FRP (Fiberglass Reinforced Plastic) has become a crucial material in modern engineering and construction due to its unique combination of strength, durability, and lightweight properties. As industries evolve, the demand for innovative solutions grows, making FRP increasingly relevant. One notable application is the FRP cable threading pipe, designed to protect and facilitate the installation of cables in various environments, similar to the use of FRP cable tray systems that offer structural support and protection. Its excellent corrosion resistance and thermal insulation make it ideal for sectors like telecommunications and energy. With a growing emphasis on sustainability and efficiency, FRP products continue to offer advantages over traditional materials, ensuring they remain at the forefront of modern applications. This innovative solution is transforming how we approach cable management in complex projects. The FRP cable threading pipe is lightweight, strong, corrosion-resistant, flame-retardant, and protects power and communication cables from damage.

What is FRP Cable Threading Pipe

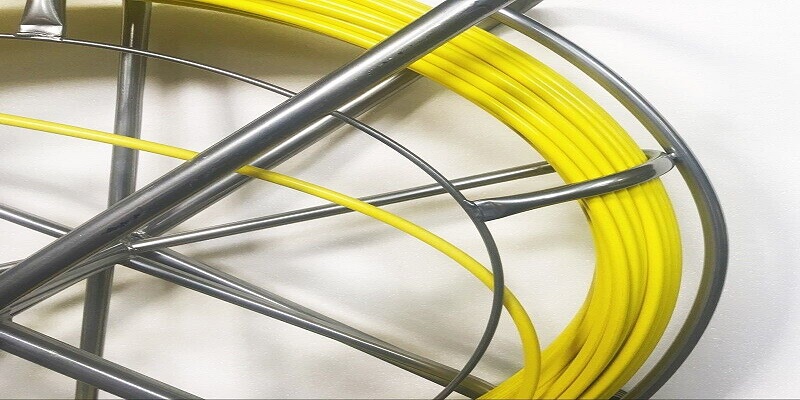

The FRP cable threading pipe is a specialized conduit designed to protect and streamline the installation of cables across various environments. This innovative solution combines the lightweight and durable characteristics of fiberglass with advanced engineering techniques. For instance, China FRP cable threading pipe has become a prominent choice in the industry due to its superior strength, corrosion resistance, and reliability. Here are key aspects of FRP cable threading pipe definition and primary function.

Material Composition

The FRP cable threading pipe is constructed from fiberglass reinforced with a resin matrix. This unique combination results in a pipe that is not only strong and resilient but also significantly lighter than traditional materials, making it easier to handle and transport.

Corrosion Resistance

One of the standout features of FRP cable threading pipe is its exceptional resistance to corrosion and chemical exposure. Unlike metal pipes, which can rust and degrade over time, FRP remains unaffected by moisture and a wide range of chemicals, ensuring long-lasting performance in demanding environments.

Thermal Insulation

The low thermal conductivity of the FRP cable threading pipe provides excellent insulation for the cables it houses. This feature is particularly beneficial in preventing overheating and protecting sensitive electrical components from temperature fluctuations that could compromise their functionality.

Smooth Interior

The inner surface of the FRP cable threading pipe is designed with a smooth finish, which minimizes friction during cable installation. This ensures that cables can be fed through the pipe easily, reducing the risk of damage and allowing for quicker installation processes.

Versatile Applications

FRP cable threading pipes are widely used in various sectors, including telecommunications, energy, and industrial applications. Their adaptability allows for use in both underground and overhead installations, catering to different project requirements and environmental conditions.

Ease of Installation

The lightweight nature of FRP cable threading pipes simplifies the installation process, requiring less manpower and reducing labor costs. This advantage is particularly important for large-scale projects where efficiency and speed are critical.

Longevity and Durability

Designed for longevity, the FRP cable threading pipe has a service life that often exceeds that of traditional piping materials. With minimal maintenance needs, it provides a cost-effective solution for cable management, ultimately reducing replacement and repair expenses over time.

Incorporating these features, the FRP cable threading pipe effectively addresses the challenges of cable protection and installation, making it an essential component in modern infrastructure projects.

Elastomeric Coating: The Role of Fiberglass Tape

The Manufacturing Process of FRP Cable Threading Pipes

The manufacturing of FRP cable threading pipe involves a meticulous process that combines high-quality materials and cutting-edge technology to produce durable and reliable products suitable for various applications. Here is a step-by-step description of how these pipes are manufactured:

Step 1: Selection of Materials

The first step involves selecting the right type of materials. High-strength fiberglass and resins such as polyester or epoxy are the main components. The choice of materials affects the pipe’s final properties, including its strength, flexibility, and resistance to environmental factors.

Step 2: Cutting and Preparing Fiberglass

Fiberglass strands are cut to the correct length and prepared based on the specifications of the frp cable threading pipe to be made. This preparation ensures that the fiberglass will properly bond with the resin to create a strong composite material.

Step 3: Immersion of Fiberglass

The cut and prepared fiberglass strands are immersed in a resin fiberglass bath tube. This step is crucial as it ensures that each strand of fiberglass is completely coated with resin, making it possible to achieve the desired degree of durability and resistance in the final product.

Step 4: Molding

After the fiberglass strands are thoroughly coated with resin, they are wound around a mandrel or passed through an extrusion process, depending on the desired shape and thickness of the FRP cable threading pipe. This step is where the actual shape of the pipe is formed.

Step 5: Curing Process

Once the resin-coated fiberglass is in place, the pipe undergoes a curing process. This involves heating the pipe in a controlled environment to harden the resin. Curing transforms the resin and fiberglass into a solid, robust structure, similar to a solid fiberglass pole, giving the FRP cable threading pipe its final strength and durability.

Step 6: Cooling

After curing, the FRP pipe is allowed to cool at a controlled rate. This stage is vital to prevent the formation of internal stresses that could weaken the pipe.

Step 7: Removal from the Mold

Once cooling is complete, the frp cable threading pipe is carefully removed from the mold or mandrel. This removal must be done with precision to ensure the pipe maintains its shape and structural integrity.

Step 8: Finishing Touches

The last step involves finishing touches like cutting the FRP cable threading pipe to length, drilling holes if necessary, and conducting quality assurance tests. These tests assess the pipe’s strength, flexibility, and resistance to ensure it meets all required standards and CSI specifications FRP pipe.

Through this detailed manufacturing process, FRP cable threading pipes are produced with consistent quality, offering superior performance and longevity in various applications where cable protection and routing are critical.

Precautions in the Manufacturing Process of FRP Cable Threading Pipe

The manufacturing process of FRP cable threading pipes involves a series of intricate steps that require precision, attention to detail, and the right conditions to ensure both smooth production and high-quality final products. From material selection to curing and finishing, each phase plays a crucial role in determining the strength, durability, and overall performance of the FRP pipes. In this section, we will outline the essential precautions that should be taken during the manufacturing process to ensure that the final FRP cable threading pipes meet the required standards for durability, safety, and performance. By focusing on these key factors, manufacturers can avoid common issues and produce high-quality, reliable products.

Material Selection and Preparation

The quality of the raw materials used in the production of FRP cable threading pipes is a critical factor that influences the final product’s durability, strength, and resistance to environmental factors such as corrosion and heat. Proper selection and preparation of materials are essential to ensure the pipes meet industry standards and perform effectively in their intended applications.

Choosing High-Quality Resins

The resin used in FRP cable threading pipes should be carefully selected based on the environment in which the pipes will be used. For example, polyester resins are commonly used for standard applications, while vinyl ester resins or epoxy resins may be preferred for harsher conditions where additional corrosion resistance is required. Manufacturers should ensure that the resin is compatible with the fiberglass reinforcement to achieve optimal bonding and strength.

Fiberglass Reinforcement

Fiberglass is the primary reinforcement material in FRP pipes. It must be of the appropriate grade and quality to provide the desired strength and durability. Fiberglass strands should be uniformly distributed within the resin to ensure consistent mechanical properties throughout the pipe. Any variations in fiber content or distribution can lead to weaknesses in the pipe, affecting its performance and lifespan.

Mold Design and Preparation

The mold design is another crucial aspect of the manufacturing process that can impact both the quality and consistency of the FRP cable threading pipes. A well-designed mold ensures that the pipes are formed to the correct specifications, with uniform wall thickness, smooth surfaces, and proper structural integrity.

Mold Cleaning and Maintenance

Before starting the production cycle, manufacturers should thoroughly clean and maintain the molds to remove any residues, dust, or other contaminants. Any leftover materials from previous batches could interfere with the bonding process, resulting in defects or inconsistencies in the final pipes. Regular inspection and cleaning of molds are essential to maintaining production quality.

Accurate Mold Specifications

The mold dimensions should be precisely engineered to ensure the correct pipe diameter and wall thickness. Even slight deviations in mold dimensions can lead to pipes that are either too thin, affecting their strength, or too thick, which can increase material costs unnecessarily. Accuracy at this stage is essential for producing consistent and high-quality products.

Manufacturing Environment Control

The manufacturing environment plays a significant role in ensuring that the FRP cable threading pipes are produced to the highest standards. Factors like temperature, humidity, and cleanliness need to be carefully controlled throughout the process to achieve the desired properties in the final product.

Temperature and Humidity Control

The curing process of FRP pipes requires precise control over the temperature and humidity levels. Too much humidity can affect the resin’s curing process, leading to poor adhesion between the resin and the fiberglass fibers. Similarly, if the temperature is too high or too low, it can lead to incomplete curing or over-curing, both of which can weaken the pipe. Maintaining an optimal environment within the production facility is crucial to ensure the resin sets correctly and achieves the desired properties.

Cleanliness of the Production Area

The production area should be kept free of dust, dirt, and other contaminants that could compromise the quality of the FRP cable threading pipes. Any foreign particles can interfere with the resin’s curing or bonding process, leading to surface defects or internal flaws. Regular cleaning and maintenance of the production area are necessary to maintain high standards of quality.

Curing and Post-Curing Process

The curing and post-curing phases of FRP pipe manufacturing are vital for ensuring that the resin properly hardens and bonds with the fiberglass, imparting the required mechanical properties. Inadequate curing can result in weak pipes that fail to meet performance standards.

Curing Time and Temperature

The pipes must undergo a curing process at the correct temperature for a specific duration to ensure that the resin fully hardens and bonds with the fiberglass reinforcement. Manufacturers should adhere to the recommended curing times for the resin being used. Under-curing can lead to soft pipes, while over-curing can cause brittleness.

Post-Curing for Enhanced Properties

Post-curing is sometimes required to enhance the properties of the FRP cable threading pipes, particularly when using advanced resins or for pipes that need to withstand extreme environmental conditions. This step ensures that the pipes achieve their maximum strength and thermal stability, improving their overall durability and lifespan.

Quality Control and Testing

Regular quality control checks and testing throughout the manufacturing process are essential to ensure that the FRP cable threading pipes meet the required specifications and standards. Testing should cover various parameters, such as mechanical strength, corrosion resistance, and heat tolerance.

Visual Inspection

Each batch of FRP cable threading pipes should undergo a thorough visual inspection to check for surface defects, inconsistencies in color, or any signs of irregularities such as cracks or bubbles. Even minor flaws can affect the pipe’s overall performance, so it is essential to catch these issues early.

Mechanical and Environmental Testing

Mechanical testing, such as flexural strength and impact resistance tests, is critical to ensure the pipes can withstand the stresses they will encounter during use. Environmental tests, such as corrosion resistance and temperature cycling, help confirm that the FRP pipes will perform as expected under different conditions.

Finishing and Packaging

Once the FRP cable threading pipes have been manufactured and passed quality control tests, the finishing and packaging processes ensure that the pipes are ready for shipment and use.

Surface Finishing

The pipes should be finished with a smooth surface to enhance their appearance and ease of installation. If necessary, manufacturers can apply a protective coating to enhance the pipe’s resistance to UV light and chemical exposure.

Packaging for Protection

Proper packaging is essential to prevent damage during transportation. Pipes should be securely wrapped and cushioned to prevent scratches, dents, or deformation that could occur during handling.

To ensure the smoothness of the manufacturing process and the quality of the final product, manufacturers of FRP cable threading pipes must carefully control various aspects of production, from material selection to final inspection. By maintaining optimal conditions for material preparation, mold design, curing, and post-curing processes, manufacturers can produce high-quality pipes that offer long-lasting protection for cables. Through regular quality control checks and effective finishing and packaging, the durability, reliability, and performance of the FRP cable threading pipes are guaranteed, ensuring they meet the necessary standards for a wide range of applications.

Applications of FRP Cable Threading Pipe

The FRP cable threading pipe finds widespread use across various industries due to its unique properties, which enhance cable protection and installation efficiency. Its versatility allows it to be integrated into numerous applications, particularly in sectors that demand reliability and durability.

Use in Industries

The FRP cable threading pipe is essential in several key industries, including:

- Telecommunications: Widely used for protecting fiber optic cables, the FRP cable threading pipe ensures signal integrity and longevity in both underground and overhead installations, accommodating the high demands of modern communication networks.

- Energy: In power generation facilities, the pipe safeguards electrical wiring and control cables, especially in renewable energy sectors like wind and solar farms, where resilience to environmental conditions is crucial for operational reliability.

- Construction: Vital for managing electrical systems in commercial and residential buildings, the FRP cable threading pipe provides a reliable conduit for wiring and cables, ensuring safety and compliance with building codes.

- Oil and Gas: Used extensively in refineries and offshore platforms, the FRP cable threading pipe protects cables from harsh environmental conditions, extreme temperatures, and chemical exposure, which are common in this industry.

- Manufacturing: In industrial plants, it facilitates the safe routing of electrical and control cables, contributing to overall operational efficiency and minimizing downtime caused by cable damage.

- Water Treatment: The pipe protects sensors and electrical components in treatment facilities, ensuring reliable monitoring and control of water quality, which is critical for environmental protection and public health.

- Transportation: Utilized in railways and airports, the FRP cable threading pipe manages communication and signaling cables, maintaining safety and operational efficiency, particularly in high-traffic areas.

- Mining: Provides robust protection for electrical and communication cables in underground and surface mining operations, where exposure to dust, moisture, and heavy equipment can threaten cable integrity.

- Aerospace: In aircraft manufacturing and maintenance, the FRP cable threading pipe protects critical wiring from mechanical damage and environmental factors, ensuring safety and reliability during operations.

- Pharmaceuticals: Employed in facilities that require stringent cleanliness and chemical resistance, the FRP cable threading pipe ensures that sensitive cables are protected from contamination and chemical exposure.

Specific Scenarios

The applications of FRP cable threading pipe extend to various specific scenarios, including:

- Underground Installations: Ideal for use in buried applications, the FRP cable threading pipe protects cables from soil pressure, moisture, and mechanical impact, ensuring reliable performance over time.

- Overhead Cable Management: Utilized in aerial installations, the pipe secures and protects cables from environmental factors such as wind, rain, and UV radiation, which can degrade cable performance.

- Chemical Plants: The FRP cable threading pipe is employed to route cables through areas with high exposure to corrosive substances, providing long-lasting protection against harsh chemicals.

- High-Rise Buildings: Facilitates vertical cable management in multi-story structures, where space and accessibility can be challenging, ensuring organized and safe routing of electrical systems.

- Industrial Warehouses: Protects cables running along high ceilings or walls, minimizing the risk of damage from heavy equipment, shelving, or personnel movement in busy environments.

- Renewable Energy Sites: The pipe secures and protects cables connecting solar panels or wind turbines to electrical systems, ensuring operational reliability in diverse weather conditions.

- Data Centers: In high-tech facilities, FRP cable threading pipes help manage the complex network of data cables, providing organization, protection, and efficient airflow in critical environments.

- Military Applications: Used in defense installations, the FRP cable threading pipe provides robust protection for communication and control systems, ensuring functionality in challenging environments.

- Smart Cities: In urban development projects, the FRP cable threading pipe is integrated into infrastructure to protect cables for smart technologies, enhancing connectivity and data collection in public spaces.

- Flood-Prone Areas: Employed in regions susceptible to flooding, the pipe protects cables from water damage, ensuring that essential services remain operational even during adverse weather conditions.

With its broad range of applications and specific use cases, the FRP cable threading pipe proves to be an invaluable solution for modern infrastructure needs, enhancing safety and efficiency across diverse industries.

FRP Cable Threading Pipe Suppliers

FRP cable threading pipe suppliers are essential entities within the construction and electrical industry, providing crucial materials that contribute significantly to the infrastructure’s efficacy and safety. Their role extends beyond mere supply, encompassing various services and technical support that ensures the optimization of these materials in diverse applications. Let’s delve deeper into the multifaceted role these suppliers play, the range of services they typically offer, and the key considerations for choosing a supplier that aligns with your project needs.

Role of Suppliers in the Industry

Suppliers of frp cable threading pipe demonstrate extensive influence within the industry through their pivotal roles:

- Material Sourcing: They are responsible for procuring high-quality raw materials essential for manufacturing premium pipes.

- Product Manufacturing: Through either direct manufacture or strategic partnerships, suppliers ensure the availability of a variety of FRP piping products.

- Quality Assurance: Rigorous testing protocols are upheld by suppliers to maintain industry standards and product reliability.

- Inventory Management: Efficient management guarantees the availability of an extensive assortment of product specifications and sizes.

- Order Fulfillment: They adeptly handle orders, ensuring precise and timely deliveries.

- Technical Support: Offering in-depth technical assistance is crucial for aiding clients in product selection and optimal use.

- Distribution Network: A well-established network ensures that suppliers can fulfill delivery requirements across different locations efficiently.

- Market Trends Analysis: Suppliers keep abreast of market dynamics and innovations, advising clients on appropriate and modern solutions.

Services Typically Offered by Suppliers

Frp cable threading pipe suppliers enhance their relevancy and value-addition through a comprehensive suite of services:

- Custom Fabrication: Tailored solutions are a hallmark of suppliers, ensuring customer specifications are met precisely.

- Product Consultations: Expert consultations support clients in navigating the complexities of product selection.

- Logistics Services: Suppliers manage the intricacies of logistics, affirming safe and punctual product deliveries.

- Technical Documentation: Access to detailed documentation and certifications authenticates compliance and quality.

- After-Sales Support: Robust after-sales services are paramount for addressing any subsequent issues or concerns effectively.

- Training and Workshops: Educational programs underscore the suppliers’ commitment to empowering clients with knowledge on product handling.

- Financing Options: Financial flexibility through various payment terms and options supports clients with diverse budgetary constraints.

- Industry Compliance Updates: Keeping clients informed about regulatory and compliance shifts is key to ensuring project integrity.

How to Choose a Reliable Supplier

Selecting the right supplier is crucial for the success of any project relying on frp cable threading pipe. Factors to consider include:

- Quality Certification: Identifying suppliers with recognized quality certifications underlines their commitment to excellence.

- Industry Experience: A proven track record in handling similar project needs is indicative of a supplier’s reliability and expertise.

- Production Capacity: Adequate production facilities ensure the supplier can meet your project demands efficiently.

- Customer Reviews and References: Testimonials from past clients provide insights into the supplier’s dependability and service quality.

- Product Range: A supplier offering a comprehensive product range signifies their ability to cater to varied project requirements.

- Technical Expertise: Expertise in FRP materials and applications is essential for providing sound advice and solutions.

- Financial Stability: A financially robust supplier is more likely to sustain quality service delivery consistently.

- Transparent Communication: Effective and open communication channels are crucial for smooth project execution and resolution of any arising issues.

By considering these points, you can ensure a strategic partnership with an FRP cable threading pipe supplier that not only meets but exceeds your project needs.

Fiberglass Columns Price at Home Depot: What to Expect

FRP Cable Threading Pipe Factory

The FRP (Fiberglass Reinforced Plastic) cable threading pipe factory plays a crucial role in the production and supply chain of the construction and electrical industry. These factories are equipped with state-of-the-art machinery and follow stringent processes to ensure that the FRP cable threading pipes produced meet the highest quality and safety standards. The production and quality control measures taken within these factories are elaborate and meticulously planned to ensure that every FRP cable threading pipe reaches the customer with guaranteed performance and durability.

How Factories Produce FRP Cable Threading Pipes

The production of FRP cable threading pipe in a factory setting involves several critical stages, each contributing to the final product’s quality and functionality:

- Raw Material Selection: Procuring high-quality raw materials is the first crucial step. The selection involves sourcing the best fiberglass and resin materials, which form the core components of FRP products.

- Design and Engineering: Before production, detailed designs are drawn up, considering the application-specific requirements. Engineering precision ensures that the pipes will have the correct diameter, thickness, and strength.

- Pultrusion Process: This is a common manufacturing process for FRP cable threading pipes, where the raw materials are pulled through a heated die to form the pipe. This process is highly efficient and allows for continuous production.

- Winding Method: For certain applications, the winding method may be employed, wherein continuous fiberglass strands and resin are wound around a rotating mandrel, creating layers that form the pipe.

- Curing and Cooling: After formation, the pipes undergo a curing process where they are solidified and then cooled. This stage is essential for achieving the desired mechanical properties and dimensional stability.

- Cutting and Trimming: Once cured and cooled, the pipes are cut to specified lengths and any excess material or irregularities are trimmed. This ensures that each pipe meets the exact size requirements.

- Quality Inspection and Testing: Every batch of pipes is subjected to rigorous testing for strength, flexibility, and durability. Tests can also include checking for chemical and corrosion resistance based on the anticipated environment of use.

Quality Control and Assurance in Factories

Quality control and assurance are pivotal in the FRP cable threading pipe manufacturing process, ensuring the products meet stringent standards:

- Raw Material Inspection: Upon arrival at the factory, all raw materials undergo thorough inspection and testing to confirm their quality and suitability for production.

- In-process Monitoring: During the manufacturing process, continuous monitoring and adjustments ensure that production parameters remain within the defined quality standards.

- Compliance with Standards: Factories adhere to international quality standards such as ISO and ASTM, ensuring that the FRP cable threading pipes are manufactured according to globally recognized specifications.

- Final Product Testing: Completed pipes are subjected to a series of tests, including pressure tests, flexural strength tests, and environmental resistance tests, to ensure they meet the required performance criteria.

- Documented Quality Procedures: Factories maintain documented quality control procedures, which include detailed records of inspections, test results, and corrective measures taken for any non-conformities.

- Continuous Improvement Programs: Implementing continuous improvement programs helps in the constant enhancement of quality control measures, ensuring that the manufacturing process evolves with the latest standards and technological advances.

Through these detailed manufacturing and quality control processes, the FRP cable threading pipe factory ensures that its products offer superior performance, reliability, and longevity, catering to the demanding needs of the construction and electrical industries.

Wholesale FRP Cable Threading Pipe Exporter

The global market for FRP (Fiberglass Reinforced Plastic) cable threading pipes is expansive, providing broad opportunities for exporters. These pipes, renowned for their strength, durability, and resistance to corrosion, are in high demand in various sectors, including telecommunications, power distribution, and industrial construction. Wholesale FRP cable threading pipe exporters play a pivotal role in bridging the gap between manufacturers and the international market, ensuring a steady flow of these essential components to regions where demand is highest.

Understanding the Export Market for FRP Cable Threading Pipes

The export landscape for FRP cable threading pipes includes a diverse range of markets, each with unique requirements and regulations. Among the notable players in this field is “cbro fiberglass,” a company that has established itself as a key figure in the global supply chain for FRP products. Cbro Fiberglass and similar exporters leverage their expertise and networks to meet the global demand efficiently. Three primary facets characterize the export market for these products:

- Global Demand Variability: The requirement for FRP cable threading pipes varies significantly across different regions, influenced by developmental projects, upgrades in infrastructure, and advancements in telecommunications and power distribution networks.

- Regulatory Compliance: Exporters must navigate the complex web of international standards and regulations. This includes ensuring that products meet the specific construction and material standards set by various countries and international bodies.

- Logistical Efficiency: The ability to manage logistics effectively, from production to delivery, is crucial. This includes optimizing shipping routes, managing customs clearance, and ensuring timely delivery to meet project deadlines.

Challenges and Considerations in Exporting These Products

Exporting FRP cable threading pipes involves overcoming several obstacles to ensure smooth international transactions and customer satisfaction:

- Quality Assurance Across Borders: Maintaining consistent quality in products that meet both the manufacturer’s standards and the importing country’s regulations is a persistent challenge. Variations in standards and expectations can pose significant hurdles.

- Cultural and Language Barriers: Exporters must often navigate differences in language and business practices when dealing with clients from various parts of the world, requiring effective communication strategies and sometimes local representation.

- Currency Fluctuations and Payment Risks: Dealing in international markets exposes exporters to currency risk and challenges in securing payments across different banking systems and regulations.

- Shipping and Logistics Challenges: Unexpected delays, damage during transport, and increased costs due to distance or geopolitical tensions can impact the efficiency of supply chains.

- Customs and Import Tariffs: Understanding and complying with the diverse customs procedures and import tariffs of different countries is crucial. Failure to comply can lead to delays, fines, and even seizure of products.

- After-Sales Support and Warranty Issues: Providing adequate after-sales support, managing warranties, and handling returns or repairs for international clients can be complex and costly.

By tackling these challenges head-on, wholesale FRP cable threading pipe exporters can enhance their market presence, forge stronger relationships with international clients, and contribute significantly to the global distribution of these essential construction materials. As infrastructure and telecommunications continue to expand globally, the role of skilled and knowledgeable exporters in fulfilling the demand for FRP cable threading pipes becomes increasingly critical.

Advantages of Using FRP Cable Threading Pipe

The utilization of FRP cable threading pipe has become increasingly prominent in various industries due to its exceptional properties. These pipes, crafted from fiberglass reinforced plastic, offer a versatile and durable solution for cable management and protection, much like fiberglass reinforced plastic decking, which provides strength and corrosion resistance in different applications. Outlined below are eight key advantages of using FRP cable threading pipes, each illustrating why they are preferred over traditional materials like steel or PVC.

- Durability: FRP cable threading pipe is highly resistant to wear and tear, ensuring a long service life. Its robust construction means it can withstand harsh conditions without deteriorating, making it a cost-effective choice for long-term applications.

- Resistance to Corrosion and Chemicals: One of the most outstanding attributes of FRP cable threading pipes is their inherent resistance to corrosion. Unlike metal pipes, FRP does not rust or corrode when exposed to aggressive chemicals, salty air, or wastewater, maintaining its integrity over time.

- Lightweight: FRP cable threading pipe is significantly lighter than metal alternatives, which simplifies transportation and handling. This characteristic reduces the overall installation costs and manpower requirements, offering an economic advantage in project management.

- Ease of Installation: The lightweight nature, coupled with the flexibility of FRP, makes the installation process straightforward. These pipes can be easily cut, drilled, and fitted on-site, requiring no heavy machinery or specialized equipment, thus accelerating the installation process.

- Energy Efficiency: The insulation properties of FRP cable threading pipes help mitigate energy losses when used to protect electrical cables. This can lead to reduced operational costs over time, as well as offering added protection against temperature fluctuations.

- Non-Conductive: FRP is an excellent insulator, meaning it does not conduct electricity. This non-conductive property makes FRP cable threading pipes an ideal choice for electrical and communication cable applications, enhancing safety by reducing the risk of electrical accidents.

- Minimal Maintenance: The durability and resistance to environmental factors mean that FRP cable threading pipes require minimal maintenance. This can result in substantial savings, as the need for regular repairs or replacements is significantly reduced.

- Aesthetic Flexibility: FRP cable threading pipes can be produced in a variety of colors and can be designed to blend with the surrounding environment or in conformity with the aesthetic vision of a project. This flexibility allows for installations that are not only functional but also visually appealing.

By integrating all these advantages, FRP cable threading pipes offer a sophisticated and economically viable solution for cable protection and management. Their unique combination of durability, resistance to various elements, and user-friendly characteristics make them an increasingly popular choice across a multitude of industries.

Challenges and Limitations of FRP Cable Threading Pipe

Despite the numerous advantages associated with FRP cable threading pipe, there are several challenges and limitations that users may encounter. Understanding these potential hurdles, and the solutions or workarounds for them, can ensure that projects utilizing FRP maintain their intended efficiency and effectiveness. Here, we explore eight significant issues and how they can be addressed.

- Brittleness: While FRP cable threading pipes are known for their strength, they can be brittle compared to metal pipes. This means they might crack under impact or if mishandled.

- Solution: Careful handling and installation practices can mitigate this issue. Training for personnel on how to handle FRP materials properly is essential.

- Thermal Conductivity: Though FRP is a good insulator, its thermal expansion rate can be higher than that of traditional materials. This might cause issues in environments with wide temperature variations.

- Solution: Using expansion joints and proper installation techniques can accommodate the thermal expansion and contraction of FRP cable threading pipes.

- Cost Considerations: Initially, FRP cable threading pipe can be more expensive than traditional materials like PVC or some metals, making budgeting for projects challenging.

- Solution: Taking into account the lower maintenance costs and longer lifespan of FRP can demonstrate cost-effectiveness over time.

- Fabrication and Repair Complexity: Fabricating or repairing FRP cable threading pipes may require specialized equipment and knowledge not always available on-site.

- Solution: Employing specialized contractors or training existing staff in FRP fabrication and repair techniques can overcome this challenge.

- UV Degradation: Prolonged exposure to ultraviolet (UV) light can degrade the resin components in FRP, affecting its structural integrity.

- Solution: Applying UV-resistant coatings can protect FRP cable threading pipes from sunlight damage.

- Chemical Sensitivity: While FRP is generally resistant to chemicals, certain resins can be sensitive to specific substances, potentially leading to degradation over time.

- Solution: Choosing the correct type of resin that is compatible with the environmental conditions and chemicals anticipated in the application area is vital.

- Limited Standardization: The FRP industry suffers from a lack of standardization, which can make it difficult to compare products and ensure compatibility.

- Solution: Working closely with reputable manufacturers who can provide technical guidance and standardized product specifications can help mitigate this issue.

- Installation Expertise: Proper installation is crucial for maximizing the benefits of FRP cable threading pipes, but there is often a lack of experienced contractors.

- Solution: Offering specialized training sessions for contractors and construction personnel can increase the pool of expertise available for FRP installation projects.

By acknowledging these challenges and implementing the suggested solutions, stakeholders can effectively utilize FRP cable threading pipes in their projects, leveraging their numerous benefits while minimizing potential drawbacks.

FRP Cable Threading Pipe Manufacturers

The landscape of FRP cable threading pipe manufacturing is competitive, with numerous players striving to carve out their market share. To differentiate themselves from competitors, manufacturers use various strategies that underscore their unique selling propositions. Here, we will discuss eight distinct methods that FRP cable threading pipe manufacturers adopt to stand out.

- Innovative Material Compositions: One way manufacturers distinguish themselves is by developing proprietary resin formulas or composite materials that enhance the performance characteristics of FRP cable threading pipes, such as increased durability or resistance to environmental factors.

- Customization Capabilities: Offering custom-tailored solutions allows manufacturers to meet the specific needs of clients. This could include custom dimensions, shapes, or even tailored physical properties for the FRP cable threading pipe to suit unique project requirements.

- Sustainability Practices: Eco-friendliness is a significant differentiator as manufacturers emphasize the use of sustainable practices and materials. Some might offer recyclable or lower-environmental-impact FRP cable threading pipes or adopt greener production processes.

- Technological Advancements: Investing in the latest manufacturing technologies can lead to more precise and efficient production, resulting in higher-quality FRP cable threading pipes. Advanced automation or quality control techniques can also contribute to this differentiation.

- Superior Installation Support: Manufacturers can set themselves apart by offering exceptional installation support. This includes providing detailed guides, on-site assistance, or training for contractors to ensure the best use and installation of their FRP cable threading pipes.

- Certification and Testing: Undergoing rigorous testing and achieving certifications from recognized industry bodies can provide a competitive edge. Compliance with standards often reassures clients of the quality and reliability of the FRP cable threading pipes.

- Responsive Customer Service: Manufacturers that prioritize customer service and provide timely and helpful support to their clients can create lasting relationships. Responsiveness to inquiries, issues, or assistance requests can heavily influence customer loyalty and preference.

- Extended Warranties and Guarantees: By offering more extended warranty periods or comprehensive guarantees, manufacturers can demonstrate their confidence in the longevity and performance of their FRP cable threading pipes.

Each of these strategies enables FRP cable threading pipe manufacturer to offer a compelling value proposition to their customers, ensuring they remain competitive in a market that requires constant innovation and commitment to quality.

Explore The Benefits Of Fiberglass Pilings For Sale For Docks

Inspection and Maintenance of FRP Cable Threading Pipes to Ensure Longevity and Performance

Regular inspection and maintenance of FRP cable threading pipes are essential to ensure their long-term functionality and to maximize their service life. These pipes are used in challenging environments, where they are exposed to various physical, chemical, and environmental factors. Proper inspection allows early identification of potential issues such as cracks, corrosion, or improper installation, while timely maintenance ensures the pipes continue to operate at peak performance. This section will explore the essential steps and precautions involved in inspecting and maintaining FRP cable threading pipes to ensure they provide durable and reliable cable protection throughout their lifecycle.

Inspection of FRP Cable Threading Pipes

Inspection is the first step in identifying any potential problems with FRP cable threading pipes. Regular visual checks and more detailed assessments are necessary to detect any wear, damage, or signs of weakness that could compromise the performance of the pipes. By performing thorough inspections, any issues can be addressed promptly to prevent further damage.

Visual Inspection for Surface Damage

The most common inspection method is a visual examination of the FRP cable threading pipes. This involves checking the pipes for any surface damage, including cracks, scratches, abrasions, or deformations that may have occurred due to mechanical stress or environmental factors.

- Look for cracks or splits: Cracks along the length of the pipe can lead to structural failure, which might allow moisture or other damaging elements to affect the internal cables.

- Check for discoloration: Fading or discoloration can indicate UV degradation, which weakens the material.

- Inspect for signs of impact: Dents or dents from physical impacts should be noted, as they can compromise the integrity of the pipe.

Internal Inspection

Occasionally, a more thorough internal inspection may be required to ensure there are no internal flaws that could affect the pipe’s function. This might involve using cameras or other specialized tools to check for internal corrosion or blockages that could hinder the passage of cables.

- Check for corrosion or wear inside: In highly corrosive environments, internal corrosion could compromise the structural integrity of the pipe.

- Look for blockage: Make sure the pipe is free of debris or dirt that may obstruct the cables being threaded through.

Maintenance of FRP Cable Threading Pipes

Once any issues have been identified during the inspection phase, maintenance is essential to ensure the FRP cable threading pipes continue to perform optimally. Effective maintenance includes cleaning, repairing damage, and ensuring that all parts of the pipe system remain functional.

Cleaning the Pipes

Cleaning is an essential maintenance task that helps prevent build-up of dirt, debris, or chemicals that could weaken the pipe or cause issues when cables are threaded through.

- Use mild soap or detergent: A gentle cleaning solution should be used to wash the external surface of the pipes. Avoid harsh chemicals that could degrade the material.

- Avoid abrasive tools: Use soft cloths or non-abrasive brushes to avoid scratching the surface of the pipe, which could lead to weakened areas that are prone to further damage.

Repairing Surface Damage

If cracks or chips are found during the inspection, immediate repair is necessary to restore the integrity of the FRP cable threading pipes.

- Patch minor cracks: Small cracks can often be repaired using epoxy-based fillers designed for FRP materials. The repair compound should be applied carefully to ensure it forms a smooth, even surface.

- Reinforce damaged areas: In cases where the damage is more extensive, reinforcing the pipe with additional fiberglass cloth and resin may be required. This helps to restore the pipe’s strength and durability.

Preventative Maintenance

Preventative maintenance can also be performed to avoid future issues, extending the lifespan of the FRP cable threading pipes.

- Apply UV-resistant coatings: To protect against UV degradation, consider applying a protective coating that provides a barrier against sun exposure. This is especially important for outdoor installations where pipes are exposed to sunlight.

- Inspect seals and joints: Check any joints or seals for wear and ensure they are properly fitted to prevent leaks or damage to the pipe.

Precautions During Inspection and Maintenance

Proper precautions must be taken to ensure that the inspection and maintenance processes do not cause further damage to the FRP cable threading pipes. Understanding the specific characteristics of FRP materials is key to performing these tasks without compromising the pipe’s integrity.

Handling the Pipes with Care

Since FRP pipes are strong but can be brittle under certain conditions, it is essential to handle them with care during both inspection and maintenance.

- Avoid excessive force: Do not apply excessive pressure or impact while inspecting or cleaning the pipes, as this could cause cracks or structural damage.

- Wear protective gloves: Handling fiberglass material directly can lead to skin irritation, so it’s important to wear protective gloves during the process.

Avoiding Harsh Chemicals

During the cleaning process, avoid using harsh chemicals or abrasive materials that could cause degradation of the FRP cable threading pipes. Stick to mild cleaners that are specifically designed for use with fiberglass products.

- Use gentle cleaners: Always use cleaners that are compatible with FRP material, as harsh chemicals can break down the resin matrix and weaken the pipes.

Checking for Compatibility of Repair Materials

If repairs are needed, always ensure that the repair materials (such as fillers, resins, or coatings) are compatible with the type of resin used in the FRP cable threading pipes.

- Use manufacturer-recommended repair products: For optimal results, it’s best to use repair products recommended by the pipe manufacturer. This ensures compatibility and avoids introducing materials that may not bond well with the existing FRP structure.

Regular inspection and maintenance of FRP cable threading pipes are crucial for ensuring that they continue to perform effectively and protect the cables inside. By conducting thorough inspections, cleaning, repairing surface damage, and applying preventative maintenance measures, the longevity and functionality of the pipes can be greatly extended. Care should be taken to follow the proper precautions during these processes to avoid inadvertently causing further damage to the pipes. Through proactive maintenance, FRP cable threading pipes can provide reliable service for many years, safeguarding the cables they protect and ensuring efficient performance in various environments.

Why Choose FRP Cable Threading Pipes? Advantages of Using FRP Cable Threading Pipes

When it comes to simplifying and protecting cable installations in various environments, the use of FRP cable threading pipes is an effective and popular solution. These pipes, made of fiberglass reinforced plastic (FRP), are designed to protect cables from mechanical damage, environmental factors, and chemical exposure. The advantages of using FRP cable threading pipes are vast, offering not only protection but also durability, lightweight design, and cost-effectiveness. This section will explore the reasons why FRP cable threading pipes are a preferred choice, delving into their unique properties and how they provide long-lasting solutions for cable management.

Corrosion Resistance

One of the key advantages of FRP cable threading pipes is their exceptional corrosion resistance. FRP pipes are made with a resin matrix reinforced with fiberglass, which gives them inherent protection against harsh environmental conditions. This makes them particularly suitable for applications where cables are exposed to moisture, chemicals, or saltwater.

Durable in Harsh Environments

Unlike metal pipes, which can corrode or rust over time when exposed to water or chemicals, FRP cable threading pipes are resistant to these environmental factors. This ensures a longer lifespan for the pipes and the cables they protect, reducing the need for frequent maintenance and replacement.

Ideal for Underground and Marine Applications

FRP pipes are ideal for use in underground or marine environments where corrosion could compromise the safety and reliability of electrical and communication cables. Their ability to withstand these harsh conditions makes them an essential part of many cable protection systems.

Lightweight and Easy to Install

FRP cable threading pipes are significantly lighter than metal alternatives, making them easier to transport, handle, and install. The lightweight nature of these pipes helps reduce installation time and costs, and it also makes them easier to manage in tight spaces or areas that are difficult to access.

Ease of Handling

Due to their lower weight, FRP cable threading pipes can be carried and manipulated without the need for heavy lifting equipment or additional labor, reducing overall project costs.

Quick and Simple Installation

The light weight also facilitates quicker installation, as workers can easily move and position the pipes without causing physical strain or delays. This is especially beneficial in construction projects where time is of the essence, allowing contractors to complete cable installations faster.

Flame Retardant and Electrical Insulation

FRP cable threading pipes offer excellent flame retardant properties, making them a safe option for protecting cables in environments prone to fire hazards. Additionally, the electrical insulation properties of FRP prevent the risk of electrical shorts or shocks, ensuring the safety of both the cables and the surrounding infrastructure.

Fire Resistance

The flame retardant nature of FRP pipes prevents them from being easily ignited in case of fire, reducing the risk of fire spreading through the cable system. This makes them an ideal choice for installations in industrial, commercial, and residential buildings where fire safety is a concern.

Electrical Safety

The electrical insulation properties of FRP pipes provide an added layer of safety for electrical systems. This is particularly important when running cables through high-voltage areas, as it prevents potential electrical hazards from affecting workers or surrounding equipment.

Heat Resistance

In many installations, particularly those in high-temperature environments, heat resistance is crucial to ensure the longevity and performance of the cable and the pipe itself. FRP cable threading pipes are known for their heat resistance, which ensures that they can withstand high temperatures without compromising their structural integrity.

High-Temperature Tolerance

FRP pipes can withstand high temperatures without becoming deformed, cracked, or weakened. This makes them suitable for use in environments like power plants, chemical processing facilities, and industrial machinery, where temperature fluctuations are common.

Protection for Sensitive Cables

By providing heat resistance, FRP cable threading pipes protect the cables inside from overheating, ensuring that electrical and communication systems continue to function efficiently in extreme conditions.

Cost-Effective Solution

While FRP cable threading pipes may have a higher initial cost compared to some other materials, their long lifespan, minimal maintenance, and energy efficiency make them a cost-effective choice in the long term.

Lower Maintenance Costs

The corrosion resistance and durability of FRP pipes mean fewer repairs and replacements over time, reducing the total cost of ownership. They require less frequent maintenance and are not subject to the same wear and tear as traditional metal pipes, which can corrode over time.

Energy Efficiency

The insulating properties of FRP pipes help to reduce energy loss, especially when cables are exposed to extreme temperatures. This makes them more energy-efficient, contributing to lower energy consumption and operational costs in systems that require thermal management.

FRP cable threading pipes offer a wide range of advantages, including corrosion resistance, lightweight design, flame retardant properties, and heat resistance. These characteristics make them an excellent choice for cable protection in various environments, including industrial, commercial, and residential applications. Their ease of installation, combined with cost-effectiveness and safety features, ensures that they are a reliable and long-lasting solution for protecting power and communication cables. Whether used in underground, marine, or high-temperature environments, FRP cable threading pipes are a smart choice for anyone seeking durable, efficient, and safe cable management solutions.

Alternative Methods for Cable Protection and Installation Compared to FRP Cable Threading Pipes

When installing and protecting cables in various environments, several solutions can be employed in addition to FRP cable threading pipes. While FRP pipes offer a range of benefits such as corrosion resistance, lightweight design, and heat insulation, other methods may be more suitable depending on the specific requirements of a project, such as cost, environmental conditions, or installation complexity. These alternative methods include PVC (Polyvinyl Chloride) conduits, metallic conduits, rigid electrical tubing (RET), and cable trays. In the following sections, we will explore each of these options in detail and compare their features with FRP cable threading pipes.

PVC Conduits

PVC conduits are one of the most common alternatives to FRP cable threading pipes for cable protection and installation. PVC is a versatile plastic material that is easy to work with and cost-effective, making it a popular choice in both residential and commercial installations. Like FRP pipes, PVC conduits are available in various sizes and configurations, and they provide protection against mechanical damage, dirt, and moisture.

Advantages of PVC Conduits

- Cost-Effective: PVC conduits are typically more affordable than FRP pipes, making them a popular choice for budget-conscious projects.

- Ease of Installation: PVC is lightweight and easy to cut, making it convenient for installation without special tools or equipment.

- Non-Corrosive: PVC is resistant to many types of corrosion, similar to FRP pipes, and is particularly useful in applications where water or mild chemicals are present.

Differences from FRP Cable Threading Pipes

While PVC conduits offer corrosion resistance, they are not as strong or durable as FRP cable threading pipes. PVC can become brittle over time, especially under UV exposure, and may not be suitable for high-temperature or heavy-duty applications. In contrast, FRP pipes offer superior heat resistance, impact strength, and corrosion resistance in harsher environments, such as marine or industrial settings.

Metallic Conduits

Metallic conduits, typically made of steel or aluminum, provide a strong and secure method for protecting cables. These conduits are often used in industrial and commercial applications where added strength and physical protection are required. They offer high mechanical strength, making them ideal for environments prone to heavy impact or mechanical stresses.

Advantages of Metallic Conduits

- High Strength and Durability: Metallic conduits offer excellent protection against physical damage, making them ideal for high-risk environments where cables are exposed to heavy impact or pressure.

- EMI Shielding: Metal conduits can provide electromagnetic interference (EMI) shielding, which is beneficial in areas where cables need to be protected from electrical noise or interference.

- Fire Resistance: Metal is naturally fire-resistant, offering an extra layer of safety in case of fire hazards.

Differences from FRP Cable Threading Pipes

While metallic conduits offer superior physical protection, they have notable drawbacks compared to FRP cable threading pipes:

- Weight: Metallic conduits are much heavier than FRP pipes, making them harder to transport and install.

- Corrosion: Unlike FRP, metallic conduits are susceptible to corrosion, especially in wet or chemically aggressive environments. FRP pipes, on the other hand, are highly corrosion-resistant and more suitable for corrosive environments.

- Electrical Conductivity: Metallic conduits can conduct electricity, which can be a disadvantage in certain installations where electrical safety is a concern. FRP pipes provide electrical insulation, reducing the risk of electrical hazards.

Rigid Electrical Tubing (RET)

Rigid Electrical Tubing (RET) is another method used for protecting and routing electrical cables. RET is typically made of metal, such as steel, and is used in situations where a rigid and durable solution is needed for cable installation. It is often used in commercial and industrial applications where there is a need for a long-lasting and protective cable pathway.

Advantages of Rigid Electrical Tubing

- Durability: RET provides strong protection against impact and external physical stresses.

- Structural Integrity: The rigidity of the tubing offers enhanced structural support, especially when cables need to be run along long distances or through tight spaces.

- Fire Resistance: Like other metallic options, RET has natural fire-resistant properties, making it a safe choice for installations in areas prone to fire hazards.

Differences from FRP Cable Threading Pipes

- Weight and Installation Complexity: RET is heavier than FRP cable threading pipes and may require more labor and time for installation. The added weight and rigid structure can also make it more challenging to maneuver.

- Corrosion Issues: Similar to metallic conduits, RET is prone to corrosion over time, especially in damp environments. In contrast, FRP pipes have superior corrosion resistance in wet and chemically aggressive environments.

- Electrical Conductivity: RET conducts electricity, which could pose a safety risk in certain situations. FRP pipes, on the other hand, are non-conductive, ensuring greater electrical safety.

Cable Trays

Cable trays are an open framework system used for supporting cables, often employed in large commercial or industrial settings. These trays provide a simple way to organize and route multiple cables across large areas, offering both accessibility and flexibility in cable management.

Advantages of Cable Trays

- Flexibility: Cable trays are ideal for installations where cables may need to be frequently added or changed. They allow easy access for modifications and maintenance.

- Ventilation: The open design of cable trays allows for better airflow around cables, which can prevent overheating and improve the performance of the cables.

- Organizational Benefits: Cable trays help keep cables organized and prevent tangling or damage during maintenance.

Differences from FRP Cable Threading Pipes

- Protection Level: Cable trays provide less physical protection for cables compared to FRP cable threading pipes. Cables inside trays are exposed to potential external damage, such as impacts or environmental factors like dust or chemicals.

- Aesthetic and Safety Considerations: FRP cable threading pipes provide a more aesthetically pleasing and safer solution for routing cables through walls, ceilings, or underground, as they offer complete protection. Cable trays, while flexible and useful, do not fully encase and protect the cables.

In addition to FRP cable threading pipes, there are several alternative methods available for cable protection and installation, each offering unique advantages depending on the specific requirements of the installation. PVC conduits are cost-effective but lack the durability of FRP pipes. Metallic conduits provide high strength and EMI shielding but are heavier and susceptible to corrosion. Rigid electrical tubing (RET) offers structural integrity and fire resistance but lacks the corrosion resistance of FRP pipes. Cable trays are versatile and flexible but provide limited physical protection for cables.

When choosing the right method for a project, factors such as environmental conditions, installation complexity, and safety considerations must be taken into account. For many applications, FRP cable threading pipes remain the best choice due to their corrosion resistance, lightweight design, and superior protection against physical damage, heat, and electrical hazards.

FAQs about FRP Cable Threading Pipe

FRP piping, or Fiberglass Reinforced Plastic piping, is a type of pipe made from a composite material that consists of a polymer matrix reinforced with fiberglass. This combination results in a lightweight yet strong and durable piping solution. FRP piping is known for its excellent corrosion resistance, making it ideal for transporting chemicals and other fluids in various industries, including oil and gas, water treatment, and construction. Additionally, FRP piping is flexible, allowing it to withstand changes in temperature and pressure without losing structural integrity. Its smooth inner surface reduces friction losses, enhancing flow efficiency. Furthermore, FRP pipes are available in various sizes and pressure ratings, making them suitable for a wide range of applications. Overall, the use of FRP piping is becoming increasingly popular due to its longevity, low maintenance requirements, and environmental benefits compared to traditional materials.

FRP in cable refers to the use of Fiberglass Reinforced Plastic as a protective material for electrical and fiber optic cables. FRP offers several advantages, such as high strength, lightweight, and excellent resistance to corrosion and environmental factors. This makes FRP an ideal choice for cable management in various applications, including telecommunications, construction, and energy. The use of FRP cable threading pipes helps protect cables from physical damage and environmental exposure while maintaining their performance. Additionally, FRP’s non-conductive properties make it a safe option for electrical applications, as it minimizes the risk of short circuits or other electrical hazards. With its ability to endure harsh conditions, FRP enhances the longevity and reliability of cable systems, making it a preferred choice for engineers and project managers seeking durable solutions for cable installations.

The primary difference between FRP and PVC pipes lies in their materials and properties. FRP (Fiberglass Reinforced Plastic) pipes are composed of a composite material that combines a polymer matrix with fiberglass reinforcement, giving them superior strength and durability. In contrast, PVC (Polyvinyl Chloride) pipes are made from a plastic polymer and are generally lighter and easier to handle. While both types of pipes offer good corrosion resistance, FRP pipes excel in applications involving harsh chemicals and high temperatures, thanks to their enhanced structural integrity. Additionally, FRP pipes can accommodate higher pressure ratings compared to PVC. On the other hand, PVC pipes are often more cost-effective for standard plumbing applications and are widely used in residential and commercial settings. Ultimately, the choice between FRP and PVC depends on the specific requirements of the project, including the environment, pressure demands, and chemical exposure.

FRP (Fiberglass Reinforced Plastic) and GRP (Glass Reinforced Plastic) pipes are often used interchangeably, but there are some distinctions worth noting. Both types of pipes utilize fiberglass as a reinforcing agent; however, the terminology can differ based on regional preferences and specific applications. Generally, FRP refers to any composite material that incorporates fiberglass and resin, while GRP specifically emphasizes the glass fiber component. The primary difference lies in their manufacturing processes and the types of resins used. FRP pipes may use a variety of resin systems, such as vinyl ester or epoxy, providing flexibility for different applications, whereas GRP pipes typically use polyester resins. In terms of performance, both types of pipes offer excellent corrosion resistance and mechanical strength, making them suitable for transporting fluids in various industries. Ultimately, the choice between FRP and GRP will depend on project requirements, including chemical compatibility, temperature, and pressure ratings.

There are several methods of joining FRP (Fiberglass Reinforced Plastic) pipes, each selected based on the application requirements, pipe size, and environmental factors. The most common methods include:

Flanged Connections: This method involves attaching the pipe ends to flanges, which are then bolted together. Flanged connections are ideal for systems that require frequent disassembly or maintenance. They ensure a secure, leak-proof seal, making them commonly used in industrial settings.

Threaded Connections: In this method, the ends of the FRP pipes are threaded, allowing them to be screwed together. This method is often used for smaller diameter pipes and is convenient for installations where tight spaces or easy assembly are crucial.

Butt Fusion: In butt fusion, the ends of the pipes are heated and then fused together, creating a strong, seamless bond. This method provides a high-strength joint and is often used for larger pipes in demanding environments.

Adhesive Bonding: Using specialized FRP adhesives, the pipe ends are bonded together. This method is simpler but is typically used for applications with less pressure or stress.

FRP stands for Fiberglass Reinforced Plastic, a composite material made by combining a plastic matrix with fiberglass reinforcement. The fiberglass fibers, typically made from glass, are embedded into the plastic resin, which can be made from materials like epoxy, polyester, or vinyl ester. This reinforcement gives the resulting material enhanced strength, durability, and resistance to various environmental factors such as moisture, chemicals, and temperature extremes. FRP is lightweight yet strong, making it a preferred material for a wide range of applications, including piping systems, construction, automotive parts, and electrical enclosures. FRP is particularly valued for its ability to withstand harsh conditions where traditional materials like steel or wood might degrade, offering a longer lifespan and reduced maintenance costs.

While FRP (Fiberglass Reinforced Plastic) is a strong and durable material, it is not necessarily stronger than steel in terms of tensile strength. Steel is known for its superior strength and ability to withstand high loads and stresses. However, FRP offers several key advantages over steel in specific applications, particularly in terms of weight-to-strength ratio. FRP is much lighter than steel, which makes it easier to handle, transport, and install, especially in large-scale systems like cable threading pipes or industrial piping networks. Additionally, FRP has excellent corrosion resistance, making it a better choice for applications exposed to chemicals, moisture, or saltwater environments, where steel would rust. The unique combination of strength, low weight, and corrosion resistance makes FRP cable threading pipes and similar systems highly effective in industries like oil and gas, marine, and construction, where weight, durability, and environmental resistance are critical factors.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.