Discount fiberglass sheets are versatile materials commonly used in various applications, including construction, automotive, and marine industries. Their lightweight yet strong composition makes them ideal for reinforcing structures, providing insulation, and creating waterproof barriers. The affordability of discount fiberglass sheets is essential for budget-conscious projects, allowing both professionals and DIY enthusiasts to access high-quality materials without overspending. This cost-effectiveness ensures that projects remain within budget while maintaining durability and performance. Whether used for roofing, boat repairs, or electrical insulation, discount fiberglass sheets offer a practical solution that balances quality with affordability, making them a popular choice across different sectors. Save money with discount fiberglass sheets from GangLong Fiberglass, offering strength, electrical properties, and chemical resistance in various sizes and styles.

What are Discount Fiberglass Sheets

Benefits of Using Discount Fiberglass Sheets

The benefits of discount fiberglass sheets extend to their affordability. By choosing these cost-effective materials, individuals and businesses can save money while still achieving high-quality results. The savings realized from purchasing discount fiberglass sheets can be redirected into other aspects of a project, such as labor or additional materials, ultimately enhancing the overall quality and scope of work.

Discount fiberglass sheets are also environmentally friendly. They can be produced from recycled materials, contributing to sustainable building practices. As more consumers and builders prioritize eco-friendly solutions, the demand for discount fiberglass sheets continues to grow. This trend allows for the integration of environmentally responsible materials without significantly increasing project costs.

Tips for Purchasing Discount Fiberglass Sheets

When looking to purchase discount fiberglass sheets, consider a few tips to ensure you are making a wise investment. First, always check the specifications of the sheets, including thickness and load-bearing capacity. These factors are critical for determining whether the sheets will meet the requirements of your specific project. GangLong Fiberglass offers a range of options that cater to various applications, ensuring that you can find the right fit for your needs.

Second, do not hesitate to ask suppliers about their return policies and warranty options. Understanding the terms can help you make an informed decision, particularly if you are purchasing in bulk or trying a new product line. This approach is beneficial when exploring discount fiberglass sheets, as it provides peace of mind regarding your investment.

Key Considerations When Choosing Discount Fiberglass Sheets

When selecting discount fiberglass sheets, several factors should be considered to ensure the right choice for specific applications. One critical aspect is the thickness and dimensions of the sheets, which can vary based on intended use. It is essential to evaluate the required specifications to achieve optimal performance in the desired application.

The type of resin used in the production of fiberglass sheets is another important consideration. Different resins offer varying levels of durability, chemical resistance, and UV stability. Understanding these properties can help in selecting the right product that meets project requirements. GangLong Fiberglass provides a range of options to accommodate diverse needs, ensuring that customers can find suitable materials.

Final Thoughts on Discount Fiberglass Sheets

Discount fiberglass sheets offer a versatile and affordable solution for various applications, including roofing, construction, automotive, and marine use. Their durability, weather resistance, and eco-friendly fiberglass properties make them an excellent choice for both professionals and DIY enthusiasts. By exploring options for discount fiberglass sheets, individuals can achieve high-quality results without overspending, making them a valuable addition to any project.

Applications of Discount Fiberglass Sheets

Discount fiberglass sheets have a wide array of applications beyond roofing. In the construction industry, these sheets are frequently used as fiberglass wall sheets, providing insulation and structural support. Their lightweight nature makes them easy to handle and install, which is advantageous for both contractors and DIY enthusiasts. Moreover, fiberglass sheets are often utilized in the automotive sector for body panels and repairs due to their strength and resistance to corrosion.

Marine applications are another significant area for discount fiberglass sheets. Boat builders and repair specialists frequently use these sheets because of their ability to withstand harsh marine environments. Discount fiberglass sheets can be employed to create hulls, decks, and other components that require strength and durability while remaining lightweight.

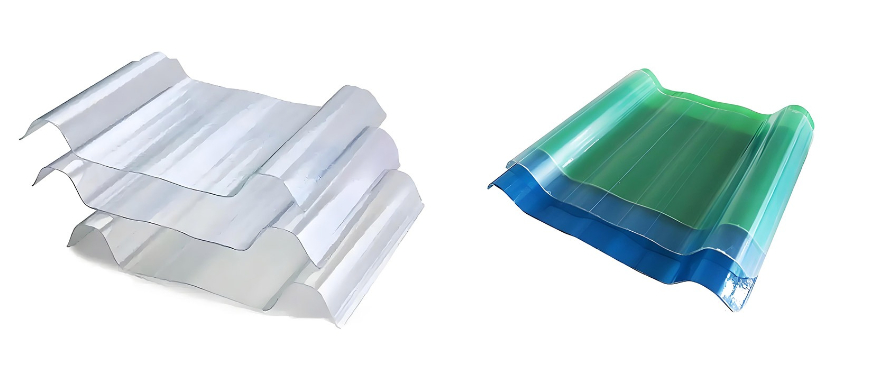

Fiberglass Roof Sheets

Fiberglass roof sheets are increasingly popular in both residential and commercial buildings due to their unique properties and benefits. These sheets offer a lightweight yet durable option for roofing solutions, making them suitable for various architectural styles and designs. Common applications include covering patios, greenhouses, and even entire commercial roofs. The versatility of fiberglass roof sheets allows them to be used in areas requiring enhanced aesthetics and practical functionality.

The advantages of using fiberglass roof sheets are significant. They provide excellent weather resistance, which is crucial for maintaining the integrity of a building over time. These sheets are resistant to UV rays, minimizing the risk of degradation from sunlight exposure. Additionally, fiberglass roof sheets are waterproof, effectively protecting structures from rain and moisture infiltration. Their durability also extends to their ability to withstand harsh environmental conditions, including wind and hail.

Finding discount fiberglass sheets for roofing projects can be straightforward if you know where to look. Various suppliers, including local hardware stores and specialized online retailers, often have sales or promotions on fiberglass sheets. It’s beneficial to keep an eye on seasonal sales events or clearance sections where you can find high-quality fiberglass roof sheets at reduced prices. Shopping online allows you to compare prices and find the best deals without having to visit multiple stores.

Custom Solutions with Discount Fiberglass Sheets

When working on specialized projects, the need for customized materials becomes increasingly important. Discount fiberglass sheets can be tailored to fit specific dimensions, properties, and applications, making them versatile for a range of industries, including construction, automotive, and manufacturing. Many suppliers, such as GangLong Fiberglass, offer customization options that allow for flexibility in size, thickness, and other characteristics, ensuring the materials meet the unique demands of your project. Below, we’ll explore the key benefits and considerations of ordering custom solutions with discount fiberglass sheets.

Custom Sizes and Thicknesses for Precision

In some cases, standard fiberglass sheet sizes and thicknesses might not be suitable for your project. Whether you’re working on large-scale construction, creating specialized molds, or reinforcing structures, having the ability to custom order fiberglass sheets can significantly improve the accuracy and performance of your project. By specifying the exact dimensions you need, you can avoid waste and ensure a precise fit, whether you require thin sheets for light-duty applications or thicker materials for increased strength.

Tailoring Properties for Specific Applications

Beyond size and thickness, fiberglass sheets can also be customized for specific properties that suit unique applications. For example, you may need fiberglass sheets with enhanced chemical resistance, moisture resistance, or electrical insulating properties. Suppliers like GangLong Fiberglass offer customization to ensure the sheets meet the exact functional requirements of your project. This allows you to select fiberglass that is best suited to withstand environmental conditions, mechanical stress, or electrical demands, resulting in a more efficient and durable final product.

Cost-Effective Custom Solutions with Discount Fiberglass Sheets

One of the primary benefits of custom fiberglass sheets is that they offer cost-effective solutions without sacrificing quality. Discount fiberglass sheets provide an opportunity to purchase tailored materials at competitive prices, ensuring that your project stays within budget while still achieving the necessary specifications. By ordering customized sheets in bulk or during sales events, you can save even more, making them a great option for businesses or individuals looking to complete projects at a lower cost without compromising on material quality.

Fast Turnaround Times for Custom Orders

When working with custom orders, quick turnaround times are often a key factor. Many suppliers, including GangLong Fiberglass, offer efficient processing times for custom sheet orders, ensuring that your project timeline is not delayed. Whether you need a small batch of customized fiberglass sheets for a prototype or a larger quantity for production, timely delivery is crucial to maintaining the flow of your work. Choosing a supplier known for its reliability and efficiency can help you complete your projects on schedule.

Versatility Across Industries

Custom discount fiberglass sheets are used across a wide range of industries and applications. In construction, they can be used for structural reinforcement or creating durable roofing solutions. In automotive manufacturing, fiberglass sheets can be molded to create lightweight, high-strength components. The versatility of fiberglass sheets makes them a preferred choice for many industries, and the ability to customize them ensures they meet the specific needs of any project. Whether your project requires specialized material properties, sizes, or thicknesses, customized fiberglass sheets offer an ideal solution.

Custom solutions with discount fiberglass sheets provide an array of benefits that can significantly enhance the effectiveness and functionality of your project. From custom sizes and thicknesses to tailored properties, fiberglass offers flexibility, strength, and cost-effectiveness, making it a valuable material for a variety of applications. By choosing a reliable supplier, such as GangLong Fiberglass, you can take full advantage of these custom options, ensuring that your project is completed with the highest quality materials at a reasonable cost.

Discount Fiberglass Sheets: Essential for Marine Applications

Discount fiberglass sheets play a crucial role in the construction and repair of boats, providing a reliable and effective material option for marine environments. Understanding the significance of high-quality fiberglass sheets is essential for anyone involved in boating or marine repairs.

Fiberglass Sheets for Boats: Importance and Benefits

Using high-quality discount fiberglass sheets in boat construction and repair is vital for ensuring durability and performance. These sheets offer exceptional strength-to-weight ratios, making them ideal for marine applications where every ounce counts. When properly applied, fiberglass sheets can enhance the structural integrity of boats, allowing them to withstand harsh conditions at sea.

The ability of fiberglass sheets to resist water intrusion is another significant benefit. Boats are constantly exposed to moisture, and using materials that can withstand this environment is essential. Discount fiberglass sheets are engineered to provide excellent waterproofing, preventing issues such as delamination and corrosion that can occur with lesser materials. This resistance is crucial for maintaining the longevity of a vessel.

Characteristics of Discount Fiberglass Sheets for Marine Applications

Discount fiberglass sheets suitable for marine applications possess several key characteristics that set them apart. First, they are designed to be lightweight yet incredibly strong, enabling easy handling during installation. This quality also contributes to the overall performance of the boat, ensuring that it can achieve optimal speeds while maintaining stability.

Additionally, these fiberglass sheets are manufactured with UV-resistant properties, which protect the material from the harmful effects of prolonged sun exposure. This is particularly important for boats that spend extended periods on the water. The UV protection helps prevent degradation and maintains the aesthetic appeal of the fiberglass over time.

Discount fiberglass sheets are also known for their chemical resistance. Marine environments often expose materials to various chemicals, including saltwater and fuel. Fiberglass sheets designed for marine use can withstand these harsh conditions without losing their structural integrity or appearance.

Applications of Discount Fiberglass Sheets in Boat Construction

Discount fiberglass sheets are utilized in various applications within boat construction and repair. They are commonly used for hulls, decks, and superstructures, providing a strong and durable surface that can withstand the rigors of marine life. In addition, these sheets can be easily molded and shaped to fit various designs and specifications, making them versatile for custom boat builds.

In the repair sector, discount fiberglass sheets are frequently used for patching damaged areas. The ability to easily cut and apply these sheets allows for quick repairs that can restore a boat’s integrity without extensive downtime. The strong bond created by the fiberglass ensures that repairs hold up against the stresses of the water.

The Key of Choosing the Right Discount Fiberglass Sheets

Choosing the right discount fiberglass sheets for specific marine applications requires careful consideration of several factors. First, it’s essential to evaluate the thickness of the sheets, as this can impact both strength and flexibility. Thicker sheets may be necessary for structural components, while thinner sheets might suffice for cosmetic repairs.

Another important factor is the type of fiberglass resin material used in the fiberglass sheets. Polyester resin is commonly used for general applications, while epoxy resin may be preferred for more demanding environments due to its superior bonding strength and resistance to moisture. Knowing the specific needs of the boat will help in selecting the most suitable type.

It’s also essential to consider the finish of the discount fiberglass sheets. A smooth finish can be advantageous for aesthetic reasons, while a textured surface might provide better grip in certain applications. Evaluating the intended use will guide the selection process.

Maintenance of Discount Fiberglass Sheets in Marine Settings

Maintaining discount fiberglass sheets is crucial for ensuring their longevity and performance. Regular inspections should be conducted to identify any signs of wear, such as cracks or discoloration. If any damage is detected, timely repairs should be made to prevent further deterioration.

Cleaning the fiberglass sheets is also an important maintenance task. Using mild soap and water can help remove dirt and grime without damaging the surface. Avoiding harsh chemicals is essential, as these can break down the resin and compromise the integrity of the fiberglass.

Additionally, applying a UV-protective coating can further enhance the lifespan of discount fiberglass sheets. This extra layer of protection helps to shield the material from the sun’s harmful rays, reducing the risk of fading and degradation over time.

Innovations in Discount Fiberglass Sheets for Marine Use

The manufacturing of discount fiberglass sheets has seen several innovations aimed at improving performance and usability in marine environments. Advancements in resin technology have led to the development of more durable and resilient materials, which can withstand extreme weather conditions and prolonged exposure to water.

Incorporating additives to enhance the strength and flexibility of fiberglass is another trend. These innovations allow for lighter sheets that maintain the necessary structural integrity, facilitating easier installation and better overall boat performance.

Moreover, the introduction of eco-friendly manufacturing processes is gaining traction. Many manufacturers are now focusing on sustainability, ensuring that discount fiberglass sheets are produced with minimal environmental impact. This shift not only benefits the environment but also meets the increasing consumer demand for greener products.

Economic Benefits of Using Discount Fiberglass Sheets

The use of discount fiberglass sheets can provide significant economic advantages for boat builders and repair professionals. The affordability of these sheets compared to other materials allows for cost-effective construction and repair solutions. This cost savings can be particularly beneficial for smaller operations or individual boat owners looking to manage expenses without sacrificing quality.

Additionally, the durability of discount fiberglass sheets contributes to long-term savings. The reduced need for repairs and replacements over time means lower maintenance costs, allowing boat owners to invest their resources elsewhere.

Furthermore, the versatility of fiberglass sheets means they can be used in various applications beyond boat construction, such as in the automotive and aerospace industries. This wide range of uses increases their value as an investment, as they can serve multiple purposes throughout their lifecycle.

The Future of Discount Fiberglass Sheets in Marine Applications

The future of discount fiberglass sheets in marine applications looks promising as technological advancements continue to shape the industry. Ongoing research into new materials and manufacturing techniques is likely to yield even stronger and lighter fiberglass options that can better withstand the demands of marine environments.

As the push for sustainability grows, the focus on eco-friendly materials and processes will likely increase. This trend may lead to the development of biodegradable or recyclable fiberglass sheets, further aligning the industry with global sustainability goals.

Overall, the continued innovation in discount fiberglass sheets will provide boat builders and owners with even more reliable, efficient, and cost-effective solutions for their marine needs.

Overview of the Fiberglass Sheet Market in Australia

The fiberglass sheet market in Australia has experienced significant growth due to the increasing demand for versatile and durable materials across various industries. These sheets are widely utilized in construction, automotive, marine, and electrical applications due to their lightweight yet strong properties. The popularity of discount fiberglass sheets has further contributed to this market expansion, offering consumers budget-friendly options without compromising on quality. Local manufacturers like GangLong Fiberglass have emerged as key players, catering to a diverse clientele by providing a range of products designed to meet specific needs.

Regional Suppliers and Their Pricing Strategies

Australia boasts a network of regional suppliers who play a crucial role in the fiberglass sheet market. These suppliers often adopt competitive pricing strategies to attract customers, particularly those seeking discount fiberglass sheets. By offering bulk purchase discounts or promotional sales, they enable customers to acquire quality materials at reduced prices. Additionally, local suppliers benefit from lower shipping costs and faster delivery times, which can be a significant advantage for businesses looking to minimize operational delays.

Many suppliers in Australia, including GangLong Fiberglass, focus on establishing strong relationships with customers, providing personalized service, and ensuring consistent product availability. This customer-centric approach allows them to maintain a loyal customer base while also attracting new clients seeking cost-effective solutions. As the demand for fiberglass sheets continues to rise, regional suppliers are likely to adapt their pricing strategies to remain competitive in the market.

Tips on How to Remove Gummy Tape from Fiberglass Rod

Benefits of Purchasing Locally Sourced Fiberglass Sheets

Purchasing locally sourced discount fiberglass sheets is more than just a cost-saving decision; it is a strategic move that benefits consumers, businesses, and communities in multiple ways. Beyond the apparent advantages of lower prices and accessibility, local sourcing impacts transportation costs, regional economies, project timelines, and environmental sustainability. This comprehensive approach to material procurement ensures that buyers not only meet their project needs but also contribute to broader positive outcomes. Below, we delve into these benefits in greater detail, providing a structured exploration of why local sourcing is a valuable choice.

Cost Savings and Transportation Efficiency

One of the most significant advantages of locally sourcing discount fiberglass sheets is the financial benefit gained from reduced transportation costs. When suppliers are located nearby, the logistics of delivery become simpler and less expensive.

Details:

- Lower Shipping Costs: Shorter distances mean reduced fuel usage, lower freight charges, and no need for long-haul transport.

- Minimized Handling Fees: Fewer intermediaries and handling processes can further cut down costs.

- Quick Delivery: Faster transit times reduce the risk of project delays, especially when materials are urgently needed.

Strengthening Regional Economies

Sourcing locally also has a profound impact on the local economy. By purchasing discount fiberglass sheets from regional suppliers, buyers support businesses within their community, fostering economic growth and stability.

Details:

- Job Creation: Local businesses grow and create employment opportunities for residents.

- Revenue Circulation: Money spent locally often circulates within the community, benefiting other businesses and services.

- Community Engagement: Stronger connections between suppliers and consumers lead to long-term partnerships and mutual growth.

Tailored Solutions and Expertise

Local suppliers often have a deeper understanding of the specific needs of their customers. This enables them to provide tailored solutions that larger, distant suppliers may not offer.

Details:

- Customized Products: Local vendors can adapt their offerings to meet unique project requirements, such as specific thicknesses, finishes, or grades of fiberglass sheets.

- Better Communication: Being in the same region ensures clear and direct communication, reducing misunderstandings.

- On-Site Support: Local suppliers can provide on-site advice or assistance, further enhancing the customer experience.

Environmental Sustainability

Purchasing locally sourced discount fiberglass sheets is an environmentally conscious choice, reducing the carbon footprint associated with long-distance transportation.

Details:

- Lower Emissions: Shorter shipping distances mean less fuel consumption and fewer greenhouse gas emissions.

- Reduced Packaging Waste: Local suppliers often use minimal packaging for nearby deliveries, cutting down on waste.

- Sustainable Practices: Many local businesses adopt eco-friendly practices to meet community expectations, aligning with buyers’ sustainability goals.

Improved Project Efficiency

Timely access to materials is critical for efficient project management. Local suppliers provide the reliability and flexibility needed to meet demanding schedules.

Details:

- Quicker Turnaround: Materials can be delivered rapidly, helping projects stay on track.

- Flexible Quantities: Local suppliers are often more accommodating with order sizes, whether for small-scale repairs or large construction projects.

- Immediate Resupply: In case of unexpected shortages, local vendors can quickly restock materials, avoiding costly delays.

Building Trust and Long-Term Partnerships

Establishing relationships with local suppliers fosters trust and encourages long-term collaboration, which can be mutually beneficial for both parties.

Details:

- Reliability: Local vendors are invested in maintaining their reputation, ensuring consistent quality and service.

- Priority Service: Repeat customers often receive priority for orders, deliveries, and special requests.

- Negotiation Opportunities: Close relationships may allow for better discounts, credit terms, or personalized deals.

Opting for locally sourced discount fiberglass sheets is a choice that goes beyond financial savings. It brings economic, logistical, environmental, and relational benefits that enhance project outcomes and support local communities. By choosing local suppliers, buyers not only fulfill their immediate needs but also contribute to sustainable practices and long-term growth. For anyone seeking quality fiberglass sheets at an affordable price, local sourcing is undoubtedly a strategic and impactful decision.

Key Features of an FRP Cable Threading Pipe Factory Explained

Maintenance and Care of Discount Fiberglass Sheets

To ensure that your discount fiberglass sheets maintain their durability, performance, and aesthetic appeal, proper maintenance is key. These sheets are resistant to many elements, but they still require regular care to prevent degradation over time. Whether you’re using them in construction, automotive applications, or for other projects, understanding the best practices for maintaining fiberglass sheets will help prolong their lifespan and preserve their functionality. Below, we’ll explore different aspects of maintaining discount fiberglass sheets, from routine cleaning to inspecting for damage and protecting them from harsh conditions.

Regular Cleaning to Maintain Appearance

Cleaning your discount fiberglass sheets regularly is essential to keeping them looking good and functioning well. Simple cleaning routines like rinsing with water and using a mild detergent can effectively remove dust, dirt, and grime. This will help maintain both the appearance and structural integrity of the sheets. It is important to avoid using abrasive materials, such as harsh scrubbing brushes or abrasive sponges, as they may scratch the surface. A soft cloth or non-abrasive sponge is recommended to gently wipe the surface, preserving the sheet’s smooth finish. Additionally, make sure to rinse thoroughly to prevent detergent buildup, which could cause the surface to dull over time. Regular cleaning not only helps maintain the appearance of the fiberglass but also prevents dirt buildup, which can lead to degradation if left unchecked.

Avoid Harsh Chemicals and Abrasive Cleaners

While fiberglass is durable, exposure to harsh chemicals and abrasive cleaners can degrade the resin and weaken the structural integrity of the sheets. It’s crucial to avoid using strong solvents, acids, or ammonia-based cleaners that can strip away the resin layer or cause discoloration. If you need to remove tougher stains, opt for specialized fiberglass cleaners that are gentle yet effective. Always follow the manufacturer’s instructions for cleaning to ensure the longevity of your discount fiberglass sheets. Additionally, when dealing with fiberglass sheets that are used outdoors, such as in roofing or automotive applications, it’s important to ensure that no corrosive substances come into contact with the sheets, especially over prolonged periods, as this can cause weakening and deterioration.

Periodic Inspection for Wear and Damage

Routine inspections of your discount fiberglass sheets are essential to identify any signs of wear, damage, or potential issues before they become serious problems. Pay special attention to high-traffic areas or locations exposed to extreme weather conditions, as these are more susceptible to damage. Look for any cracks, chips, or signs of delamination, which could indicate structural problems. Early detection of issues allows for timely repairs, which can prevent further damage and extend the lifespan of your fiberglass sheets. For sheets used in high-stress environments, such as in construction or automotive parts, checking for any signs of warping, fading, or cracks is especially important to ensure their continued effectiveness. Regular inspections ensure that the sheets continue to provide the necessary strength and protection over time.

Protecting Fiberglass Sheets from Harsh Conditions

While fiberglass sheets are known for their resilience, they can still be affected by prolonged exposure to extreme environmental conditions such as UV radiation, heavy moisture, and severe temperature fluctuations. To protect your discount fiberglass sheets, consider applying a UV-resistant coating or protective sealant, especially if they are exposed to direct sunlight for extended periods. This will help prevent UV degradation and fading, keeping the material strong and visually appealing. Additionally, if fiberglass sheets are used in environments with high humidity, such as in bathrooms or coastal areas, applying a water-resistant sealant may be beneficial to prevent moisture from affecting the resin. By adding this extra layer of protection, you can further extend the lifespan of your fiberglass sheets and maintain their performance.

Storage and Handling for Longevity

Proper storage and handling of fiberglass sheets are crucial in maintaining their integrity. When storing your discount fiberglass sheets, ensure they are kept in a dry, cool, and well-ventilated area. Excessive heat or humidity can lead to resin degradation, and improper storage can result in bending or warping. When handling fiberglass sheets, take care to avoid any impact or pressure that could cause cracks or dents. Always store them flat and avoid stacking heavy objects on top of them, which can lead to deformation. If transporting or moving the sheets, ensure they are adequately supported and protected from any sharp edges or surfaces that could cause damage during the process.

Maintaining the Structural Integrity of Fiberglass Sheets

In addition to regular cleaning and inspection, maintaining the structural integrity of your discount fiberglass sheets involves ensuring that the resin remains intact. Over time, even fiberglass sheets can experience wear due to environmental factors, especially in areas subjected to physical stress. If damage such as cracking or chipping occurs, it’s important to repair the fiberglass promptly. Specialized fiberglass repair kits are available to restore damaged areas by filling in cracks and reapplying resin. Properly repaired sheets can continue to perform as expected, ensuring long-term durability and strength. Regular touch-ups and maintenance on the structural integrity of the fiberglass are especially important in high-demand applications where performance is critical.

Proper maintenance and care of discount fiberglass sheets are essential for prolonging their lifespan and ensuring optimal performance. Regular cleaning, careful inspection for damage, protection from harsh chemicals and environmental conditions, and proper storage are key factors in keeping fiberglass sheets in good condition. By following these maintenance practices, you can maximize the value and utility of your discount fiberglass sheets, ensuring they remain functional and visually appealing for many years to come.

Top FRP Cable Threading Pipe Suppliers You Should Know

FAQs about Discount Fiberglass Sheets

Fiberglass pricing can vary based on several factors, including the type, quality, and application. Generally, fiberglass is considered a cost-effective material, particularly when compared to alternatives like carbon fiber or metals. The affordability of fiberglass is one of its major advantages, making it accessible for various applications, from construction to automotive and marine uses. However, while the base material may be inexpensive, the overall cost can increase when factoring in installation, labor, and additional components required for specific projects. It’s essential to consider the long-term benefits of fiberglass, such as durability and low maintenance costs, which can offset the initial expenditure. For those looking for a balance between performance and budget, fiberglass often emerges as a favorable option.

The longevity of fiberglass sheets can vary depending on several factors, including environmental conditions, maintenance practices, and the specific type of fiberglass used. Generally, fiberglass sheets are known for their durability and resistance to various elements. Under optimal conditions, fiberglass sheets can last for decades, often ranging from 20 to 50 years. They are resistant to rot, decay, and many chemicals, making them suitable for use in demanding environments. Proper installation and regular maintenance can significantly enhance their lifespan. For example, keeping the sheets clean and addressing any minor damages promptly can prevent further deterioration. In applications like roofing or marine use, the expected lifespan might be affected by exposure to UV radiation, saltwater, or extreme temperatures, so it’s essential to consider these factors when evaluating durability.

When comparing the strength of fiberglass mat and fiberglass cloth, it’s important to note that they serve different purposes and have distinct characteristics. Fiberglass cloth is typically stronger than fiberglass mat due to its tighter weave and higher fiber content. This strength makes fiberglass cloth ideal for applications requiring structural integrity, such as in boat building and automotive parts. It provides excellent tensile strength and is suitable for reinforcement in high-stress areas. On the other hand, fiberglass mat is often used for its bulk and ability to conform to complex shapes. While it may not be as strong as fiberglass cloth, it offers good overall strength and is effective in applications like molds and surface layers. Ultimately, the choice between fiberglass mat and fiberglass cloth will depend on the specific requirements of the project, including desired strength, weight, and flexibility.

Yes, fiberglass is available in sheets, which are typically sold in various sizes and thicknesses, making it suitable for a wide range of applications. You can purchase fiberglass sheets from hardware stores, home improvement centers, and online retailers. The sheets may be made from woven fiberglass cloth that has been bonded together to form a flat, rigid surface. These sheets are commonly used in construction, automotive repairs, boat building, and DIY projects. When purchasing fiberglass sheets, you can choose from different grades depending on your needs, whether it’s for insulation, reinforcement, or durability. If you’re looking for discount fiberglass sheets, shopping around during sales events or checking online suppliers might help you find good deals. Be sure to check the dimensions and thickness to ensure they suit your project requirements.

The number of layers of fiberglass cloth you should use depends on the specific application and the level of strength or durability required. Typically, for lightweight repairs or small projects, one to two layers may be sufficient. However, for applications requiring additional strength or structural integrity, such as boat building or automotive repairs, three to four layers may be necessary. Each layer of fiberglass cloth should be thoroughly saturated with resin to bond the layers together. For larger surfaces, it’s advisable to add more layers to prevent flexing or cracking. Discount fiberglass sheets can often be purchased in bulk, allowing you to save on costs while ensuring you have enough material to apply multiple layers. Be sure to follow the manufacturer’s guidelines on recommended layer thicknesses for optimal results.

Fiberglass cloth itself is resistant to moisture, but it can absorb water if it’s not properly sealed with resin. When fiberglass is used in projects like boat building or roofing, it is usually coated with a resin that bonds the cloth fibers together and creates a waterproof barrier. If the cloth gets wet before the resin is applied or if there is damage to the resin layer, the fiberglass may absorb water and lose its structural integrity. Discount fiberglass sheets often come in large quantities and can be used for projects where exposure to moisture is a concern, but it’s crucial to ensure the resin is properly applied and cured. Wet fiberglass cloth can also be challenging to work with, so it’s essential to store it in dry conditions before use.

Yes, overlapping fiberglass cloth is common in many applications. When working with fiberglass cloth, it’s often necessary to overlap the edges of the sheets to ensure a strong bond and reinforce the surface. Overlapping creates additional layers of protection and can increase the strength and durability of the fiberglass structure. For larger projects, such as creating molds or repairing large surfaces, overlapping is essential to ensure even coverage. It is recommended to overlap by about 2 inches to avoid weak points and improve adhesion. However, the key to a successful overlap is ensuring the resin thoroughly soaks through both layers to create a seamless, strong bond. Discount fiberglass sheets often come in larger sizes, making it easier to overlap when covering big surfaces for your projects.

It’s generally not recommended to touch fiberglass cloth with your bare hands, as the fibers can irritate your skin. Fiberglass is made up of tiny, sharp particles that can easily penetrate the skin and cause itching, redness, and rashes. When working with fiberglass, it’s advisable to wear gloves, long sleeves, and safety glasses to protect yourself from the fibers. Some discount fiberglass sheets are sold as part of kits that include safety instructions, so it’s always a good idea to follow those guidelines. After cutting or handling fiberglass cloth, wash your hands and skin thoroughly with soap and water to remove any lingering fibers. If you happen to touch fiberglass, gently brush off the fibers with a cloth before they can cause irritation.

Fiberglass cloth does not go bad in the same way organic materials do, but it can degrade over time if exposed to extreme conditions. For example, if the fiberglass cloth is stored in a humid or wet environment, it can absorb moisture, which may affect its strength and ability to bond with resin. Discount fiberglass sheets, if not stored correctly, may become difficult to work with due to increased brittleness or difficulty achieving proper adhesion. Proper storage is essential to maintaining its effectiveness—keep fiberglass cloth in a dry, cool place, away from direct sunlight and moisture. Always check the condition of the cloth before use to ensure it has not deteriorated. Properly sealed and stored fiberglass cloth can last indefinitely, especially when not exposed to harsh elements.

Cutting fiberglass requires specific tools to ensure smooth edges and prevent damage to the material. Typically, fiberglass sheets are cut using a fine-toothed saw, utility knife, or rotary tool. When using a utility knife, it’s important to score the fiberglass repeatedly before snapping it along the cut line. If you’re using a saw, make sure it has fine teeth to avoid fraying the edges. Wearing protective gloves, goggles, and a dust mask is recommended to avoid skin irritation and respiratory issues, as cutting fiberglass produces fine particles. Discount fiberglass sheets, available in various sizes, can be cut to fit your specific project needs. After cutting, it’s also a good idea to smooth out the edges with sandpaper to remove any sharp points or strands.

Laying fiberglass sheets involves several key steps to ensure a strong, durable finish. Start by preparing the surface where the fiberglass will be applied, ensuring it’s clean, dry, and free of contaminants. Apply a layer of resin to the surface to act as a bonding agent. Then, cut your discount fiberglass sheets to the desired size, and lay them onto the resin-coated surface. Press the sheets down firmly to eliminate air bubbles, and ensure full contact between the cloth and resin. Apply additional resin over the top of the fiberglass cloth, using a brush or roller to saturate the cloth completely. Allow the resin to cure before adding more layers or finishing the surface. Proper handling and application are key to achieving a strong fiberglass bond.

The time you can wait between layers of fiberglass largely depends on the type of resin you’re using and the ambient temperature. In general, it’s important to apply the next layer while the resin is still tacky or “green,” but not fully cured. This allows the layers to bond together without the need for sanding. If too much time passes between layers, the surface may become too hard to achieve a strong bond, requiring sanding before applying additional layers. For most resins, you can wait anywhere from 30 minutes to a few hours between layers. Always follow the instructions provided with your discount fiberglass sheets and resin to determine the optimal waiting time for your specific project. Ensure each layer is fully cured before applying additional coats for the best results.

Fiberglass roof panels are highly durable and can last anywhere from 20 to 50 years, depending on factors like weather conditions, installation quality, and maintenance. Discount fiberglass sheets used for roofing applications are typically designed to withstand harsh environmental conditions such as extreme temperatures, UV exposure, and moisture. Over time, these panels may experience fading or minor wear, but they generally maintain their strength and functionality for decades. Proper installation, such as ensuring adequate sealing and ventilation, can extend the lifespan of fiberglass roof panels. Regular cleaning and inspections can also help prolong their durability, as debris and accumulated dirt may impact performance. Investing in quality discount fiberglass sheets can give you long-term savings without sacrificing durability.

Fiberglass Reinforced Plastic (FRP) sheets and polycarbonate sheets are both durable materials used for a variety of applications, but they differ in their composition and properties. FRP sheets are made by embedding fiberglass cloth into a plastic resin, providing high strength, impact resistance, and corrosion resistance. These sheets are often used in industrial and construction settings. Polycarbonate sheets, on the other hand, are made from a transparent thermoplastic material that is highly resistant to impact and UV radiation. Polycarbonate is more flexible and can be transparent, making it ideal for applications like skylights or protective barriers. Discount fiberglass sheets are generally more rigid and heavier compared to polycarbonate, which is often chosen for projects requiring light transmission or more flexibility. When looking for materials for structural reinforcement or long-lasting durability, discount FRP sheets can provide cost-effective solutions over polycarbonate.

Several materials are stronger than fiberglass, depending on the context of the strength required. Carbon fiber is often considered stronger than fiberglass, offering higher tensile strength, stiffness, and lighter weight. Carbon fiber is commonly used in aerospace, automotive, and sporting equipment where high strength-to-weight ratios are crucial. Aramid fibers, like Kevlar, are also stronger than fiberglass, with excellent impact resistance and durability, often used in bulletproof vests and high-performance applications. While fiberglass, including discount fiberglass sheets, is known for its strength and affordability, materials like carbon fiber and Kevlar excel in areas requiring extreme strength or flexibility. For most general construction, boat building, or industrial applications, fiberglass remains a reliable and cost-effective material choice. However, if ultimate strength is a priority, higher-end materials like carbon fiber may be more appropriate, albeit at a higher price point.

The strongest type of fiberglass is typically a high-performance variant known as “S-glass” (or Style S), which offers superior strength and impact resistance compared to standard E-glass. S-glass is made from a different chemical composition and features higher tensile strength and durability, making it ideal for high-stress applications like aerospace, automotive parts, and advanced manufacturing. Discount fiberglass sheets generally feature E-glass, which is the most commonly used fiberglass type. While E-glass is strong, cost-effective, and easy to work with, it doesn’t match the tensile strength of S-glass. If you’re seeking strong fiberglass for industrial or structural reinforcement projects, S-glass may be a better choice, though it typically comes at a higher price. Discount fiberglass sheets made from E-glass are still highly suitable for many applications where the highest strength isn’t essential, providing good performance at a lower cost.

Generally, fiberglass is cheaper than acrylic when comparing similar sheet sizes and thicknesses. Discount fiberglass sheets are widely available at lower costs than acrylic sheets, making fiberglass a more affordable option for construction, insulation, and reinforcement projects. Acrylic, while also a durable material with good optical clarity and weather resistance, typically comes at a higher price due to its more complex manufacturing process and its aesthetic appeal. Acrylic sheets are often used for applications where transparency and clarity are essential, such as windows, displays, or signage. Fiberglass, on the other hand, is preferred for structural applications where strength, durability, and low cost are prioritized. For those on a budget, discount fiberglass sheets offer a cost-effective solution for a variety of building and repair needs. However, for projects requiring clarity and visual appeal, acrylic might still be the better choice despite its higher cost.

In most cases, plexiglass (also known as acrylic) is cheaper than polycarbonate, making it the more budget-friendly option for many projects. Discount fiberglass sheets tend to be even more affordable than both plexiglass and polycarbonate when it comes to material costs for reinforcement and structural applications. While plexiglass offers a high degree of transparency and is easier to work with than polycarbonate, it tends to be more brittle and less impact-resistant. Polycarbonate, though more expensive, offers better durability, impact resistance, and temperature tolerance, making it ideal for high-stress environments such as safety barriers, eyewear, and roofing. The choice between plexiglass and polycarbonate depends on the balance of cost, strength, and transparency required. For structural reinforcement or non-transparent applications, discount fiberglass sheets are often more cost-effective than both, providing excellent durability and strength at a lower price point compared to polycarbonate or plexiglass.

Fiberglass cloth can typically withstand temperatures up to 1000°F (538°C) without degradation, making it a heat-resistant material. When used in applications like insulation, its high melting point ensures durability under extreme conditions. For those looking to purchase discount fiberglass sheets, it’s essential to ensure the heat resistance meets your project’s requirements, as lower-quality sheets may have a reduced threshold due to impurities or thinner fibers. Always check the product’s specifications for its thermal tolerance before buying at a discounted rate.

Fiberglass sheets vary in thickness based on their intended application, ranging from 0.03 inches (0.75 mm) for thin sheets to 0.5 inches (12.7 mm) or more for structural uses. When considering discount fiberglass sheets, ensure the thickness aligns with your project needs. Thinner sheets are ideal for flexible applications, while thicker sheets offer greater strength and durability. It’s advisable to confirm the precise dimensions, as discounted sheets might not meet standard tolerances.

A 2 oz fiberglass cloth typically has a thickness of about 0.0037 inches (0.094 mm). This lightweight cloth is ideal for applications requiring minimal weight addition, such as model building or light repairs. When shopping for discount fiberglass sheets, remember that thinner cloth offers less structural strength but is easier to handle and mold. Check for any irregularities in the weave, as discounted products may sometimes have minor defects.

A 4 oz fiberglass cloth is generally 0.0075 inches (0.19 mm) thick. This medium-weight fabric balances flexibility and strength, making it popular for laminating and repairs. When exploring discount fiberglass sheets, ensure the cloth’s consistency and weave integrity. While discounted options are cost-effective, variations in thickness or weave may occur, so inspect the product details to avoid compromises in performance.

Fiberglass is strong but not as strong as Kevlar. While fiberglass offers excellent tensile strength, Kevlar surpasses it in toughness, impact resistance, and weight-to-strength ratio. However, discount fiberglass sheets provide a cost-effective solution for many applications where extreme strength isn’t a primary concern. For general-purpose usage, fiberglass is sufficient, but Kevlar is better for high-performance needs like body armor or aerospace components.

Yes, fiberglass is an excellent material for roofing due to its durability, water resistance, and weatherproof properties. Discount fiberglass sheets are especially attractive for cost-effective roofing solutions, providing long-lasting protection without a significant investment. Ensure the sheets are UV-resistant and have a proper finish to prevent degradation over time. Fiberglass roofing panels are lightweight, easy to install, and ideal for residential and commercial projects.

Fiberglass sheets are highly fire-resistant but not entirely fireproof. They can endure high temperatures without combusting and are often treated to enhance their fire-retardant properties. For discount fiberglass sheets, verify that the product complies with fire safety standards. While cost-effective, some discounted materials may lack advanced treatments, making them less resistant to flames or heat exposure.

Fiberglass matting comes in various grades, including chopped strand mat (CSM), woven roving, and continuous filament mat. Each grade serves different applications, from general repairs to structural reinforcement. When selecting discount fiberglass sheets, consider the grade that suits your needs. Chopped strand mat, for example, is cost-effective and versatile but may lack the uniform strength of woven roving.

Carbon fiber is often considered superior to fiberglass due to its higher strength-to-weight ratio and stiffness. However, carbon fiber is significantly more expensive. For those on a budget, discount fiberglass sheets offer excellent performance and affordability for general use. If maximum performance isn’t required, fiberglass remains a practical choice for various applications, including insulation, repairs, and construction.

The best clothing for working with fiberglass insulation includes long-sleeved shirts, pants, gloves, and safety goggles to minimize skin and eye irritation. Choose tightly woven fabrics to prevent fiberglass particles from penetrating. When handling discount fiberglass sheets, the same precautions apply, as lower-priced products may shed more fibers due to less stringent manufacturing processes. Always wear a dust mask to protect against inhaling fine particles.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.