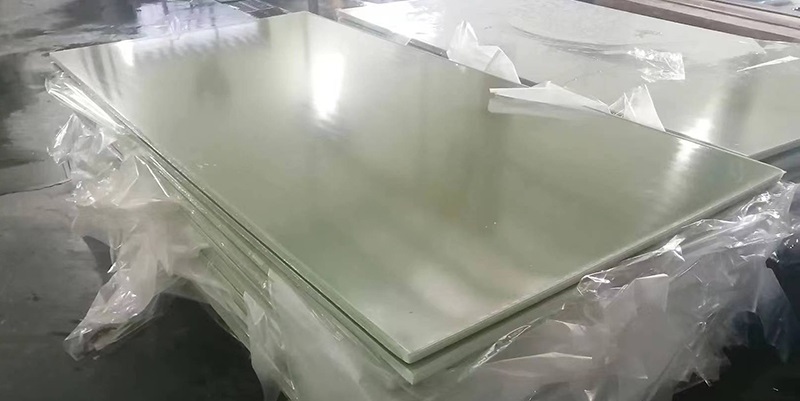

Fiberglass sheets are known for their low thermal conductivity, making them an excellent choice for reducing heat transfer in buildings. Typically measured in watts per meter-kelvin (w/mk), the fiberglass sheet thermal conductivity values demonstrate its efficiency in energy conservation. Compared to traditional materials, fiberglass sheets offer significant advantages due to their lightweight nature and strong insulating properties. As energy efficiency becomes increasingly important, understanding the thermal conductivity of fiberglass sheets helps builders and homeowners make informed decisions about insulation options. Epoxy fiberglass sheet, in particular, offer lower thermal conductivity compared to traditional materials, making them a valuable choice for effective insulation. By utilizing fiberglass sheets, one can enhance the overall thermal performance of structures while potentially reducing energy costs. Fiberglass sheet thermal conductivity (1–1.05 W/m·K) depends on fiber type and resin, offering lightweight, efficient heat transfer resistance.

The Key of Fiberglass Sheet Thermal Conductivity

The thermal conductivity of the glass fiber in the fiberglass insulation (ks) is about 1–1.05 W/(m K) and that of air at the room temperature (kg) is . 026 W/(m K). Thus, the ratio of the two, α is in the range of 38.5–40.4.

What is fiberglass sheet thermal conductivity? This property is fundamental to understanding how fiberglass sheets function as effective insulators. Fiberglass sheets are engineered to minimize heat transfer, making them ideal for a wide range of applications, including their use as fiberglass sheet for partition systems. These partitions are particularly effective in creating energy-efficient spaces by reducing heat flow between areas.

The thermal conductivity of fiberglass sheets is typically low, measured in watts per meter-kelvin (W/mK), which indicates their efficiency in resisting heat flow. This makes fiberglass sheets for partition an excellent choice in both residential and commercial settings where temperature control and insulation are priorities. By incorporating fiberglass sheet partitions, structures can achieve better energy efficiency, reduce utility costs, and maintain comfortable interior environments.

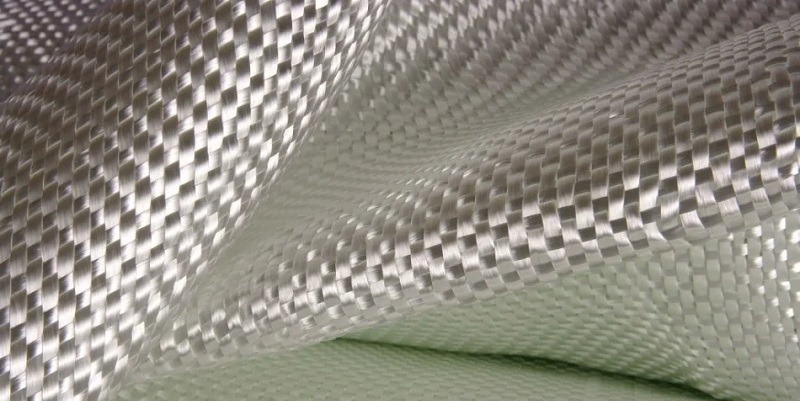

The key to fiberglass sheet thermal conductivity lies in its structure. The arrangement of glass fibers within the resin matrix creates air pockets that contribute to the insulation properties of the material. These air pockets act as barriers to heat flow, reducing the rate at which heat is transferred through the fiberglass sheets. This is often referred to as the fiberglass sheet rate of thermal conductivity, where a lower rate indicates better insulation performance.

When selecting fiberglass sheets for thermal insulation, it is important to consider the specific requirements of the application. For instance, fiberglass sheets used in high-temperature environments may require different formulations or thicknesses to maintain their effectiveness. Understanding parameters such as the fiberglass sheet rate of thermal conductivity can help in choosing the right type of fiberglass sheet for a given project.

Thermal Conductivity Measurement

Thermal conductivity is a measure of a material’s ability to conduct heat. For fiberglass sheets, the lower the thermal conductivity value, the better the material insulates against temperature fluctuations. This measurement is crucial for architects and builders when selecting insulation materials. The fiberglass sheet thermal conductivity plays a significant role in determining the overall energy performance of a building.

Importance in Construction

Fiberglass sheets are increasingly popular in modern construction due to their impressive thermal performance. The fiberglass sheet thermal conductivity allows these materials to effectively reduce energy loss, which is particularly beneficial in climates with extreme temperatures. As energy regulations become stricter, the need for efficient insulation materials has never been more critical. Using fiberglass sheets can lead to lower heating and cooling costs, making them a smart investment for property owners.

Applications in Insulation

Fiberglass sheets, including solid fiberglass sheets, are widely used in various insulation applications. The thermal conductivity of fiberglass sheets makes them suitable for insulating walls, roofs, and floors. Their lightweight nature allows for easy handling and installation, which can save both time and labor costs during construction. Furthermore, solid fiberglass sheets can be cut to fit any space, offering versatility in application. These features make fiberglass sheets, particularly solid fiberglass sheets, ideal for use in both new constructions and renovations.

Benefits of Fiberglass Composites

Fiberglass composites, which include fiberglass sheets, enhance the thermal insulation properties of buildings. The fiberglass sheet thermal conductivity is a key factor in achieving energy efficiency. Composites are engineered to combine the strengths of different materials, resulting in a product that not only insulates but also provides structural integrity. This is particularly beneficial in applications where strength and thermal performance are both required.

Environmental Considerations

The fiberglass sheet thermal conductivity also ties into environmental sustainability. As the world focuses on reducing carbon footprints, the use of fiberglass sheets can contribute to energy savings. Proper insulation minimizes the need for heating and cooling, leading to lower energy consumption. GangLong Fiberglass products are designed with these environmental considerations in mind, allowing builders to create energy-efficient structures.

Resistance to Moisture and Chemical Damage

Fiberglass sheets offer excellent resistance to moisture and chemical damage, which further enhances their suitability for insulation. Unlike some traditional insulation materials, fiberglass does not absorb water, which can lead to mold growth and decreased insulation performance. The fiberglass sheet thermal conductivity remains effective even in humid environments, making these materials a reliable choice for various applications.

Longevity and Durability

Durability is a key advantage of fiberglass sheets, and the fiberglass sheet melting point plays a crucial role in this. With a high melting point ranging from 1,000°F (537°C) to 1,500°F (815°C), fiberglass sheets can withstand extreme temperatures without compromising their structural integrity. This heat resistance, combined with their low thermal conductivity, ensures that fiberglass sheets maintain their insulating properties over time. Unlike other insulation materials that can sag or settle, fiberglass sheets retain their effectiveness, leading to lower maintenance costs and fewer replacements throughout the life of a building. This makes fiberglass sheets not only durable but also a cost-effective solution for long-term use in construction.

Compatibility with Other Materials

Fiberglass sheets are also compatible with various building materials. The fiberglass sheet thermal conductivity allows for easy integration into existing structures. Whether combined with wood, metal, or other insulation types, fiberglass sheets can enhance overall thermal performance. This adaptability makes them a favorite among builders and architects looking to create energy-efficient designs.

Performance in Extreme Conditions

In regions with extreme temperatures, the fiberglass sheet thermal conductivity proves its worth. These sheets perform admirably in both hot and cold climates, providing consistent insulation regardless of external conditions. This reliability is crucial for maintaining comfortable indoor environments while also reducing energy costs. The thermal performance of fiberglass sheets makes them an excellent choice for buildings located in areas with significant temperature variations.

Future Trends in Insulation

As technology advances, the fiberglass sheet thermal conductivity is expected to improve even further. Innovations in material science could lead to even lower thermal conductivity values, enhancing the already impressive insulating properties of fiberglass sheets. Builders and homeowners alike will benefit from these advancements, making fiberglass sheets an essential component of future construction practices.

Fiberglass Sheet Thermal Conductivity

Fiberglass sheets are widely recognized for their thermal properties, particularly their thermal conductivity. Understanding fiberglass sheet thermal conductivity is crucial for various applications, from construction to industrial uses. The thermal conductivity of a material indicates its ability to conduct heat, which can significantly impact the efficiency and performance of products that utilize these sheets.

What is Fiberglass Sheet Thermal Conductivity?

Fiberglass sheet thermal conductivity is primarily influenced by its composition and structure. Fiberglass is made from fine strands of glass fibers that are woven together and then combined with a resin. This combination results in a lightweight, strong material that exhibits excellent insulation properties. The thermal conductivity of fiberglass sheets typically falls within a certain range, making them suitable for insulation applications where heat retention or dissipation is crucial.

The thermal conductivity of fiberglass sheets can vary depending on factors such as density, resin type, and manufacturing process. Generally, fiberglass sheets have a low thermal conductivity value, which means they resist heat flow effectively. This property makes them ideal for use in environments where temperature regulation is essential, such as in construction materials for walls, roofs, and floors.

How about Factors Affecting Fiberglass Sheet Thermal Conductivity?

Several factors influence fiberglass sheet thermal conductivity, including the type of resin used, the density of the fiberglass, and the thickness of the sheets. Resin plays a critical role in defining the thermal properties of fiberglass sheets. Epoxy and polyester resins, for example, can offer different thermal performance characteristics.

The density of the fiberglass also significantly impacts thermal conductivity. Higher density fiberglass sheets tend to have lower thermal conductivity, as they contain more glass fibers and less air, which reduces the insulation capability. Conversely, lower density sheets may allow for higher thermal conductivity, making them less effective for insulation purposes.

Additionally, the thickness of the fiberglass sheets is a crucial consideration. Thicker sheets generally provide better insulation, as they create a more substantial barrier to heat transfer. Therefore, when designing a project that requires fiberglass sheets, it is vital to evaluate these factors to ensure optimal thermal performance.

Discover If Are Fiberglass Rods Used in Camping Chairs Cheap

The Key of Applications of Fiberglass Sheets Based on Thermal Conductivity

Applications of fiberglass sheets are diverse, and their thermal conductivity plays a significant role in determining their suitability for various tasks. In the construction industry, fiberglass sheets are commonly used in insulation panels for walls and roofs. For instance, fiberglass wall sheets are often installed in residential and commercial buildings to improve thermal performance, helping maintain comfortable indoor temperatures by reducing heat loss in winter and keeping interiors cooler in summer. Understanding the temp rating for fiberglass sheets is essential in selecting the right material for these applications, as it ensures the sheets can withstand varying temperature conditions without compromising their insulating properties.

In industrial applications, fiberglass sheets are frequently utilized in environments requiring temperature regulation. Fiberglass wall sheets, for example, are particularly effective in insulation for equipment housings, refrigeration units, and HVAC systems, where their ability to minimize heat transfer ensures greater energy efficiency. By leveraging the thermal properties of fiberglass sheets, businesses can achieve significant energy savings while maintaining optimal operational conditions.

Moreover, fiberglass sheets are increasingly being adopted in the automotive and aerospace industries. Their lightweight nature and exceptional thermal insulating properties make them a preferred choice for vehicle interiors or aircraft panels, reducing overall weight while maintaining performance. These applications contribute to enhanced fuel efficiency and support broader sustainability efforts.

How about Testing Thermal Conductivity of Fiberglass Sheets?

Testing the thermal conductivity of fiberglass sheets is a critical process to ensure that they meet the required specifications for various applications. The most common method for determining thermal conductivity is through standardized laboratory tests, which measure the rate of heat flow through the material and confirm adherence to fiberglass sheet specifications.

During testing, samples of fiberglass sheets are subjected to controlled temperature conditions. The thermal conductivity is calculated based on the temperature difference between the two surfaces of the sheet and the amount of heat transferred over a specific period. This data not only evaluates the insulation efficiency of the fiberglass sheets but also ensures they align with the stated fiberglass sheet specifications.

Manufacturers often conduct these tests to certify their products, ensuring they adhere to industry standards and meet the specifications needed for various uses. Clients seeking fiberglass sheets for specific applications should inquire about thermal conductivity testing results and verify that the products meet the required fiberglass sheet specifications for optimal performance.

The Key of Maintaining Thermal Efficiency in Fiberglass Sheets

Maintaining the thermal efficiency of fiberglass sheets involves proper installation and care. Incorrect installation can compromise the insulation properties of the sheets, leading to reduced thermal performance. It is crucial to follow recommended installation guidelines to ensure that the fiberglass sheets are placed correctly and securely.

Additionally, environmental factors can affect the thermal conductivity of fiberglass sheets over time. Exposure to moisture, extreme temperatures, and chemical substances may degrade the resin and glass fibers, impacting their insulating properties. Regular maintenance and inspection of fiberglass sheets can help identify potential issues and prolong their lifespan.

For optimal performance, it is advisable to keep fiberglass sheets clean and free from debris. Accumulated dirt or contaminants can hinder their ability to insulate effectively. By taking care of fiberglass sheets, users can maximize their thermal efficiency and ensure that they continue to perform as intended.

Innovative Uses: Can You Reshape Fiberglass Rods Effectively

How about Innovations in Fiberglass Sheet Thermal Conductivity?

The field of fiberglass materials is continuously evolving, with ongoing research aimed at enhancing thermal conductivity properties. Innovations in resin formulations, manufacturing techniques, and composite materials are being explored to improve the insulation capabilities of fiberglass sheets.

New developments may include the integration of advanced fibers or additives that enhance the thermal resistance of fiberglass sheets. These innovations can lead to products that provide superior insulation while maintaining lightweight characteristics. As technology advances, manufacturers like GangLong Fiberglass are likely to introduce products that leverage these improvements, offering customers enhanced performance and efficiency.

Additionally, the emphasis on sustainability is driving research into eco-friendly resin options that retain excellent thermal insulation properties. By focusing on sustainable materials and processes, the fiberglass industry can continue to meet growing environmental standards while providing high-performance insulation solutions.

How about Cost-Effectiveness of Fiberglass Sheets Based on Thermal Conductivity?

Cost-effectiveness is another crucial consideration regarding fiberglass sheet thermal conductivity. While the initial investment in fiberglass sheets may be higher than some other insulating materials, their long-term benefits often outweigh the costs. The energy savings achieved through effective thermal insulation can lead to substantial reductions in utility bills over time.

Moreover, fiberglass sheets typically have a longer lifespan than many traditional insulation materials. This durability means fewer replacements and maintenance costs, contributing to their overall cost-effectiveness. When evaluating insulation options, it is essential to consider both upfront costs and potential long-term savings.

Essential Tips on How to Fish Wire with Fiberglass Rods

Methods to Enhance Fiberglass Sheet Thermal Conductivity

Enhancing fiberglass sheet thermal conductivity is crucial for optimizing their performance in various applications. By adjusting material composition, fiber alignment, and manufacturing methods, significant improvements in heat transfer properties can be achieved. Below are the key strategies to enhance the thermal conductivity of fiberglass sheets.

Fiber Type and Orientation

- The type of glass fiber (continuous, chopped, or woven) and its orientation significantly impact thermal conductivity. Adjusting fiber alignment improves heat transfer characteristics.

Resin Type

- Choosing thermoset resins instead of thermoplastic resins enhances thermal performance, particularly at elevated temperatures.

Fiber Volume

- Increasing the volume of glass fibers within the composite can improve its thermal conductivity.

Fillers and Additives

- Incorporating fillers enhances thermal conductivity, crack resistance, and fire resistance, while additives improve durability, electrical properties, and thermal efficiency.

Manufacturing Methods

- Techniques like pultrusion, compression molding, resin transfer molding, and casting result in varying thermal properties based on the material’s structure.

Hybrid Composites

- Using hybrid materials, such as combining synthetic glass fibers with natural fibers like coconut shells, achieves lower thermal conductivity while maintaining strength and sustainability.

Improving the thermal conductivity of fiberglass sheets requires a multifaceted approach involving material selection, process optimization, and innovative hybrid designs. These strategies not only enhance the heat transfer capabilities of fiberglass sheets but also contribute to cost efficiency, sustainability, and improved overall performance.

Fiberglass Thermal Insulation Sheets

Fiberglass thermal insulation sheets are advanced materials designed to deliver superior thermal resistance in various applications. Manufactured from fine glass fibers, these sheets are lightweight yet highly efficient at reducing heat transfer. Their excellent insulating capabilities make them an essential choice in construction, manufacturing, and HVAC systems. With growing emphasis on energy efficiency, fiberglass thermal insulation sheets are a strategic investment that enhances comfort while reducing energy costs.

Types of Fiberglass Thermal Insulation Sheets

- Unfaced Fiberglass Sheets

- Lacking a vapor barrier, these are ideal for walls, roofs, and attics in moisture-free environments.

- Faced Fiberglass Sheets

- Equipped with a vapor barrier, these are perfect for areas prone to moisture, preventing condensation and mold.

- High-Density Fiberglass Sheets

- Suitable for industrial applications, offering higher compressive strength for durability under load.

- Acoustic Fiberglass Sheets

- Combining thermal insulation with sound attenuation, these are ideal for spaces requiring noise control.

Applications of Fiberglass Thermal Insulation Sheets

- Residential Construction: Enhance energy efficiency in walls, ceilings, and floors.

- Commercial Buildings: Insulate HVAC systems to minimize energy loss.

- Industrial Environments: Regulate temperatures in factories and warehouses.

- Automotive and Aerospace: Reduce heat transfer in critical components.

- Refrigeration and Cold Storage: Maintain temperatures for energy-sensitive products.

Features and Advantages

- Excellent Thermal Performance: High R-values for maximum energy savings.

- Fire Resistant: Non-combustible properties meet safety standards.

- Moisture Resistant: Faced options protect against humidity and condensation.

- Eco-Friendly: Made with recycled materials to support sustainability.

- Cost-Effective: Affordable with long-term energy savings, ensuring high value.

Fiberglass thermal insulation sheets provide a versatile and efficient solution for insulation needs, meeting a range of application demands while prioritizing safety, performance, and sustainability.

FAQs about Fiberglass Sheet Thermal Conductivity

Fiberglass is generally not considered a good thermal conductor. Instead, it is classified as an insulator, which means it resists the flow of heat. This property makes fiberglass an excellent choice for applications requiring thermal insulation, such as in building construction and automotive manufacturing. The effectiveness of fiberglass as an insulator is due to its structure, which contains numerous tiny air pockets. These air pockets significantly reduce heat transfer, making fiberglass an effective barrier against thermal conductivity. Therefore, if you’re looking for materials to enhance thermal efficiency in buildings or vehicles, fiberglass is a beneficial option. However, for applications requiring high thermal conductivity, other materials like metals are more appropriate.

The k value, or thermal conductivity value, for fiberglass typically ranges from 0.20 to 0.50 W/m·K, depending on the specific type and density of the fiberglass used. This value measures the material’s ability to conduct heat; lower values indicate better insulating properties. Fiberglass is often used in insulation products, where its relatively low k value is advantageous for reducing heat transfer and enhancing energy efficiency. Various factors, such as the manufacturing process, thickness, and specific formulation, can affect the k value of fiberglass. For precise applications, it is crucial to consult the manufacturer’s specifications to ensure that the chosen fiberglass meets the required thermal performance standards.

The thermal conductivity of fiberglass reinforced plastic (FRP) sheets typically ranges from 0.15 to 0.30 W/m·K. This range depends on the specific type of resin used in the composite, the fiberglass reinforcement, and the manufacturing process. Like fiberglass, FRP sheets are excellent insulators due to their low thermal conductivity values, making them suitable for various applications, including construction, automotive, and marine industries. The thermal insulating properties of FRP sheets help reduce heat transfer, contributing to energy efficiency in buildings and vehicles. When selecting FRP sheets for a project, it is essential to consider their thermal properties to ensure they meet specific insulation requirements.

The thermal conductivity (kk) of fiberglass insulation typically ranges from 0.035 to 0.045 W/m·K. This value indicates its effectiveness as a thermal insulator, as materials with lower kk-values are better at resisting heat flow. Fiberglass insulation owes its low thermal conductivity to its structure, composed of fine glass fibers interspersed with air pockets. These air pockets trap heat and reduce conduction and convection, making fiberglass ideal for applications like residential and commercial insulation. However, the exact value can vary depending on factors such as density, fiber orientation, and the specific manufacturing process. Fiberglass insulation’s thermal conductivity also changes slightly with temperature, but this variation is usually negligible under typical usage conditions. Its low kk-value makes it a preferred choice for energy efficiency in buildings, as it minimizes heat transfer and helps maintain stable indoor temperatures.

The thermal coefficient of fiberglass refers to its thermal expansion coefficient, which measures how much it expands or contracts with temperature changes. For fiberglass, this coefficient typically ranges between 5 × 10⁻⁶ to 10 × 10⁻⁶ per °C. This low thermal expansion coefficient is advantageous in applications requiring dimensional stability over a wide range of temperatures, such as in building materials, composite structures, and insulation panels. The low expansion rate ensures that fiberglass does not warp or deform significantly with fluctuating temperatures, which can help maintain the integrity of the structures it supports. Additionally, fiberglass’s stability under temperature variation complements its insulating properties, making it reliable for thermal control applications. Understanding its thermal expansion characteristics is crucial when fiberglass sheets are used in combination with other materials that may expand or contract at different rates.

The kk-value of fiberglass is another term for its thermal conductivity, which is typically around 0.035 to 0.045 W/m·K. This low kk-value underscores fiberglass’s high insulating capabilities, as materials with lower kk-values resist heat transfer more effectively. The kk-value depends on the density and configuration of the fiberglass material; denser configurations may have slightly higher kk-values due to reduced air pockets. For instance, fiberglass boards and sheets designed for structural applications might exhibit different thermal conductivity values than loose-fill fiberglass insulation. The kk-value plays a vital role in thermal engineering, as it determines the material’s efficiency in applications such as HVAC systems, building insulation, and industrial equipment. Choosing fiberglass with an appropriate kk-value ensures optimal thermal resistance and energy efficiency for the intended purpose.

Fiberglass does not “absorb” heat in the sense of retaining and conducting it efficiently; instead, it is designed to resist heat transfer. Its structure consists of fine glass fibers interspersed with air pockets, which are poor conductors of heat. This composition allows fiberglass to act as an excellent thermal insulator. Rather than absorbing heat, it slows down the movement of thermal energy through conduction, convection, and radiation. The trapped air within the material further enhances its insulating properties, making it effective in maintaining temperature stability. Fiberglass insulation is commonly used in walls, ceilings, and HVAC systems because it minimizes heat loss during winter and reduces heat gain during summer. While fiberglass may retain some heat briefly when exposed to high temperatures, its low thermal conductivity prevents significant heat absorption, making it ideal for applications requiring thermal resistance.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.