- Home

- Fiberglass Shell

GangLong Fiberglass Fiberglass Shell Factory

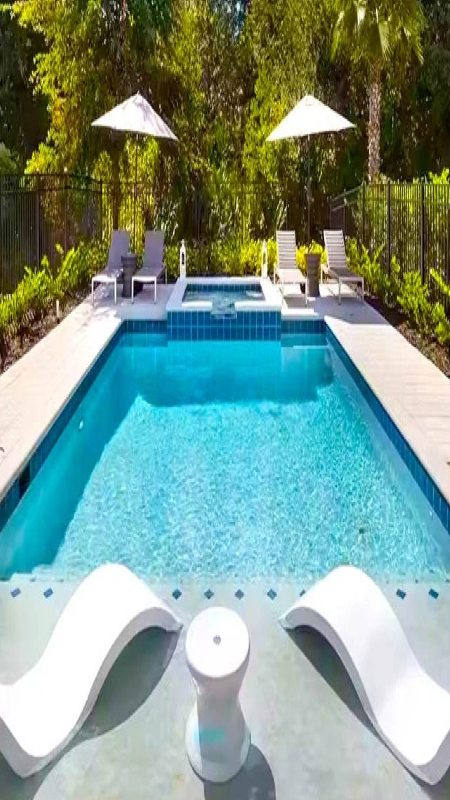

When selecting the perfect Fiberglass Shell for your inground pool, consider factors such as your backyard’s layout, your family’s lifestyle, and your aesthetic preferences. At GangLong Fiberglass, a variety of custom Fiberglass Shells are available, each customizable with options like inlaid tiles, tanning ledges, bubblers, and LED lights to enhance both the functionality and appearance of your pool. This allows the Fiberglass Shell not only to serve as a swimming facility but also to elevate the overall aesthetic of your home’s exterior.

The popularity of Fiberglass Shells among homeowners is due to their numerous benefits, including durability and minimal maintenance requirements. These shells resist common pool problems such as algae buildup and chemical wear, making them a superior choice for a long-lasting swimming pool solution. Additionally, the quick installation process of Fiberglass Shells means you can enjoy your new pool sooner.

For those facing renovations, a drop-in Fiberglass Shell is a convenient solution to modify an existing pool structure, especially when reducing its size or altering its shape. This method provides a straightforward way to upgrade without the extensive construction typically associated with traditional pool renovations. Fiberglass shells, known for their resistance to algae buildup and chemical wear, offer a durable, low-maintenance solution in various sizes, making them an ideal choice for both permanent pools and mobile homes.

Simplifying Your Life: Key Functionalities

| Attributes | Details |

|---|---|

| Place of Origin | Hebei, China |

| Brand Name | GangLong Fiberglass |

| Application | 100% Fiberglass Cloth, Silicone Coating |

| Technology | Silicone Coated Fiberglass Cloth |

| Surface treatment | Silicone Coating |

| Processing services | Molding, Welding, Cutting |

| Application | Indoor, Home, Garden |

| Technology | Manual/Molding |

| Model | Customizable |

| Surface treatment | Smooth |

| Color | Customized Color |

| Advantages | Compression/Corrosion/Fireproof |

| Shape | Customized Shape |

| Features | Fashionable |

| Quality | 100% Quality Assurance |

| Design | Welcome OEM |

| Shipping | Mainly by Sea |

News

- Exploring the Benefits of Carbon Fiber Apparel

- How to Work with Carbon Fiber Successfully

- Carbon Fiber Suit: The Future of Lightweight Armor

- Is Carbon Fiber Armor the Future of Protection?

- Why White Carbon Fiber is Popular in Automotive Design

- Transparent Carbon Fiber Sheets: Strength Meets Clarity in Design

- Chopped Carbon Fiber Mat for Lightweight Reinforcement

- Carbon Fiber EG Hatch: Upgrade Your Civic Today

- The Benefits of Using Structural Carbon Fibre in Engineering

- How Many Layers of Layered Carbon Fiber Are Needed?

What is a Fiberglass Shell?

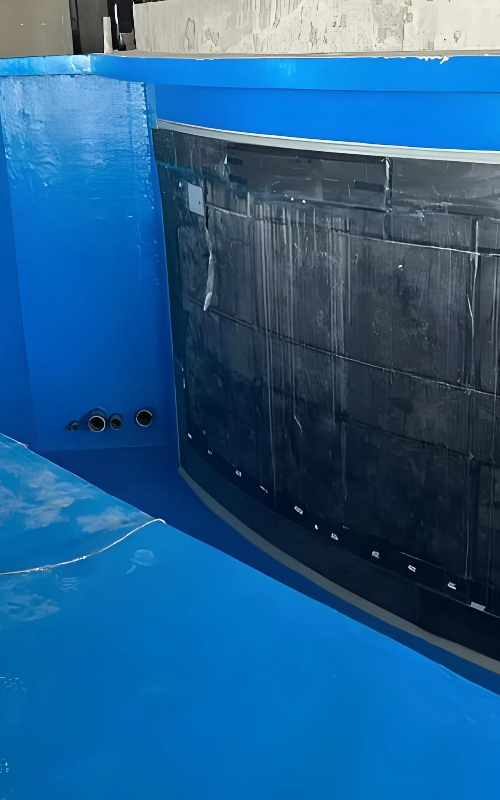

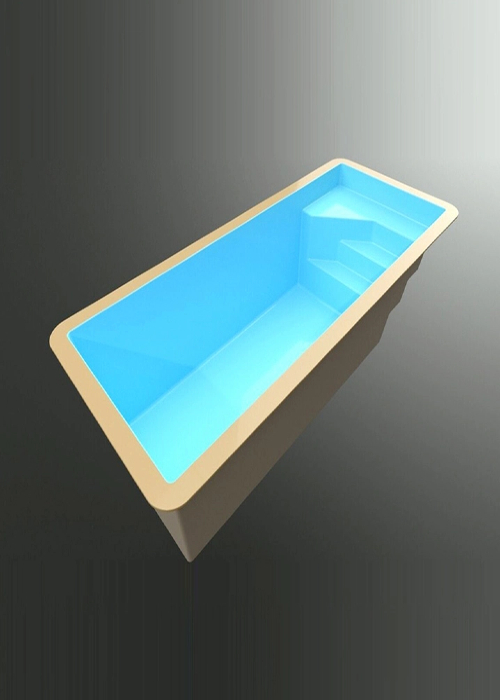

A Fiberglass Shell is a one-piece, pre-fabricated structure made from reinforced fiberglass materials, specifically designed to serve as the main body of an inground swimming pool. The manufacturing process of a Fiberglass Shell begins with the creation of a mold, which is used to shape the shell into various sizes and designs. Layers of fiberglass are then applied to this mold, with each layer contributing to the shell’s overall strength and durability. The final step involves coating the Fiberglass Shell with a protective gel coat that not only gives it a smooth finish but also adds to its resistance against the harsh chemicals commonly found in pool water.

Fiberglass shells are renowned for their resilience and ability to withstand extreme environmental conditions, making them a popular choice for homeowners seeking a long-lasting pool solution. Unlike traditional pool construction methods that involve concrete or vinyl liners, a Fiberglass Shell is less susceptible to cracking, algae growth, and other common issues, significantly reducing the need for maintenance. Additionally, the smooth surface of the Fiberglass Shell prevents scratches and abrasions, ensuring that it remains in pristine condition for many years.

The advantages of choosing a Fiberglass Shell over traditional pool construction materials are numerous. Besides being more durable, these shells are also quicker to install, often taking just a few days compared to weeks or even months required for concrete pools. This speed not only reduces labor costs but also allows homeowners to enjoy their new pool much sooner. Furthermore, the low maintenance requirements of a Fiberglass Shell make it a cost-effective option in the long run, as it requires fewer chemicals and less frequent cleaning than other types of pools.

Common Fiberglass Shell Pool Shapes and How to Choose the Right One

Fiberglass shell pools are available in a variety of shapes, each offering distinct benefits and aesthetics.

Common Fiberglass Shell Pool Shapes

Rectangular or Linear

The classic linear shape features clean, straight lines, making it a timeless choice for any pool area. Its simple design can be enhanced with accessories like waterfalls, spas, or lighting. This shape is ideal for those who prefer a straightforward, functional pool.

Freeform

A freeform pool offers dramatic curves or relaxed, wave-like shapes that maximize swimming space while creating a more casual, natural look. This is a great option for those seeking a unique, organic shape that blends well with landscaping and adds a sense of movement to the pool area.

Roman Inspired by the design of ancient Roman villas, the Roman pool shape combines two long straight sides with arched semicircles. It provides a timeless, elegant alternative to the rectangular pool while offering the same functionality and ample swimming space. Kidney-Shaped The kidney shape is sleek, modern, and asymmetrical, making it ideal for smaller spaces. Its unique design allows for a more creative, stylish pool without sacrificing functionality, perfect for homeowners with limited backyard space. When choosing a fiberglass shell pool shape, consider the size and layout of your backyard, as well as your personal style preferences. For larger spaces, a rectangular or Roman pool may be the best fit, providing plenty of room for swimming and entertainment. If you’re working with a smaller space, the kidney-shaped or freeform pool can offer a more compact yet still visually striking design. Think about how the pool will complement your landscape and the ambiance you wish to create—whether that’s a modern, natural, or classic aesthetic—and select the shape that suits both your space and lifestyle.How to Choose the Right Shape

Choosing the Right Fiberglass Shell Size and Shape

Selecting the correct size and shape for your fiberglass shell pool is crucial for maximizing enjoyment and ensuring the pool fits your space and needs.

Common Fiberglass Shell Pool Sizes

Small Pools:

Size Range: Typically 10-14 feet wide and 20-30 feet long.

Best For: Smaller backyards or homes with limited space. These pools are perfect for relaxation, lounging, or children to play. Popular shapes for small pools include kidney, freeform, and smaller rectangular models.

Medium Pools:

Size Range: Usually 14-18 feet wide and 30-40 feet long.

Best For: Families who want a pool large enough for swimming laps and entertaining guests but don’t have the space for an oversized pool. Medium-sized pools work well in most suburban yards. Linear and Roman shapes are popular at this size.

Large Pools:

Size Range: 18-20 feet wide and 40-45 feet long or more.

Best For: Larger properties where space isn’t a limiting factor. Large pools are perfect for lap swimming, diving, or hosting large gatherings. These pools are often rectangular or freeform, offering ample room for a variety of pool activities.

Start by measuring your backyard to determine the maximum size of pool you can comfortably install. Keep in mind that you will need space around the pool for decking, landscaping, and safety zones. Consider how you’ll use the pool. If you want to swim laps, a longer rectangular pool (30 feet or more) might be ideal. For families with children, a smaller, shallower pool may be better. If you plan to host gatherings, a larger pool with ample space for guests is a good choice. Larger pools require more maintenance, including cleaning and chemical balancing. Think about how much time you’re willing to spend on pool upkeep. Smaller pools generally require less effort and cost for maintenance. The shape of the pool can affect its visual appeal. Freeform pools are more flexible and can fit into irregular spaces, while linear and Roman pools offer a more formal, structured look. Choose the shape and size that complements your home’s design and landscaping. By considering your space, pool usage, and aesthetic goals, you can select the most suitable fiberglass shell size and shape to enjoy a perfect swimming experience.How to Choose the Right Pool Size

Available Space

Intended Use

Maintenance Considerations

Aesthetic Preferences

Fiberglass Shell for Sale: What to Look For

Inground Fiberglass Pool Shells for Sale

When searching for an inground Fiberglass Shell for sale, it’s important to understand the various types available to ensure you choose the best fit for your needs. Fiberglass Shells come in a wide range of sizes, shapes, and designs, from compact plunge pools to large family pools with integrated features like steps, tanning ledges, and seating areas. The selection process should start with determining the intended use of the pool—whether it’s for leisure, exercise, or a mix of both—so you can narrow down the options based on your specific requirements.

Pool size is a critical factor to consider when choosing a Fiberglass Shell. Smaller shells are ideal for compact spaces or for use as plunge pools, while larger shells offer more versatility and can accommodate various activities such as swimming, lounging, and entertaining. Shape is another key consideration; while rectangular shells are classic and great for lap swimming, freeform designs offer a more natural look and can blend seamlessly into landscaped environments.

It’s also essential to consider the depth of the Fiberglass Shell, especially if the pool will be used by children or for activities that require varying water levels. Additionally, many Fiberglass Shells offer customization options, allowing you to add features like built-in spas, water features, or specialized coatings that enhance durability and appearance.

If you’re looking for a reliable manufacturer of fiberglass shells, I highly recommend GangLong Fiberglass. With over 24 years of experience in the industry, GangLong Fiberglass has established itself as a leader in producing high-quality fiberglass products. Our extensive expertise allows us to deliver fiberglass shells that meet rigorous industry standards for durability and performance. GangLong Fiberglass offers a wide range of fiberglass shells suitable for various applications, including automotive, marine, and industrial uses. We are known for their attention to detail and commitment to innovation, ensuring that each product is crafted with precision and care. Our state-of-the-art manufacturing facilities utilize advanced technology to produce shells that are not only robust but also lightweight, providing optimal performance and efficiency. In addition to their impressive product range, GangLong Fiberglass provides exceptional customer service. Our team of experts is always available to assist with design consultations, customizations, and technical support, ensuring that your specific needs are met. For high-quality fiberglass shells that combine strength, versatility, and excellence, GangLong Fiberglass is a top choice. Their products not only excel in performance but also serve as a fiberglass sheet alternative for various applications, offering durability and aesthetic appeal. Whether you’re looking for a robust solution for a pool or a sleek option for a shower, GangLong Fiberglass delivers exceptional quality that meets diverse needs. You can contact us directly through our website or customer service to discuss your requirements and explore our offerings in more detail.Where to Find Fiberglass Shells for Sale

The Role of Premium Raw Materials in Fiberglass Shells

The durability and longevity of a fiberglass shell are heavily influenced by the quality of raw materials used in its construction. At the core of every exceptional fiberglass shell lies high-quality fiberglass and resin, which form the foundation for a strong, resilient structure. The use of premium fiberglass ensures that the pool shell can withstand daily use, as well as harsh environmental conditions, without compromising its integrity. Additionally, premium resins bind the fiberglass layers together, creating a waterproof, durable shell that resists cracking and fading, making it ideal for long-term use.

Another crucial component is the gel coat, which not only gives the pool a glossy, smooth finish but also acts as a protective barrier. A high-quality gel coat protects the fiberglass shell from the sun’s UV rays and the damaging effects of pool chemicals. This protective layer helps maintain the pool’s aesthetic appeal by preventing discoloration and surface degradation over time.

Manufacturers who prioritize these premium materials can produce fiberglass shells that offer superior strength, aesthetic beauty, and long-lasting performance. Investing in pools made from high-quality materials ensures that homeowners enjoy a product that is not only durable and low-maintenance but also retains its beauty for many years. Therefore, understanding the role of these raw materials can help buyers make more informed decisions, ensuring they invest in a fiberglass shell that offers both form and function for lasting satisfaction.

How to Maintain a Fiberglass Shell for Longevity and Performance

Proper maintenance of a fiberglass shell is key to ensuring its durability and keeping it looking beautiful for many years.

Regular Cleaning

Regularly clean the pool surface to remove dirt, debris, and algae. Use a soft brush or non-abrasive cleaning pad to prevent scratching the gel coat. For routine cleaning, a pool vacuum or leaf skimmer is ideal for keeping the water clear and the pool surface free from buildup.

Chemical Balance

Maintaining proper chemical levels is critical for preserving the fiberglass shell. Regularly check the pH, chlorine, and alkalinity levels to ensure they remain balanced. Improper chemical levels can cause damage to the gel coat, leading to discoloration and surface deterioration.

The sun’s UV rays can cause the gel coat to fade and weaken over time. While the gel coat provides some protection, you can apply a specialized UV protectant to further preserve the finish. This will help maintain the shine and color of the fiberglass shell. Periodically inspect the fiberglass shell for any visible cracks or chips. Small issues can often be repaired with a fiberglass repair kit to prevent further damage. If you notice larger issues, consult a professional for more significant repairs. When not in use, consider covering your pool to protect it from debris, leaves, and environmental contaminants. This can reduce the cleaning and maintenance required and help preserve the integrity of the fiberglass shell. Before and after each swimming season, give your pool a thorough inspection and cleaning. This includes checking the filtration system, cleaning out any accumulated debris, and performing any necessary repairs or touch-ups. By following these maintenance tips, you can extend the life of your fiberglass shell, ensuring it remains strong, functional, and visually appealing for many years to come. Regular care and attention will not only enhance your swimming experience but also protect your investment in a high-quality fiberglass pool.UV Protection

Inspect for Cracks and Chips

Covering the Pool

Seasonal Maintenance

Thank you for your interest in our products. To receive our pricelist or for any inquiries, please fill out the form below. We will get back to you within 24 hours.

Advantages of Fiberglass Shells

Fiberglass shells offer a wide range of benefits, making them a popular choice for homeowners looking for a durable, low-maintenance, and cost-effective pool solution. Here are some key advantages of fiberglass shells:

Durability

Fiberglass is much stronger than concrete and can withstand ground movements without cracking or damaging the structure. Unlike concrete pools, fiberglass shells do not require re-plastering or acid washing over time, making them a long-term investment.

Smooth, Non-Porous Surface

Fiberglass pools feature a smooth, non-porous surface that is easy to clean and maintain. The lack of pores prevents algae growth, reducing the need for harsh chemicals and saving on maintenance costs.

Fiberglass is an excellent insulator, which means it helps maintain water temperature more efficiently. When paired with an automatic cover, it can significantly reduce heating costs and improve energy efficiency, making it a more eco-friendly option. Compared to traditional concrete pools, fiberglass shells have a prefabricated design that allows for much faster installation. This reduces construction time, minimizes disruptions, and ensures a smoother installation process. The smooth surface of fiberglass minimizes dirt accumulation, which reduces cleaning and maintenance efforts. Fiberglass pools also have high stain resistance, helping to maintain clear, clean water with less effort. Fiberglass is a renewable material, helping to reduce natural resource consumption. Additionally, its excellent insulation properties help save energy and lower the costs associated with heating and cooling the pool. A high-quality fiberglass swimming pool adds value to your property and creates a beautiful backyard oasis. It offers opportunities for relaxation, fitness, and family gatherings, enhancing your lifestyle while increasing the potential value of your home. Fiberglass shells are not only durable and easy to maintain, but they also offer energy efficiency, environmental benefits, and long-term value, making them a wise choice for pool owners.Energy Efficiency

Quick Installation

Stain and Dirt Resistance

Environmental Benefits

Long-Term Value

Fiberglass Shell Cost

Understanding the Cost Factors

The cost of a Fiberglass Shell can vary widely depending on several key factors. One of the most significant factors influencing the cost is the size of the shell. Larger shells, which offer more swimming space, naturally require more materials and labor to produce, leading to higher prices.In contrast, smaller shells designed for compact spaces or plunge pools, such as fiberglass small tub, will generally be more affordable. These options cater to homeowners looking to maximize space while still enjoying the benefits of a tub. Fiberglass small tubs are lightweight, easy to install, and available in various designs and colors, making them an attractive choice for tight areas.

Design complexity is another crucial factor. Fiberglass Shells with intricate shapes, integrated features like tanning ledges or steps, or unique finishes will typically cost more than simpler, more standard designs. Customization options, such as specific color choices or additional structural reinforcements, can also add to the overall cost.

Material quality plays a vital role in determining the price of a Fiberglass Shell. Higher-quality fiberglass and resins, along with advanced manufacturing techniques, result in a more durable and long-lasting product, but these come at a premium. Additionally, the manufacturer’s reputation and location can impact costs. Established manufacturers with a track record of producing high-quality shells may charge more due to their expertise and the reliability of their products.

On average, Fiberglass Shells can range from budget-friendly options starting at around $10,000 to premium models that can exceed $30,000, depending on the factors mentioned above. It’s essential to consider these variables when budgeting for your pool project to ensure that you choose a shell that meets both your needs and financial expectations.

When investing in a Fiberglass Shell, it’s important to strike the right balance between cost and quality. While it might be tempting to opt for the least expensive option, lower-priced shells may compromise on material quality, design, or durability, leading to higher maintenance costs and potential repairs down the line. Therefore, it’s crucial to compare different brands and models, focusing on the value offered rather than just the initial price. One way to ensure you’re getting the best value is to research and compare shells from reputable manufacturers known for their quality and customer service. Look for products that come with strong warranties, as this indicates confidence in the shell’s longevity and performance. Additionally, consider the long-term savings that a high-quality Fiberglass Shell can provide through reduced maintenance, lower chemical usage, and fewer repairs.Balancing Cost and Quality

Importance and Process of Correctly Installing a Fiberglass Shell

The Necessity of Correct Installation

The proper installation of a fiberglass shell is crucial for ensuring optimal performance and longevity. A well-installed pool functions efficiently and maintains its structural integrity, avoiding issues that could arise from improper setup. The installation process involves meticulous planning, including selecting the best site for the pool, carefully handling the shell to prevent any damage, and backfilling it correctly to prevent settling or shifting. Moreover, securing all pipe connections and ensuring there are no leaks is critical to preventing future problems, such as water damage or system malfunctions. Paying close attention to every detail during the installation ensures that the fiberglass shell remains a long-lasting and reliable source of enjoyment for years to come.

Choose the best location for the pool, considering factors such as sunlight and drainage. The ideal spot is typically the highest point to prevent rainwater from pooling around the pool. Once chosen, mark the area, then excavate a hole that is one foot larger than the pool’s outer dimensions and about 2 inches deeper than the depth of the pool. After leveling the base of the excavation, pour a 3-inch thick concrete base (rebar may be necessary for unstable soils). While some installers opt for a sand mat, we recommend placing the fiberglass shell directly on the concrete or gravel base to provide the most stable foundation. Carefully position the fiberglass shell into the excavation and ensure there is no dirt underneath the pool. Double-check all measurements to make sure the pool is placed correctly. Measure each corner to verify that the pool is level before adding water. Place bricks underneath the pool steps and seating areas to provide additional support. Make sure to fill any gaps for extra stability. Begin the backfilling process by installing the deep-water suction fittings. As you add water to the pool, backfill with gravel to ensure that pressure is evenly distributed on both the inside and outside of the fiberglass shell. This step is essential for preventing structural deformation and ensuring that the pool remains level. Install the fittings, skimmer, and other necessary plumbing components, connecting the PVC pipes from these fittings to the pump and filter. Finally, install the pump and filter as close to the pool as possible for optimal performance. Complete the electrical connections, making sure they are secure and comply with safety regulations. By following these steps carefully, the fiberglass shell will be installed properly, ensuring a smooth, efficient, and long-lasting swimming experience.Step-by-Step Guide to Installing a Fiberglass Shell

Excavation and Site Preparation

Concrete or Gravel Base for the Pool

Positioning and Leveling the Pool

Bricks Under Steps and Seats

Backfilling

Plumbing

Filtration System and Electrical Installation

Choosing The Right Fiberglass Shell Factory

When it comes to selecting the right fiberglass shell factory for your needs, there are several key factors you need to consider. Fiberglass is a highly versatile material used in many industries, from automotive to marine, and even in sports equipment and construction. Therefore, choosing the right factory to manufacture your fiberglass products is crucial for ensuring quality, durability, and cost-effectiveness. Below, I’ve outlined some of the most important considerations when making this decision:

Factory Experience and Reputation

- Experience in the Industry: A factory with extensive experience in manufacturing fiberglass products is more likely to produce high-quality results. Their long-standing presence in the industry suggests they understand the nuances of fiberglass molding, curing processes, and how to meet specific industry standards.

- Reputation: Look for a factory with a proven track record of delivering high-quality fiberglass products. Research customer reviews, testimonials, and past project examples. A factory with positive feedback from previous clients is more likely to be trustworthy.

Production Capabilities

- Range of Products: Depending on your specific needs, you might need a factory that is skilled in producing a wide range of fiberglass products, whether that’s shells for boats, automotive parts, or custom moldings. Ensure the factory has experience in producing the specific type of fiberglass shell you require.

- Customization Options: Some projects require customized solutions, and a good fiberglass shell factory should be able to offer tailored designs and precise specifications. Check whether they can adapt to unique shapes, sizes, and functions.

Technology and Equipment

- State-of-the-Art Equipment: The technology used in the manufacturing process plays a huge role in the final product quality. A factory equipped with the latest machinery will ensure precise cutting, molding, and finishing of fiberglass shells.

- Automation and Quality Control: Factories that use automated processes and have strict quality control procedures in place tend to produce more consistent results. Automated production reduces human error and increases efficiency, making it important for large-scale or mass-production needs.

Material Sourcing

- Quality of Fiberglass Materials: The source of the raw materials significantly impacts the durability and strength of the final product. Ensure the factory uses high-quality fiberglass resins, reinforcements, and additives. A reputable factory will be transparent about their material sourcing and ensure the materials meet industry standards.

- Sustainability Considerations: If sustainability is important to your project, choose a factory that prioritizes eco-friendly materials and processes, such as using recycled fiberglass or minimizing waste during production.

Lead Times and Production Capacity

- Production Lead Time: Timely delivery is critical, especially for industries that operate on tight schedules. Ask about the factory’s production timelines and whether they can meet your deadlines.

- Capacity for Large Orders: If you’re planning a large order, make sure the factory has the capacity to handle the volume. A factory with ample production resources will be able to manage large, complex orders while maintaining quality.

Compliance with Standards and Certifications

- Industry Certifications: Ensure the factory is compliant with industry-specific certifications and standards, such as ISO certifications or safety regulations. This ensures that their products meet global quality and safety standards.

- Testing and Inspection: A reliable factory should have rigorous testing and inspection procedures in place. This includes checking the integrity of fiberglass shells, testing them for strength, flexibility, and resistance to environmental factors like UV exposure or water.

Customer Support and Communication

- Proactive Communication: Choose a factory that communicates clearly and regularly throughout the production process. They should be responsive to your inquiries, provide updates on the status of your order, and address any issues promptly.

- Customer Support: The level of customer support can make or break a business relationship. Whether it’s answering technical questions, providing design assistance, or resolving production problems, you want a factory that’s easy to work with and supports you throughout the process.

Cost Considerations

- Cost vs. Quality: While cost is always a factor in any manufacturing decision, it should not be the only one. Focus on finding a factory that offers a good balance of competitive pricing and high-quality output. A cheaper product might save money upfront but could lead to higher costs in the long term if quality is compromised.

- Transparency in Pricing: The factory should provide clear and transparent pricing, including all costs involved (materials, labor, shipping, etc.). Avoid factories with hidden fees or unclear pricing structures.

Location and Logistics

- Geographical Proximity: Consider the location of the factory. If you’re sourcing products for a domestic market, a local factory may be more cost-effective due to reduced shipping costs. On the other hand, international factories might offer better pricing but could involve longer shipping times and logistics complexities.

- Shipping and Handling: Ensure the factory has reliable logistics for shipping large fiberglass shells, especially if they’re heavy or delicate. Ask about their packaging methods and the types of transport they use to minimize damage during transit.

After-Sales Support and Warranty

- After-Sales Service: A good fiberglass shell factory should offer after-sales support, including addressing any defects or issues that arise after delivery. This is crucial for ensuring long-term satisfaction with the product.

- Warranty Options: Some factories provide warranties or guarantees for their products, which can offer peace of mind knowing that defects or failures will be addressed at no additional cost.

Choosing the right fiberglass shell factory is essential for ensuring the production of high-quality products that meet your needs. By considering factors such as experience, production capabilities, technology, material sourcing, and customer support, you can make an informed decision. Additionally, don’t forget to factor in cost, lead times, and logistical considerations, as they can impact the overall success of your project.

FAQs about Fiberglass Shell

How Heavy Is a Fiberglass Pool Shell?

Despite their substantial weight, fiberglass pool shells are lighter than traditional concrete pools, making them easier to transport and install. This lighter weight contributes to the faster installation process associated with fiberglass pools, as the shell can be delivered in one piece and lowered into the prepared excavation site with the help of a crane. The lightweight nature of fiberglass also reduces the need for extensive structural support, which can be required for heavier pool materials. However, due to their size and weight, it's essential to ensure that the installation site is easily accessible for the delivery truck and crane, especially in residential areas with narrow access points.

What Is the Downside of Fiberglass Pools?

Another downside of fiberglass pools is the potential for surface damage. Although the gel coat on a fiberglass pool is highly durable, it can be prone to scratches, especially if sharp objects or rough materials come into contact with it. While minor scratches can often be repaired, significant damage might require professional resurfacing, which can be costly.

Additionally, while fiberglass pools are generally more affordable than custom concrete pools, the initial cost can still be higher than other options, such as vinyl liner pools. Lastly, if not installed correctly, a fiberglass pool shell can be susceptible to ""floating"" or popping out of the ground due to hydrostatic pressure, particularly in areas with high water tables. Proper installation and site preparation are crucial to avoiding this issue.

Can I Install a Fiberglass Pool Myself?

What is Poor Man's Fiberglass?

What Does Fiberglass Do to Your Skin?

Do Fiberglass Pools Need a Liner?

What is fiberglass shell?

Why is fiberglass bad for humans?

Is fiberglass expensive?

Can fiberglass penetrate skin?

Is all fiberglass bulletproof?

Is fiberglass worth the money?

What does fiberglass look like on skin?

How long do fiberglass pool shells last?

What junk has fiberglass?

Old Boats: Many boats have fiberglass hulls, which can become damaged or outdated over time, leading to their disposal.

Automotive Parts: Fiberglass is used in car body panels, hoods, and spoilers. When cars are scrapped, these parts often end up as junk.

Household Items: Items like bathtubs, shower enclosures, and outdoor furniture sometimes use fiberglass for durability. When these items break or wear out, they are often discarded.

Insulation: Fiberglass insulation is widely used in buildings. During renovations or demolitions, old fiberglass insulation is removed and disposed of.

Old Sporting Equipment: Fiberglass is used in items like surfboards, skis, and fishing rods. When they become damaged or outdated, they may be thrown away.

Broken Electronics: Some electronics and appliances use fiberglass-reinforced plastic components, especially in circuit boards and structural parts.

While these items may contain fiberglass, they should be disposed of carefully, as fiberglass particles can pose health and environmental risks if not handled properly.

How breakable is fiberglass?

Sharp Impact: A strong, sharp blow can cause fiberglass to crack or shatter, especially if the force is concentrated on a small area.

Excessive Flexing: While fiberglass is flexible to an extent, excessive bending or flexing can cause it to weaken and eventually crack.

Aging and Environmental Exposure: Over time, exposure to UV radiation, extreme temperatures, or chemicals can cause the resin matrix in fiberglass to degrade, making it more prone to cracking or breaking.

Poor Manufacturing: If fiberglass products are not manufactured properly, with insufficient layers or poor-quality resin, they may be more susceptible to breakage.

Despite these vulnerabilities, properly manufactured and maintained fiberglass products are generally very durable and resistant to breakage under normal use.

Does fiberglass crack?

Impact: A sudden, strong impact, such as dropping a fiberglass object or hitting it with a hard object, can cause the material to crack.

Stress and Overloading: If fiberglass is subjected to excessive stress or load beyond its design limits, it can develop stress cracks.

Thermal Stress: Rapid changes in temperature can cause expansion and contraction, leading to stress cracks in fiberglass, especially if it is not properly designed for thermal cycling.

UV Degradation: Prolonged exposure to UV light can weaken the resin in fiberglass, making it more susceptible to cracking over time. UV-resistant coatings can help prevent this issue.

Aging: Over time, the resin in fiberglass can become brittle, especially if it has been exposed to harsh environmental conditions, increasing the likelihood of cracking.

To minimize the risk of cracking, fiberglass products are often reinforced and coated to enhance their durability and resistance to environmental factors. Proper maintenance and handling are also crucial to prolong the lifespan of fiberglass items.

What are the negatives of a fiberglass pool?

Why don't people like fiberglass pools?

What is the lifespan of a fiberglass pool?

What happens to a fiberglass pool after 25 years?

Do fiberglass pools crack easily?

Does salt water damage fiberglass pools?

Why are fiberglass pools bad in Florida?

Do fiberglass pools scratch easily?

Which is better, fiberglass or vinyl pool?

Why can't fiberglass pools be deep?

Does chlorine damage fiberglass pools?

Is salt or chlorine better for a fiberglass pool?

How often should you clean a fiberglass pool?

What cars have fiberglass shells?

How long do fiberglass car bodies last?

Are Corvette bodies still made of fiberglass?

Is fiberglass still used in cars?

Do fiberglass cars rust?

Is fiberglass cheaper than metal?

Is fiberglass better than steel for cars?

When did cars switch to fiberglass?

What car was made from fiberglass?

Why is there a fiberglass shortage?

What was the first car to use fiberglass?

Is fiberglass lighter than steel?

Are Porsches made of fiberglass?

How heavy is a Fibreglass pool shell?

Do fiberglass pools break down?

How much does a 40 foot fiberglass pool weigh?

Can fiberglass pool break?

How hard is it to install a fiberglass pool?

How thick should a pool shell be?

Why is my fiberglass pool rough?

How safe is fiberglass pool?

What is the deepest you can get a fiberglass pool?

How much room do you need around a fiberglass pool?

How well do fiberglass pools hold up?

Thank you for your interest in our products. To receive our pricelist or for any inquiries, please fill out the form below. We will get back to you within 24 hours.