or accommodating other building components. Below is a detailed explanation to provide clarity from multiple perspectives.

Hollow vs. Solid Custom Fiberglass Columns

- Hollow Columns:

Most custom fiberglass columns are manufactured as hollow structures. These columns are created using a molding process where fiberglass material is layered around a cylindrical or tapered form. Hollow columns offer significant advantages:

- Lightweight: Their hollow design makes them easier to handle, transport, and install compared to solid alternatives.

- Versatility: Hollow columns can wrap around existing structural supports like steel, wood, or concrete posts, making them ideal for decorative coverings.

- Cost-Effective: Producing hollow columns uses less material, reducing both manufacturing and shipping costs.

- Solid Columns:

Solid fiberglass columns are also available and are typically designed for specific load-bearing purposes. These columns feature a dense fiberglass core that enhances their strength and weight-bearing capacity. Solid columns are used when structural support is required without an additional internal post.

Applications of Hollow Custom Fiberglass Columns

- Decorative Use: Hollow columns are often used for aesthetic purposes where no structural support is required. They can be designed in a variety of shapes, sizes, and styles to match architectural themes.

- Structural Wrapping: Hollow columns can be split and installed around load-bearing elements, such as wooden or steel beams, to provide a finished and elegant look without compromising the strength of the core structure.

- Utility Accommodation: The hollow interior of fiberglass columns can house electrical wiring, plumbing, or other utility systems, making them functional as well as visually appealing.

Structural Capabilities of Hollow Columns

While hollow custom fiberglass columns are often used for decorative purposes, they can also serve structural roles with proper reinforcement:

- Internal Supports: When load-bearing capacity is required, hollow fiberglass columns can house steel, concrete, or wooden posts that carry the load. The fiberglass column acts as a protective and decorative covering.

- Load-Bearing Capacity: Some hollow columns are engineered with thicker walls or added reinforcement to meet specific load-bearing requirements, making them suitable for structural use without an internal post.

Manufacturing Process

The majority of custom fiberglass columns are manufactured as hollow units using a molding process:

- Fiberglass sheets or resin materials are layered around a mold, creating a hollow shell.

- The column is then cured, sanded, and finished for durability and appearance.

This process allows for the creation of columns with consistent strength, lightweight properties, and customizable shapes.

How to Choose Between Hollow and Solid Columns

- Choose Hollow Columns When:

- The columns are for decorative purposes.

- You need to wrap them around an existing structural post.

- You want to integrate utilities (e.g., wiring) inside the column.

- Lightweight installation is a priority.

- Choose Solid Columns When:

- The columns need to bear significant structural loads without additional internal supports.

- You require extra durability for high-stress applications.

Custom fiberglass columns are often hollow, offering lightweight versatility, ease of installation, and adaptability for decorative and functional purposes. However, for load-bearing applications, hollow columns can be reinforced with internal supports, or solid fiberglass columns can be used. The choice between hollow and solid designs depends on your project’s structural and aesthetic needs.

FAQs about Custom Fiberglass Columns

Yes, fiberglass columns can be cut, but it is essential to follow the correct procedure and use the right tools to ensure a precise cut without damaging the structural integrity of the column. Fiberglass columns are often shipped in longer lengths, allowing them to be trimmed on-site to fit the exact height required for a specific installation. To cut fiberglass columns, a fine-toothed saw, such as a carbide-tipped circular saw, is recommended. This type of tool provides a smooth cut while minimizing the risk of splintering the fiberglass material.

When cutting a fiberglass column, it’s important to measure carefully and ensure that the column remains level. Improper cutting can lead to uneven surfaces, which may cause issues during installation. Additionally, while the column can be trimmed, the cut end should be sealed and properly finished to prevent moisture penetration. For load-bearing columns, it’s essential to check with the manufacturer, like GangLong Fiberglass, to ensure that the structural capacity is not compromised after cutting. Always use safety gear, such as goggles and masks, to protect yourself from fiberglass dust during the process.

Fiberglass columns are widely considered a great option for both residential and commercial buildings due to their durability, versatility, and low maintenance requirements. Unlike wood, fiberglass is resistant to rot, insects, and moisture, making it ideal for outdoor applications where exposure to the elements is a concern. Additionally, fiberglass columns do not warp, crack, or decay over time, ensuring that they maintain their structural integrity and aesthetic appeal for many years.

Another advantage of fiberglass columns is their strength-to-weight ratio. They are lightweight compared to materials like stone or concrete, making them easier to handle during installation while still providing significant structural support. Fiberglass columns are also available in a wide variety of styles, sizes, and finishes, allowing for customization to fit various architectural designs, from classical to contemporary.

Homeowners and contractors alike appreciate the minimal maintenance required for fiberglass columns. They can be painted or left with their natural finish, and they require no regular sealing or treatments, unlike wood. Overall, fiberglass columns are a good investment due to their longevity, strength, and aesthetic flexibility.

Fiberglass columns are engineered to support significant weight, making them an ideal choice for load-bearing applications. The exact weight capacity of a fiberglass column depends on several factors, including its size, design, and whether it is reinforced. Typically, a standard fiberglass column can support several thousand pounds, with some reinforced models capable of bearing even more.

For instance, load-bearing fiberglass columns from manufacturers like GangLong Fiberglass are designed to support structures such as porch roofs, balconies, and other overhead architectural features. These columns are tested to meet or exceed specific weight-bearing requirements based on local building codes. It is not uncommon for a well-constructed fiberglass column to support upwards of 10,000 to 12,000 pounds, depending on the column’s diameter and wall thickness.

However, it’s essential to consult with the manufacturer to determine the exact load-bearing capacity of a particular column model. Proper installation is also critical to ensure that the column distributes weight evenly and maintains its structural integrity over time. When installed correctly, fiberglass columns provide reliable support for heavy structures.

Custom fiberglass columns are known for their exceptional durability and long lifespan, often lasting 50 years or more with proper care. Fiberglass is inherently resistant to moisture, rot, insect damage, and warping, making it ideal for both indoor and outdoor applications. Unlike wood or metal, fiberglass columns can withstand extreme weather conditions, including humidity, temperature fluctuations, and UV exposure. Additionally, they require minimal maintenance, ensuring their longevity without frequent repairs or replacements. Their robust composition makes them a popular choice for homeowners and architects seeking a reliable, long-lasting structural and decorative solution. Whether installed in residential or commercial settings, custom fiberglass columns provide stability and aesthetic appeal for decades. To maximize their lifespan, regular cleaning and periodic inspections can help identify and address any superficial wear. Overall, fiberglass columns are a durable, cost-effective investment for long-term use.

Yes, custom fiberglass columns can be cut to meet specific size or design requirements. This flexibility makes them a versatile option for both structural and decorative purposes. Fiberglass columns are typically manufactured as hollow or solid units, and with the right tools—such as a circular saw with a fine-tooth blade—they can be trimmed without compromising their strength or integrity. It is important to take precise measurements before cutting to ensure an accurate fit for your project. Always wear appropriate protective gear, including a mask and safety glasses, to avoid inhaling fiberglass dust during the cutting process. Additionally, sealing the cut ends with primer or resin is recommended to maintain the column’s durability and prevent moisture infiltration. Professional assistance may be helpful if structural load-bearing columns need to be resized. Proper cutting techniques ensure that custom fiberglass columns remain functional and visually appealing after modification.

Yes, custom fiberglass columns can be load-bearing, depending on their design and manufacturing specifications. Structural fiberglass columns are engineered to support substantial weight, making them suitable for use as load-bearing components in construction projects. They are designed with reinforced materials that enhance their strength and ability to bear axial loads. Fiberglass columns undergo rigorous testing to meet load-bearing standards, providing reliable structural support for porches, entrances, or pergolas. However, it’s essential to confirm the weight capacity with the manufacturer to ensure the column meets your project’s requirements. For decorative fiberglass columns, which are not intended to bear weight, structural supports such as steel or wood may be added inside the column. Custom fiberglass columns offer the advantage of combining strength with aesthetics, providing both support and visual appeal without warping, cracking, or succumbing to rot. Always consult a professional to verify load-bearing specifications.

Yes, it is recommended to prime custom fiberglass columns before painting, especially if they are not pre-primed by the manufacturer. Fiberglass surfaces are often smooth, which can make it challenging for paint to adhere properly. Applying a high-quality bonding primer creates a uniform surface that improves paint adhesion and ensures a durable, long-lasting finish. Before priming, the column surface should be thoroughly cleaned to remove dust, dirt, or grease. Lightly sanding the surface can also help the primer adhere better. Once primed, the fiberglass columns can be painted with exterior-grade acrylic latex paint, which provides excellent weather resistance and UV protection. This process is particularly important for outdoor columns exposed to the elements. Priming and painting not only enhance the appearance of custom fiberglass columns but also protect them from wear, ensuring they remain visually appealing for years to come.

Fiberglass is highly durable and resistant to many environmental factors, but it can deteriorate over time if not properly maintained. Custom fiberglass columns are designed to withstand moisture, UV exposure, and temperature fluctuations, making them less prone to rot, rust, or warping compared to wood or metal. However, prolonged exposure to intense UV rays can cause the surface to fade, chalk, or lose its sheen over decades. To prevent deterioration, applying a protective paint or UV-resistant coating is recommended. Physical damage, such as cracks or chips, can occur due to impact, but these can be easily repaired with fiberglass resin. Regular cleaning and maintenance can significantly slow the aging process. Overall, fiberglass has exceptional longevity and is far more durable than alternative materials, ensuring that custom fiberglass columns remain strong, functional, and attractive for many years with minimal upkeep.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.