Fiberglass sheet for table top applications has become a popular choice in modern furniture design due to its versatility and durability. This material is lightweight yet incredibly strong, making it ideal for supporting heavy loads while maintaining a sleek appearance. Fiberglass sheets can be easily molded into various shapes and sizes, allowing for unique and customized table designs. Additionally, they are resistant to water, stains, and heat, which makes them suitable for both indoor and outdoor use. With minimal maintenance, fiberglass sheet for table top surfaces can last for many years, offering an excellent balance of functionality and aesthetics for homes and commercial spaces alike. Fiberglass sheet for table top is durable, versatile, lightweight for easy cleaning, and customizable to fit various sizes, ideal for modern furniture.

Lifespan of Fiberglass Sheet for Table Top

Fiberglass sheet for table top surfaces is known for its impressive durability and long-lasting performance. With proper care, these table tops can last anywhere from 10 to 20 years or even longer. The lifespan depends on several factors, including the quality of the fiberglass material and the level of maintenance it receives.

Expected Lifespan with Proper Care

The typical lifespan of fiberglass sheet for table top applications ranges between 10 and 20 years. However, with high-quality materials and regular upkeep, some fiberglass table tops can exceed this range. Maintenance plays a critical role in preserving the appearance and functionality of the table top over time. Regular cleaning, along with the application of protective coatings, helps extend its lifespan.

Key factors that influence the lifespan include:

- Quality of materials: High-grade fiberglass lasts longer and performs better under stress.

- Level of maintenance: Routine cleaning and sealing can prevent scratches and damage.

- Environmental conditions: Indoor settings generally offer a longer lifespan, while outdoor use requires additional protection against the elements.

Importance of Quality Materials in Extending Durability

Choosing top-quality materials for your fiberglass sheet for table top is crucial to ensuring its durability. The higher the quality of the fiberglass, the better it will resist daily wear and tear, moisture, and heat. Cheaper materials may degrade faster, leading to cracks, discoloration, or warping.

Advantages of high-quality fiberglass sheet for table top:

- Durability: Resists impact and heavy use without cracking or breaking.

- Weather resistance: Perfect for outdoor use, as it handles moisture and sunlight better than other materials.

- Low maintenance: Quality fiberglass requires less frequent repairs or replacements, reducing long-term costs.

Disadvantages of low-quality fiberglass sheet for table top:

- Reduced lifespan: Cheap fiberglass sheet for table top may wear out faster and require early replacement.

- Greater risk of damage: Inferior materials are more prone to scratches, dents, and other surface damage.

- Higher maintenance needs: May require more frequent cleaning, sealing, or refinishing to maintain appearance.

Examples and Case Studies

Studies have shown that fiberglass sheet for table top surfaces, when made with premium materials and cared for properly, often outlast traditional wood and glass table tops. For example:

- Case Study 1: A fiberglass table used in a coastal outdoor environment lasted over 15 years with minimal signs of wear, thanks to regular application of UV-protective sealants.

- Case Study 2: In a high-traffic office setting, fiberglass sheet for table top surfaces remained scratch-free and retained their gloss after 12 years of consistent use and maintenance.

Fiberglass Sheets for Shower: Upgrade Your Bathroom Design

Factors That Influence the Lifespan of Fiberglass Sheet for Table Top

The longevity of a fiberglass sheet for table top depends on various factors that affect its performance over time. Understanding these factors can help you maintain the durability and functionality of the table top for years to come. Below are the key elements that play a significant role in determining the lifespan of fiberglass sheets used in table tops.

Quality of the Fiberglass Sheets

The quality of the fiberglass sheet for table top is the most crucial factor in its longevity. High-quality fiberglass is more resistant to damage, weathering, and daily wear, ensuring a longer service life. Low-quality fiberglass may degrade faster, making it prone to cracks and surface damage.

Key benefits of using high-quality fiberglass sheet for table top include:

- Higher strength: Resists impacts and heavy use without showing signs of damage.

- Improved resistance to moisture and UV rays: Ideal for both indoor and outdoor applications.

- Smoother surface finish: Less likely to chip or develop rough patches over time.

Drawbacks of low-quality fiberglass sheet for table top include:

- Shorter lifespan: Faster wear and tear, requiring earlier replacements.

- More maintenance: Low-quality sheets often need frequent repairs and refinishing to maintain their appearance.

Proper Installation Techniques for Long-Lasting Results

The installation process of fiberglass sheet for table top also plays a significant role in its durability. Improper installation can lead to uneven surfaces, warping, or even premature cracking. Following the correct techniques ensures that the sheet adheres well to the surface, providing a sturdy and durable finish.

Key factors to consider during installation:

- Surface preparation: Ensuring the table surface is clean and smooth before applying the fiberglass sheet is essential for proper bonding.

- Correct adhesive application: Using the appropriate adhesive or fastening method guarantees that the fiberglass sheet for table top remains securely attached.

- Expertise of the installer: A professional installation minimizes the risk of future damage and ensures a long-lasting result.

Improper installation can result in:

- Peeling and warping: Poor adhesion or inadequate surface preparation can lead to early damage.

- Weak spots: Incorrect installation may cause areas of the table top to become more susceptible to damage under stress.

Environmental and Usage Conditions that Impact Wear and Tear

The environment in which a fiberglass sheet for table top is used greatly influences its lifespan. While fiberglass is durable, factors such as temperature, humidity, and exposure to sunlight can affect its performance over time. Indoor use typically results in a longer lifespan, while outdoor environments present additional challenges.

Environmental factors impacting the durability of fiberglass sheet for table top:

- Exposure to UV rays: Continuous sunlight can cause fading or brittleness over time, especially if the fiberglass is not UV-protected.

- Moisture and humidity: Excess moisture can weaken the fiberglass, particularly in outdoor or coastal settings.

- Extreme temperatures: Sudden temperature changes can cause expansion and contraction, leading to cracks or warping.

Usage factors that affect the wear and tear of fiberglass sheet for table top:

- Frequency of use: Tables that are used frequently may experience more scratches or dents, requiring extra maintenance.

- Weight load: Heavy objects placed on the fiberglass sheet can cause surface damage if not handled carefully.

Examples of how environmental and usage factors affect fiberglass sheet for table top:

- Example 1: A fiberglass table used in a high-humidity outdoor environment showed signs of moisture damage after five years, despite initial protective coatings.

- Example 2: In a busy office space, a fiberglass sheet for table top lasted over 12 years with minimal damage, thanks to proper maintenance and a controlled indoor climate.

By understanding these factors, you can ensure that your fiberglass sheet for table top is well-protected and capable of lasting for many years.

How to Maintain a Fiberglass Sheet for Table Top

Maintaining a fiberglass sheet for table top properly ensures its longevity, aesthetic appeal, and performance over time. By incorporating regular cleaning, protective measures, and careful use, you can extend the life of your table top and keep it looking new. Below are essential maintenance practices to help preserve the condition of your fiberglass table top.

Regular Cleaning Practices to Prevent Surface Damage

Regular cleaning is crucial to prevent surface damage and maintain the glossy finish of a fiberglass sheet for table top. Dust, grime, and spills can accumulate over time, leading to scratches or dulling the surface if not addressed promptly.

Effective cleaning tips for fiberglass sheet for table top include:

- Use a soft cloth: Avoid abrasive materials that can scratch the surface. A microfiber cloth works best.

- Mild soap and water: Gentle cleaning agents help remove dirt without damaging the fiberglass. Avoid harsh chemicals.

- Rinse and dry thoroughly: After cleaning, rinse with clean water and dry the surface to prevent water spots or streaks.

Avoid:

- Abrasive cleaners: These can cause scratches and dull the surface.

- Harsh chemicals: Strong cleaning agents can weaken the fiberglass and lead to discoloration over time.

Application of Protective Sealants to Prolong the Lifespan

Applying a protective sealant is an excellent way to extend the lifespan of a fiberglass sheet for table top. Sealants create an additional barrier that protects against moisture, UV rays, and other environmental factors that can degrade the surface.

Benefits of using protective sealants for fiberglass sheet for table top:

- UV protection: Sealants with UV blockers help prevent fading or brittleness caused by prolonged sun exposure.

- Moisture resistance: Protects against water damage, especially in outdoor or high-humidity environments.

- Improved durability: Sealants strengthen the surface, reducing the risk of scratches and impact damage.

Recommended steps for applying sealants:

- Clean the surface: Ensure the fiberglass sheet for table top is free from dust and debris before applying the sealant.

- Apply evenly: Use a soft cloth or sponge to spread the sealant in thin, even layers.

- Reapply periodically: Depending on usage and environmental conditions, reseal every 6-12 months to maintain protection.

Tips for Avoiding Scratches and Other Forms of Damage During Daily Use

Preventing scratches and damage is key to preserving the appearance of a fiberglass sheet for table top. While fiberglass is a durable material, it can still be vulnerable to everyday wear and tear, especially in high-use environments.

Practical tips for avoiding damage:

- Use coasters and placemats: Protect the surface from hot or sharp objects that can cause scratches or heat damage.

- Avoid dragging heavy items: Lift items instead of dragging them across the surface to prevent gouges or scratches.

- Furniture pads: Place felt or rubber pads under objects, such as vases or decorative items, to prevent damage to the fiberglass surface.

Examples of damage prevention:

- Case Study 1: A fiberglass sheet for table top used in a busy office was kept scratch-free for over five years by regularly using coasters and placing protective pads under heavy items.

- Case Study 2: In a family kitchen, the use of placemats and monthly reapplication of a protective sealant helped maintain the glossy finish of a fiberglass sheet for table top for over a decade.

By following these maintenance practices, you can ensure that your fiberglass sheet for table top remains in excellent condition, providing long-lasting beauty and functionality.

Fiberglass Sheet for Table Top Price and Cost Considerations

When choosing a fiberglass sheet for table top, understanding the price range and what factors influence cost is essential. The price of fiberglass sheets varies based on several factors, including thickness, size, and quality. This section will explore these cost considerations in detail and provide a comparison with other materials commonly used for table tops.

Breakdown of Average Costs Based on Thickness and Size

The cost of fiberglass sheet for table top applications largely depends on the sheet’s thickness and size. Thicker and larger sheets are typically more expensive due to the additional materials required for production. For example, a 4×8 fiberglass sheet for table top is one of the most common sizes available and provides ample coverage for most standard table designs.

Average price ranges for fiberglass sheet for table top based on size and thickness:

- Thin sheets (1/8 inch): These are generally less expensive, with prices starting at a lower range. Suitable for lightweight and decorative applications.

- Medium thickness sheets (1/4 inch): Offers a balance between strength and cost, often priced in the mid-range. Ideal for tables requiring moderate durability.

- Thick sheets (1/2 inch or more): These thicker sheets provide superior strength but come with a higher price tag. Recommended for heavy-duty or high-traffic areas.

Common price points for a 4×8 fiberglass sheet for table top:

- 1/8 inch thick, 4×8 sheet: Generally falls in the lower price range, making it affordable for most DIY projects.

- 1/4 inch thick, 4×8 sheet: This is the most popular choice for table tops, with prices in the moderate range.

- 1/2 inch thick, 4×8 sheet: This option is more expensive but ideal for heavy-duty applications where durability is crucial.

Factors Influencing the Price of Fiberglass Sheets

Several factors contribute to the overall cost of a fiberglass sheet for table top, and understanding these can help you make an informed purchasing decision. The price is not just determined by the size and thickness but also by the quality of the fiberglass, the supplier, and additional treatments or coatings.

Key factors influencing the price of fiberglass sheet for table top include:

- Quality of the fiberglass: High-quality fiberglass, reinforced for extra durability, will be more expensive than lower-grade options.

- Size and thickness: Larger and thicker sheets naturally cost more, but they offer increased strength and longevity.

- Supplier: Prices can vary significantly between suppliers, so it’s essential to compare quotes to get the best value.

- Additional treatments: UV protection, anti-scratch coatings, and other specialized treatments can increase the cost but provide added value in terms of durability and maintenance.

Lightweight fiberglass sheets for cars – ideal for customization

Where to Find Fiberglass Sheet for Table Top Near Me

At GangLong Fiberglass, we understand that finding the right fiberglass sheet for table top projects can be challenging, especially if you’re looking for quality and affordability. Whether you’re sourcing locally or online, knowing where to look and how to make informed choices is crucial for your project’s success.

Tips for Sourcing Fiberglass Sheets Locally and Online

When searching for fiberglass sheet for table top near you, it’s essential to consider both local and online suppliers. Local stores offer the advantage of seeing and feeling the materials in person, while online suppliers often provide a broader selection and competitive pricing.

Here’s how we at GangLong Fiberglass recommend you go about it:

- Visit local hardware stores: Some may stock fiberglass sheets, though selection could be limited.

- Look for specialized fiberglass suppliers: Specialty stores often carry higher quality materials and offer more size and thickness options.

- Check online marketplaces: Online suppliers can give you access to more variety, custom options, and better prices. Be sure to review shipping costs for larger items like fiberglass sheet for table top.

How to Compare Suppliers to Get the Best Quality and Price

At GangLong Fiberglass, we always advise our clients to compare suppliers to ensure they get both quality and value for their investment. Comparing not only prices but also the supplier’s reputation and material quality is essential to making the right choice.

Consider these key factors when comparing suppliers for fiberglass sheet for table top:

- Material quality: Ensure the fiberglass sheets meet industry standards. High-quality sheets last longer and provide better performance.

- Supplier reputation: Look at reviews and ratings to gauge a supplier’s reliability. At GangLong Fiberglass, we pride ourselves on maintaining a high standard of customer satisfaction.

- Pricing and shipping costs: While some suppliers may offer lower upfront prices, consider hidden costs like shipping, especially for large items like 4×8 fiberglass sheet for table top.

- Customization options: Not all suppliers offer custom sizes, so check if your project requires specific dimensions.

Customizing Fiberglass Sheets to Fit Unique Table Designs

One of the biggest advantages of choosing fiberglass sheet for table top is its versatility and ease of customization. At GangLong Fiberglass, we provide a range of custom options to fit your unique table designs. Whether you need a specific size, shape, or finish, our fiberglass sheet specifications allow the sheets to be tailored to your exact requirements.

Benefits of customizing your fiberglass sheet for table top include:

- Perfect fit: Get the exact size for your table without the need for additional cutting or adjustments.

- Unique designs: Fiberglass allows for creative design options, including transparent finishes, colors, and texturing.

- Durability in any setting: Custom fiberglass sheets are ideal for outdoor or indoor use, ensuring that they withstand environmental factors while maintaining aesthetic appeal.

Examples of customization projects:

- Case Study 1: A client needed a fiberglass sheet for a large outdoor dining table. We customized a 4×8 fiberglass sheet for table top, ensuring UV protection and weather resistance.

- Case Study 2: A designer approached us for a sleek, minimalist coffee table. We provided a custom-cut transparent fiberglass sheet for table top, giving the table a modern aesthetic with added durability.

At GangLong Fiberglass, we’re here to help you find the best fiberglass sheet for table top near you, ensuring the perfect blend of quality, customization, and price for your project.

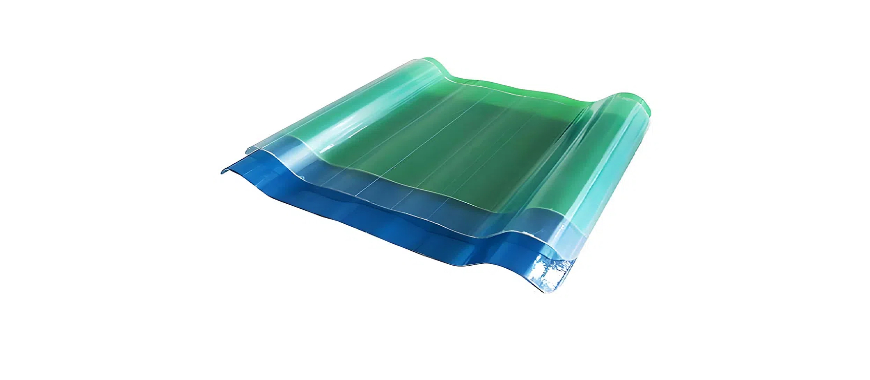

Transparent Fiber Sheet for Table

Transparent fiber sheet for table tops has gained popularity in modern furniture design due to its unique combination of visual appeal and durability. Unlike traditional opaque fiberglass, transparent sheets offer a sleek, contemporary look while retaining the core benefits of fiberglass materials. Whether you’re designing a coffee table or a dining surface, using a transparent fiber sheet for table applications can enhance the overall aesthetic without compromising strength.

Overview of Transparent Fiber Sheet for Table Applications

Transparent fiberglass sheet for table tops can be used in a variety of furniture designs, particularly where modern or minimalist aesthetics are desired. These sheets offer a glass-like appearance but with much higher durability, making them suitable for both residential and commercial spaces.

Common applications for transparent fiber sheet for table include:

- Coffee tables: Achieve a modern, clean look without the fragility of glass.

- Dining tables: A transparent surface can make small dining areas feel more open and airy.

- Outdoor tables: The material’s durability makes it resistant to environmental wear, ideal for outdoor furniture.

Benefits of Using Transparent Fiberglass for Table Tops

Choosing a transparent fiberglass sheet for table top provides several advantages over traditional materials like glass or wood. Its unique properties allow for creative designs without sacrificing functionality or longevity.

Key benefits of transparent fiberglass sheet for table top:

- Modern aesthetics: Transparent fiberglass mimics the look of glass while offering a lighter, more flexible material. Its sleek design is perfect for contemporary spaces.

- Durability: Unlike glass, transparent fiberglass is highly resistant to impacts, scratches, and weathering. This makes it ideal for high-traffic areas or outdoor use.

- Lightweight: Transparent fiberglass sheets are much lighter than glass, making transportation, installation, and movement easier without compromising on strength.

- UV resistance: With proper treatment, transparent fiberglass resists fading or yellowing from UV exposure, making it suitable for outdoor settings.

Possible drawbacks:

- Less clarity than glass: While transparent fiberglass is clear, it may not have the same level of optical clarity as tempered glass.

- Surface texture options: Some transparent fiberglass sheets may have a slight texture, which could affect the finish.

Cost Considerations for Transparent Fiberglass Sheet Versus Other Table Top Materials

When comparing the cost of transparent fiberglass sheet for table tops to other materials, it generally falls between glass and laminate. Although more expensive than standard fiberglass or laminate, transparent fiberglass offers better durability and long-term savings through reduced maintenance and replacements.

Factors influencing the cost of transparent fiberglass sheet for table top:

- Sheet thickness: Thicker transparent fiberglass sheets provide more strength, with options like high strength fiberglass sheets offering enhanced durability, though at a higher cost.

- Additional treatments: UV protection or scratch-resistant coatings can increase the price but enhance durability.

- Custom sizes: Custom-cut sheets may have a higher upfront cost, but they provide a perfect fit for unique designs.

Cost comparisons with other table top materials:

- Glass: Transparent fiberglass is typically more affordable than tempered glass, with the added benefit of being shatter-resistant.

- Laminate: While laminate is cheaper, it doesn’t offer the same modern aesthetic or durability as transparent fiberglass.

- Wood: Depending on the type, wood can be either more or less expensive, but it requires more maintenance over time than transparent fiberglass.

Examples of cost-effective uses:

- Case Study 1: A restaurant needed durable, modern-looking table tops. Transparent fiberglass sheets were chosen over glass, saving on replacement costs due to breakage.

- Case Study 2: In a small office, transparent fiberglass sheets were used to create sleek, open-design desks, providing a minimalist look at a lower cost than traditional glass.

By considering these factors, you can make an informed decision when selecting transparent fiberglass sheet for table top projects, balancing aesthetics, durability, and cost.

Top-rated fiberglass sheet repair kit for effective fixes

Benefits of 4×8 Fiberglass Sheet for Table Top

The 4×8 fiberglass sheet for table top applications is one of the most popular choices for those looking to cover larger surfaces efficiently. These sheets offer practical advantages in terms of size, installation, and customization, making them an ideal solution for various types of tables. Whether you’re working on a dining table, conference table, or outdoor furniture, 4×8 sheets provide the flexibility and coverage needed for seamless design and durability.

Why 4×8 Fiberglass Sheets Are a Popular Choice for Larger Table Surfaces

The 4×8 fiberglass sheet for table top surfaces is highly regarded for its ability to cover larger areas without the need for multiple pieces or seams. This standard size is perfect for projects that require more surface coverage, providing a clean, professional look that smaller sheets cannot achieve.

Key reasons why 4×8 fiberglass sheets are a popular choice:

- Ideal for large tables: Perfect for dining tables, workstations, and conference tables, reducing the need for joins or overlaps.

- Uniform appearance: One single sheet ensures a smooth, uninterrupted surface for a more polished look.

- Versatile for different spaces: Can be used indoors or outdoors, adapting to various environmental conditions while maintaining durability.

Practical Benefits of Using Larger Sheets for Seamless Installation and Minimal Cutting

Using a 4×8 fiberglass sheet for table top applications offers significant practical advantages, particularly in terms of ease of installation and reducing the need for excessive cutting. The larger size allows for fewer joins, resulting in a more seamless surface and less time spent adjusting or aligning smaller pieces.

Benefits of using 4×8 fiberglass sheets for table tops:

- Seamless installation: Larger sheets minimize the need for multiple sections, creating a smoother surface with fewer visible seams.

- Less cutting and waste: With a 4×8 sheet, the need for trimming or additional cuts is greatly reduced, leading to less material waste and a faster installation process.

- Stronger overall structure: Fewer seams and joins mean less opportunity for the table top to weaken over time, making it more structurally sound and longer-lasting.

Potential drawbacks of larger sheets:

- Handling: While ideal for large surfaces, the 4×8 fiberglass sheet for table top may be more challenging to handle due to its size. Proper support and care during installation are necessary.

- Storage space: Larger sheets require more storage space before installation, which might be a consideration for smaller workshops or DIY projects.

Cost and Availability of 4×8 Fiberglass Sheets

The cost and availability of 4×8 fiberglass sheets for table top surfaces can vary based on factors like material quality, supplier location, and any additional treatments such as UV protection or scratch resistance. However, these sheets generally offer good value for larger projects due to their size and the reduced need for additional materials or pieces.

Factors affecting the cost of 4×8 fiberglass sheet for table top:

- Quality of the fiberglass: Higher-quality sheets with enhanced durability or additional coatings may cost more but offer better longevity and performance.

- Customization: If custom sizes or treatments are needed, this may increase the overall cost.

- Supplier availability: Regional differences in supplier availability can influence pricing. Larger suppliers may offer competitive pricing due to economies of scale.

Cost comparisons with other sizes:

- Smaller sheets: While smaller sheets may initially seem cheaper, using multiple sheets for a large surface can increase the overall cost due to additional cutting, joins, and waste.

- Custom-cut sheets: Custom-cut 4×8 fiberglass sheets for table top can be more expensive upfront, but they save time and effort during installation and often lead to a more polished result.

Examples of cost-effective uses:

- Case Study 1: A large outdoor dining table was built using a single 4×8 fiberglass sheet for table top. The seamless installation reduced overall project time and resulted in a professional finish.

- Case Study 2: A conference table in a modern office was designed using a 4×8 fiberglass sheet for table top, offering a clean, durable surface that required minimal maintenance.

By choosing 4×8 fiberglass sheets for table top applications, you gain the benefits of a larger surface area, seamless installation, and cost efficiency, all while maintaining durability and aesthetic appeal.

The Best fiberglass sheet for table top

Fiberglass sheet for table top applications offers a unique blend of durability, aesthetics, and versatility, making it an excellent choice for various furniture designs. Whether you are crafting a custom dining table, a sleek coffee table, or an outdoor workstation, the benefits of fiberglass far outweigh those of traditional materials like wood, glass, or laminate.

Summary of the Key Benefits of Using Fiberglass Sheet for Table Top Applications

Fiberglass sheet for table top surfaces provides multiple advantages, from strength to visual appeal. Here’s a quick recap of its main benefits:

- Durability: Fiberglass sheets are resistant to scratches, impacts, and weather, making them ideal for high-traffic areas or outdoor use.

- Low maintenance: Fiberglass requires minimal upkeep compared to other materials, thanks to its resistance to stains, water, and fading.

- Aesthetic flexibility: Whether you prefer a transparent finish or a sleek modern look, fiberglass can be customized to suit various styles.

- Seamless design options: Larger sheets, such as 4×8, provide seamless coverage for large table surfaces, reducing the need for cutting and joins.

Importance of Choosing High-Quality Fiberglass Sheets for Longevity and Aesthetic Appeal

When investing in a fiberglass sheet for table top, it’s crucial to choose high-quality materials to ensure both longevity and aesthetic value. Low-grade fiberglass can lead to premature wear, discoloration, and surface damage, reducing the overall lifespan of your table top.

Why high-quality fiberglass matters:

- Longer lifespan: Premium fiberglass sheets can last for years, especially with proper maintenance.

- Better appearance: High-quality materials maintain their finish longer, resisting wear from daily use.

- Reduced maintenance costs: Investing in a superior fiberglass sheet means fewer repairs or replacements, saving money over time.

Final Tips on Maintenance, Care, and Customization Options for Fiberglass Table Tops

To keep your fiberglass sheet for table top in top condition, regular maintenance and careful usage are essential. Following these final tips will help preserve its look and function for many years:

- Regular cleaning: Wipe down the surface with a soft cloth and mild detergent to prevent buildup of dirt and grime.

- Protective sealants: Apply a UV-resistant or scratch-resistant coating to maintain the integrity of the surface, especially for outdoor tables.

- Use protective pads: Avoid dragging heavy objects across the surface, and use coasters or placemats to prevent accidental damage.

- Customization options: Fiberglass can be cut to fit specific table designs or treated with various finishes, offering endless design possibilities.

By choosing the right fiberglass sheet for table top and maintaining it well, you can enjoy the beauty and durability of your furniture for years to come.

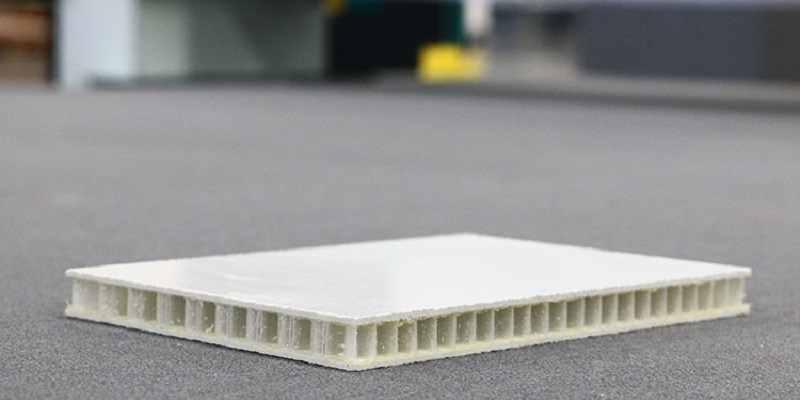

Corrugated Fiberglass Sheet for Table Top: A Durable and Aesthetic Choice

Corrugated fiberglass sheet is a practical and visually appealing material for creating fiberglass sheet for table tops. While traditionally used for roofing or wall cladding, its unique properties make it an excellent option for furniture design. These sheets are made by reinforcing fiberglass with resin, forming a durable and lightweight material. The corrugated design adds a textured profile that sets it apart from flat fiberglass sheets, making it a standout choice for modern and industrial-style table tops.

Unique Aesthetic Appeal

The corrugated pattern offers a bold, contemporary look that can transform ordinary tables into statement pieces. This texture can also be used creatively to play with light and shadow, adding depth and character to spaces.

Lightweight and Easy to Handle

Despite their robust construction, corrugated fiberglass sheets are lightweight, making them easy to cut, install, and reposition. This is especially beneficial in commercial settings where tables may need frequent rearrangement.

Exceptional Durability

Corrugated fiberglass is highly resistant to wear and tear. Its reinforced structure withstands scratches, impacts, and bending, ensuring a long lifespan for the table top.

Waterproof and UV Resistant

Fiberglass inherently resists moisture, making corrugated sheets ideal for both indoor and outdoor use. Their UV resistance ensures they maintain their color and integrity even under prolonged sun exposure.

Customizable and Versatile

Corrugated fiberglass sheets come in various colors, finishes, and thicknesses, allowing for a high degree of customization. Whether the table is intended for a minimalist office setting or an eclectic dining area, the material can be tailored to suit.

Low Maintenance

The smooth yet textured surface is easy to clean and resists stains, making it ideal for high-use areas like cafes, restaurants, or shared workspaces.

By incorporating corrugated fiberglass sheet into table top design, furniture makers and interior designers can combine style, functionality, and durability, offering a modern solution for diverse applications.

How to Choose a Reliable Fiberglass Sheet for Table Top Supplier

Selecting the right supplier for fiberglass sheet for table top applications is crucial to ensure quality, durability, and customization options.

Key Considerations to Guide Your Choice

Assess Product Quality

- Look for suppliers who use high-grade fiberglass reinforced plastic (FRP) for their sheets.

- Check for certifications such as ISO or other quality assurance standards.

- Request samples to evaluate the sheet’s finish, thickness, and durability.

Evaluate Customization Options

- Choose a supplier who offers a variety of colors, textures, and sizes to meet your specific design needs.

- Ensure they can provide pre-cut sheets or custom shapes for your table top dimensions.

Consider Pricing and Value

- Compare prices among suppliers but prioritize value over cost. A slightly higher price for superior durability and aesthetics is often worth it.

- Inquire about bulk discounts if purchasing for commercial applications.

Review Supplier Reputation

- Look for reviews, testimonials, or case studies to verify the supplier’s reliability and customer satisfaction.

- Check their experience in providing fiberglass sheets for furniture applications.

Check Delivery and Support Services

- Confirm the supplier’s ability to deliver within your timeline, especially for large-scale projects.

- Ensure they offer support services such as technical guidance or installation advice.

Sustainability Practices

- Opt for suppliers who use eco-friendly manufacturing processes, aligning with modern sustainability standards.

By carefully evaluating these factors, you can choose a fiberglass sheet for table top supplier who delivers high-quality materials tailored to your needs, ensuring long-term satisfaction and performance.

GangLong Fiberglass: Advantages as a Fiberglass Sheet for Table Top Supplier

GangLong Fiberglass stands out as a reliable supplier of fiberglass sheet for table top solutions, combining cutting-edge manufacturing capabilities with customer-focused service. Here are the key advantages of partnering with GangLong Fiberglass:

Expertise in Fiberglass Manufacturing

GangLong Fiberglass specializes in the production of high-performance fiberglass products, including fiberglass-reinforced plastic (FRP) materials. Leveraging years of expertise in the industry, the company delivers top-tier quality tailored to meet diverse requirements.

Customizable Solutions

With capabilities in R&D and design, GangLong Fiberglass offers tailored fiberglass sheets in various thicknesses, colors, and finishes. Whether you need a durable outdoor table top or a sleek indoor design, the company adapts its products to suit your specifications.

Superior Material Strength and Durability

GangLong Fiberglass sheets combine the rigidity of metal with the toughness of FRP, ensuring durability, resistance to wear, and long service life. This makes their products ideal for high-traffic commercial or industrial settings.

Corrosion and Aging Resistance

Their fiberglass sheets are designed to withstand corrosion, UV exposure, and environmental factors, ensuring lasting quality and minimal maintenance for both indoor and outdoor applications.

Experienced Technical Support

The company’s team of technical personnel provides hands-on guidance, from material selection to installation, ensuring your project is executed seamlessly. GangLong Fiberglass excels in building cable management systems and can extend its technical expertise to table top applications.

Innovative Management and Sustainability

GangLong Fiberglass employs innovative management practices and incorporates sustainability into its manufacturing process. This ensures eco-friendly production and adherence to modern environmental standards.

Proven Track Record and Customer Trust

With a reputation built on trust and quality, GangLong Fiberglass serves domestic and international clients, delivering products that meet stringent industry standards. Their long-standing relationships with customers highlight their commitment to excellence.

Partnering with GangLong Fiberglass means you benefit from a supplier that blends traditional craftsmanship with modern technology, delivering fiberglass sheet for table top solutions that are durable, versatile, and reliable.

Types of Fiberglass Sheet for Table Top Designs

Fiberglass sheet for table top designs offers versatility and functionality, catering to various needs and environments. Below are the types of fiberglass tabletops and their unique characteristics:

Outdoor Fiberglass Tabletops

Designed for patios, decks, and poolside areas, outdoor fiberglass tabletops are built to withstand harsh weather conditions. These tabletops resist fading under direct sunlight and are moisture- and mildew-resistant, making them ideal for rainy or humid environments. Lightweight yet durable, they are easy to rearrange, adapting seamlessly to different outdoor spaces.

Round Fiberglass Tabletops

Round fiberglass tabletops are perfect for intimate dining areas, bistros, or small kitchens. Their shape encourages interaction and conversation, making them great for social gatherings. Available in various sizes, these tables range from compact side tables to larger dining tables, ensuring a fit for any space and style.

Square Fiberglass Tabletops

Square fiberglass tabletops maximize corner spaces and are ideal for compact arrangements or placement against walls. They feature a stable, flat surface that is easy to clean, making them practical for environments prioritizing hygiene, such as cafes or healthcare facilities. These tabletops come in multiple sizes and styles to suit different functional and aesthetic needs.

Rectangular Fiberglass Tabletops

Rectangular fiberglass tabletops are the go-to choice for large gatherings or formal dining settings. Their elongated shape accommodates more people and is available in a variety of sizes to suit both casual and formal occasions. Additionally, these tabletops can save space by being placed against walls or corners when not in use.

Fiberglass sheet for table top designs provides practical solutions with stylish versatility, meeting the demands of various settings and preferences.

Features and Functions of Fiberglass Sheet for Table Top Designs

Fiberglass sheet for table top designs offers a combination of functionality, durability, and aesthetic versatility, making them an ideal choice for both residential and commercial use.

Here are their key features and functions:

Lightweight Construction

Fiberglass is a composite material made of glass fibers and a resin matrix, resulting in a lightweight yet sturdy tabletop. This makes fiberglass sheet for table tops easy to lift, reposition, or clean, even with larger sizes. Paired with a heavier base for stability, the tabletop remains easy to handle, offering unmatched convenience in transportation and rearrangement.

Exceptional Durability

Fiberglass is highly resistant to punctures, scratches, and impacts, maintaining its structural integrity under heavy use. It does not dent under the weight of heavy objects or when bumped, making it ideal for high-traffic areas like cafes, outdoor patios, or commercial dining spaces. This durability ensures long-term use without frequent repairs or replacements, even in demanding environments.

Heat Resistance

The resin coating on fiberglass sheet for table tops provides excellent heat resistance. Hot items like coffee cups, takeout containers, or restaurant utensils can be safely placed on the surface without causing scorching or bubbling. This feature is particularly beneficial in dining areas, ensuring the table top retains its appearance and functionality over time.

Weather Resistance

Fiberglass sheet for table tops is designed to withstand harsh environmental conditions. The material resists damage from water, UV rays, and extreme temperatures. Unlike wood, it does not rot or warp from moisture, and its UV-resistant resin prevents fading or weakening when exposed to direct sunlight. Fiberglass is also resistant to cracking under high temperatures, making it ideal for outdoor use in varying climates.

Low Maintenance and Long-Lasting

With its smooth surface and resistance to wear, fiberglass sheet for table tops requires minimal upkeep. Simple cleaning routines are sufficient to keep the tabletop looking new. The combination of durability and weather resistance ensures a long lifespan, even with regular use in challenging environments.

By combining lightweight handling, durability, heat resistance, and weatherproof properties, fiberglass sheet for table top designs deliver an ideal blend of practicality and style for modern furniture needs.

Applications of Fiberglass Sheet for Table Top Designs

Fiberglass sheet for table top designs is versatile and widely used across various settings, thanks to its durability, aesthetic appeal, and practicality. Here are the common applications:

Dining and Coffee Tables

Fiberglass sheet for table tops is an excellent choice for dining and coffee tables due to its durability and ease of maintenance. Its glossy finish enhances the table’s appearance, making it suitable for both formal dining rooms and casual settings. With a variety of colors and patterns, fiberglass blends seamlessly into diverse interior decor styles.

Picnic and Patio Tables

Fiberglass tabletops are ideal for outdoor use, such as picnic and patio tables. Their water-resistant properties prevent moisture absorption, reducing the risk of mold growth during rainy seasons. The smooth, non-porous surface resists stains and scratches, making them a practical and low-maintenance option for outdoor spaces.

Work Tables and Workbenches

Fiberglass tabletops are perfect for heavy-duty work tables and workbenches. Their robust construction withstands impacts and heavy loads without damage. Additionally, the non-porous surface is easy to clean, ensuring that dirt, spills, and dust can be wiped away effortlessly, making them ideal for workshops, garages, and industrial environments.

Craft and Hobby Tables

For craft and hobby tables, fiberglass sheet for table tops provides a smooth, scratch-resistant surface that facilitates creative activities. The durable material prevents damage from sharp tools like scissors or knives, while its bright colors and patterns inspire artistic endeavors, enhancing productivity and creativity.

Commercial Dining Tables

Fiberglass tabletops are a popular choice in commercial settings such as cafes, restaurants, and bars. Their easy-to-clean surfaces are perfect for high-traffic environments, and the ability to stack tables when not in use adds to their practicality. Customizable designs, including logo printing, make them a great tool for promoting brand identity in commercial spaces.

By catering to residential, outdoor, and commercial needs, fiberglass sheet for table top applications provide a versatile solution that meets the demands of various markets.

How to Choose the Perfect Fiberglass Sheet for Table Top

Selecting the right fiberglass sheet for table top requires careful consideration of various factors to meet consumer needs and preferences. Here’s a comprehensive guide to help business owners make informed choices:

Size and Shape

Fiberglass tabletops come in a variety of sizes and shapes to accommodate different spaces. Large rectangular or oval tabletops are ideal for customers looking to enhance spacious areas, while round or square tabletops suit compact spaces, maximizing functionality without compromising aesthetics.

Styles and Designs

Stocking a diverse range of styles and designs ensures appeal to a broad audience. Modern designs with sleek, minimalist aesthetics cater to contemporary tastes, while ornate and textured styles attract those with traditional preferences. Unique and bold patterns can satisfy customers looking for standout, eye-catching designs.

Durability

Durability is a key factor for customers. Choose fiberglass sheet for table tops from reputable manufacturers that offer high-quality resin finishes and reinforced edges. These features ensure long-lasting products that withstand daily use, making them ideal for high-traffic or outdoor settings.

Ease of Maintenance

The low-maintenance nature of fiberglass table tops is a significant selling point. Select options that can be cleaned effortlessly with mild soap and water, providing customers with convenience and value.

UV Resistance

For customers intending to use tables outdoors, UV resistance is essential. UV-resistant fiberglass table tops prevent fading and deterioration from prolonged sunlight exposure, making them ideal for patios, decks, and other sunny locations.

Lightweight Design

Lightweight fiberglass sheet for table tops is easy to transport and rearrange, making them a practical choice for consumers who frequently move or relocate furniture. Business owners should consider weight as a factor when selecting inventory, as this feature enhances usability and versatility.

By evaluating these aspects, business owners can confidently select fiberglass sheet for table top options that cater to diverse customer needs, ensuring satisfaction and long-term usability.

FAQs about Fiberglass Sheet for Table Top

Yes, fiberglass is an excellent material for table tops due to its durability, versatility, and low maintenance requirements. Fiberglass sheet for table top surfaces is resistant to scratches, impacts, and moisture, making it ideal for both indoor and outdoor applications. It also offers great design flexibility, as fiberglass can be molded into various shapes and sizes to fit different table styles. Additionally, fiberglass is lightweight compared to other materials like glass, which makes it easier to handle and install. This combination of strength and aesthetic appeal makes fiberglass a popular choice for modern table designs in homes and commercial spaces alike.

Fiberglass sheet for table top surfaces typically lasts between 10 to 20 years with proper care and maintenance. High-quality fiberglass sheets, especially those with protective coatings like UV or scratch resistance, can have an even longer lifespan. Regular cleaning and the occasional application of protective sealants help prolong its durability, ensuring that it retains its appearance and functionality over time. Factors like environmental conditions and usage frequency can also impact its longevity, but with proper upkeep, fiberglass table tops remain a reliable and long-lasting option for furniture.

Fiberglass panels are commonly referred to by several names depending on their specific use, structure, or finish. They are often called fiberglass sheets, fiberglass reinforced panels (FRP), or simply fiberglass boards. In the context of furniture, a fiberglass sheet for table top purposes is usually what people mean when referring to this material. FRP is a term more commonly used in industrial or architectural contexts, while sheets and boards are used in everyday furniture making or DIY projects. Despite the different names, these materials all share the same core properties of strength, durability, and versatility.

Yes, table top epoxy can be used on fiberglass surfaces to enhance both appearance and durability. Applying epoxy resin to a fiberglass sheet for table top purposes creates a smooth, glossy finish that is resistant to scratches and water. It also acts as a protective layer that seals the fiberglass, making it even more durable for everyday use. Epoxy is particularly useful if you want to create a high-shine, glass-like surface while maintaining the inherent strength of fiberglass. However, proper preparation of the fiberglass surface is essential to ensure the epoxy adheres well, resulting in a long-lasting and beautiful finish.

Fiberglass is an excellent material for table tops due to its strength, durability, and resistance to environmental factors. It provides a lightweight yet sturdy surface, making it ideal for both indoor and outdoor use. Fiberglass is resistant to water, UV rays, and stains, which ensures long-lasting performance in a variety of settings. Additionally, its smooth finish and customizable appearance allow for a variety of aesthetic options, including gloss, matte, or textured surfaces. For commercial spaces, fiberglass table tops are easy to clean and maintain, which is a significant advantage in high-traffic environments. While it may not provide the natural warmth of wood or the elegance of stone, fiberglass offers unmatched practicality, especially in environments where resilience is key. It’s also a cost-effective solution compared to other durable materials like stainless steel or granite. With proper care, fiberglass table tops can retain their appearance and functionality for many years.

Yes, fiberglass is readily available in sheet form and is widely used in various applications, including table tops. Fiberglass sheets come in different thicknesses, finishes, and sizes, allowing for customization based on specific needs. These sheets are typically composed of fiberglass reinforced plastic (FRP), which combines the strength of glass fibers with the versatility of a plastic resin. When buying fiberglass sheets for a table top, you can choose between flat sheets or textured ones, depending on the desired aesthetic and functional properties. Many manufacturers offer pre-cut sheets for specific dimensions, or you can purchase larger panels and trim them to size. Fiberglass sheets are available through building material suppliers, specialty hardware stores, and online retailers. Their versatility and relatively easy installation make them a popular choice for DIY projects or professional furniture manufacturing.

Fiberglass roof panels typically have a lifespan of 20 to 30 years, depending on the quality of the material and exposure to environmental factors. For table tops, the durability is even more pronounced since they are not subjected to constant UV exposure, extreme temperatures, or heavy impacts as roofing materials are. Fiberglass is inherently resistant to corrosion, rot, and pests, which contributes to its longevity in furniture applications. Over time, some fading or surface wear may occur, especially if the table top is used outdoors, but this can often be mitigated with UV-resistant coatings or proper maintenance. Regular cleaning and avoiding abrasive treatments can help fiberglass retain its structural integrity and aesthetic appeal for decades. The long-lasting nature of fiberglass is one reason it’s a preferred material for applications like table tops, where reliability and minimal upkeep are critical.

Fiberglass is moderately priced compared to other materials like wood, metal, or natural stone. Its cost largely depends on the type, thickness, and finish of the sheet you choose. While fiberglass is not the cheapest option, it offers an excellent balance of affordability and performance. For table tops, fiberglass sheets are more cost-effective than high-end materials like quartz or granite while providing superior durability compared to traditional wood or laminate. The price also reflects the material’s benefits, including its lightweight nature, resistance to wear, and ease of maintenance. Additionally, fiberglass has a long lifespan, which can offset its initial investment by reducing the need for replacements or repairs. For commercial settings where durability is critical, the slightly higher upfront cost of fiberglass is often justified by its longevity and low maintenance requirements.

When comparing fiberglass and polycarbonate for table tops, each material has distinct advantages. Fiberglass is better suited for applications requiring durability, lightweight construction, and a customizable finish. It is resistant to scratches, stains, and environmental factors, making it ideal for long-term use. Polycarbonate, on the other hand, is known for its impact resistance and transparency, often used in applications like windows or protective barriers. For table tops, fiberglass typically outperforms polycarbonate in terms of heat resistance, ease of maintenance, and design flexibility. Polycarbonate can scratch more easily and may require specialized coatings to maintain its clarity. While polycarbonate is slightly more expensive, its primary advantage is its shatter-resistant property, which may not be as relevant for a table top. Overall, fiberglass is the preferred choice for table tops due to its cost-effectiveness, durability, and versatility in both residential and commercial settings.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.