A hex beam fiberglass antenna is a directional antenna designed with a unique hexagonal structure that offers superior signal performance. Its hexagonal shape provides excellent directional gain, making it ideal for long-distance communication and reducing interference from unwanted signals. The hex beam antenna is widely used in amateur radio and other communication applications where high efficiency is required. Fiberglass is a critical material in the construction of these antennas because it offers both strength and durability. Hex beam fiberglass components are lightweight yet robust, ensuring that the antenna can withstand harsh weather conditions while maintaining its performance over time, making it a reliable choice for various environments. High-quality hex beam fiberglass, featuring durable, UV-protected materials for superior performance and longevity.

What is Hex Beam Fiberglass?

Hex beam fiberglass is a vital component in the construction of hexagonal beam antennas, offering unmatched strength, flexibility, and weather resistance. These fiberglass elements, manufactured by companies such as GangLong Fiberglass, are designed to provide structural integrity and support for antenna systems used in amateur radio, commercial broadcasting, and communication networks. The lightweight yet durable nature of hex beam fiberglass makes it an optimal choice for ensuring that antennas perform efficiently over long periods and in diverse environmental conditions.

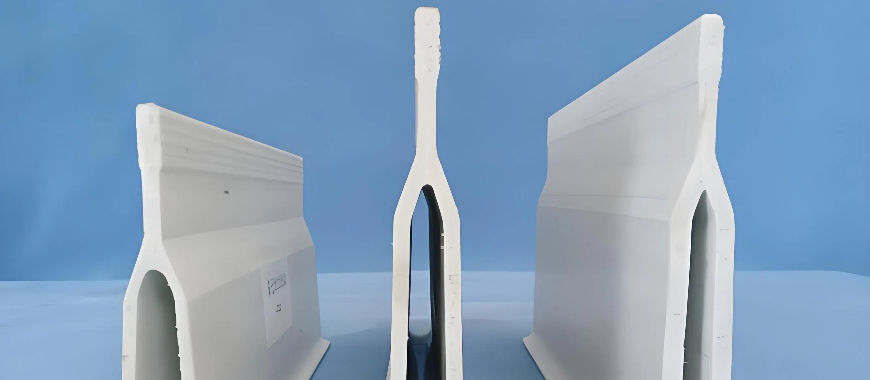

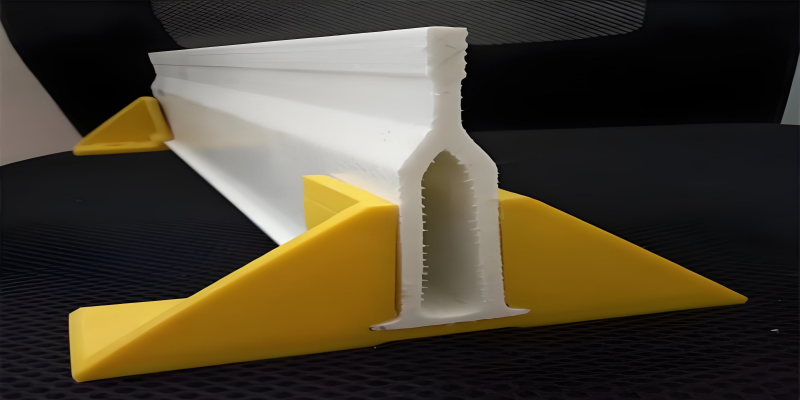

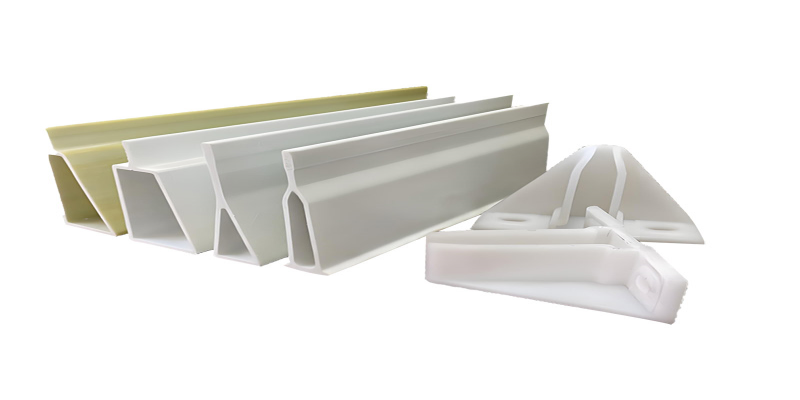

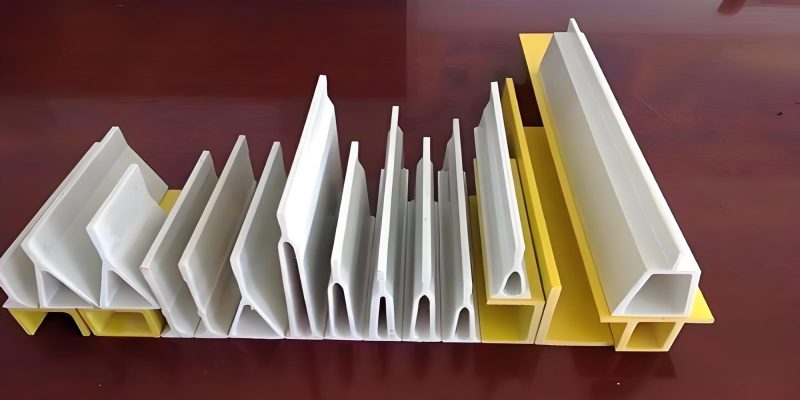

Hex beam fiberglass refers to the fiberglass rods and tubing used to construct hex beam antennas. Known for their hexagonal shape, these antennas offer a compact design while providing excellent directional gain and bandwidth. The fiberglass elements, including fiberglass tie beams, each serve a specific purpose—while hex beam fiberglass forms the primary structural framework, the tie beams provide additional reinforcement, helping to distribute forces evenly and ensuring the antenna maintains its shape and stability.

The construction of hex beam fiberglass involves the use of high-quality fiberglass composites, which combine fiberglass strands with a resin matrix. This combination results in a material that is both lightweight and strong, making it capable of supporting the antenna’s components without adding unnecessary weight. The pultrusion process used in the manufacturing of these beams ensures a consistent cross-section and high tensile strength, providing the necessary rigidity to maintain the antenna’s shape and performance.

The Purpose of a Hex Beam Feed Point

The feed point of a hex beam antenna is a crucial element in the antenna’s overall performance, as it is the location where the transmission line connects to the antenna elements. This connection point is responsible for efficiently transmitting and receiving radio frequency (RF) signals, making it essential for the antenna’s operation.

Explanation of the Feed Point in Transmitting and Receiving Signals

The feed point of a hex beam antenna is where the RF signals are fed into the antenna elements. In transmitting mode, the feed point allows the signal from the transmitter to be transferred to the antenna, where it is radiated into the atmosphere as electromagnetic waves. In receiving mode, the antenna captures incoming RF signals, and the feed point facilitates the transfer of these signals to the receiver for processing.

Hex beam fiberglass plays a vital role in maintaining the integrity and performance of the feed point. The non-conductive nature of fiberglass ensures that the antenna elements are electrically isolated from the supporting structure, preventing signal loss or interference. The fiberglass support columns provide additional structural stability, whlie the fiberglass elements support the antenna’s geometry, ensuring that the feed point remains in the correct position for optimal signal transmission and reception.

Best Practices for Optimizing Feed Point Connections

Optimizing the feed point connections of a hex beam antenna is essential for achieving the best possible performance. The goal is to minimize signal loss and ensure efficient transfer of RF energy between the transmission line and the antenna elements. Several best practices can be followed to achieve this optimization:

- Proper Alignment: The hex beam fiberglass elements must be correctly aligned to maintain the antenna’s shape and ensure that the feed point is positioned accurately. Proper alignment helps maintain the correct impedance and radiation pattern of the antenna, resulting in better signal gain and directivity.

- Secure Connections: Ensuring that all connections at the feed point are secure is crucial. This includes using high-quality connectors and ensuring a tight fit between the transmission line and the antenna elements. Loose or corroded connections can lead to signal loss and degraded performance.

- Weatherproofing: The feed point of a hex beam antenna is exposed to the elements, making it susceptible to moisture, corrosion, and UV damage. Using hex beam fiberglass components helps protect the feed point from these environmental factors. Additionally, applying weatherproofing materials such as coaxial sealant or heat shrink tubing around the feed point connections can further protect against moisture ingress and corrosion.

- Balun Integration: Incorporating a balun (balanced-to-unbalanced transformer) at the feed point can improve impedance matching and reduce common-mode currents. This helps ensure efficient energy transfer and minimizes signal distortion, leading to improved antenna performance.

Durability of Fiberglass in Protecting Feed Point Elements

Hex beam fiberglass offers superior durability, making it an excellent choice for protecting the feed point elements of an antenna. Unlike metal supports, which can corrode and degrade over time due to exposure to moisture, salt, and UV radiation, fiberglass is highly resistant to these environmental factors. The robust construction of GangLong Fiberglass beams ensures that they can withstand harsh weather conditions without compromising the structural integrity of the antenna, making these fiberglass beams an excellent choice for demanding environments.

Fiberglass is also non-conductive, which is essential for preventing electrical interference at the feed point. By using fiberglass elements, the antenna’s electrical properties remain consistent, reducing the risk of signal loss or distortion caused by unintended electrical conductivity. This non-conductive property ensures that the RF signals are transmitted and received efficiently, maintaining the antenna’s performance over time.

Installation and Maintenance of Hex Beam Fiberglass Antennas

Proper installation and maintenance of hex beam fiberglass antennas are essential to ensure their long-term performance and reliability. The lightweight and durable nature of fiberglass simplifies the installation process, while its resistance to environmental factors reduces the need for ongoing maintenance.

Installation Guidelines

- Assembling the Antenna: When assembling a hex beam antenna, it is important to follow the manufacturer’s instructions for installing the fiberglass elements. In cases where the design requires joining fiberglass two beams together, ensure a strong and secure connection to maintain the structural stability of the antenna. GangLong Fiberglass beams are designed to fit together securely, providing a stable framework for the antenna wires. Careful assembly ensures that the antenna maintains its shape and that the feed point is positioned correctly for optimal signal performance.

- Mounting the Antenna: Hex beam fiberglass antennas can be mounted on masts, towers, or rooftops, depending on the desired height and coverage area. The lightweight nature of fiberglass makes it easier to lift and position the antenna without the need for heavy lifting equipment. It is important to ensure that the mounting structure is stable and can withstand the wind and weather conditions in the area.

- Securing the Feed Point: The feed point of the hex beam antenna should be securely connected to the transmission line and properly weatherproofed to prevent moisture ingress. Using high-quality connectors and weatherproofing materials helps protect the feed point from the elements and ensures efficient signal transfer.

Maintenance Tips

- Regular Inspections: Periodically inspect the hex beam fiberglass antenna for signs of wear, damage, or corrosion. While fiberglass is highly resistant to environmental factors, checking the antenna’s components ensures that it remains in optimal condition.

- Cleaning: Clean the fiberglass elements and feed point connections as needed to remove dirt, dust, or debris that may accumulate over time. Use a mild detergent and water to clean the fiberglass surfaces without causing damage.

- Tightening Connections: Ensure that all connections, including the feed point, antenna wires, and mounting hardware, are tight and secure. Loose connections can lead to signal loss and reduced performance.

The Role of Hex Beam Fiberglass

Hex beam fiberglass plays a pivotal role in the construction and functionality of hexagonal beam antennas. This advanced material, provided by manufacturers like GangLong Fiberglass, is crucial for ensuring that hex beam antennas maintain their structural integrity, efficiency, and durability over time. Hex beam fiberglass is specifically engineered to offer superior strength, flexibility, and weather resistance, making it ideal for outdoor antenna applications that require precise signal transmission and reception.

The role of a hex beam rotator is fundamental in enhancing the performance of a hex beam antenna. The rotator is a motorized device that allows users to adjust the antenna’s direction, optimizing its orientation for the best possible signal strength and clarity. By enabling precise control over the antenna’s direction, the rotator ensures that the hex beam can focus on specific signal sources, maximizing the gain and directivity of the antenna system.

Importance of the Rotator in Adjusting the Direction of the Hex Beam

The rotator is a key component in hex beam antenna setups, especially in amateur radio and professional communication systems where signal directionality is vital. By adjusting the antenna’s orientation using the rotator, operators can fine-tune the direction of the hex beam to point towards desired transmission or reception sources, such as specific radio stations, satellites, or other communication systems.

Hex beam fiberglass components are integral to the overall functionality of the rotator and the antenna. The hex beam fiberglass arms provide the necessary support for the antenna’s elements, ensuring that they remain aligned even as the rotator changes the direction of the beam. This stability is crucial for maintaining the hex beam’s precise radiation pattern and minimizing signal loss. The ability to adjust the antenna’s direction using the rotator ensures that the hex beam can achieve its high front-to-back ratio and narrow beamwidth, which are essential characteristics for reducing interference and enhancing signal clarity.

The rotator’s ability to adjust the hex beam antenna’s direction also plays a significant role in expanding the coverage area. By rotating the antenna to focus on different areas of the sky, operators can effectively target signals from various directions, whether for long-distance (DX) communication or local contacts. This directional flexibility makes hex beam antennas, supported by hex beam fiberglass components, an invaluable asset for amateur radio enthusiasts, emergency communication networks, and commercial broadcasters.

Choosing the Right Rotator for Your Setup

Selecting the appropriate rotator for a hex beam antenna setup is crucial for optimizing its performance and ensuring smooth operation. Several factors should be considered when choosing a rotator, including the size and weight of the antenna, the environmental conditions, and the desired level of control.

- Load Capacity: The rotator must be capable of handling the weight and wind load of the hex beam antenna, including all hex beam fiberglass components. GangLong Fiberglass beams are lightweight yet strong, reducing the overall load on the rotator. However, it is important to select a rotator with a sufficient load capacity to accommodate the antenna’s size and structure, ensuring reliable operation even in windy conditions.

- Control Precision: The precision of the rotator’s control is essential for accurately pointing the hex beam antenna in the desired direction. Advanced rotators offer fine control over the antenna’s orientation, allowing operators to make minute adjustments to optimize signal reception and transmission. This precision is particularly important for long-distance communication, where slight changes in direction can significantly impact signal strength.

- Durability: The rotator must be durable and weather-resistant to withstand outdoor conditions. Since the rotator is exposed to elements such as rain, wind, and UV radiation, it is important to choose a model designed for outdoor use. High-quality rotators are built with robust materials and weatherproof seals to protect internal components from moisture and corrosion, ensuring long-term reliability.

- Control Interface: The control interface of the rotator should be user-friendly and compatible with the operator’s equipment. Some rotators offer remote control capabilities, allowing operators to adjust the antenna’s direction from a distance. This feature is particularly useful for amateur radio enthusiasts who need to make frequent adjustments to the antenna’s orientation during operation.

How Fiberglass Components Help in Ensuring Smooth Rotation

Hex beam fiberglass components are vital in ensuring the smooth rotation of the antenna when operated by the rotator. The lightweight nature of fiberglass reduces the overall load on the rotator, making it easier for the motor to adjust the antenna’s direction without straining the mechanism. This ease of movement is essential for maintaining the rotator’s performance and longevity, especially in setups where frequent adjustments are required.

The rigidity of hex beam fiberglass also plays a crucial role in stabilizing the antenna elements during rotation. GangLong Fiberglass beams are designed to maintain their shape and alignment, even as the rotator moves the antenna through different orientations. This stability prevents flexing or sagging of the antenna elements, which could otherwise affect the radiation pattern and reduce signal quality. By providing a stable framework, hex beam fiberglass ensures that the antenna’s directional characteristics remain consistent, maximizing the effectiveness of the rotator’s adjustments.

Additionally, hex beam fiberglass is resistant to environmental factors such as moisture, UV radiation, and temperature fluctuations. This durability protects the antenna’s structure from degradation, ensuring that the rotator can continue to operate smoothly over time. The non-conductive properties of fiberglass also help prevent electrical interference, which is essential for maintaining the integrity of the signals being transmitted and received by the antenna.

Types of fiberglass insulation: Making the right choice

Benefits of Hex Beam Fiberglass in Antenna Systems

Hex beam fiberglass offers several advantages that make it the preferred choice for constructing hex beam antennas. Its unique properties enhance the antenna’s performance, durability, and ease of use, making it suitable for various communication applications.

Lightweight and High Tensile Strength

Hex beam fiberglass is known for its exceptional strength-to-weight ratio, providing the necessary support for antenna elements without adding excessive weight. This lightweight characteristic is particularly valuable when mounting the antenna on masts or towers, as it reduces the load on the supporting structure. The high tensile strength of fiberglass ensures that the antenna maintains its shape and alignment, even in challenging weather conditions.

The combination of lightweight and strength also contributes to the ease of installation and adjustment of the hex beam antenna. Operators can position the antenna more easily, and the rotator can rotate the antenna smoothly without overloading the motor. This ease of handling makes hex beam fiberglass antennas a practical choice for both amateur and professional installations.

Corrosion Resistance and Weather Durability

Hex beam fiberglass is inherently resistant to corrosion, making it an ideal material for antennas exposed to outdoor environments. Unlike metal components, which can corrode and degrade when exposed to moisture, saltwater, or pollutants, fiberglass remains unaffected by these elements. This corrosion resistance ensures that the hex beam antenna maintains its structural integrity and performance over time, even in harsh weather conditions.

The durability of hex beam fiberglass extends to its ability to withstand extreme temperatures and UV radiation. This weatherproof nature ensures that the antenna can operate reliably in a variety of climates, from hot, sunny environments to cold, snowy regions. The use of fiberglass in the construction of hex beam antennas reduces the need for maintenance and extends the lifespan of the antenna system, providing a long-term solution for communication needs.

Electrical Insulation for Enhanced Signal Clarity

The non-conductive properties of fiberglass are essential for ensuring the optimal performance of hex beam antennas. By using hex beam fiberglass as the supporting structure, the antenna elements are electrically isolated from the mast and other metal components. This electrical isolation prevents unintended signal distortion and ensures that the antenna maintains its designed radiation pattern and impedance characteristics.

The non-conductive nature of fiberglass also helps minimize signal interference, resulting in clearer and more consistent signal transmission and reception. Whether used in amateur radio, emergency communication networks, or commercial broadcasting, hex beam fiberglass enhances the overall performance of the antenna system by reducing the risk of signal loss and interference. Additionally, wide flange beam fiberglass can be employed in the structural framework of antenna installations, offering the same non-conductive properties and ensuring that the entire system remains free from signal distortion while providing robust support.

Hex beam fiberglass antennas are a popular choice among amateur radio operators and communication enthusiasts due to their unique structure and outstanding performance. These antennas use a hexagonal design that enhances signal transmission, while the use of fiberglass components ensures strength, durability, and longevity in a wide range of environments. Fiberglass is a preferred material for hex beam construction because it offers a lightweight yet sturdy solution, resistant to weather and corrosion. The combination of the hexagonal design and fiberglass materials makes these antennas perfect for reliable long-distance communication.

Painting Hex Beam Fiberglass

Painting a fiberglass Hex Beam antenna can enhance its appearance and provide extra protection against environmental factors such as UV rays, moisture, and temperature fluctuations. Here’s a detailed guide on how to properly paint a fiberglass Hex Beam:

Why Paint a Fiberglass Hex Beam?

- UV Protection: Painting provides an additional layer of UV protection, which helps to prevent the fiberglass from becoming brittle and degrading due to sun exposure.

- Corrosion Resistance: Although fiberglass doesn’t rust like metal, painting can help protect any metal components (like the hardware) from corrosion, especially in salty or humid environments.

- Aesthetic Appeal: Painting can improve the overall appearance of the antenna, especially if you want it to blend in with its surroundings.

- Increased Longevity: The protective coating helps in extending the lifespan of the antenna by shielding it from environmental elements.

Preparation Before Painting

- Clean the Surface: Thoroughly clean the fiberglass surface of the Hex Beam to remove any dirt, dust, or debris. Use a mild soap solution and a soft cloth or sponge. For tougher grime or grease, consider using a degreaser or a fiberglass cleaner.

- Dry the Fiberglass: Allow the fiberglass to completely dry after cleaning. Any moisture left on the surface can affect paint adhesion.

- Light Sanding (Optional): Lightly sand the fiberglass surface with fine-grit sandpaper (around 220-grit). This will help the paint adhere better to the surface by creating a slightly rough texture. Be careful not to sand too aggressively, as you don’t want to damage the material.

Choosing the Right Paint

- Type of Paint: Use a high-quality, UV-resistant paint formulated for fiberglass or outdoor use. Paints designed for marine or automotive applications are often good choices since they offer durability and resistance to environmental conditions.

- Acrylic or Polyester-Based Paint: Acrylic-based paints are commonly recommended for fiberglass due to their flexibility and ability to adhere well to the surface. Polyester-based paints are also effective but may be more prone to chipping if the fiberglass is flexed.

- UV-Resistant Paint: Ensure the paint has UV protection to prevent it from fading or cracking under prolonged sun exposure.

Applying the Paint

- Use a Spray Paint or Brush: Depending on your preference, you can either spray paint or use a brush to apply the paint. Spray painting provides a smooth, even finish, while brushing might result in more texture but gives you better control.

- If using spray paint, hold the can 6-8 inches away from the surface and apply light, even coats.

- If brushing, use a high-quality synthetic brush designed for use on fiberglass surfaces to avoid leaving brush marks.

- Multiple Thin Coats: Apply several thin coats of paint rather than one thick coat. Allow each coat to dry completely before applying the next. This ensures better coverage and prevents drips or streaks.

- Drying Time: Allow the paint to dry thoroughly between coats (usually 1-2 hours depending on the paint type and weather conditions). Full curing may take up to 24 hours, depending on the manufacturer’s instructions.

Protective Clear Coat (Optional)

- After painting, you can apply a clear polyurethane or marine-grade varnish over the painted surface for added protection. This extra layer can help preserve the paint finish and add further resistance to UV rays, moisture, and physical damage.

- Make sure to choose a clear coat that is also UV-resistant and suitable for outdoor use.

Maintenance After Painting

- Regular Inspections: Even after painting, periodically inspect the Hex Beam for any signs of paint degradation, cracking, or chipping.

- Touch-ups: If you notice any spots where the paint has chipped or worn away, touch them up with more paint as needed.

- Cleaning: Avoid harsh cleaning agents that could damage the paint or fiberglass. Use a soft cloth and mild cleaning solution to gently clean the antenna when necessary.

Painting your fiberglass Hex Beam can improve its aesthetics, protect it from environmental wear and tear, and extend its lifespan. With proper preparation, the right materials, and a careful painting process, you can give your antenna an effective and durable finish.

Lifespan of Hex Beam Fiberglass

The lifespan of a Hex Beam made from fiberglass typically depends on several factors such as environmental conditions, usage, and the quality of the materials used in construction. Here’s a detailed explanation:

Material Durability

- Fiberglass Construction: Hex Beams are often made with fiberglass due to its lightweight, high-strength properties, and resistance to corrosion. Fiberglass is generally resistant to the elements, which gives it a long lifespan. However, exposure to UV rays, moisture, and temperature fluctuations can degrade fiberglass over time.

- UV Exposure: Ultraviolet (UV) rays from the sun can cause the fiberglass to become brittle and weakened. Over time, this leads to the degradation of the material, which may result in cracks or breaks. Most high-quality fiberglass antennas come with UV-resistant coatings to extend their lifespan.

Environmental Factors

- Weather and Climate: Hex Beams exposed to harsh climates, such as areas with high humidity, extreme temperatures, or saltwater environments, may experience accelerated wear and tear. For example, antennas near the ocean may suffer from saltwater corrosion, despite being made of fiberglass.

- Wind Resistance: The wind load on the structure can affect its longevity. Hex Beams, though durable, must be properly installed and mounted to withstand high winds. Over time, constant exposure to strong winds may cause the materials to fatigue or loosen.

Maintenance and Care

- Regular Inspections: Regular maintenance and checks for signs of damage such as cracks, delamination, or rusting can prolong the lifespan of a Hex Beam. Simple actions like cleaning and checking for loose fittings can make a big difference in how long the antenna lasts.

- Protective Coatings: Applying additional protective coatings or paints designed for fiberglass can increase its resistance to UV damage, moisture, and other environmental factors.

General Lifespan

- Typical Range: A well-maintained fiberglass Hex Beam can last anywhere from 10 to 20 years or more, depending on the conditions it’s exposed to and how well it’s cared for. However, over time, you might notice a decrease in performance due to material degradation, especially if it hasn’t been maintained or has been subjected to harsh conditions.

Performance Degradation

- Even though fiberglass doesn’t corrode like metal, prolonged exposure to the elements can still lead to performance degradation. This can manifest as a reduction in signal strength or structural integrity, making it necessary to replace parts of the beam or the entire structure.

A fiberglass Hex Beam’s lifespan is influenced by its environment, care, and the quality of materials. With proper care, it can last for several decades, but if neglected, environmental factors could lead to damage and a reduction in performance.

What are the Components of a Hex Beam Hub?

The hub is a critical component in any hex beam fiberglass antenna. It serves as the central connection point for all the antenna’s spreaders and elements. Without the hub, the hex beam’s unique hexagonal structure would not be possible. The hub ensures that the spreaders are aligned correctly, creating the necessary shape that gives the hex beam its directional properties. It also helps distribute the mechanical load across the spreaders, allowing the antenna to remain stable even in harsh weather conditions.

Materials Used in Manufacturing Hex Beam Hubs

The materials used in the hub’s construction are crucial for ensuring the long-term durability of the hex beam fiberglass antenna. Hubs are typically made from high-strength metals or composites, but they must also be compatible with the fiberglass spreaders. At GangLong Fiberglass, the hubs are designed with corrosion-resistant materials that can withstand exposure to moisture, salt air, and UV radiation. This ensures that the hex beam remains operational in various climates without degradation. The hub’s durability is especially important when the antenna is mounted outdoors, where it may be exposed to heavy winds, rain, and snow.

Integration of Fiberglass Spreaders with the Hub

The spreaders are the arms of the hex beam that extend outward from the hub, forming the antenna’s hexagonal shape. Fiberglass is an ideal material for these spreaders because it combines strength with flexibility. Fiberglass spreaders can handle the mechanical stress of supporting the antenna elements while remaining lightweight enough to reduce the overall load on the antenna structure. The integration of the fiberglass spreaders with the hub is carefully engineered to ensure that the spreaders maintain their position and alignment over time, even in challenging weather conditions. This precise alignment is critical for the hex beam fiberglass antenna to function efficiently, as it directly affects the antenna’s directional capabilities and signal clarity.

How About the Role of a Hex Beam Rotator?

The rotator plays a vital role in the overall functionality of a hex beam fiberglass antenna by allowing users to adjust the direction of the antenna. One of the greatest advantages of a hex beam is its directional gain, which focuses radio waves in a particular direction for stronger transmission and reception. A rotator allows operators to take full advantage of this feature by turning the antenna to face the desired direction without manual repositioning. With the use of a high-quality rotator, the antenna can be easily rotated 360 degrees to optimize communication in any direction.

Choosing the Right Rotator for a Hex Beam Fiberglass Antenna

When selecting a rotator for a hex beam fiberglass antenna, several factors must be considered, including the size and weight of the antenna and the environmental conditions it will face. GangLong Fiberglass offers rotators specifically designed for lightweight hex beam antennas, ensuring smooth and reliable operation. The rotator must be strong enough to support the weight of the antenna while allowing for precise adjustments in all weather conditions. For example, a rotator used with a hex beam fiberglass antenna must be able to handle wind loads and remain stable during high winds without losing its directional accuracy.

How Fiberglass Components Help in Ensuring Smooth Rotation

Fiberglass components used in hex beam antennas help reduce the overall weight of the antenna, which in turn reduces the strain on the rotator. This is especially important for maintaining smooth, accurate rotation over time. Because fiberglass is lightweight yet strong, it helps ensure that the antenna can be turned easily without putting excessive wear on the rotator. Additionally, the flexibility of fiberglass spreaders allows the antenna to move with the wind, reducing the risk of damage during rotation.

The Key of a Hex Beam Feed Point

The feed point is where the signal is fed into the hex beam fiberglass antenna, and it plays a crucial role in determining the antenna’s performance. It is the location where the coaxial cable connects to the antenna elements, allowing the signal to be transmitted or received. A properly designed feed point ensures that the signal is efficiently transferred to the antenna elements without significant loss or interference.

Optimizing Feed Point Connections for Better Signal Transmission

To optimize the feed point in a hex beam fiberglass antenna, it is important to ensure that the connections are clean and secure. Loose or corroded connections at the feed point can lead to signal loss or increased noise, reducing the overall performance of the antenna. Using high-quality connectors and materials is essential for maintaining a reliable connection over time. GangLong Fiberglass feed points are designed with corrosion-resistant materials to ensure long-lasting performance, even in environments where moisture or salt air could cause degradation.

Fiberglass as a Protective Material for Feed Point Elements

Fiberglass plays a vital role in protecting the feed point from environmental damage. The non-conductive nature of fiberglass makes it an ideal material for insulating the feed point, reducing the risk of interference from external electrical sources. Additionally, fiberglass is resistant to moisture, UV radiation, and temperature fluctuations, ensuring that the feed point remains functional even in harsh outdoor conditions. This helps prolong the lifespan of the antenna and ensures consistent signal performance.

Importance of Support Spacing to Control FRP Pipe Deflection

Benefits of Using Fiberglass Hex Beam Spreaders

Fiberglass spreaders are one of the most important components of a hex beam fiberglass antenna. These spreaders provide the structural framework that supports the antenna elements while maintaining the antenna’s unique hexagonal shape. The use of fiberglass in spreaders offers several benefits that contribute to the antenna’s overall performance and durability.

Strength and Lightweight Properties of Fiberglass Spreaders

Fiberglass is known for its exceptional strength-to-weight ratio, which makes it an ideal material for antenna spreaders. Hex beam fiberglass spreaders are strong enough to support the weight of the antenna elements and withstand the mechanical stress caused by wind and weather. At the same time, fiberglass spreaders are lightweight, which reduces the overall load on the antenna structure and makes installation easier. This combination of strength and lightness is crucial for maintaining the integrity of the hex beam while ensuring that it remains stable in all conditions.

How Fiberglass Spreaders Enhance Stability in Hex Beam Antennas

The stability of a hex beam fiberglass antenna is directly related to the quality and alignment of its spreaders. Fiberglass spreaders provide the necessary rigidity to keep the antenna elements in the correct position, ensuring that the antenna’s directional properties are maintained. The flexibility of fiberglass also allows the spreaders to bend slightly in response to wind or mechanical stress without breaking or losing their shape. This helps prevent damage to the antenna during storms or high winds and ensures that the hex beam remains operational even in challenging weather conditions.

Tips for Installing Fiberglass Spreaders

When installing fiberglass spreaders on a hex beam fiberglass antenna, it is important to ensure that the spreaders are securely attached to both the hub and the antenna elements. Proper alignment is key to ensuring that the antenna functions correctly, as even small misalignments can affect the antenna’s directional gain and signal clarity. It is also important to inspect the spreaders regularly for signs of wear or damage, especially in environments where the antenna is exposed to extreme weather conditions.

Choosing The Right Hex Beam Fiberglass Spreader

Choosing the right fiberglass spreader for your Hex Beam antenna is an important decision to ensure the antenna’s structural integrity, performance, and durability. The spreaders are essential components that hold the elements of the antenna in place and maintain the correct shape. Here are the factors to consider when selecting the right fiberglass spreader for your Hex Beam:

Material Quality

- Fiberglass Composition: Ensure that the fiberglass spreaders are made from high-quality, durable fiberglass. Look for spreaders that are designed to withstand environmental stresses such as wind, UV exposure, and temperature fluctuations. Some fiberglass materials are reinforced with resins or other additives to increase strength and resistance to cracking or breaking.

- UV Resistance: Fiberglass is generally UV resistant, but over time, constant exposure to the sun can weaken it. Ensure the spreaders have been treated with UV-resistant coatings or are made from UV-stabilized fiberglass, which will prolong their lifespan and prevent brittleness.

Strength and Flexibility

- Strength-to-Weight Ratio: The spreaders should have a high strength-to-weight ratio, meaning they should be lightweight yet strong enough to withstand the tension from the antenna elements, as well as wind forces and other environmental stresses.

- Flexibility: While the spreaders need to be strong, they also need to have some flexibility to prevent snapping under high winds or storms. A good fiberglass spreader should bend slightly without breaking, which allows it to absorb wind loads and other stresses more effectively.

Diameter and Length of the Spreaders

- Diameter: The diameter of the fiberglass spreaders impacts the overall strength of the Hex Beam. Generally, thicker spreaders are stronger but heavier. The right diameter depends on the size of your antenna and the specific requirements for your setup.

- Length: The length of the spreaders needs to match the design of the Hex Beam. It should be long enough to properly support the antenna elements while also providing sufficient spacing. Longer spreaders are often used for larger antennas, while shorter spreaders are suitable for smaller setups.

Tensile Strength

- Resistance to Tension: The spreaders need to be able to withstand the tension applied by the antenna elements. This means they should have a high tensile strength, preventing them from bending or breaking under the weight and tension of the antenna.

- Reinforcement: Some fiberglass spreaders may be reinforced with metal inserts or have additional layers of resin for added strength. These types can handle more significant forces and are often used in large or high-wind environments.

Wind Resistance

- Aerodynamic Design: Fiberglass spreaders should be designed with wind resistance in mind. Smooth, aerodynamic spreaders reduce wind drag, which can help maintain the structural integrity of the Hex Beam under windy conditions.

- Wind Load: Consider the expected wind speeds in your area. If you’re in a region with frequent high winds or storms, opt for more robust spreaders with greater wind resistance. The spreaders should also allow for some flexibility to absorb the force of the wind.

Compatibility with the Hex Beam Design

- Design and Configuration: Ensure that the spreaders are designed to fit your specific Hex Beam antenna model. Some Hex Beams may require spreaders with specific diameters, lengths, or designs to ensure proper spacing and element alignment.

- Adjustable Spreaders: Some fiberglass spreaders come with adjustable lengths or configurations, giving you more flexibility in tuning the antenna for optimal performance.

Choosing the right fiberglass spreaders for your Hex Beam involves considering several factors, such as strength, flexibility, UV resistance, compatibility with the antenna design, and environmental conditions. By selecting high-quality, durable spreaders that are well-suited to your location and antenna requirements, you can ensure the longevity, stability, and performance of your Hex Beam antenna.

Key Benefits of Using Kraft Faced Fiberglass Insulation in Walls

FAQs about Hex Beam Fiberglass

The Hexbeam and spider beam are both directional antennas used for amateur radio, but they differ in design and construction. A Hexbeam antenna has a hexagonal shape and typically offers a more compact design, which makes it easier to install in smaller spaces. The spider beam, on the other hand, uses a spreader configuration that resembles the legs of a spider, often resulting in a larger and more complex setup. In terms of performance, both antennas offer good gain and directivity, but the Hexbeam is known for being more lightweight and easier to assemble. The spider beam may provide slightly higher gain due to its size, but it can be more cumbersome to install and maintain compared to the Hexbeam.

The ideal height for a Hexbeam antenna depends on several factors, including the desired operating frequency and surrounding environment. In general, the best height for a Hexbeam is around 30 to 40 feet above the ground. This height provides a good balance between performance and ease of installation. When installed at this height, the Hexbeam can achieve optimal performance in terms of signal strength, gain, and directivity. Lower installations, such as 20 feet, can still perform well but may experience reduced signal reach. For higher frequencies, like 10 meters, lower heights may work effectively, while for lower frequencies, such as 20 meters, placing the Hexbeam higher can improve overall performance.

A Hexbeam works by focusing radio waves in a specific direction, allowing for stronger signal transmission and reception. Its unique hexagonal shape provides directional gain, which helps boost signal strength in the desired direction while reducing interference from other angles. The Hexbeam consists of multiple elements arranged in a hexagonal pattern, with each element tuned to a specific frequency band. This design allows the Hexbeam to cover multiple bands with a single antenna setup. When radio waves are transmitted from the Hexbeam, they are concentrated in a narrow beam, increasing the effective radiated power in that direction. This makes the Hexbeam an ideal choice for long-distance communication and contesting, as it offers high gain and good directivity while minimizing interference from unwanted signals.

What is the lightest Hexbeam?

The weight of a Hexbeam antenna varies depending on its design and materials, but typically, a lightweight Hexbeam can weigh anywhere from 10 to 15 pounds (4.5 to 6.8 kg). The lightest versions are usually built with lightweight yet durable materials such as fiberglass for the boom and spreaders, along with wire elements for the antenna’s radiating parts. Many manufacturers focus on creating portable versions of Hexbeams for field use, which often results in a lower weight. These Hexbeams typically use aluminum or other composite materials to reduce overall weight without compromising performance. For example, a Hexbeam made with lightweight fiberglass or carbon fiber components can be significantly lighter than one made from all-metal parts. It’s important to consider the strength-to-weight ratio when choosing materials, as the Hexbeam needs to be sturdy enough to withstand wind and other environmental factors, while still being easy to handle and transport.

Is a Hexbeam directional?

Yes, a Hexbeam is a directional antenna. It is designed to focus its signal in a specific direction, allowing for higher gain in that direction while minimizing signals in other directions. The Hexbeam operates by using multiple elements arranged in a hexagonal shape, typically six sides, to create a radiation pattern that is more focused than an omnidirectional antenna, which radiates in all directions. Hexbeams can be rotated to aim the antenna in different directions, further enhancing their directional properties. This allows operators to concentrate their signal on a particular area, which is especially useful for long-distance communication, such as HF radio contacts. Additionally, the antenna can be optimized to improve front-to-back ratio, minimizing unwanted signals coming from the rear of the antenna.

What is the difference between I-beam, H-beam, and W-beam?

The terms I-beam, H-beam, and W-beam generally refer to different types of beam antennas used in various radio applications. These beams are named after the shape of their support structures or the arrangement of their elements.

I-beam: Typically refers to a type of antenna beam with a simple, straight structure, usually in the shape of the letter “I.” The design is often used in Yagi-style or similar directional antennas. It offers a straightforward support structure for elements but is not usually used for hexagonal antenna designs.

H-beam: This refers to antennas that use an “H” shape for their structural framework. The “H-beam” usually applies to antenna designs like certain Yagis or other directional antennas. The H-shaped frame can provide greater structural integrity and durability while maintaining a reasonable weight. The arrangement of elements may vary, but the “H” shape often refers to how the antenna is supported and constructed.

W-beam: Similar to the H-beam, but with the structure resembling the letter “W.” It can be used in various antenna types, including multiband beams. The “W-beam” typically describes a design that enhances directional performance or improves the efficiency of the antenna while adding structural support.

In contrast, a Hexbeam specifically refers to a hexagonal-shaped design, which differs in terms of element configuration, but may share structural similarities with these beam types in terms of providing directional capability.

What is the best hex beam?

The best Hexbeam depends on several factors, including the specific needs of the operator, the operating frequencies, and the available space. However, one of the most highly recommended Hexbeam designs is the one offered by manufacturers like “Hexbeam Antenna” or designs by companies like “The Hexbeam Company,” which offer quality, durable, and well-tested antennas. Key attributes to look for in the best Hexbeam include:

Durability: The materials should be weather-resistant, with fiberglass or aluminum commonly used in construction.

Performance: Look for antennas with good gain (around 6 to 9 dBi typically), low SWR (Standing Wave Ratio), and excellent front-to-back ratio.

Ease of Assembly: Some Hexbeams are known for their easy setup and disassembly, making them ideal for portable operations or field use.

Cost-effectiveness: Good performance at a reasonable price is often a priority for amateur radio operators.

It is essential to assess your specific needs—such as frequency coverage, portability, and durability—when selecting the best Hexbeam. An antenna that works well for one person’s setup may not be the best choice for someone else.

What is the turning radius of a hex beam?

The turning radius of a Hexbeam refers to the space required for the antenna to rotate fully. Since the Hexbeam is a directional antenna, it typically needs to be mounted on a rotator to allow for rotation to change its direction. The turning radius is influenced by factors such as the size of the antenna and the mounting system. On average, a Hexbeam may require a turning radius of approximately 12 to 15 feet (3.5 to 4.5 meters). This ensures that the antenna can rotate freely without obstruction, providing optimal directional capabilities. The turning radius could be larger for antennas designed for longer ranges or more significant frequencies. Smaller, portable Hexbeams may have a smaller turning radius, making them more suitable for mobile or temporary installations.

How does a hex beam work?

A Hexbeam antenna works by using a unique six-element design arranged in a hexagonal shape, which allows it to focus its radiation in a specific direction. The hexagonal shape provides multiple elements that interact with each other to create a directional signal. These elements are generally spaced apart to create the correct phase relationship, which maximizes gain in the forward direction and minimizes it in other directions.

When the antenna is fed with RF energy (typically through a coaxial cable and balun), the current flows through the elements, causing them to radiate electromagnetic waves. The arrangement of these elements results in a radiation pattern that is concentrated in a specific direction, giving the Hexbeam its directional properties. The Hexbeam is often mounted on a rotator to allow the operator to adjust the antenna’s direction, focusing the signal on a specific target or area for optimal performance.

How high does a hexbeam need to be?

The height at which a Hexbeam antenna should be mounted depends on several factors, including the desired frequency range, local terrain, and the purpose of the antenna (e.g., long-range communication or local coverage). For optimal performance, Hexbeam antennas should be placed at a height where they can clear surrounding obstacles, such as buildings or trees, to minimize signal blockage and interference.

A common recommendation for height is at least 20 to 30 feet (6 to 9 meters) above ground level for general use, though higher placements may improve performance further, especially for lower-frequency bands where the signal needs to propagate over longer distances. The optimal height also depends on factors like the ground conductivity and the specific region’s terrain.

How long is a hex beam spreader?

The length of the spreaders used in a Hexbeam depends on the design and the frequency band for which the antenna is intended. In general, for a typical 20-meter Hexbeam, the spreaders usually range between 6 to 8 feet (approximately 1.8 to 2.4 meters) in length. The spreaders are placed at specific angles to support the six radiating elements and maintain the hexagonal shape. The length of the spreaders is directly related to the size of the antenna and its ability to maintain the proper spacing between elements, which is crucial for achieving the desired directional characteristics and radiation pattern.

How much does a hex beam weigh?

The weight of a Hexbeam antenna can vary significantly based on its construction and the materials used. Generally, a typical Hexbeam weighs between 10 to 25 pounds (approximately 4.5 to 11.3 kg). The lightweight versions are built using materials such as fiberglass and aluminum, which are both durable and easy to handle. These models are designed to be portable and suitable for temporary or field use. However, heavier Hexbeams made from stronger materials, such as steel or heavier-grade aluminum, can weigh more but may offer greater durability and longer lifespan. The weight also depends on the size of the antenna, the type of elements used, and whether it’s a compact or large design intended for different frequency bands.

What size is the Hexbeam?

The size of a Hexbeam antenna depends on the frequency bands it is designed to operate on. For a standard Hexbeam used on the 20-meter band, the spreaders will typically have a diameter of around 10 to 12 feet (approximately 3 to 3.7 meters). The boom, or central support structure, usually measures 6 to 8 feet (around 1.8 to 2.4 meters). As the frequency bands change, the size of the antenna changes as well. For lower frequencies like 40 meters, the size will increase, and for higher frequencies like 10 meters, the antenna will be smaller. The overall size of the Hexbeam is compact compared to other large directional antennas, such as Yagi antennas, which makes it an attractive option for those with limited space.

Does a hexbeam need a balun?

Yes, a Hexbeam antenna typically requires a balun (BALanced to UNbalanced device). The Hexbeam is a balanced antenna, meaning the two halves of the antenna are symmetrically arranged. To connect this balanced antenna to a coaxial cable (which is unbalanced), a balun is necessary to ensure the proper transfer of RF energy. The balun also helps to match the impedance of the antenna (typically 50 ohms) to the feedline, reducing the risk of signal loss and reflection. In addition to improving impedance matching, the balun also helps prevent RF currents from flowing on the shield of the coaxial cable, which could cause interference and performance degradation.

What is the gain of a hex beam antenna?

The gain of a Hexbeam antenna is typically around 6 to 9 dBi (decibels over isotropic). This gain is higher than that of an omnidirectional antenna, making the Hexbeam a more effective choice for long-distance communication. The directional nature of the Hexbeam helps to concentrate the signal in a specific direction, improving the signal strength and range in that direction while minimizing interference from other areas (such as the rear of the antenna). The Hexbeam provides a good balance of gain and directivity, offering excellent performance with a compact design. The gain can vary slightly depending on the design, frequency, and size of the Hexbeam, but it generally offers better performance than many other smaller directional antennas.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.