Grating clips are essential components used to secure grating systems to their supporting structures. These clips ensure the stability and safety of the grating, preventing shifting or displacement. Grating clip types come in various materials, each suited for different environments and load requirements. Common applications include industrial flooring, drainage covers, walkways, and platforms in sectors like construction, manufacturing, and utilities. When selecting grating clips, it’s important to consider factors such as material strength, corrosion resistance, and ease of installation. Choosing the correct grating clip type can improve durability, reduce maintenance, and enhance safety across various applications. Understanding these features ensures optimal performance and longevity of grating systems.

Grating Clip Types

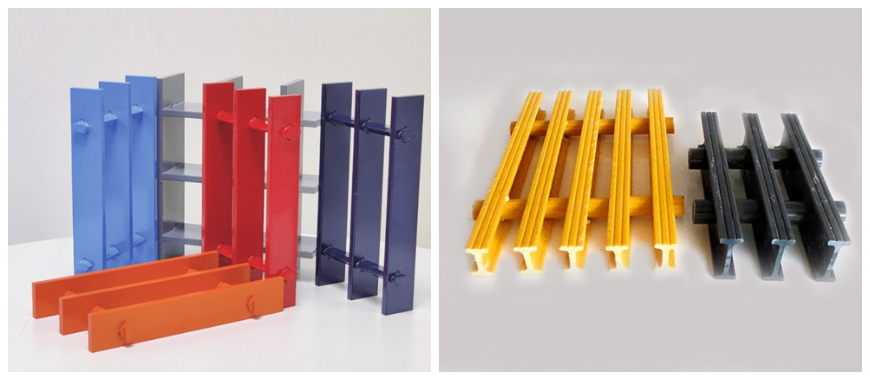

Grating clips are vital components in securing grating systems to various structures. These clips come in different designs, materials, and sizes to accommodate various applications. The primary purpose of grating clips is to ensure that grating remains fixed and secure, preventing any displacement or damage. Grating clip types include J-bolts, G-clips, and other fasteners, each offering specific advantages depending on the grating material and environment. The selection of the right type of grating clip is critical to ensuring optimal functionality, longevity, and safety of the grating system.

Explanation of Types of Grating Clips

Grating clips are designed to work with different grating systems, and the type of clip used depends on the material and installation requirements. Grating clip types such as J-bolts and G-clips are particularly effective in various applications, each providing specific benefits depending on the project’s needs.

J-Bolts for Metal Grating

J-bolts are commonly used for securing metal grating to supporting structures. These clips provide a strong, reliable hold, especially in industrial environments where grating systems endure heavy foot traffic or machinery loads. J-bolts are ideal for high-stress situations, as they are designed to withstand significant pressure without loosening or breaking. They are typically used in areas with heavy machinery, loading docks, industrial plants, and warehouse floors, ensuring that grating remains securely fastened even under intense pressure. Their versatility also allows them to be used in both temporary and permanent installations.

G-Clips for Simple, Tool-Free Installation

G-clips are another popular type of grating clip types offering a simple, effective method for securing grating without the need for additional tools. These clips are widely used in smaller-scale applications where ease of installation is a priority. They are typically used in less demanding environments, such as pedestrian walkways, outdoor landscaping projects, or any area where a secure, yet straightforward solution is needed. G-clips provide a quick installation process, saving time and effort, while still offering a sufficient level of security for grating.

In addition to these, there are also heavy-duty grating clips designed for use in demanding environments such as chemical plants or high-traffic walkways. These clips provide increased holding power and resistance to corrosion, ensuring the grating remains secure even under extreme conditions. The choice of grating clip type largely depends on the installation environment, load requirements, and the type of grating being used.

Importance of Selecting the Right Grating Clip Type

Selecting the right grating clip type is crucial for the performance and longevity of the grating system. Each clip type is engineered to suit specific needs and applications, and using the wrong one can result in instability, damage to the grating, or safety hazards. For example, using a standard clip in high-load environments could lead to clip failure, compromising the entire grating structure. On the other hand, using a heavy-duty clip in a low-load application may be unnecessary, leading to increased costs without added benefit.

The right grating clip type ensures that the grating stays securely in place, even under pressure from heavy machinery, foot traffic, or harsh environmental conditions. It also plays a key role in reducing maintenance costs by preventing early wear or failure of the grating system. The long-term effectiveness of a grating system depends on the careful selection of grating clips that are compatible with the specific material and installation conditions.

Overview of Materials Used in Grating Clips

Grating clips are available in several materials, including steel, metal alloys, and wood, each providing different benefits depending on the application. Steel grating clips are the most commonly used, offering a high level of strength and durability. They are ideal for use in industrial environments, where heavy-duty performance is required. Stainless steel is often chosen for its resistance to rust and corrosion, making it suitable for outdoor or harsh environments where exposure to moisture is common.

Metal grating clips, particularly those made from aluminum or galvanized steel, are lighter in weight but still provide adequate strength for many applications. These clips are often used in medium-duty applications or where weight is a concern. Wood grating clips, although less common, are used when securing grating to wooden surfaces. These clips are ideal for applications in residential areas or places where the grating system is not subjected to heavy loads.

Choosing the Right Wire Grating for Your Project

Steel Grating Clip Types

Steel grating clips are among the most widely used fasteners in the construction industry. As one of the essential grating clip types, these clips are specifically designed to secure metal grating systems to their supporting structures, ensuring stability and durability. Steel grating clips are versatile and suitable for both light and heavy-duty applications, providing secure attachment even in challenging environments. The strength and reliability they offer make them a preferred choice in industrial, commercial, and infrastructure projects.

Steel grating clips are widely chosen for their robust performance in industrial settings, particularly in environments exposed to heavy loads, foot traffic, and harsh weather conditions. Their durability makes them a preferred choice for large-scale construction projects, including commercial buildings, factories, and public infrastructure. These clips ensure that grating systems stay in place, preventing any potential accidents due to shifting or loose grating. The material composition and design of steel clips offer a balance between strength and cost-effectiveness, which contributes to their widespread use in a variety of industries.

Benefits of Using Steel Clips in Various Environments

One of the key benefits of using steel grating clips is their superior strength, which ensures secure attachment in demanding environments. Steel clips provide excellent grip and hold, making them ideal for industrial applications where high levels of foot traffic or heavy machinery are common. These clips can withstand significant weight loads and pressure without bending or breaking, offering long-term reliability in high-stress conditions.

Another benefit is the corrosion resistance of steel clips, particularly those made from stainless steel or galvanized steel. These clips are highly resistant to rust and degradation, making them suitable for outdoor or wet environments, such as marine applications, wastewater treatment plants, or chemical processing facilities. The longevity of steel grating clips reduces maintenance needs and ensures that the grating system remains functional and secure for extended periods.

Steel grating clips also offer ease of installation. With a simple design, they can be quickly and efficiently installed without requiring specialized tools or labor-intensive processes. This reduces installation time and associated costs, making them an attractive option for construction projects with tight deadlines or budgets.

Examples of Projects That Use Steel Grating Clips

Steel grating clips are commonly used in a wide range of projects, including industrial, commercial, and infrastructure developments. For instance, in industrial settings such as power plants and manufacturing facilities, steel grating clips are essential for securing grating used in walkways, platforms, and machine guards. These clips ensure that the grating remains firmly in place despite the heavy equipment and foot traffic that are common in these environments.

Steel grating clips are also used extensively in public infrastructure projects, such as bridges, tunnels, and public transit systems. In these high-traffic areas, the grating systems must be secure to prevent accidents and maintain structural integrity. Steel clips are favored for their strength and reliability in these demanding applications.

In addition to industrial and infrastructure projects, steel grating clips are often used in commercial construction, including retail stores, office buildings, and parking garages. Steel clips are a cost-effective solution for securing grating in these settings, where durability and stability are crucial but the environmental conditions may not be as harsh as in industrial environments.

Metal Grating Clip Types

Aluminum Grating Clip Types

Benefits of Aluminum Grating Clips

Aluminum grating clips are particularly valued for their lightweight nature, making them an ideal choice for projects where reducing the overall weight is crucial. These clips are typically used in applications such as pedestrian walkways, rooftops, and ventilation covers. The lightness of aluminum allows for easier installation, minimizing the labor costs and time required for setup.

- Ease of Installation: Aluminum grating clips are easy to handle and install due to their lightweight properties. This reduces the effort needed during the installation process, making them ideal for projects with tight deadlines.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer that resists corrosion. This makes aluminum grating clips perfect for use in environments where moisture or weather exposure is common, such as rooftops or outdoor walkways.

- Cost-Effectiveness: Aluminum is a cost-effective material compared to other metals like stainless steel or galvanized steel. This makes it a budget-friendly option for large-scale construction projects that require large quantities of grating clips.

- Aesthetic Appeal: Aluminum has a sleek, modern appearance, making it an excellent choice for architectural projects where aesthetics play a significant role. It maintains its appearance over time, even in outdoor settings, without discoloration or degradation.

Applications of Aluminum Grating Clips

Aluminum grating clips are commonly used in pedestrian walkways, rooftops, and ventilation covers, where their lightweight properties and corrosion resistance are highly valued. These clips are also used in architectural projects where the aesthetic quality of the material is important.

Galvanized Steel Grating Clip Types

Benefits of Galvanized Steel Grating Clips

Galvanized steel grating clips are designed to offer superior strength and durability, making them suitable for use in heavy-duty applications. They are commonly used in outdoor and industrial settings, where the ability to withstand high loads and heavy traffic is essential. The process of galvanization ensures that the steel is coated with a protective zinc layer, which significantly enhances its resistance to rust and corrosion.

- Strength and Durability: Galvanized steel clips are known for their strength, making them ideal for heavy-duty applications such as industrial plants, warehouses, and public infrastructure projects. These clips can handle high-pressure and heavy loads without compromising their integrity.

- Corrosion Resistance: The zinc coating on galvanized steel provides an effective barrier against corrosion, even in harsh weather conditions. This feature is crucial in outdoor environments or areas with high humidity where other materials might deteriorate quickly.

- Long-Term Performance: Due to the durability of galvanized steel, these clips offer long-term performance, reducing the need for frequent replacements. This is particularly advantageous for projects in industrial settings where equipment and infrastructure undergo constant stress.

- Wide Application Range: Galvanized steel clips are versatile and can be used in various applications, from highways and bridges to airports and warehouses. Their strength and corrosion resistance make them the go-to choice for high-traffic environments.

Brass Grating Clip Types

Benefits of Brass Grating Clips

Brass grating clips are specifically designed for environments where chemical corrosion resistance is a critical factor. These clips are commonly used in chemical plants, industrial facilities, and other specialized settings where exposure to corrosive substances is a concern. Brass is known for its ability to withstand harsh chemical environments, ensuring the stability and safety of grating systems.

- Chemical Corrosion Resistance: Brass clips are resistant to a wide range of chemicals, including acids, alkalis, and solvents. This makes them ideal for use in chemical plants and areas with frequent exposure to corrosive substances.

- Strength and Durability: Brass is a durable material that can withstand significant mechanical stress, making these clips suitable for demanding industrial environments. They help maintain the stability of grating systems, even in heavy-duty settings.

- Longevity: Brass clips are highly resistant to wear and tear, offering a long service life even in harsh environments. Their longevity reduces the need for frequent maintenance or replacements, which is beneficial in cost-intensive industries.

- Non-Sparking: Brass is a non-sparking material, which is crucial for certain industrial applications where sparks could lead to fire hazards. This makes brass grating clips a safer option for use in environments where flammable materials are present.

Heavy Duty Clamp for Grating: Best Options Explained

Wood Grating Clip Types

Wood grating clips are designed to secure wooden grating panels in construction projects, ensuring they stay in place while preserving the aesthetic qualities of the wood. As one of the key grating clip types, these clips provide a discreet and efficient method for attaching wooden grating to supporting structures, without compromising the visual appeal of the wood. Wood grating clips are commonly used in decking, walkways, and other outdoor construction applications where a natural wood appearance is desired, making them a popular choice for residential and commercial projects alike.

Wood grating clips provide an effective solution for securing wood grating without compromising the material’s appearance or integrity. In addition to offering a secure fastening system, these clips prevent wood from splitting or cracking during installation, which is a key consideration when working with natural materials.

When to Choose Wood Grating Clips Over Other Materials

Wood grating clips are the ideal choice when the appearance of natural wood is a priority. Unlike steel or metal clips, which can detract from the wood’s visual appeal, wood clips maintain the aesthetic integrity of wooden surfaces. These clips are best suited for applications with moderate load-bearing requirements, such as residential decking or garden walkways.

Another factor to consider is the weight of the grating. Wood is generally lighter than metal, making wood grating clips the preferable option for securing wooden panels. They also offer ease of installation and removal, making them an ideal choice for projects where future adjustments or replacements may be necessary.

Installation Guidelines for Wood Grating Clips

To ensure a secure installation, wood grating clips should be positioned at regular intervals along the edges of the wooden grating panels. It is essential to pre-drill holes before attaching the clips to prevent cracking or splitting of the wood. This will also help achieve a tighter fit and avoid unnecessary damage to the material.

Additionally, the clips should be aligned correctly to avoid instability in the grating system. If the clips are misaligned, the grating may shift or become loose over time. The use of corrosion-resistant fasteners, such as galvanized or stainless steel screws, is recommended for outdoor applications, as these materials will withstand exposure to moisture and weather conditions.

Heavy Duty Grating Clip Types

Overview of Heavy-Duty Grating Clips for Industrial Use

Heavy-duty grating clips are designed for use in environments that require extra strength and durability. These clips are specifically suited for industrial settings where grating systems must bear heavy loads, such as in manufacturing plants, warehouses, and power stations. Heavy-duty clips ensure the grating panels remain secure, even under high traffic or machinery.

The main feature of heavy-duty grating clips is their robust construction, often made from galvanized or stainless steel, to withstand harsh environments and extreme conditions. These clips are designed to prevent the grating from shifting, providing a reliable fastening solution that can handle demanding industrial applications.

Key Features of Heavy-Duty Clips

- Strength and Durability: Heavy-duty grating clips are typically made from high-strength materials, such as stainless steel or galvanized steel. These clips are designed to withstand high loads, making them ideal for industrial and high-traffic environments.

- Corrosion Resistance: These clips are often treated with corrosion-resistant coatings, ensuring they can withstand exposure to chemicals, moisture, and outdoor elements without rusting or deteriorating.

- Reinforced Design: Heavy-duty grating clips usually have reinforced edges or locking mechanisms that enhance their ability to grip and secure the grating, preventing it from loosening over time.

- Long-Term Reliability: Because of their robust construction, heavy-duty clips offer long-term performance, reducing the need for frequent maintenance or replacements in high-traffic or industrial settings.

Use Cases Where Heavy-Duty Clips Are Necessary

Heavy-duty grating clips are essential in areas exposed to heavy foot traffic, machinery, or equipment. For example, industrial plants, power stations, and warehouses require heavy-duty clips to ensure grating remains secure despite constant pressure and mechanical stress. These clips help maintain a safe and stable environment, even in environments where the grating system is regularly subjected to heavy loads.

Additionally, heavy-duty clips are necessary in public infrastructure projects such as airports, bridges, and railway stations, where safety and durability are critical. These applications demand a reliable fastening solution to keep the grating intact despite the high volume of pedestrians and vehicles.

In construction projects, heavy-duty grating clips are used on elevated platforms, walkways, or staircases that support significant weight. These clips provide a secure and stable fastening system to ensure that the grating system remains intact and functions as intended, even under challenging conditions.

Types of Floor Grating Clamps and Their Benefits

Grating Clip Installation and Best Practices

Proper installation of grating clip types is crucial to ensuring the stability and safety of grating systems. The correct installation method varies based on the type of grating clip used, whether it is aluminum, galvanized steel, brass, or any other material. Using the right techniques helps to secure the grating in place, preventing it from shifting or becoming loose over time. In this section, we will explore the best practices for installing grating clip types and the common mistakes to avoid, ensuring a secure and long-lasting installation.

Proper Installation Methods for Types of Grating Clips

Each type of grating clip, whether metal, wood, or other materials, requires a specific installation approach. Ensuring that each clip is installed correctly is essential for maximizing the grating system’s longevity.

- Aluminum Grating Clips: These clips are lightweight and easy to install. Typically, aluminum clips are attached with screws or bolts, ensuring they are securely fixed to the grating. The clips should be positioned evenly across the grating, ensuring that weight is distributed uniformly to prevent any misalignment.

- Galvanized Steel Grating Clips: Steel clips, known for their strength, require a more robust installation process. These clips should be mounted using heavy-duty fasteners, ensuring that they can hold the grating in place under heavy loads. In some cases, welding may be used to further secure the clips, especially in industrial or high-traffic areas.

- Brass Grating Clips: For brass clips, it is important to follow precise installation procedures, especially in chemically sensitive environments. These clips should be tightened to the manufacturer’s recommendations to avoid any stress that may compromise their chemical resistance or durability.

- Wood Grating Clips: Wood clips require special care to ensure they do not crack or warp during installation. Wood grating clips should be securely fixed with screws that penetrate deeply into the wood, providing a stable and reliable hold. The clips should be spaced evenly across the grating to provide uniform support.

Common Mistakes to Avoid During Installation

Even experienced installers can make mistakes when working with grating clips, which can affect the integrity of the grating system. Avoiding common errors during installation will ensure the grating system performs optimally.

- Incorrect Spacing of Clips: One common mistake is improper spacing between grating clips. If clips are placed too far apart, the grating may not be securely held in place, leading to instability. Conversely, if clips are placed too close together, the grating may become misaligned. Proper spacing is essential for maintaining the balance and strength of the entire system.

- Using the Wrong Clip for the Material: Using an inappropriate type of grating clip for the material of the grating can lead to a variety of issues. For example, using aluminum clips in industrial applications where heavy loads are common can result in the clips breaking or deforming. Always choose the right clip type based on the specific project requirements.

- Over-tightening Clips: Over-tightening grating clips can cause damage to both the clip and the grating itself. This can lead to warping or cracking of the material. It is important to tighten clips just enough to secure the grating without applying excessive force.

- Neglecting Corrosion Prevention: In outdoor or industrial environments, corrosion can be a serious issue if clips are not installed with adequate protective measures. Failing to use corrosion-resistant clips or protective coatings can significantly shorten the lifespan of the grating system.

How to Ensure Maximum Durability and Security

Ensuring the durability and security of grating systems requires a combination of proper installation techniques, regular maintenance, and using the right materials for each application.

- Routine Inspection and Maintenance: Regular inspections of grating clips should be carried out to identify any signs of wear or damage. Clips that are loose or damaged should be replaced immediately to prevent accidents. A regular maintenance schedule will extend the life of the grating system and ensure safety.

- Protective Coatings: For outdoor applications, grating clips should be coated with anti-corrosion materials, especially if they are made of steel or metal. Galvanized clips offer inherent protection, but additional coatings, such as epoxy or powder coating, can offer extra layers of protection, ensuring longevity.

- Use of High-Quality Materials: The durability of the grating system largely depends on the quality of the clips and materials used. Using high-quality, corrosion-resistant clips is a crucial step in ensuring the longevity of the system, especially in harsh environments.

- Secure Attachment: Proper attachment of clips to the underlying surface is essential for preventing slippage or instability. Always ensure that clips are fastened securely and that they provide sufficient support for the grating material.

Choosing the Right Grating Clip Types

Choosing the right grating clip type is essential for ensuring the stability, safety, and longevity of a grating system. Each type of grating clip type—whether it is metal, wood, or another material—has its own unique benefits and is suitable for specific applications. Selecting the proper clip is not only about material compatibility but also about ensuring that the grating remains securely in place, regardless of the environmental conditions or load it will bear. In this section, we will recap the key factors that influence the choice of grating clips and provide final tips for making the best selection for your project.

Aluminum, galvanized steel, brass, and wood grating clips each offer distinct advantages. Aluminum clips are lightweight and corrosion-resistant, making them ideal for architectural applications. Galvanized steel clips offer durability and strength, perfect for high-traffic industrial settings. Brass clips are resistant to chemical corrosion and are used in specialized environments. Wood clips, on the other hand, are used for grating systems in wooden structures.

Final Tips on Selecting the Right Grating Clip for Your Project

To ensure the success of your project, always consider the following factors when selecting a grating clip:

- Environmental Conditions: Consider the exposure to weather, chemicals, and physical stress. This will help determine whether aluminum, steel, brass, or wood is the best material for the clips.

- Load Requirements: Choose clips that are strong enough to support the weight of the grating in high-traffic or industrial settings.

- Installation Ease: Evaluate how easy the clips are to install. For large-scale projects, choosing clips that are easy to install can save time and labor costs.

- Long-Term Performance: Consider how long the grating clips will last under the expected conditions. Durability is key to minimizing maintenance and replacement costs.

By keeping these tips in mind, you can select the appropriate grating clip type that ensures the stability, security, and longevity of your grating system.

FAQs about Grating Clip Types

Grating comes in various types, each suited for different applications. The most common types are steel, fiberglass, metal, and wood grating. Steel grating is often used in industrial and high-traffic areas due to its strength and durability. Fiberglass grating, known for its corrosion resistance, is ideal for environments exposed to chemicals and moisture. Metal grating, including galvanized and stainless steel, is used in both industrial and outdoor settings, where corrosion resistance is important. Wood grating, typically used for aesthetic purposes, is common in decking, garden paths, and non-industrial areas. These different types of grating offer unique advantages depending on the environment, load requirements, and appearance desired. It is essential to select the appropriate type of grating based on factors such as strength, durability, and resistance to corrosion, as well as the specific needs of the installation site. Understanding the various grating types allows you to choose the right material for your project.

Choosing the correct size clip for grating is crucial for ensuring a secure and stable installation. The size of the clip depends on the thickness of the grating and the gap between the grating panels. Standard clips are typically used for most grating installations, but for thicker grating or larger panel gaps, larger clips may be required. It’s important to measure the grating’s thickness and the space between the panels to ensure the clip fits properly and can hold the grating securely. For heavy-duty applications, such as in industrial environments, heavy-duty clips may be necessary to support higher loads. Always check the manufacturer’s specifications for recommended clip sizes based on the type and size of grating. Using clips that are too small or large can lead to instability, poor performance, and potential safety risks. Proper sizing of the grating clip ensures the grating stays securely in place, even in high-traffic or load-bearing areas.

A G clip is a type of grating clip used to secure grating panels to support structures. The G clip is shaped like the letter “G,” which allows it to grip the edges of the grating and the supporting surface firmly. These clips are commonly used in applications where grating needs to be securely fastened to metal or other types of framing systems. G clips are popular because they provide a strong, reliable connection and are easy to install. They are available in various sizes and materials to accommodate different grating types, such as steel, fiberglass, or aluminum. The main advantage of a G clip is its versatility, as it can be used for various grating types and in both industrial and commercial applications. Additionally, G clips are designed to withstand significant pressure, making them ideal for use in high-traffic or heavy-duty environments. They are an essential component for securing grating systems in both temporary and permanent installations.

Grating clips are used to secure grating panels to a support structure, ensuring stability and preventing movement. To use grating clips, first, align the grating panels with the support structure, ensuring that the gaps between panels are consistent. Next, place the clips over the edges of the grating, ensuring that they fit securely around both the grating and the support beams. Depending on the type of clip, you may need to fasten them with screws or bolts. Some clips are designed to be self-locking, while others may require additional fasteners for added security. It is essential to ensure the clips are tightly secured, as loose clips can result in grating displacement, posing safety risks. For heavy-duty applications, such as in industrial settings, be sure to use clips that can support the weight and load-bearing requirements of the grating. Regularly inspect the clips for wear and tear to maintain a safe and stable grating system over time.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.