- Home

- Epoxy Fiberglass Sheet

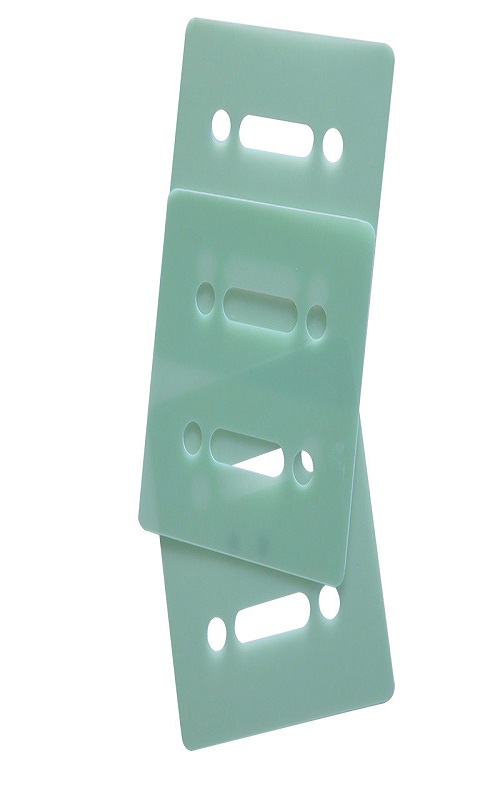

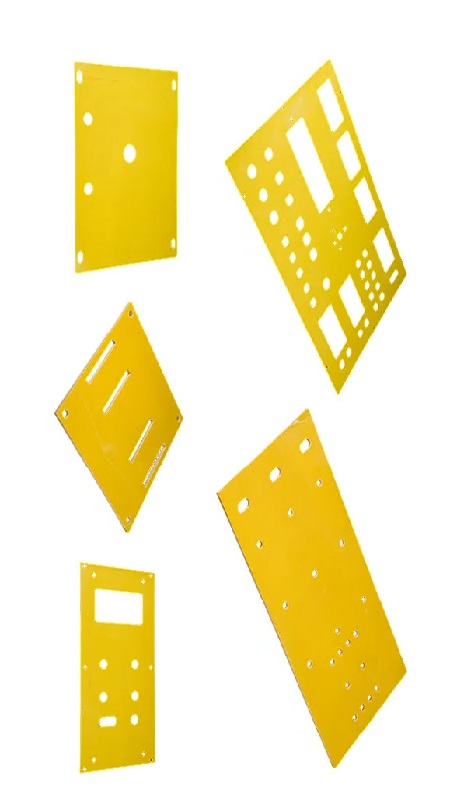

GangLong Durable Epoxy Fiberglass Sheet Materials Wholesale

GangLong epoxy fiberglass sheet has extremely high mechanical strength, good dielectric loss properties, and good electric strength properties. Epoxy Fiberglass Sheet is a high-strength laminate made from fiberglass prepreg reinforced with epoxy resin, autoclave-cured at high temperatures and pressures to achieve a strong, rigid form that retains its shape permanently. This process ensures flat, lightweight sheets with minimal voids or imperfections, making them suitable for a variety of fiberglass sheet uses, such as pattern templates, surface sheeting, or anywhere a flat, smooth Epoxy Fiberglass Sheet is needed. These uses extend across multiple industries, including aerospace, automotive, and electronics, where precision and durability are key.

Epoxy Fiberglass Sheet is versatile and all-around laminates, his material exhibits excellent dimensional stability, high mechanical strength, superior adhesive properties, and outstanding chemical resistance, effective both at room temperature and under humid or moist conditions.Their durability, resistance to heat, chemicals, and moisture, make them suitable for a wide range of applications including electrical insulation, mechanical components, and even specialty items in industries like aerospace and industrial manufacturing.

Simplifying Your Life: Key Functionalities

| Attribute | Details |

|---|---|

| Product Name | Epoxy Fiberglass Sheet |

| Place of Origin | Hebei, China |

| Brand Name | GangLong Fiberglass |

| Material | Fiberglass cloth, Epoxy resin |

| Type | Electrical Insulation Sheet |

| Application | High Voltage, Transformers, Motors, Electrical Insulation Protection |

| Rated Voltage | 600V to 35kV |

| Color Options | Customizable |

| Thickness Range | Customizable |

| Size Options | Customizable |

| High-Temperature Resistance | Excellent resistance to temperature fluctuations |

| Durability | High-quality fiberglass ensures long-lasting performance |

| Processing Service | Cutting, Custom Shapes |

| Standards | ISO9001, ISO14001, ROHS, NEMA, IEC |

| MOQ (Minimum Order Quantity) | 1 Piece |

News

- Exploring the Benefits of Carbon Fiber Apparel

- How to Work with Carbon Fiber Successfully

- Carbon Fiber Suit: The Future of Lightweight Armor

- Is Carbon Fiber Armor the Future of Protection?

- Why White Carbon Fiber is Popular in Automotive Design

- Transparent Carbon Fiber Sheets: Strength Meets Clarity in Design

- Chopped Carbon Fiber Mat for Lightweight Reinforcement

- Carbon Fiber EG Hatch: Upgrade Your Civic Today

- The Benefits of Using Structural Carbon Fibre in Engineering

- How Many Layers of Layered Carbon Fiber Are Needed?

What are Epoxy Fiberglass Sheets?

An Epoxy Fiberglass Sheet is a composite material that combines the strength and durability of fiberglass with the adhesive and protective properties of epoxy resin. These sheets are produced by laminating layers of fiberglass cloth with epoxy resin under high pressure and temperature, resulting in a solid, high-strength laminate. The manufacturing process ensures that each Epoxy Fiberglass Sheet is lightweight yet exceptionally strong, providing high mechanical performance in demanding environments. Key properties of these sheets include fire resistance, which makes them suitable for applications requiring safety against combustion, and excellent electrical insulation, which is crucial in the electronics and electrical industries. Additionally, the sheets exhibit superior chemical resistance, allowing them to withstand exposure to corrosive substances without degrading.

Common Sizes and Specifications

Epoxy Fiberglass Sheets are available in a variety of sizes to meet different application needs, with the 4×8 epoxy fiberglass sheet being one of the most commonly used. These sheets typically come in standard thicknesses ranging from 1/16 inch to 1 inch, although custom sizes and thicknesses can be manufactured to suit specific project requirements. The choice of thickness depends on the intended application, with thinner sheets often used for lightweight structural applications and thicker sheets preferred for heavy-duty uses where high strength is necessary. Additionally, these sheets are available in different grades, with FR4 being a popular choice due to its fire retardant properties and excellent electrical insulation. This variety in sizes and specifications makes the Epoxy Fiberglass Sheet a versatile option for a wide range of industrial and commercial applications.

Common Sizes

Epoxy fiberglass sheets are available in a variety of thicknesses and dimensions. The most common sizes are:

- Thickness: 0.2mm to 50mm (thicknesses above 10mm are less common and may require custom orders).

- Standard Sheet Sizes:

- 1000mm x 1200mm (39.4″ x 47.2″)

- 1220mm x 2440mm (48″ x 96″)

- 915mm x 1830mm (36″ x 72″)

- Larger sizes may be available depending on the supplier and specific requirements.

Specifications

Epoxy fiberglass sheets are manufactured according to several key specifications that define their mechanical and electrical properties. Some of the primary specifications include:

- UL94 V-0 Rating: Epoxy fiberglass sheets generally meet the UL94 V-0 standard, indicating that they are flame-retardant and self-extinguishing.

- Dielectric Strength: Typically, the dielectric strength of epoxy fiberglass sheets ranges from 30 to 80 kV/mm (kilovolts per millimeter), depending on the thickness.

- Temperature Resistance: These sheets can typically withstand temperatures up to 130°C (266°F) continuously, with some high-performance grades capable of handling even higher temperatures.

- Flexural Strength: The flexural strength of epoxy fiberglass sheets can range from 100 to 150 MPa, depending on the thickness and specific grade of the material.

- Tensile Strength: Tensile strength typically ranges from 200 to 600 MPa, depending on the grade and thickness of the material.

- Surface Resistance: Epoxy fiberglass sheets have excellent surface resistance and are highly effective as electrical insulators.

- Water Absorption: Low water absorption (usually less than 0.1%) ensures minimal impact on electrical properties even in humid conditions.

- Color: Standard epoxy fiberglass sheets are usually green or brown, although other colors can be produced upon request.

Epoxy Fiberglass Sheet Materials

Epoxy fiberglass sheets are composite materials consisting of a fiberglass reinforcement combined with an epoxy resin matrix. These materials are widely used in various industrial and electrical applications due to their excellent mechanical properties, electrical insulation capabilities, and resistance to heat and chemicals.

Composition of Epoxy Fiberglass Sheets

The fundamental materials used in epoxy fiberglass sheets are:

- Fiberglass Reinforcement (Glass Fiber):

- Glass Fiber: The core reinforcement material is woven glass fiber, which provides structural strength, flexibility, and impact resistance. The fiberglass is typically made from a type of glass called E-glass, which has high tensile strength and good thermal and electrical insulation properties.

- Types of Fiberglass: In some cases, other types of fiberglass, such as S-glass or E-glass, may be used depending on the strength requirements and application.

- Epoxy Resin (Epoxy Matrix):

- Epoxy Resin: The resin used to bind the fiberglass filaments together is epoxy, a thermosetting polymer known for its strong adhesive properties, high mechanical strength, and excellent resistance to heat, chemicals, and electrical current. Epoxy resins are created by polymerizing epoxide compounds with hardening agents (such as amines or anhydrides), forming a rigid and durable matrix.

- Advantages of Epoxy: Epoxy resins offer superior bonding, low shrinkage, and excellent dielectric properties. The high crosslinking density of epoxy resins also enhances the overall strength and performance of the material.

Types of Epoxy Fiberglass Sheets

Depending on the resin content, type of glass fiber, and curing process, various grades and types of epoxy fiberglass sheets can be produced:

FR4:

- Standard Grade: The most widely used grade of epoxy fiberglass sheet, FR4 is recognized for its flame-retardant properties, making it suitable for electronic and electrical applications. It is a standard material for printed circuit boards (PCBs) and electrical insulation.

- UL94 V-0 Rating: FR4 sheets typically meet the UL94 V-0 standard, which ensures that the material is flame-retardant and self-extinguishing.

FR5:

- Higher Temperature Resistance: FR5 is an upgraded version of FR4 with improved heat resistance, able to withstand higher continuous operating temperatures (up to 150°C or 302°F) without significant degradation.

- Applications: FR5 is used in applications where higher thermal performance is necessary, such as in high-power electrical components and more demanding environments.

G-10:

- Higher Mechanical Strength: G-10 is a grade of epoxy fiberglass material that offers excellent mechanical strength, rigidity, and electrical insulation. It is often used in applications requiring high strength-to-weight ratios.

- Applications: G-10 is commonly used for insulating mechanical components, switchgear, and electrical housings.

G-11:

- Enhanced Thermal Properties: G-11 is similar to G-10 but with enhanced thermal stability and higher resistance to heat. It is typically used in applications where higher mechanical strength and electrical insulation are needed at elevated temperatures.

- Applications: G-11 is used in demanding mechanical and electrical applications, such as electrical insulation for high-voltage systems.

Other Grades:

- CEM-1, CEM-3: These grades are commonly used for PCB manufacturing and have specific properties suited to different types of circuit boards, with CEM-1 offering a balance of strength and thermal performance, and CEM-3 providing a more cost-effective solution for certain applications.

- S-Glass Fiberglass: For applications that require very high mechanical strength and impact resistance, S-glass fiberglass may be used in conjunction with epoxy resins.

Applications of Epoxy Fiberglass Sheets

Epoxy fiberglass sheets are used in a wide range of industries due to their robust properties. Key applications include:

- Printed Circuit Boards (PCBs): The most common use for FR4 epoxy fiberglass sheets is in the manufacturing of PCBs. They are used as the base material for circuit boards in electronics such as computers, mobile phones, and consumer devices.

- Electrical Insulation: Epoxy fiberglass sheets provide electrical insulation for transformers, electric motors, capacitors, and other high-voltage electrical equipment.

- Structural Components: Due to their high mechanical strength, epoxy fiberglass sheets are used in mechanical applications such as support beams, electrical housings, and switchgear.

- Aerospace and Military: Epoxy fiberglass materials are used in aerospace, military, and automotive industries for components requiring both high strength and fire resistance.

- Marine Applications: In marine environments, epoxy fiberglass is used for boat construction, as it is highly resistant to water absorption and corrosion.

Environmental Considerations

- Recyclability: Epoxy fiberglass materials are difficult to recycle due to the combination of fiberglass and resin, which makes them more challenging to break down compared to pure plastics or metals.

- Environmental Impact: While epoxy fiberglass materials have a long lifespan and offer excellent performance, the production of epoxy resins and fiberglass involves the use of energy-intensive processes and non-renewable raw materials. Some industries are exploring more sustainable alternatives to reduce the environmental impact.

Epoxy fiberglass sheets are versatile materials with exceptional mechanical strength, electrical insulation properties, and heat resistance. These characteristics make them indispensable in many industries, especially electronics, electrical engineering, and aerospace. The different grades and types of epoxy fiberglass sheets, such as FR4, G-10, and G-11, offer tailored solutions for a wide range of applications, from printed circuit boards to industrial insulation and structural components.

Epoxy Fiberglass Sheet Technical Properties and Physical Properties

Epoxy fiberglass sheets, particularly in their most common grade (FR4), are known for their exceptional electrical insulation, mechanical strength, and resistance to heat and chemicals. These properties make them highly suitable for various applications, including printed circuit boards (PCBs), electrical insulation, structural components, and more. Below is a detailed description of the technical and physical properties of epoxy fiberglass sheets.

Technical Properties of Epoxy Fiberglass Sheets

These properties are related to the material’s behavior under specific conditions and are important for understanding the performance in various environments and applications.

Dielectric Properties (Electrical Insulation)

Dielectric Strength: The dielectric strength of epoxy fiberglass sheets measures their ability to withstand electrical stress without breaking down. It is typically between:

- 30 kV/mm to 80 kV/mm, depending on the grade and thickness of the material.

- This makes epoxy fiberglass highly suitable for insulating electrical and electronic components, such as PCBs, transformers, and other high-voltage equipment.

Dielectric Constant (Relative Permittivity): The dielectric constant is a measure of a material’s ability to store electrical energy in an electric field. For epoxy fiberglass sheets, the typical dielectric constant is:

- 4.0 to 4.5 at 1 MHz.

- This means epoxy fiberglass is a good insulator, although not as efficient as materials like Teflon.

Dissipation Factor: This property indicates how much energy is lost as heat when an electric field is applied. A lower dissipation factor is preferred for electrical insulation.

- Typically around 0.02 to 0.03 at 1 MHz, which is acceptable for most PCB applications.

Thermal Properties

Continuous Operating Temperature: Epoxy fiberglass sheets can withstand high temperatures due to the thermal stability of both the resin and fiberglass:

- FR4: Typically 130°C (266°F) continuous operating temperature.

- FR5 and G-11: Can handle temperatures up to 150°C (302°F) and higher in certain grades.

Thermal Conductivity: The thermal conductivity of epoxy fiberglass sheets is relatively low compared to metals, which means they do not dissipate heat quickly.

- Typically ranges between 0.2 to 0.3 W/m·K (watts per meter per Kelvin).

Thermal Expansion Coefficient: The coefficient of thermal expansion (CTE) is an important property in electronics, as it indicates how much the material will expand or contract with temperature fluctuations.

- Epoxy fiberglass sheets have a low CTE, typically around 25 to 50 ppm/°C (parts per million per degree Celsius).

Flame Retardancy

- UL94 Flammability Rating: Epoxy fiberglass sheets, especially those made from FR4 resin, generally meet the UL94 V-0 standard, which means they are self-extinguishing when exposed to flame for a short period.

- This flame-retardant property is crucial for electronics, electrical components, and structural uses in fire-sensitive environments.

Electrical Conductivity

- Surface Resistivity: Epoxy fiberglass sheets have excellent surface resistivity, making them non-conductive and highly effective as electrical insulators.

- Surface resistivity typically ranges from 10^12 to 10^14 ohms.

- Volume Resistivity: Epoxy fiberglass also exhibits high volume resistivity, preventing the flow of electrical current through the material.

- Typically between 10^14 to 10^16 ohm·cm, depending on the grade and resin content.

Physical Properties of Epoxy Fiberglass Sheets

These properties describe the material’s behavior under various mechanical, thermal, and environmental conditions.

Mechanical Strength

Tensile Strength: Tensile strength refers to the material’s ability to resist being pulled apart or deformed under stress.

- Epoxy fiberglass sheets have a tensile strength typically ranging from 200 MPa to 600 MPa (megapascals), depending on the specific grade (e.g., FR4, G-10, G-11).

- FR4: Around 250 MPa.

Flexural Strength: Flexural strength is the ability of the material to withstand bending without breaking.

- Epoxy fiberglass sheets typically have a flexural strength of 100 MPa to 150 MPa.

- FR4: Around 120 MPa.

Compressive Strength: Compressive strength is the material’s ability to resist being compressed or squashed.

- Epoxy fiberglass sheets typically have a compressive strength of around 300 to 500 MPa, depending on the grade.

Impact Resistance

- Izod Impact Strength: The Izod impact strength measures the material’s resistance to sudden impacts or shocks.

- Epoxy fiberglass sheets typically have an Izod impact strength of 5 to 10 J/m (joules per meter).

- Although not as high as metals, these sheets are still relatively impact-resistant and suitable for mechanical applications that require moderate strength.

Hardness

- Rockwell Hardness: The hardness of epoxy fiberglass sheets is usually measured using the Rockwell scale, which indicates the material’s resistance to indentation.

- Typically around HRB 80 to 90 (Rockwell B scale) for FR4 material, depending on the resin and fiberglass content.

Density and Weight

- Density: The density of epoxy fiberglass sheets determines how much mass the material has in a given volume, influencing its weight and handling.

- Typical density ranges from 1.8 to 2.0 g/cm³ (grams per cubic centimeter).

- This is relatively lightweight for a composite material, making it ideal for structural components where weight is a concern.

Water Absorption

- Water Absorption: One of the key advantages of epoxy fiberglass sheets is their low water absorption, which ensures that the material’s mechanical and electrical properties are not significantly degraded in humid or wet conditions.

- Typically less than 0.1% water absorption, which helps maintain the stability of electrical insulation properties.

Moisture Resistance

- Moisture Resistance: Epoxy fiberglass materials are resistant to moisture absorption, which is crucial in preventing the degradation of electrical and mechanical properties in high-humidity environments.

- FR4 typically maintains its integrity even in environments with high moisture content, ensuring consistent performance in damp or wet conditions.

Epoxy fiberglass sheets (e.g., FR4, G-10, G-11) offer a unique combination of high electrical insulation, mechanical strength, thermal resistance, and flame retardancy, making them essential in applications across electronics, electrical insulation, and mechanical components. Understanding these technical and physical properties helps engineers and designers choose the right material for specific needs, such as PCBs, transformers, motors, and structural parts in both general and demanding environments.

Epoxy Fiberglass Sheet Manufacturing Process

The manufacturing process of epoxy fiberglass sheets involves the combination of glass fiber reinforcement and epoxy resin through various steps to form a durable, high-performance composite material. The process typically includes the weaving of glass fiber, impregnation with epoxy resin, curing, and finishing. Below is a detailed overview of the steps involved in the manufacturing of epoxy fiberglass sheets, particularly for standard grades like FR4, G-10, and G-11.

Raw Materials

The key raw materials involved in the production of epoxy fiberglass sheets are:

Glass Fiber: Typically E-glass, which is woven into mats or cloths. Glass fibers provide the reinforcement to the sheet, giving it high strength and resistance to mechanical stress.

Epoxy Resin: A thermosetting resin that binds the glass fibers together. The epoxy resin is a polymer composed of epoxide groups that undergo a curing process when mixed with a hardener (curing agent), creating a solid, durable material.

Hardener: The curing agent that, when mixed with epoxy resin, causes the material to solidify. Common hardeners include amines or anhydrides.

Additives: Sometimes, additional chemicals or modifiers (such as flame retardants, fillers, or plasticizers) are added to adjust the properties of the finished sheet, such as improving fire resistance or modifying the flexibility and toughness.

Glass Fiber Weaving

- Weaving: The glass fiber is woven into a fabric or mat, which serves as the reinforcing material for the epoxy resin. The fibers are typically woven in a plain weave, twill weave, or other patterns, depending on the strength and flexibility required for the application.

- The glass fiber can be made into different forms, such as continuous filament or chopped strand mat (CSM), based on the requirements of the product.

- Mat or Cloth: After weaving, the fiberglass fabric can be either in the form of a woven cloth or a chopped strand mat (CSM). Woven fabrics are more common for standard grades like FR4, while mats are often used in certain applications that require bulk reinforcement.

Resin Impregnation (Saturation)

- Resin Impregnation: The woven or mat fiberglass is then impregnated with the liquid epoxy resin. This process is often performed by:

- Hand Lay-up: Fiberglass sheets are laid on a flat surface, and epoxy resin is applied manually or by spraying.

- Resin Transfer Molding (RTM): In this method, fiberglass is placed in a mold, and epoxy resin is forced into the fibers under pressure. This is a more automated process, ensuring uniform resin distribution.

- Filament Winding: In some cases, continuous filaments of glass fiber are wound onto a rotating mandrel and impregnated with epoxy resin.

- Saturation Process: The resin is carefully impregnated to ensure that all the glass fibers are completely coated. This ensures optimal bonding between the fibers and the resin. The amount of resin used depends on the specific grade and application requirements.

Curing Process

Curing: After the resin has been applied to the fiberglass, the material needs to undergo a curing process. This step is crucial because it transforms the resin from a liquid state into a hard, durable solid.

- Heat Curing: The impregnated fiberglass is placed in an oven or autoclave, where heat is applied to activate the curing agent (hardener) in the epoxy resin. This chemical reaction causes the resin to harden and form a strong, stable polymer network.

- The curing temperature and time vary depending on the type of resin used and the specific product grade. For instance, FR4 typically cures at around 120°C (248°F) for 1–2 hours.

- Some materials, like G-10, may require higher curing temperatures (around 150°C (302°F)) to achieve higher thermal resistance.

Curing Stages:

- Pre-cure: Initial curing that gives the sheet a tacky or semi-solid form.

- Full Cure: The final stage, where the epoxy fully hardens into a rigid material.

Pressing and Laminating (Optional)

In some cases, epoxy fiberglass sheets are laminated to increase thickness or to create multi-layer boards (e.g., for use in PCBs). Multiple layers of impregnated fiberglass fabric are stacked, and the resin is cured under heat and pressure to form a solid laminate.

Compression Molding: The impregnated fiberglass fabric is placed in a mold, and pressure is applied during the curing stage. This is often used in the production of thicker sheets or specific grades like G-11, which require higher mechanical strength and thermal stability.

Cooling and Solidification

After the curing process, the material is allowed to cool. Cooling should be done gradually to avoid warping or internal stresses in the material. This stage allows the epoxy resin to harden fully and stabilize the fiberglass sheet.

Post-Cure: In some cases, a post-curing step is performed, where the material is exposed to heat again (at a lower temperature) for a specific period. This step ensures that the epoxy resin achieves its maximum strength and thermal resistance.

Finishing and Cutting

Trimming and Cutting: After curing, the epoxy fiberglass sheet is removed from the curing press or oven, and it is trimmed to the desired size. Standard sheet sizes are typically 1000mm x 1200mm (39.4” x 47.2”) or 1220mm x 2440mm (48” x 96”), although custom sizes are also common.

Sanding and Surface Treatment: The edges of the sheet are sanded, and the surface may be treated or polished, depending on the intended use. The material may also be coated with a protective layer, such as a surface lacquer or protective film, to improve its appearance or environmental resistance.

Drilling and Machining: For applications that require specific shapes or holes (e.g., for use in printed circuit boards or mechanical parts), the material is drilled or routed using CNC machines. Epoxy fiberglass sheets can be easily cut, drilled, and shaped into components.

Quality Control

- Inspection and Testing: After manufacturing, the epoxy fiberglass sheets undergo a series of quality control tests to ensure they meet the desired mechanical, electrical, and thermal properties. Common tests include:

- Visual Inspection: Checking for defects, such as air bubbles or uneven resin distribution.

- Mechanical Testing: Tensile strength, flexural strength, and hardness tests.

- Electrical Testing: Dielectric strength, resistivity, and insulation resistance tests.

- Flame Retardancy Testing: Ensuring that the material meets UL94 V-0 or other flammability standards.

Packaging and Shipping

- Once the epoxy fiberglass sheets pass quality control, they are packaged and shipped to customers. Packaging may involve wrapping the sheets in protective film or paper to prevent damage during transit. Custom-sized sheets may also be bundled according to specific customer requirements.

The manufacturing of epoxy fiberglass sheets is a highly controlled and intricate process that combines the strength of glass fibers with the durability and electrical insulation properties of epoxy resin. This process results in a composite material that is widely used in applications ranging from printed circuit boards (PCBs) to structural components in electrical, aerospace, and industrial industries. Understanding each step of the process ensures high-quality, consistent production of epoxy fiberglass sheets for diverse and demanding applications.

Epoxy Fiberglass Sheet Price

GangLong Wholesale Epoxy Fiberglass Sheet Price

GangLong is synonymous with excellence in fiberglass sheet manufacturing, offering top-tier epoxy fiberglass sheets designed to meet diverse industrial and commercial needs. Known for their outstanding performance and reliability, GangLong epoxy fiberglass sheets are tailored to provide unmatched value while maintaining competitive pricing.

Uncompromising Quality at Affordable Prices

At GangLong, we believe that quality should never be sacrificed for affordability. Our epoxy fiberglass sheets are meticulously crafted using high-strength fiberglass fabric impregnated with premium epoxy resin. This ensures a superior product that offers:

- Durability: With exceptional resistance to environmental factors, GangLong fiberglass sheets maintain their structural integrity even under harsh conditions.

- Lightweight Strength: Despite being lightweight, our sheets deliver unparalleled strength, making them ideal for demanding applications.

- Versatility: Suitable for use in construction panels, insulation, protective covers, and various industrial applications.

Competitive Pricing for Wholesale Buyers

GangLong provides fair and competitive wholesale pricing, allowing our clients to access premium-quality epoxy fiberglass sheets at cost-effective rates. Whether you’re sourcing materials for large-scale construction projects or specialized industrial uses, our pricing structure is designed to deliver value for money.

The price of an Epoxy Fiberglass Sheet is influenced by several factors, each contributing to the overall cost. One of the primary factors is the quality of the epoxy resin used in the manufacturing process. Higher-grade resins, such as those with enhanced fire resistance or superior electrical insulating properties, tend to increase the cost of the sheet. Similarly, the fiberglass content plays a significant role; fiberglass sheets with higher fiberglass density offer greater strength and durability, but they also come at a higher price. The manufacturing process itself also impacts the price of an Epoxy Fiberglass Sheet. Advanced production techniques that ensure consistent quality and minimal defects may add to the cost, but they also result in a more reliable product. Additionally, the size and thickness of the sheet are crucial determinants of price. Larger and thicker sheets require more raw materials and longer production times, which naturally increases the cost. Custom-sized sheets, tailored to specific project needs, are generally more expensive than standard sizes due to the additional labor and material handling involved. This customization can be essential for specialized applications, but it’s important to weigh the benefits against the higher cost. For those looking to purchase a 4×8 epoxy fiberglass sheet, understanding the typical price range is essential for budgeting and planning. The cost of a standard 4×8 Epoxy Fiberglass Sheet can vary depending on the thickness and grade. For example, a thinner sheet (around 1/16 inch) might be priced between $50 to $100, while a thicker sheet (1 inch) could range from $200 to $400 or more, depending on the specific properties required, such as fire retardancy or enhanced electrical insulation. Market trends and regional availability can also influence the pricing of Epoxy Fiberglass Sheets. In regions with high demand or limited supply, prices may be higher. Additionally, fluctuations in the cost of raw materials, such as epoxy resin and fiberglass, can lead to price changes over time. Buyers should also consider additional costs such as shipping, especially for large or bulk orders, as these can significantly affect the final price. Understanding these factors can help you make informed purchasing decisions and select the right Epoxy Fiberglass Sheet for your needs while staying within budget.Factors Affecting Epoxy Fiberglass Sheet Price

Price Range for Popular Sizes

Epoxy Fiberglass Sheet Laminate

An epoxy fiberglass sheet laminate is a composite material that combines glass fiber with epoxy resin to create a durable, high-performance sheet. These laminates are valued for their exceptional mechanical strength, electrical insulation properties, and resistance to heat, moisture, and chemicals. They are widely used in industries such as electronics, aerospace, automotive, marine, and industrial equipment.

Structure of Epoxy Fiberglass Sheet Laminate

The structure of an epoxy fiberglass laminate consists of several layers of woven or non-woven fiberglass impregnated with epoxy resin. The layers are stacked together and then cured under heat and pressure to form a rigid, durable composite. The key components are:

Fiberglass: The reinforcement material, typically woven into cloth or mat form. It provides strength, stiffness, and electrical insulation properties to the laminate.

Epoxy Resin: The matrix material that binds the fiberglass layers together. Epoxy resin is a thermosetting polymer that hardens when mixed with a curing agent. It is known for its excellent adhesive properties, high mechanical strength, and resistance to heat, moisture, and chemicals.

Curing Agent (Hardener): The substance that triggers the curing reaction in the resin, causing it to solidify and form a durable, rigid laminate.

Properties of Epoxy Fiberglass Laminates

Epoxy fiberglass laminates are known for their excellent combination of physical, mechanical, and electrical properties, which make them suitable for a wide range of applications:

Tensile Strength: Epoxy fiberglass laminates have high tensile strength, typically ranging from 200 MPa to 600 MPa, depending on the grade. This makes them ideal for mechanical applications requiring high strength.

Flexural Strength: They exhibit good flexural strength, typically between 100 MPa to 150 MPa, allowing them to resist bending under stress.

Dielectric Strength: Epoxy fiberglass laminates offer excellent electrical insulation, with dielectric strength typically ranging from 30 kV/mm to 80 kV/mm. This makes them suitable for use in electrical insulation applications, such as printed circuit boards (PCBs) and transformers.

Thermal Resistance: The material can withstand elevated temperatures. For example, G-11 laminates can resist continuous temperatures up to 150°C (302°F), while G-10 and FR4 typically withstand 130°C (266°F).

Flammability: Many epoxy fiberglass laminates meet UL94 V-0 standards for flame retardancy, meaning they are self-extinguishing when exposed to flame, an important property for electrical and electronic applications.

Density: The density of epoxy fiberglass laminates is typically around 1.8 to 2.0 g/cm³, which is relatively lightweight compared to metals, making it suitable for applications where weight is a concern.

Moisture Absorption: These laminates have very low moisture absorption, usually less than 0.1%, which helps maintain their mechanical and electrical properties in humid environments.

Applications of Epoxy Fiberglass Laminates

Epoxy fiberglass laminates are used in a wide variety of applications due to their combination of strength, insulation properties, and heat resistance. Common uses include:

- Printed Circuit Boards (PCBs): The most common use for FR4 epoxy fiberglass laminate, providing a stable base for electrical components and circuit paths.

- Electrical Insulation: Used in transformers, motors, capacitors, and other electrical equipment for insulation and protection.

- Mechanical Components: Employed in switchgear, electrical housings, and structural components that require high strength and electrical resistance.

- Aerospace and Military: In high-performance applications where strength, lightweight, and resistance to heat and harsh environments are critical.

- Automotive and Marine: Used in applications such as insulating supports, electrical components, and heat-resistant parts.

- Industrial Equipment: Epoxy fiberglass laminates are used for components requiring durability, insulation, and mechanical strength in various industrial environments.

Epoxy fiberglass sheet laminates are essential materials in many high-performance applications due to their combination of strength, electrical insulation properties, and resistance to heat and chemicals. The process of weaving glass fibers, impregnating them with epoxy resin, curing the material, and finishing the laminate ensures that the final product meets the demanding requirements of industries such as electronics, electrical, aerospace, and automotive.

Thank you for your interest in our products. To receive our pricelist or for any inquiries, please fill out the form below. We will get back to you within 24 hours.

Applications of Epoxy Fiberglass Sheets

Industrial and Commercial Uses

An Epoxy Fiberglass Sheet is a versatile material widely used across various industries due to its unique combination of strength, durability, and electrical insulation properties. In the electronics industry, these sheets are commonly used as insulation panels, circuit board substrates, and protective barriers for sensitive electronic components, thanks to their excellent dielectric properties and resistance to high temperatures. The aerospace industry relies on Epoxy Fiberglass Sheets for structural components that demand lightweight materials without compromising on strength. These sheets are often used in interior panels, support structures, and protective coverings, where both fire resistance and mechanical integrity are critical.

In the automotive industry, Epoxy Fiberglass Sheets play a key role in manufacturing components that require high strength-to-weight ratios, such as battery enclosures, underbody shields, and structural reinforcements. Their ability to withstand harsh environmental conditions makes them ideal for use in vehicles exposed to extreme temperatures and corrosive substances.

Specifically, 4×8 epoxy fiberglass sheets are widely used in construction and manufacturing applications. In construction, they are utilized for wall panels, flooring, and roofing, where their fire retardant properties and structural stability offer significant safety and durability benefits. In manufacturing, these sheets are employed in creating molds, templates, and fixtures that require precise dimensions and consistent performance under mechanical stress.

Beyond standard industrial and commercial uses, Epoxy Fiberglass Sheets are also tailored for specialized applications where their properties can be fully leveraged to meet unique demands. In the marine industry, for example, these sheets are used in the construction of boat hulls, decks, and other components that require high resistance to water, salt, and chemicals. Their lightweight nature combined with high tensile strength ensures that marine vessels remain durable and efficient. In electrical systems, Epoxy Fiberglass Sheets are indispensable for creating insulating barriers and components in high-voltage environments. Their ability to maintain electrical insulation under extreme conditions makes them ideal for use in transformers, switchgear, and other critical electrical infrastructure. These sheets can also be customized with specific thicknesses, finishes, and grades to meet the stringent requirements of these high-performance environments. Epoxy Fiberglass Sheets are increasingly being used in renewable energy sectors, such as wind turbines, where they serve as protective layers and structural supports that must endure harsh weather conditions and mechanical loads. Their adaptability to various forms of customization, including size, shape, and material composition, makes them a valuable resource for engineers and designers working on innovative projects that push the boundaries of traditional materials.Specialized Applications

Considerations When Buying Epoxy Fiberglass Sheets

Important Factors to Consider

When purchasing an Epoxy Fiberglass Sheet, it’s essential to consider several critical factors to ensure that the material meets the specific needs of your project. One of the primary considerations is the load rating of the sheet. Depending on your application, the sheet may need to support significant weight or withstand high mechanical stress. It’s crucial to select a sheet with a load rating that aligns with these demands to avoid structural failures.

Electrical properties are another key factor, particularly if the Epoxy Fiberglass Sheet will be used in applications involving high voltage or sensitive electronic equipment. The sheet’s dielectric strength and insulation capabilities must be adequate to prevent electrical breakdowns and ensure safety.

Environmental resistance is also vital, especially if the sheet will be exposed to harsh conditions such as extreme temperatures, humidity, or corrosive chemicals. In such cases, selecting a sheet with high resistance to these factors will ensure long-term durability and performance. Additionally, you should consider the thickness and grade of the sheet. Thicker sheets generally offer greater strength and durability but may be more difficult to work with and more expensive. The grade of the epoxy resin used in the sheet also affects its performance, with higher grades providing better fire resistance, chemical resistance, and overall longevity.

Another important aspect is the temp rating for fiberglass sheets. If the sheet will be used in environments with fluctuating or extreme temperatures, it’s essential to choose a sheet that can handle the thermal demands without degrading or losing strength.

Ensuring Compliance with Industry Standards

Ensuring that your Epoxy Fiberglass Sheet complies with relevant industry standards is crucial for both safety and performance. These standards often dictate the minimum requirements for mechanical strength, electrical insulation, fire resistance, and environmental durability. Common standards include those set by organizations such as ASTM (American Society for Testing and Materials) and UL (Underwriters Laboratories), which certify materials for various industrial and safety applications.

When purchasing an Epoxy Fiberglass Sheet, it’s important to verify that the product meets these standards. Reputable suppliers will often provide documentation or certification to confirm compliance. If this information is not readily available, it’s advisable to request it or consider purchasing from a different supplier.

Additionally, another important consideration often overlooked is fiberglass sheets disposal. Once the material reaches the end of its life cycle, it’s essential to follow proper disposal procedures to avoid environmental harm. Some fiberglass materials may need to be disposed of at specific facilities or following guidelines to ensure compliance with environmental regulations.

Understanding the specific standards relevant to your industry can help you select the most appropriate material. For example, in the electronics industry, standards may focus on dielectric properties and flame retardancy, while in construction, load-bearing capacity and environmental resistance might be more critical. Ensuring compliance not only helps prevent potential legal and safety issues but also guarantees that the sheet will perform as expected in your application.

FAQs about Epoxy Fiberglass Sheets and Epoxy Resin

What is the difference between epoxy and fiberglass board?

Fiberglass board, on the other hand, is a rigid composite material made of fiberglass strands embedded in a resin matrix. It's used for insulation, structural reinforcement, and fireproofing, providing strength, heat resistance, and moisture resistance.

In short, epoxy is a liquid resin, while fiberglass board is a solid, pre-formed material, often used together in composite structures.

How long does epoxy fiberglass take to dry?

Will fiberglass resin harden without hardener?

Is epoxy fiberglass waterproof?

Why won't my fiberglass resin harden?

Insufficient hardener: If the correct amount of hardener is not mixed with the resin, it will not initiate the curing process.

Improper mixing: The resin and hardener must be thoroughly mixed. Uneven mixing can lead to patches of resin that remain sticky.

Temperature: Resin cures best in warm temperatures. If the temperature is too low, the curing process will slow down or halt altogether.

Expired materials: Resin or hardener that has passed its shelf life may not react properly, preventing the resin from hardening.

What happens if Fibreglass resin gets wet?

Incomplete curing: Water can interfere with the chemical curing process, leaving the resin soft or sticky.

Weak bond: The presence of moisture can weaken the bond between the resin and the fiberglass, compromising the structural integrity of the material.

Surface issues: Water exposure can cause surface imperfections such as cloudiness or air bubbles.

For industrial use, ensuring a dry environment during curing is essential for optimal performance.

How many coats of epoxy over fiberglass?

First coat: This acts as a primer, saturating the fiberglass.

Second coat: It helps build thickness and strength.

Third coat (optional): For extra durability, especially in marine applications, a third coat can be applied.

Each coat should be allowed to partially cure (still tacky) before applying the next layer for good adhesion.

What can l use to harden fiberglass resin?

How long does epoxy need to dry before rain?

How long before epoxy resin is cured?

How do you apply epoxy to fiberglass?

Surface Preparation: Clean the surface thoroughly to remove dust, oils, and debris.

Mixing the Epoxy: Mix the resin and hardener according to the manufacturer’s specifications, ensuring thorough mixing to avoid incomplete curing.

Apply the Epoxy: Use a roller or brush to apply a thin layer of epoxy to the fiberglass.

Lay Fiberglass Cloth: Apply the fiberglass cloth to the surface, pressing it into the wet epoxy.

Saturate the Cloth: Apply additional epoxy over the cloth, ensuring full saturation.

Repeat as Necessary: For strength, multiple layers may be applied, with each coat allowed to reach a tacky state before the next application.

How to dry resin with a hair dryer?

Set the hair dryer to a low heat setting.

Hold it at a distance from the resin to avoid blowing dust or bubbles into the surface.

Move it back and forth to evenly distribute heat.

Note: Overheating can cause the resin to cure unevenly or form air bubbles, which is why controlled heat sources like heat lamps are recommended for industrial applications.

How long does it take for 2 parts epoxy to cure?

Can you repair fiberglass with epoxy?

What will fiberglass resin not stick to?

Plastic: Many plastics, especially polyethylene and polypropylene, are non-stick to fiberglass resin.

Wax paper: It has a smooth surface coated with wax that prevents resin bonding.

PVA release agents: Used in mold-making to ensure the fiberglass does not adhere to the mold surface.

Teflon: The non-stick surface of Teflon prevents resin bonding.

Silicone: Silicone-based surfaces or sealants will not bond with fiberglass resin.

In industrial settings, these materials are often used as release agents to avoid adhesion during composite manufacturing.

Which epoxy is best for fiberglass?

Structural bonding: Ensures high strength for repairs.

Waterproof: Essential for marine applications.

UV-resistant: If the fiberglass will be exposed to sunlight.

Some high-performance industrial epoxies include bisphenol-A based epoxies for increased chemical resistance.

Can cracked fiberglass be repaired?

Clean and sand the cracked area.

Cut fiberglass cloth to fit the crack.

Apply epoxy resin to the crack, lay the fiberglass cloth over it, and saturate with additional resin.

Let it cure, then sand and finish as needed.

For industrial applications, stress-bearing areas may require additional reinforcement or layers of fiberglass.

How do you bond fiberglass to fiberglass?

Surface Preparation: Clean both surfaces and roughen them with sandpaper to remove contaminants and improve adhesion.

Epoxy Application: Mix epoxy resin with hardener and apply a thin layer to one or both surfaces.

Fiberglass Cloth: Lay fiberglass cloth over the resin and apply more resin to fully saturate the cloth.

Clamping or Weighting: Use clamps or weights to ensure even bonding during curing.

For industrial bonds, multiple layers of fiberglass and epoxy may be used for added strength.

Will fiberglass resin eventually cure?

Can you fix stress cracks in fiberglass?

Identify the cause: Address the underlying issue that caused the stress cracks, such as structural flexing or excessive load.

Surface Preparation: Sand the cracked area to remove damaged fiberglass and expose fresh material.

Fiberglass Patch: Apply epoxy resin and fiberglass cloth over the cracks to strengthen the area.

Finish: Sand and apply a finish coat to restore the surface.

Industrial repairs often involve multiple layers of fiberglass and epoxy to ensure the strength of the repaired area.

How do you prepare fiberglass for epoxy?

Cleaning: Remove any contaminants like dirt, oil, or grease using acetone or a similar solvent.

Sanding: Roughen the surface with coarse-grit sandpaper (80-120 grit) to ensure a strong bond with the epoxy.

Dust Removal: Clean off any dust or debris from sanding.

Drying: Ensure the surface is completely dry before applying the epoxy.

Proper preparation is crucial in industrial settings to ensure long-lasting adhesion and performance.

What is the difference between epoxy and fiberglass resin?

Fiberglass Resin (Polyester Resin): Cheaper and easier to work with, but has lower mechanical strength and water resistance than epoxy. It cures faster but is more brittle and prone to shrinking.

In industrial applications where strength, longevity, and waterproofing are critical, epoxy is typically the better choice.

How to repair damaged fiberglass?

Inspect the Damage: Assess the extent of the damage and determine whether it's surface-level or structural.

Cut Out the Damaged Area: Remove any loose or damaged fiberglass with a grinder.

Surface Preparation: Sand the surrounding area to ensure proper adhesion.

Apply Epoxy and Fiberglass Cloth: Lay fiberglass cloth over the damaged area, apply epoxy resin, and ensure full saturation.

Layering: Apply additional layers of fiberglass for structural repairs, allowing each layer to partially cure before applying the next.

Curing and Finishing: Allow the epoxy to fully cure, then sand and finish the repaired area.

For industrial applications, multiple layers of fiberglass and epoxy are often necessary to restore strength.

What is epoxy fiberglass sheet used for?

Electrical insulation: In the production of circuit boards and electrical components due to their non-conductive properties.

Structural components: In aerospace, automotive, and marine industries for lightweight, high-strength parts.

Heat resistance: In industrial equipment where high thermal stability is required.

Protective panels: As protective barriers in chemical processing plants due to their corrosion resistance.

These sheets offer a balance of mechanical strength, chemical resistance, and electrical insulation, making them versatile for demanding industrial environments.

Can you paint over epoxy resin?

What's better epoxy or fiberglass?

Epoxy: Offers superior bonding strength, chemical resistance, and waterproofing. It is used in high-performance applications where durability and long-term reliability are critical.

Fiberglass (polyester resin): Less expensive and easier to work with but offers lower strength and water resistance than epoxy. It is often used in applications where cost is a priority over strength.

For industrial and marine applications where strength, durability, and water resistance are important, epoxy is generally the better choice.

What does fiberglass resin stick to?

Wood: Commonly used for reinforcing or waterproofing wooden structures.

Fiberglass: Bonds easily to itself, making it useful for repair work.

Metal: Adheres to metals when properly prepared by sanding and cleaning.

Concrete: Fiberglass resin can bond to concrete for reinforcement and waterproofing purposes.

Epoxy: Can bond to cured epoxy surfaces if properly sanded and cleaned.

For industrial applications, surface preparation is crucial for achieving a strong bond with fiberglass resin.

Does Fibreglass resin dry clear?

Can you epoxy over plywood?

How deep does penetrating epoxy go?

How to apply epoxy to fiberglass?

Surface Preparation: Clean the fiberglass thoroughly and sand to ensure good adhesion.

Mixing: Mix the epoxy resin and hardener according to the manufacturer’s instructions.

Application: Use a brush or roller to apply a thin layer of epoxy to the fiberglass.

Fiberglass Cloth: Lay fiberglass cloth over the wet epoxy and use additional epoxy to fully saturate the cloth.

Layering: Apply additional layers of epoxy as needed, allowing each coat to reach a tacky state before adding the next.

For industrial applications, multiple layers of epoxy and fiberglass cloth are often applied to achieve the desired strength and waterproofing.

What is the difference between fiberglass and fiberglass resin?

Fiberglass Resin: Is the adhesive material, typically polyester or epoxy, used to bond the fiberglass cloth and form a hard, durable composite.

In industrial applications, the resin bonds the fiberglass into a rigid material that provides strength and durability, while the fiberglass itself adds structural reinforcement.

Can you waterproof plywood with fiberglass resin?

Which is stronger, fiberglass resin or epoxy?

What are the disadvantages of fiberglass resin?

Lower strength: Compared to epoxy, fiberglass resin is more brittle and prone to cracking under high stress.

Water resistance: It is not as waterproof as epoxy, which can lead to issues in marine or moist environments over time.

Shorter lifespan: Fiberglass resin tends to degrade faster than epoxy when exposed to harsh chemicals or UV light.

Odor: Polyester resin has a strong, unpleasant odor due to the presence of styrene.

Shrinkage: Fiberglass resin can shrink slightly as it cures, potentially causing stress or deformities in the finished part.

What is cheaper than epoxy?

ls epoxy fiberglass waterproof?

How long does fiberglass resin last?

Is epoxy resin stronger than Gorilla glue?

How can you tell the difference between epoxy and Fibreglass?

Fiberglass resin (polyester resin): Cures faster, has a characteristic strong odor, and is more brittle once cured. It often has a slightly amber color and is less resistant to water and chemicals than epoxy.

In industrial settings, epoxy is often used for higher-strength applications, while fiberglass resin is favored for cost-effective, large-scale projects.

Does fiberglass resin get hard?

What is fiberglass epoxy resin used for?

Boat and marine construction: For building and repairing hulls and other components.

Aerospace: In the construction of lightweight, high-strength components.

Automotive: For body panels, structural components, and reinforcements.

Industrial tanks and pipes: Where chemical resistance and waterproofing are essential.

It provides superior bonding and structural integrity compared to polyester resins.

What is better than epoxy resin?

Greater flexibility: It is less brittle and better suited for applications requiring impact resistance.

Faster curing time: Polyurethane cures more quickly than epoxy.

UV resistance: Polyurethane is generally more resistant to UV degradation, making it ideal for outdoor applications.

However, epoxy remains superior for applications requiring extreme strength and chemical resistance.

How strong are 5 layers of fiberglass?

With epoxy resin, 5 layers of fiberglass can create a highly durable composite material capable of withstanding significant loads and impacts. This is often used in structural components in boats, cars, and aerospace parts.

With polyester resin, the strength is lower, but it can still provide substantial reinforcement.

The thickness and density of the fiberglass layers also impact the overall strength. In general, 5 layers can handle medium to heavy loads, depending on the application.