FRP pipe cladding, or fiberglass reinforced plastic cladding, is a vital solution for protecting and insulating piping systems in industrial environments. FRP pipe cladding solutions with good corrosion and weather resistance, high physical and mechanical strength and highly durable. It is designed to shield pipes from external elements such as extreme temperatures, corrosion, and physical damage. FRP pipe cladding is lightweight yet durable, providing long-term protection while maintaining the structural integrity of the pipes it covers. It also offers excellent resistance to chemicals and UV exposure, making it ideal for both onshore and offshore applications. By using FRP pipe cladding, industries can significantly extend the lifespan of their piping systems while reducing maintenance costs and improving overall system performance.

FRP Pipe Cladding Methods

FRP (Fiber Reinforced Plastic) pipe cladding is a method used to enhance the durability, corrosion resistance, and overall performance of pipelines. It involves applying a protective layer of FRP material over the surface of a pipe. Here’s a detailed explanation of FRP pipe cladding methods:

Purpose of FRP Pipe Cladding

- Corrosion Protection: FRP cladding protects pipes from aggressive chemicals, moisture, and environmental conditions.

- Thermal Insulation: It minimizes heat loss or gain in temperature-sensitive processes.

- Mechanical Strength: The cladding adds an extra layer of protection against mechanical impacts and stresses.

- Longevity: Enhances the service life of the pipeline by resisting wear and tear.

Methods of FRP Pipe Cladding

1. Hand Lay-Up Method

- Process:

- A resin layer is applied to the pipe surface manually using brushes or rollers.

- Fiber reinforcement (such as fiberglass mats or woven fabrics) is placed over the resin.

- Additional layers of resin and reinforcement are alternated until the desired thickness is achieved.

- The cladding is allowed to cure under ambient or controlled conditions.

- Advantages:

- Simple and cost-effective for small to medium-scale projects.

- Ideal for complex shapes and field applications.

- Limitations:

- Labor-intensive and slower compared to automated methods.

- Requires skilled labor for consistent quality.

2. Spray-Up Method

- Process:

- A spray gun is used to apply chopped fibers and resin onto the pipe surface.

- Layers are built up until the required thickness is achieved.

- The cladding is then cured, either at ambient temperature or with heat.

- Advantages:

- Faster than the hand lay-up method.

- Suitable for large surface areas.

- Limitations:

- Difficult to achieve uniform thickness.

- Requires specialized equipment.

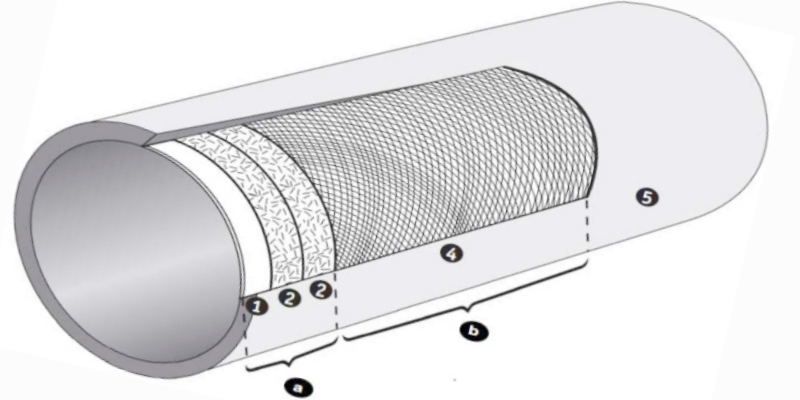

3. Filament Winding

- Process:

- Continuous strands of fiberglass impregnated with resin are wound around the pipe in a controlled pattern.

- The winding angle and thickness are adjusted based on mechanical and thermal requirements.

- The structure is cured in place.

- Advantages:

- High strength-to-weight ratio and precise control over thickness.

- Ideal for cylindrical and large-diameter pipes.

- Limitations:

- Requires specialized machinery.

- Limited flexibility for non-cylindrical shapes.

4. Preformed FRP Cladding Panels

- Process:

- Pre-fabricated FRP panels are manufactured off-site.

- These panels are then bonded or mechanically fastened onto the pipe surface.

- Joints are sealed with resin or adhesive to ensure a continuous layer.

- Advantages:

- Quick installation with minimal on-site work.

- Consistent quality as panels are produced in controlled conditions.

- Limitations:

- Less adaptable to irregular shapes or field modifications.

5. Pultrusion and Wrapping

- Process:

- Pultruded FRP sheets or tapes are wrapped around the pipe, usually in combination with resin.

- Layers are built up to achieve the desired protection.

- Advantages:

- Effective for straight pipes.

- Quick and efficient for long runs.

- Limitations:

- Not suitable for complex geometries.

Key Considerations

- Material Selection:

- Resins (e.g., polyester, vinyl ester, epoxy) are chosen based on chemical and thermal requirements.

- Fibers (e.g., glass, carbon, or aramid) provide mechanical strength.

- Surface Preparation:

- Proper cleaning and roughening of the pipe surface are critical to ensure good adhesion.

- Curing Process:

- Ambient or heat curing ensures the resin hardens properly, affecting the overall performance.

- Environmental Factors:

- Humidity, temperature, and UV exposure during installation can influence the quality of the cladding.

Applications

- Chemical processing pipelines.

- Oil and gas pipelines exposed to harsh environments.

- Water and wastewater treatment facilities.

- Insulated pipelines for thermal regulation.

By selecting the appropriate FRP cladding method and materials, engineers can significantly enhance the durability and performance of pipelines in demanding conditions.

The Key of FRP Pipe Cladding

FRP pipe cladding is a crucial method for protecting fiberglass reinforced plastic (FRP) pipes from external environmental factors and mechanical damage. Cladding involves covering the surface of the pipe with a protective layer that acts as a barrier against physical, thermal, and chemical influences. Proper cladding not only enhances the durability and longevity of FRP pipes but also improves their overall performance in various industrial applications. GangLong Fiberglass offers advanced FRP pipe cladding solutions tailored to different environmental and operational requirements.

Cladding serves as the first line of defense for FRP pipes, especially when they are exposed to harsh environmental conditions such as UV radiation, moisture, chemical exposure, and physical impacts. FRP pipe cladding from GangLong Fiberglass provides a protective shield that prevents the underlying pipe from being compromised. By creating a barrier against external factors, cladding ensures that the FRP pipe retains its mechanical and chemical properties throughout its service life.

In addition to protection, FRP pipe cladding also offers aesthetic benefits by providing a uniform and attractive appearance to the piping system. This is particularly important in industrial settings where pipes are visible and must conform to specific visual standards. GangLong Fiberglass offers a range of cladding options to meet the specific needs of various industries, ensuring both protection and visual appeal.

Thermal Protection

One of the primary advantages of FRP pipe cladding is its ability to provide enhanced thermal protection. Cladding acts as an insulating layer that helps regulate the temperature of the fluid within the pipe. This thermal regulation is especially crucial in applications involving temperature-sensitive fluids, where maintaining a consistent temperature is essential for process efficiency and safety.

FRP pipe cladding from GangLong Fiberglass, such as the GangLong Fiberglass Thermal Series, offers excellent thermal insulation properties. By reducing heat loss or gain, the cladding minimizes the energy required to maintain the desired fluid temperature. This leads to improved energy efficiency and reduced operational costs. Additionally, thermal protection provided by cladding prevents the formation of condensation on the pipe surface, reducing the risk of corrosion and microbial growth.

Resistance to Extreme Temperatures

FRP pipes are often used in environments with extreme temperature variations, which can affect their performance and longevity. FRP pipe cladding provides an additional layer of protection that helps the pipe withstand high and low temperatures without compromising its structural integrity. The cladding material is chosen based on its thermal resistance properties, ensuring that it can handle the specific temperature range of the application, while respecting the frp pipe temperature limits. This ensures the piping system operates efficiently and safely under varying temperature conditions.

For example, in high-temperature applications such as chemical processing, FRP pipe cladding prevents heat transfer to the surrounding environment, reducing the risk of burns or thermal damage. In low-temperature applications, such as cryogenic fluid transport, cladding prevents the pipe from becoming brittle and cracking due to thermal stress. GangLong Fiberglass offers cladding materials specifically designed for extreme temperature applications, ensuring the safe and reliable operation of the piping system.

Protection Against UV Radiation and Weathering

FRP pipes installed outdoors are susceptible to degradation caused by prolonged exposure to ultraviolet (UV) radiation and weathering. UV radiation can cause the resin matrix in FRP pipes to degrade over time, leading to surface cracking, discoloration, and reduced mechanical strength. Weathering factors such as rain, wind, and temperature fluctuations can also affect the pipe’s surface.

FRP pipe cladding provides a protective layer that shields the pipe from UV radiation and weathering effects. By blocking UV rays and preventing direct exposure to the elements, cladding helps preserve the pipe’s mechanical properties and appearance. GangLong Fiberglass’s UV-resistant cladding options are formulated to withstand prolonged outdoor exposure, ensuring that the pipe remains protected and maintains its structural integrity over time.

Mechanical Protection and Impact Resistance

FRP pipes may be subject to mechanical impacts, abrasion, and physical damage during installation, operation, or maintenance. Cladding acts as a protective barrier that absorbs and dissipates the energy from impacts, reducing the risk of damage to the underlying pipe. This mechanical protection is especially important in environments where pipes are exposed to heavy equipment, moving vehicles, or abrasive substances.

GangLong Fiberglass offers cladding solutions with enhanced impact resistance, such as the GangLong Fiberglass Impact Series. These cladding materials are designed to withstand mechanical stresses and protect the pipe from scratches, dents, and other forms of physical damage. By providing an additional layer of protection, cladding ensures that the FRP pipe remains intact and functional, even in demanding conditions.

Chemical Resistance and Corrosion Protection

In industrial settings, FRP pipes may come into contact with corrosive chemicals, acids, and solvents. While FRP pipes are inherently resistant to many chemicals, the use of cladding provides an extra layer of chemical protection. FRP pipe cladding acts as a barrier that prevents aggressive substances from reaching the pipe surface, reducing the risk of chemical degradation and corrosion.

GangLong Fiberglass’s chemical-resistant cladding options, such as the GangLong Fiberglass Chemical Series, are designed to withstand exposure to a wide range of corrosive agents. This cladding enhances the pipe’s resistance to chemical attack, ensuring that it can safely transport hazardous fluids without compromising its structural integrity. By preventing chemical infiltration, cladding enhances the FRP pipe life expectancy, thereby reducing the frequency of maintenance or replacement needed for the entire piping system.

Enhanced Safety and Compliance

FRP winding pipe cladding contributes to the safety and compliance of industrial piping systems. In facilities where pipes carry hazardous or high-temperature fluids, cladding provides an additional layer of protection that minimizes the risk of accidents, burns, and leaks. By regulating the pipe’s surface temperature and providing a physical barrier, cladding helps create a safer working environment for personnel.

Moreover, cladding ensures that the piping system complies with industry standards and regulatory requirements. Many industries have specific guidelines regarding the insulation, protection, and safety of piping systems. By using cladding that meets these standards, facilities can demonstrate their commitment to safety and regulatory compliance. GangLong Fiberglass offers cladding solutions that adhere to industry regulations, providing peace of mind and ensuring safe operation.

Aesthetic Benefits and Surface Protection

In addition to functional benefits, FRP pipe cladding offers aesthetic advantages by providing a smooth, uniform surface finish to the piping system. Cladding can enhance the appearance of the pipes, making them visually appealing and suitable for environments where aesthetics are important, such as commercial or public spaces.

GangLong Fiberglass provides a variety of cladding finishes and colors, allowing clients to choose an option that complements the design of their facility. This aesthetic enhancement is particularly valuable in settings where the piping system is visible and must conform to specific visual standards. Additionally, cladding protects the pipe’s surface from dirt, stains, and graffiti, reducing the need for cleaning and maintenance.

Customization and Adaptability of FRP Pipe Cladding

One of the key advantages of FRP pipe cladding is its adaptability and customization. Cladding can be tailored to meet the specific needs of different applications, including size, shape, material, and performance requirements. Whether it’s thermal insulation, chemical resistance, or mechanical protection, GangLong Fiberglass offers customized cladding solutions that address the unique challenges of each project.

The flexibility of FRP pipe cladding allows it to be applied to pipes of various diameters, lengths, and configurations. GangLong Fiberglass’s cladding options can be adapted to fit complex pipe geometries, including bends, elbows, and fittings, ensuring complete coverage and protection. This level of customization ensures that the cladding provides optimal performance for the intended application.

FRP pipe cladding is an essential component in enhancing the performance, protection, and longevity of FRP piping systems. By providing thermal insulation, resistance to extreme temperatures, UV protection, mechanical impact resistance, and chemical resistance, cladding ensures that FRP pipes can withstand a wide range of environmental and operational challenges. GangLong Fiberglass offers a comprehensive range of cladding solutions tailored to meet the specific needs of various industries, ensuring that their FRP pipes remain safe, functional, and visually appealing throughout their service life. Additionally, by referring to the frp pipe span chart, users can optimize the installation and support of FRP pipes, ensuring they perform at their best. With the right cladding in place, FRP piping systems can achieve optimal performance and durability, delivering reliable results in even the most demanding conditions.

How the ID of FRP Pipe Affects Fluid Flow Capacity

FRP Pipe Cladding: Best Practices for Installation

FRP pipe cladding serves as an essential protective layer for fiberglass-reinforced plastic (FRP) pipes, offering insulation, mechanical protection, and resistance to environmental factors. Proper installation of FRP pipe cladding is crucial to ensure that it provides the intended benefits, including full coverage, thermal regulation, and enhanced durability. Cladding installation requires careful planning, precise techniques, and adherence to best practices to achieve optimal results. GangLong Fiberglass provides detailed guidelines for the installation of their cladding solutions to ensure effective performance across various applications.

Preparing for FRP Pipe Cladding Installation

Before installing FRP pipe cladding, thorough preparation is necessary to ensure a smooth and effective process. This includes assessing the piping system, selecting the appropriate cladding materials, and preparing the pipe surface for cladding application.

Assessment of the Piping System: Begin by evaluating the FRP piping system to determine its specific requirements for cladding. Consider factors such as operating temperature, environmental exposure, chemical resistance, and mechanical protection. This assessment helps in selecting the right cladding material and determining the required thickness and configuration to meet the system’s needs.

Selection of Cladding Material: Fiberglass pipe insulation is an essential component for maintaining the thermal efficiency of industrial piping systems. The use of 3/4 fiberglass pipe insulation, or fiberglass tube pipe Insulation, helps to prevent heat loss, ensuring that pipes operate at the desired temperature. This insulation is particularly useful in environments where temperature regulation is critical to maintaining system performance.

Choose the appropriate cladding material based on the assessment. GangLong Fiberglass offers a range of cladding options, including the GangLong Fiberglass Thermal Series for thermal insulation, the GangLong Fiberglass Chemical Series for chemical resistance, and the GangLong Fiberglass Impact Series for mechanical protection. The selection of the right cladding material ensures that the FRP pipe cladding meets the specific demands of the application.

Surface Preparation: Proper surface preparation is critical for the effective adhesion and performance of FRP pipe cladding. Clean the pipe surface thoroughly to remove any dirt, grease, oil, or contaminants. Use appropriate cleaning agents and methods, such as solvent wiping or abrasive cleaning, to achieve a clean and dry surface. Ensure that the pipe surface is free of moisture before applying the cladding.

Step-by-Step Guide to FRP Pipe Cladding Installation

Installing FRP pipe cladding involves a series of steps that must be followed meticulously to ensure full coverage and optimal insulation. Here is a step-by-step guide to the installation process:

Cutting and Shaping the Cladding Material

Measure and Mark: Measure the dimensions of the pipe, including its diameter, length, and any bends or fittings that require cladding. Use these measurements to mark the cladding material accurately, ensuring that it will fit the pipe precisely. Precise measurements are essential to avoid gaps or overlaps that could compromise the effectiveness of the cladding.

Cut the Cladding Material: Using appropriate tools, such as shears or saws, cut the cladding material according to the marked measurements. For complex pipe geometries, such as bends or elbows, cut the cladding material into segments that can be fitted around these sections. GangLong Fiberglass provides cladding materials that are easy to cut and shape, allowing for precise customization to fit any pipe configuration.

Applying the Cladding to the Pipe

Position the Cladding: Begin by positioning the cladding material around the pipe, starting from one end and working toward the other. Ensure that the cladding is aligned with the pipe and that it covers the entire surface without leaving any gaps. For sections with bends or fittings, carefully position the cladding segments to ensure a tight fit.

Secure the Cladding: Use appropriate fasteners, such as bands, straps, or adhesives, to secure the cladding to the pipe. For thermal insulation cladding, ensure that the fasteners do not create thermal bridges that could affect the insulating properties of the cladding. GangLong Fiberglass recommends specific fastening methods for their cladding products to ensure a secure and durable installation.

Seal the Joints and Seams: Properly seal all joints and seams in the cladding to ensure complete coverage and prevent moisture or contaminants from penetrating the protective layer. Use compatible sealants, tapes, or adhesives to create a watertight and airtight seal. Sealing the joints is especially important for cladding used in outdoor or high-moisture environments, as it prevents water ingress and potential damage to the pipe.

Insulating and Protecting the Cladding

Apply Insulation (If Required): For applications that require additional thermal insulation, apply an insulating layer beneath the cladding. GangLong Fiberglass offers insulation options that can be used in conjunction with their cladding products to provide enhanced thermal protection. Ensure that the insulation is applied uniformly around the pipe to prevent thermal bridging and maximize efficiency.

Protective Coating: In environments where the cladding may be exposed to harsh conditions, such as UV radiation, chemical exposure, or abrasion, consider applying a protective coating to the cladding surface. GangLong Fiberglass provides UV-resistant and chemical-resistant coatings that can be applied to their cladding materials to enhance durability and protection.

Ensuring Full Coverage and Optimal Insulation

Ensuring full coverage and optimal insulation is vital for the effectiveness of FRP pipe cladding. Properly installed cladding provides a continuous barrier that protects the pipe from external influences and maintains its thermal performance.

Avoid Gaps and Overlaps: During installation, ensure that there are no gaps or overlaps in the cladding material. Gaps can lead to thermal losses, moisture ingress, and reduced protection, while overlaps can create thermal bridges that compromise insulation efficiency. Carefully align the cladding sections to achieve a seamless and uniform layer around the pipe.

Verify Cladding Thickness: Verify that the cladding thickness meets the design specifications for the application. The thickness of the cladding affects its thermal insulating properties and mechanical protection. GangLong Fiberglass provides cladding materials in various thicknesses to suit different requirements, ensuring that the installed cladding delivers the desired performance.

Post-Installation Inspection and Maintenance

After installing the FRP pipe cladding, conduct a thorough inspection to ensure that it has been applied correctly and meets the desired standards. The inspection process involves checking the cladding for proper fit, secure attachment, and complete sealing of joints.

Inspect for Proper Fit: Check that the cladding fits snugly around the pipe and conforms to its shape, including bends and fittings. Ensure that there are no visible gaps, overlaps, or areas where the cladding may be loose or misaligned.

Check Fasteners and Seals: Verify that all fasteners and seals are secure and properly applied. Inspect the joints and seams for any gaps or voids that may compromise the cladding’s effectiveness. If necessary, reapply sealants or adjust fasteners to ensure a tight and secure installation.

Regular Maintenance: Perform regular maintenance of the cladding to ensure its continued performance. Inspect the cladding periodically for signs of damage, such as cracks, dents, or delamination. Address any issues promptly to maintain the protective and insulating properties of the cladding. GangLong Fiberglass recommends a maintenance schedule to keep the cladding in optimal condition throughout its service life.

Addressing Challenges in FRP Pipe Cladding Installation

Installing FRP pipe cladding can present challenges, especially in complex piping systems or harsh environments. Common challenges include fitting the cladding around bends and fittings, ensuring full coverage in tight spaces, and managing thermal expansion.

Fitting Around Bends and Fittings: Cladding installation around bends, elbows, and fittings requires precision and care. Use segmented cladding pieces cut to fit the specific geometry of these sections. Apply sealant or adhesive to the joints to ensure a continuous protective layer around the bend or fitting.

Ensuring Coverage in Tight Spaces: In areas with limited access, such as narrow corridors or congested installations, take extra care to ensure full coverage. Use flexible cladding materials that can be easily maneuvered into tight spaces without compromising the integrity of the installation.

Managing Thermal Expansion: FRP pipes may expand or contract due to temperature fluctuations. To accommodate frp pipe thermal expansion, leave a small gap between the cladding segments and use flexible sealants or expansion joints. This allows the pipe to move without causing stress on the cladding or compromising its performance.

Guide in the PERMA-PIPE FRP Pipe Operating Manual

FRP Pipe Cladding: Essential Protection for Industrial Piping Systems

FRP pipe cladding, short for fiberglass-reinforced plastic pipe cladding, is a key solution for providing durable protection and insulation to industrial piping systems. In challenging environments where pipes are exposed to corrosive elements, extreme temperatures, and physical wear, FRP pipe cladding offers a lightweight yet robust layer of defense. This advanced material ensures that industrial piping systems remain efficient and reliable, contributing to the longevity of the pipes and reducing the need for frequent maintenance. FRP pipe cladding is widely used in sectors like oil and gas, chemical processing, and other industries where pipe protection is essential to maintaining operations.

What Are the Benefits of FRP Cladding Panels in Industrial Applications?

FRP cladding panels are highly valued in industrial applications for their range of protective features. The panels are designed to be lightweight yet extremely strong, making them easier to install without compromising on durability. One of the primary benefits of FRP cladding is its high resistance to corrosion. Industrial environments often expose piping systems to harsh chemicals and moisture, which can lead to significant damage over time. FRP cladding panels from GangLong Fiberglass are engineered to resist these corrosive elements, effectively extending the lifespan of the pipes they protect.

Lightweight Nature of FRP Cladding Panels

The lightweight nature of FRP cladding panels makes them ideal for large-scale industrial projects where heavy materials can be cumbersome and expensive to transport and install. Despite their low weight, FRP panels are incredibly durable, providing a protective barrier that shields pipes from external damage without adding unnecessary load to the infrastructure. This characteristic also allows for easier handling during installation, reducing labor costs and project timelines.

Durability and Longevity

Another standout benefit of FRP cladding panels is their durability. They are designed to withstand the harshest conditions, from extreme temperatures to physical impacts. Whether installed in offshore platforms or industrial plants, FRP cladding panels maintain their structural integrity for years. This long-lasting performance reduces the need for frequent repairs or replacements, helping companies save on maintenance costs over time.

Corrosion Resistance

One of the most significant threats to industrial piping systems is corrosion. Pipes exposed to chemical substances, saltwater, or humid conditions are at high risk of corrosion, which can lead to costly damage and system failures. FRP cladding panels, such as those manufactured by GangLong Fiberglass, are designed to resist corrosion, even in the most challenging environments. This resistance ensures that the pipes are protected from rust and chemical degradation, contributing to the overall reliability and efficiency of the system.

Temperature and UV Resistance

In addition to corrosion resistance, FRP cladding panels offer protection from extreme temperatures and UV exposure. Industrial pipes that operate in high-temperature environments or are exposed to direct sunlight require a protective cladding material that can withstand these conditions without degrading. FRP panels are engineered to perform well in both high and low temperatures, ensuring that the pipes are insulated and shielded from the elements. Furthermore, their UV resistance helps prevent material breakdown caused by prolonged sun exposure, making them suitable for outdoor applications.

Exploring FRP Wall Cladding for Piping Systems

FRP wall cladding is another critical component of industrial piping system protection. While FRP pipe cladding focuses on safeguarding the pipes themselves, FRP wall cladding is used to reinforce the structural integrity of walls and surrounding areas where pipes are installed. This type of cladding adds an additional layer of protection to ensure the entire piping infrastructure remains intact and functional.

Strengthening Structural Integrity with FRP Wall Cladding

The primary purpose of FRP wall cladding in piping systems is to reinforce the walls that support the pipes. These walls often bear the weight of heavy industrial pipes and are exposed to the same environmental factors as the pipes themselves. By applying FRP wall cladding, industries can ensure that the walls maintain their strength over time, preventing structural damage that could compromise the entire piping system.

Preventing Physical and Chemical Damage

Walls surrounding piping systems are frequently subjected to physical impacts, vibrations, and chemical spills. These forces can weaken the structure, leading to cracks or deterioration. FRP wall cladding is designed to provide a protective barrier that absorbs impacts and resists chemical damage. This ensures that the walls remain intact, even in harsh industrial environments, thereby reducing the risk of system failure due to compromised infrastructure.

Ensuring Long-Term Stability with FRP Wall Cladding

Long-term stability is a key concern in any industrial setting, particularly when it comes to piping systems. Walls that support pipes must be able to withstand constant pressure, weight, and exposure to corrosive substances. FRP wall cladding ensures that these walls remain stable and resistant to wear over time. By investing in FRP wall cladding, companies can protect both the pipes and the surrounding structure, contributing to the overall efficiency and safety of the facility.

Testing and Measuring the Modulus of Elasticity of FRP Pipe

FRP Pipe Cladding and Agricultural Panels

FRP (Fiber Reinforced Plastic) agricultural panels are highly durable and versatile materials specifically designed for the unique needs of agricultural environments. These panels combine strength, lightweight construction, and resistance to harsh conditions, making them a preferred choice for various agricultural applications.

Key Features of FRP Agricultural Panels

- Durability

- Impact Resistance: Can withstand physical impacts without cracking or breaking.

- Moisture Resistance: Non-porous and impervious to water, preventing warping or rotting.

- Corrosion Resistance: Resistant to chemicals like fertilizers, pesticides, and cleaning agents, ensuring longevity.

- Ease of Maintenance

- Smooth, non-porous surfaces make cleaning simple with minimal effort.

- Resistant to stains, mold, and mildew, ensuring hygiene and safety in agricultural settings.

- UV and Weather Resistance

- UV-stabilized panels maintain their integrity and color under prolonged exposure to sunlight.

- Suitable for outdoor and indoor applications in various climates.

- Lightweight Construction

- Easy to handle, transport, and install without heavy machinery.

- Customizable

- Available in various sizes, colors, and finishes to meet specific requirements.

- Can be pre-cut and shaped for easy integration into agricultural structures.

Applications of FRP Agricultural Panels

- Animal Housing

- Barns and Stables: Durable walls and ceilings that withstand scratches and impacts from livestock.

- Poultry Houses: Hygienic surfaces that resist bacteria and are easy to clean.

- Greenhouses

- Panels with high light transmission properties help maximize natural sunlight for plant growth.

- Provide excellent thermal insulation to maintain optimal growing conditions.

- Cold Storage Facilities

- Used as interior linings to ensure thermal insulation and maintain cleanliness in areas used for storing perishable goods.

- Food Processing Areas

- Ideal for environments that require strict hygiene, such as dairy farms or vegetable packing facilities.

- Silos and Storage Sheds

- Durable, moisture-resistant panels protect stored grains, feed, and equipment from environmental damage.

Advantages of FRP Agricultural Panels

- Long Lifespan

- Resistant to wear and tear, providing years of reliable performance without frequent replacements.

- Cost-Effective

- Low maintenance costs and durability make these panels a smart investment.

- Environmentally Friendly

- Reduced need for replacements minimizes waste and environmental impact.

- Improved Hygiene

- Smooth surfaces prevent the buildup of dirt, mold, and bacteria, supporting healthier farming operations.

- Aesthetic Appeal

- Available in various colors and finishes for a clean and professional look.

Installation Techniques

- Fasteners

- Panels are attached using screws or rivets, ensuring secure placement.

- Adhesive Bonding

- Seamless installation with waterproof adhesives for areas requiring airtight seals.

- Customization

- Pre-fabricated panels can be cut, drilled, and molded for easy fitment into existing structures.

| Feature | FRP Pipe Cladding | FRP Agricultural Panels |

|---|---|---|

| Purpose | Protects pipes from corrosion and damage. | Provides durable, hygienic surfaces for agricultural use. |

| Material Properties | High chemical and thermal resistance. | Waterproof, impact-resistant, and easy to clean. |

| Applications | Industrial pipelines. | Barns, greenhouses, food storage. |

| Installation | Complex (e.g., filament winding, lay-up). | Simple (fasteners, adhesives). |

Both applications leverage FRP’s exceptional properties to solve unique challenges in their respective fields, offering durable, lightweight, and cost-effective solutions.

FAQs about Frp Pipe Cladding

FRP (Fiberglass Reinforced Plastic) pipes and PVC (Polyvinyl Chloride) pipes differ significantly in terms of material properties, performance, and application suitability. FRP pipes are made from a composite material of fiberglass reinforcement and a polymer resin matrix, providing them with high strength, durability, and excellent resistance to corrosion, even in aggressive chemical environments. They are also known for their ability to withstand high temperatures and mechanical stresses, making them suitable for demanding applications such as chemical processing, industrial wastewater management, and offshore operations. On the other hand, PVC pipes are made from a thermoplastic polymer and are generally used in less demanding applications like residential plumbing, drainage, and irrigation. While PVC pipes are lightweight, easy to install, and resistant to many chemicals, they have limitations in terms of temperature resistance and mechanical strength. PVC pipes may become brittle and prone to cracking under high stress or temperature variations, whereas FRP pipes maintain their integrity in such conditions. GangLong Fiberglass’s FRP piping solutions offer a versatile and robust alternative to PVC, especially in scenarios where long-term durability, chemical resistance, and structural strength are critical factors.

The life expectancy of FRP pipes is generally very long, often exceeding 50 years when properly installed and maintained. FRP pipes are designed to withstand harsh environmental conditions, including exposure to chemicals, high temperatures, and UV radiation, without suffering from the corrosion and degradation that affect many traditional piping materials. Their resistance to internal and external corrosion makes them particularly suitable for applications involving aggressive chemicals, saltwater, or other corrosive substances. Furthermore, the inherent strength and flexibility of FRP pipes allow them to absorb mechanical stresses and impacts without cracking or breaking, enhancing their longevity. The life expectancy of FRP pipes can also be influenced by factors such as the quality of the installation, the operating environment, and regular maintenance. By choosing high-quality FRP piping products like those offered by GangLong Fiberglass and adhering to recommended installation and maintenance practices, industries can ensure that their FRP piping systems provide reliable, long-lasting service with minimal need for repair or replacement over time.

FRP piping refers to pipes made from fiberglass reinforced plastic, a composite material consisting of a polymer matrix reinforced with glass fibers. FRP piping is known for its excellent strength-to-weight ratio, corrosion resistance, and durability, making it an ideal choice for various industrial applications. Unlike traditional metal pipes, FRP pipes do not corrode when exposed to harsh chemicals, moisture, or extreme temperatures, which significantly extends their service life. Additionally, FRP piping is lightweight and easy to install, reducing transportation and labor costs. It can be customized to meet specific requirements, including varying diameters, wall thicknesses, and lengths, allowing it to be tailored to a wide range of applications, from chemical processing and wastewater treatment to marine and offshore operations. GangLong Fiberglass manufactures FRP piping solutions that are engineered to provide reliable performance in challenging environments, offering products that cater to the unique demands of different industries. With its combination of strength, flexibility, and corrosion resistance, FRP piping is a versatile and cost-effective solution for fluid transport and containment.

FRP piping refers to piping systems made from Fiber Reinforced Plastic, a composite material combining a polymer matrix with reinforced fibers like glass or carbon. FRP pipes are widely used in industries due to their excellent corrosion resistance, lightweight nature, and durability. These pipes are commonly found in chemical plants, wastewater systems, and environments with highly corrosive fluids. They are engineered to meet specific application requirements, including strength, thermal performance, and chemical resistance.

FRP stands for Fiber Reinforced Plastic. It is a composite material consisting of a polymer matrix reinforced with fibers such as glass, carbon, or aramid. The reinforcement fibers provide strength and rigidity, while the polymer matrix offers corrosion resistance and durability. FRP is used in applications like construction, piping, tanks, and automotive parts due to its lightweight and high-performance characteristics.

FRP pipes have some disadvantages, including:

High initial cost: Manufacturing FRP requires specialized processes, leading to higher costs compared to traditional materials.

Brittleness: They can be more brittle under sudden impact compared to metals.

UV sensitivity: Prolonged exposure to UV light can degrade the material unless properly protected.

Limited thermal resistance: FRP pipes may not perform well under extreme heat conditions.

Repair difficulty: Repairs can be complex, often requiring skilled technicians.

Yes, FRP is generally stronger than PVC. FRP pipes have superior tensile and compressive strength due to their reinforced fiber structure, making them more suitable for high-pressure and heavy-load applications. Additionally, FRP pipes are more resistant to chemical and environmental damage compared to PVC. However, PVC is cheaper, easier to install, and adequate for less demanding conditions.

The 4 main types of FRP are categorized based on the type of reinforcement fiber used:

Glass Fiber Reinforced Plastic (GFRP): Most common and economical, used in piping and tanks.

Carbon Fiber Reinforced Plastic (CFRP): High strength and lightweight, used in aerospace and automotive industries.

Aramid Fiber Reinforced Plastic (AFRP): High impact resistance, used in protective gear and ropes.

Basalt Fiber Reinforced Plastic (BFRP): Excellent thermal and chemical resistance, suitable for harsh environments.

FRP materials come with certain risks:

Health hazards: Dust from cutting or sanding FRP can irritate the skin, eyes, and respiratory system.

Fire risks: While some FRP types are flame-retardant, others can emit toxic fumes when burning.

Structural failure: Improper installation or overloading can cause fractures or failures.

Environmental sensitivity: Long-term exposure to UV radiation, chemicals, or extreme temperatures may degrade performance.

Proper handling, maintenance, and safety measures mitigate these risks.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.