- Home

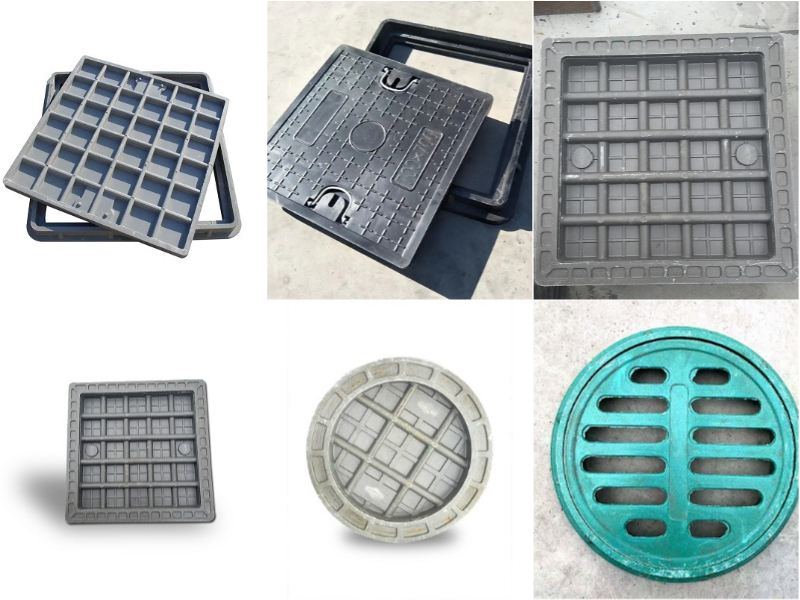

- Manhole Covers

Manhole Covers, Frames & Accessories Manufacturer

GangLong Fiberglass specializes in providing a wide range of manhole covers, maintains a large inventory of standard-size manhole covers, readily available for various applications. Whether you require a composite or a 3/8″ steel drop-in lid, GangLong Fiberglass ensures high-quality materials are used to provide the best protection for your well or sewer line. With capability to fabricate any cover or frame, We can meet any specific need.We are proud of themselves on quick turnaround times and customer satisfaction, aiming to be industry leaders in both product quality and client service.

Through our extensive collection, GangLong Fiberglass provides discreet access to essential underground utilities while maintaining the aesthetics of both residential and commercial spaces. By focusing on manhole covers, we contribute significantly to the safety and functionality of urban infrastructure, ensuring secure and accessible underground systems. GangLong Fiberglass can custom make durable and high-quality manhole covers and frames to your exact specifications, with quality service.

News

- Exploring the Benefits of Carbon Fiber Apparel

- How to Work with Carbon Fiber Successfully

- Carbon Fiber Suit: The Future of Lightweight Armor

- Is Carbon Fiber Armor the Future of Protection?

- Why White Carbon Fiber is Popular in Automotive Design

- Transparent Carbon Fiber Sheets Two Sided Gloss Twill

- Epoxy-Compatible Chopped Carbon Fiber Mat

- Carbon Fiber EG Hatch: Upgrade Your Civic Today

- The Benefits of Using Structural Carbon Fibre in Engineering

- How Many Layers of Layered Carbon Fiber Are Needed?

Thank you for your interest in our products. To receive our pricelist or for any inquiries, please fill out the form below. We will get back to you within 24 hours.

Simplifying Your Life: Key Functionalities

| Attributes | Details |

|---|---|

| Place of Origin | Hebei, China |

| Brand Name | GangLong Fiberglass |

| Product Name | Manhole Covers |

| Material | Glass Fiber Reinforced Plastic |

| Technology | High Temperature Molding |

| Processing Service | Molding |

| Surface Treatment | Customized |

| Color | Customized Color |

| Size | Customized Size |

| Features | Corrosion Resistant, Antistatic, Anti-theft and Environmentally Friendly |

| Working Temperature | -40℃ to 200℃ |

| Standard | EN124 Standard |

| Recycle Value | Zero Theft Value and Anti-theft |

| Conduction | Non-electrical conduction, non-thermal conduction |

| Noise | Less noise, less vibration |

| Applications | Utilities, Infrastructure Products, Sewage and Drainage Systems, Telecommunications, Electricity |

| Longevity | More than 30 Years |

| Supply Capacity | 6,000 Sets Per Month |

What are Manhole Covers?

Manhole covers, trench cover is a subtype of it, are sturdy, flat, circular, or rectangular coverings that sit over manholes—access points to underground utility systems such as sewers, electrical conduits, water pipelines, and telecommunication lines. They are designed to provide secure access for maintenance workers while also protecting the public from accidental falls into these often deep, hazardous spaces. Made from durable materials like cast iron, steel, or composite materials, manhole covers are engineered to withstand heavy traffic, whether from vehicles or pedestrians. Their primary function is to keep the underground utility systems secure, prevent debris or contaminants from entering, and ensure the safety of the surrounding area by keeping people and animals out of the manholes.

What are Manhole Cover Frames?

Manhole cover frames are the structural components that support the manhole cover and secure it in place. Typically made of cast iron, steel, or other strong metals, frames are designed to fit snugly around the edge of the manhole and hold the cover securely, preventing it from being displaced by external forces like traffic or environmental conditions. The frame acts as a boundary for the cover, ensuring that it remains in place, even under the weight of vehicles or heavy equipment. The design of the frame often includes a lip or groove to help hold the cover and prevent it from shifting out of alignment. In some instances, frames are designed with a built-in sealing mechanism to prevent the escape of gases or odors from the underground systems.

Frames are an integral part of the overall manhole cover system, and choosing the correct frame material and design is essential to the durability and safety of the installation. A well-constructed frame ensures that the manhole cover remains stable and effective for years of use.

What are Manhole Cover Accessories?

Manhole cover accessories are additional components or features that enhance the functionality, safety, and maintenance of manhole covers. These can include lifting devices, gaskets, locking mechanisms, and other hardware designed to aid in the installation, maintenance, or security of the manhole cover system.

- Lifting Devices: These are tools or handles that help workers safely remove and replace heavy manhole covers. Some manhole covers are equipped with lifting holes or grooves that allow for the easy attachment of lifting chains or other mechanical tools.

- Gaskets: These rubber or silicone seals fit between the manhole cover and frame to prevent water, debris, or gases from escaping into the environment. They help maintain the integrity of the underground systems and improve safety by sealing the cover tightly.

- Locking Mechanisms: In areas where security is a concern, manhole covers may include locks or security bolts to prevent unauthorized access. These mechanisms ensure that only authorized personnel can remove the cover for maintenance or inspection.

- Reflective Markers: Some manhole covers come with built-in reflective markers to increase visibility, particularly at night or in low-light conditions, reducing the risk of accidents.

By incorporating these accessories, manhole cover systems can be made safer, easier to maintain, and more secure, ensuring long-term performance and reliability in urban infrastructure.

Manhole Covers Types

Manhole covers come in a variety of designs, materials, and sizes, each tailored to specific applications and environments. Below is an overview of the most common types of manhole covers, including their definition, purpose, materials, construction, applications, advantages, and more.

Cast Iron Manhole Covers

Cast iron manhole covers are the most commonly used type, primarily because of their durability and strength. These covers are designed to withstand heavy traffic loads, weathering, and corrosion. Their purpose is to provide secure and easy access to underground utility systems while protecting the public from the hazards associated with open manholes.

Materials and Construction:

Made from cast iron, these covers are molded and hardened to create a robust and weather-resistant product. Cast iron manhole covers can either be solid or perforated, depending on the specific requirements for ventilation and drainage.

Applications and Advantages: Steel manhole covers are made from high-strength steel and are typically used in industrial, commercial, and traffic-heavy areas where additional strength is required. These covers provide access to underground utilities and help secure manholes from unauthorized access. Materials and Construction: Steel manhole covers are often galvanized or coated to prevent rust and corrosion. These covers can be fabricated with different designs, such as perforated, bolted, or hinged, depending on the intended application. Applications and Advantages: Composite manhole covers are made from advanced composite materials, typically a combination of fiberglass type, resin, and other reinforcing materials. These covers are designed to be lightweight, non-corrosive, and highly durable. Materials and Construction: The composite material provides a non-metallic option for manhole covers. The cover is resistant to weathering, chemicals, and corrosion, making it ideal for use in areas prone to aggressive environmental conditions. Applications and Advantages: Aluminum manhole covers offer an alternative to cast iron or steel manhole covers, particularly where lighter weight and corrosion resistance are priorities. Aluminum provides a durable, non-corrosive option for access covers. Materials and Construction: Made from a high-strength aluminum alloy, these covers are designed to resist rust and corrosion, making them ideal for environments with high moisture or saline conditions. Aluminum manhole covers are generally lighter than their cast iron or steel counterparts. Applications and Advantages: Traffic-rated manhole covers are specifically designed to handle heavy traffic loads, including vehicles, trucks, and buses. These covers are used in areas with high traffic volume where standard manhole covers might fail under the weight. Materials and Construction: Typically made from cast iron, steel, or composite materials, traffic-rated manhole covers are designed to meet strict load-bearing standards, which are often specified by local government or engineering codes. Applications and Advantages: Locking manhole covers are designed to prevent unauthorized access to underground systems. These covers include locking mechanisms such as keyways, bolts, or special fasteners that secure the cover in place. Materials and Construction: Locking manhole covers are typically made from cast iron, steel, or composite materials. They are designed with locking systems, such as bolt-down mechanisms or security locks, to prevent the cover from being easily removed. Applications and Advantages: Ventilated manhole covers have built-in vents or perforations that allow for the circulation of air in and out of the underground space. These covers are especially important in areas where gases, moisture, or heat might accumulate within the manhole. Materials and Construction: Ventilated covers are often made from cast iron, steel, or composite materials. They feature vents or perforated designs that allow for air flow while still maintaining structural integrity. Applications and Advantages: Custom or decorative manhole covers are designed to add aesthetic value to urban spaces while still fulfilling the function of providing access to underground utilities. These covers may feature intricate designs, logos, or patterns. Materials and Construction: Custom manhole covers are typically made from cast iron, steel, or aluminum. The surface can be custom-molded with decorative patterns or even company logos, and they may be painted or finished to match the surroundings. Applications and Advantages: The variety of manhole covers available ensures that they can meet specific needs, whether it’s durability, corrosion resistance, security, or aesthetics. Whether you’re dealing with heavy traffic, chemical exposure, or simply a desire for custom designs, there’s a manhole cover that’s designed to provide the necessary protection and functionality for any application. Understanding the different types of manhole covers and their advantages can help ensure that the right choice is made for each situation, improving safety, efficiency, and the longevity of the infrastructure.Steel Manhole Covers

Composite Manhole Covers

Aluminum Manhole Covers

Traffic-rated Manhole Covers

Locking Manhole Covers

Ventilated Manhole Covers

Custom or Decorative Manhole Covers

Heavy Duty Manhole Covers

To provide a more comprehensive overview of Heavy Duty Manhole Covers, let’s delve deeper into additional aspects:

Design and Features

Heavy Duty Manhole Covers often incorporate anti-theft features, like locking mechanisms or special bolt designs, to prevent unauthorized access. Some covers also feature non-slip surfaces to ensure safe footing, especially in areas with high pedestrian traffic. Ventilation holes may be included to allow airflow, which is critical in environments where gases may accumulate. Additionally, the covers may come with edge reinforcement or specialized ridges for added strength and stability.

Standards and Regulations

These covers are typically subject to strict industry standards and regulations to ensure safety and functionality. For example, ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization) set guidelines for load-bearing capacity, materials, and overall design. The load classification is an important specification, often rated in terms of vehicle weight—such as A15, B125, or C250—indicating the cover’s ability to handle various load levels, from pedestrians to heavy vehicles.

Installation and Maintenance

Installation of Heavy Duty Manhole Covers requires careful consideration of the underlying infrastructure, as the cover must align perfectly with the surrounding surface to ensure stability. Maintenance involves regular inspections for wear and tear, particularly for corrosion or damage from heavy vehicles. Some covers are designed with a simple lifting mechanism for easier removal during maintenance work, ensuring efficiency while preventing damage to the cover or the surrounding area.

Applications and Use Cases

Heavy Duty Manhole Covers are used in diverse settings, from roads and highways to airports, ports, and industrial plants. In high-traffic areas, they protect underground utilities like sewage systems, electrical cables, and communication lines. These covers are also essential for safety in environments like factories, where heavy machinery or vehicles constantly pass over them. In urban settings, they play a vital role in safeguarding public health by preventing contaminants from entering the sewer system.

Types of Heavy Duty Manhole Covers

- Round Manhole Covers

Design: The most common shape, round manhole covers, are typically designed with a circular opening and cover. This shape is ideal because it avoids the possibility of the cover being dislodged, which can happen with square or rectangular covers. The round design allows for equal distribution of pressure from the surrounding surface, making it an ideal choice for high-traffic areas.

Use: Commonly used in roads, highways, and streets where traffic load is a concern. The round shape ensures the cover fits securely in the frame, regardless of orientation. - Square or Rectangular Manhole Covers

Design: Square or rectangular covers provide a larger surface area and can be ideal for industrial or commercial areas where large pipes or utility vaults are located. These covers often have reinforced corners for added strength and may be used in areas that require more extensive surface coverage.

Use: Commonly found in commercial properties, warehouses, and parking lots where large amounts of space need to be covered. They are also often used in locations with larger infrastructure, such as electrical substations or larger stormwater systems. - Composite Manhole Covers

Design: Composite covers are made from materials like fiberglass, reinforced polymer, or high-strength plastic, which makes them lighter than traditional metal covers while still maintaining strength and durability. These covers are often equipped with anti-theft features and non-corrosive properties.

Use: Ideal for locations where corrosion is a major concern (e.g., coastal or industrial areas). They are also useful in areas where weight is a consideration, such as when dealing with overhead cranes or lightweight equipment. - Vented Manhole Covers

Design: These covers incorporate vents or perforations that allow for the escape of gases or pressure buildup beneath the cover. This feature is essential in areas where gases, such as methane, hydrogen sulfide, or other industrial fumes, are likely to accumulate.

Use: Used in sewage systems, chemical plants, or areas with underground storage tanks. They help to prevent dangerous buildup of gases while still ensuring the cover is secure. - Lockable Manhole Covers

Design: These manhole covers are equipped with a locking mechanism to prevent unauthorized access. The locks can be simple or complex, ranging from manual bolts to more advanced security mechanisms, such as keyed locks or tamper-resistant fasteners.

Use: Often used in urban areas, where theft or vandalism is a concern, or in industrial environments that need secure access to underground utilities or systems.

Installation Practices for Heavy Duty Manhole Covers

- Preparation of the Manhole Frame

Before the cover is installed, the frame that holds the manhole cover must be properly positioned and aligned with the surrounding road or pavement. The frame must be flush with the surrounding surface to ensure a secure fit and even load distribution. If the frame is not level or is misaligned, it can lead to premature wear, damage to the cover, or safety hazards.- Excavation and Compaction: The area surrounding the manhole must be excavated to the required depth, and the base should be compacted to ensure the frame will settle evenly.

- Concrete Bedding: A layer of concrete bedding or a special compound is sometimes applied to ensure the manhole frame is anchored properly.

- Positioning the Manhole Cover

The manhole cover should be lifted and placed into the manhole frame carefully to avoid damage to both the cover and the frame. Depending on the size and weight of the cover, specialized lifting equipment, such as cranes or lifting tools, may be required.- Alignment: Ensure that the cover is aligned with the surrounding road or pavement. For round covers, this typically involves ensuring it is placed evenly on the frame. For rectangular or square covers, additional care must be taken to ensure proper orientation and fit.

- Securing the Manhole Cover

Once positioned, the manhole cover must be secured in place to prevent it from becoming dislodged over time. Common methods include:- Bolting or Screwing: Some covers may be bolted or screwed into place using durable fasteners, especially if there are concerns about theft or tampering.

- Locking Mechanisms: For security, some covers use specialized lock systems or pins to secure the cover in place.

- Sealing and Testing

After installation, it’s essential to ensure that the manhole cover is fully sealed, especially in areas where gas or water tightness is critical. Depending on the type of cover, sealants or gaskets may be applied around the edges to ensure a tight fit. The manhole should also be tested to ensure that the cover can withstand the required load without deforming or becoming loose. - Ongoing Maintenance and Inspection

Regular maintenance is essential to ensure the long-term durability of heavy-duty manhole covers. Inspections should check for:- Corrosion: Metal covers, especially steel or cast iron, are prone to corrosion over time, particularly in coastal or industrial areas.

- Cracks or Damage: Heavy traffic can cause cracking or chipping of the cover. Regular inspections can identify these issues before they cause a safety hazard.

- Lock Functionality: For lockable covers, the locking mechanism should be inspected to ensure it is functioning correctly and remains secure.

- Replacement of Worn-out Covers

Manhole covers that show signs of excessive wear, corrosion, or damage must be replaced promptly. Over time, heavy-duty covers will degrade, especially if they are subject to extreme conditions like heavy traffic, corrosive chemicals, or environmental stress. Replacing worn-out covers can help to prevent accidents and ensure that the infrastructure continues to function as intended.

Heavy Duty Manhole Covers are crucial components for maintaining safety and functionality in high-traffic or industrial areas. Their design and materials, such as cast iron, steel, and composites, allow them to endure significant stress and environmental conditions. Understanding the different types of manhole covers and their proper installation ensures longevity, security, and compliance with safety regulations. Regular maintenance and inspections will help extend the lifespan of the covers and keep underground infrastructure protected from the elements.

Sewer Manhole Covers

Sewer manhole covers play a crucial role in urban infrastructure, acting as access points to sewer systems and safeguarding public health and the environment. These covers are designed to withstand a variety of pressures and environmental conditions, ensuring that sewer systems function efficiently while minimizing risks. Below, we delve into the function, importance, and design considerations of sewer manhole covers, as well as the materials used and factors influencing their installation and maintenance.

Function and Importance of Sewer Manhole Covers

Sewer manhole covers provide essential access to underground sewer systems for maintenance, inspection, and repairs. These covers serve multiple functions:

- Access for Maintenance and Inspection: Sewer lines often require routine checks, cleaning, and repairs to prevent blockages, ensure proper flow, and identify any potential issues such as cracks or leaks. Manhole covers allow technicians to access these systems without disrupting the surrounding environment.

- Safety and Containment: Sewer manhole covers prevent unauthorized access, reducing the risk of accidents, injuries, or contamination from hazardous materials. By providing a secure barrier, they help ensure that the contents of the sewer system do not escape, thus maintaining the safety of the public.

- Pollution Prevention: Sewer manhole covers are designed to prevent harmful sewage or wastewater from spilling into the environment. They act as barriers to keep contaminants within the sewer system, helping to safeguard nearby water sources, parks, and roads from pollution.

These functions underscore the importance of sewer manhole covers in maintaining public health, sanitation, and environmental protection.

Key Design Features of Sewer Manhole Covers

The design of sewer manhole covers takes into account factors such as durability, safety, and functionality. Several key features are incorporated into these covers to ensure they perform well in urban environments:

- Anti-Slip Surfaces: Given that sewer manhole covers are often exposed to wet or slippery conditions, anti-slip surfaces are commonly included to reduce the risk of slips and falls. This is particularly important in areas with high foot traffic or in industrial zones.

- Ventilation Holes: To allow gases, such as methane or hydrogen sulfide, to escape safely, sewer manhole covers often include ventilation holes or perforations. These ventilation features are essential for reducing the risk of pressure build-up, which could otherwise lead to dangerous explosions.

- Load-Bearing Capacity: Sewer manhole covers are designed to withstand heavy loads, including vehicle traffic, machinery, and pedestrian movement. To support these loads without warping or cracking, covers are typically constructed from strong materials like cast iron, steel, or high-density composite materials.

- Corrosion Resistance: Since sewer systems are exposed to moisture and corrosive elements, manhole covers must be designed with materials that resist rust and degradation. Materials like stainless steel, corrosion-resistant alloys, or fiberglass are often used to enhance longevity and maintain structural integrity.

- Security Features: To prevent unauthorized access, many sewer manhole covers are designed with locking mechanisms or tamper-proof features. This is especially important in high-traffic urban areas where unauthorized entry could lead to safety hazards or illegal activities.

- Durability and Longevity: Sewer manhole covers are engineered to last for many years, often under harsh conditions. The combination of robust materials and thoughtful design features ensures that these covers can withstand both environmental and mechanical stresses.

Materials Used in Sewer Manhole Covers

Sewer manhole covers are typically made from materials selected for their strength, durability, and resistance to environmental factors. The most common materials include:

- Cast Iron: Cast iron is a traditional material used for manhole covers due to its strength, durability, and ability to handle heavy loads. It also resists corrosion to some extent but may require periodic maintenance or coating to prevent rust.

- Steel: Steel is another commonly used material, offering excellent strength and resistance to impact. Steel covers are often galvanized or coated with protective layers to enhance their resistance to corrosion, particularly in areas with high humidity or exposure to chemicals.

- Composite Materials: Composite manhole covers, made from materials like fiberglass, are becoming increasingly popular due to their lightweight properties, corrosion resistance, and ability to handle heavy traffic loads. These materials are particularly useful in areas with high salt exposure, such as coastal cities or areas with cold winters where salt is used for de-icing.

- Reinforced Concrete: In some cases, reinforced concrete is used for manhole covers, particularly in areas where high load-bearing capacity is required. Concrete covers are typically used in industrial or heavy-duty applications and are reinforced with metal to improve their strength and resistance to cracking.

- Aluminum: Aluminum is lightweight and resistant to corrosion, though it is less commonly used than cast iron or steel due to its lower strength under heavy loads. It is sometimes used in lighter-duty applications or where weight is a critical factor.

Installation and Maintenance Considerations

- Installation: Proper installation is critical to ensure that sewer manhole covers fit securely and can withstand the stresses they will encounter. Installation typically requires precise measurements of the manhole opening and careful alignment to ensure the cover is level and secure. The cover must also be installed at a depth that allows for proper sealing to prevent leakage.

- Maintenance: Regular maintenance is essential for ensuring the proper functioning and longevity of sewer manhole covers. Over time, wear and tear can cause damage to the cover, including rust, cracks, or warping. Periodic inspections should be carried out to check for structural integrity and to ensure that ventilation holes are clear and functioning. Replacement of covers should occur as necessary to prevent accidents and maintain safety.

- Replacement: Sewer manhole covers are subject to significant wear, especially in high-traffic areas. The decision to replace a cover depends on factors such as corrosion, deformation, and the overall condition of the cover. Replacement covers must be selected based on the same criteria used for the original installation, including the correct size, weight-bearing capacity, and material.

Environmental Considerations

Sewer manhole covers help protect the environment by preventing the leakage of harmful substances from the sewer system into the surrounding area. In urban environments, where wastewater systems often run beneath roads and sidewalks, it is essential that manhole covers remain secure and intact to prevent contamination of soil and water sources. Additionally, ventilation features on sewer covers allow for the safe escape of potentially dangerous gases, such as methane, which can accumulate in underground systems.

Some cities are increasingly adopting sustainable materials for sewer manhole covers, such as recycled composites, to reduce environmental impact. This trend is part of a broader movement toward more eco-friendly construction materials in urban infrastructure.

Sewer manhole covers are more than just functional components of urban sanitation systems; they are essential for maintaining safety, health, and environmental protection. Designed to withstand heavy traffic, resist corrosion, and provide safe access for inspections and repairs, sewer manhole covers play an indispensable role in ensuring the proper functioning of underground infrastructure. With advancements in materials and design, these covers continue to evolve to meet the demands of modern urban environments, providing long-lasting solutions to the challenges of sanitation and waste management.

Why Are Manhole Covers Round?

Manhole covers are an essential part of urban infrastructure, providing access to underground utilities like sewage systems, electrical cables, and water lines. While these covers come in various sizes and materials, the vast majority are round. The round shape is not a random design choice—it offers a range of practical, safety, engineering, and economic advantages. Below, we explore why round manhole covers are the preferred shape from multiple perspectives.

Safety: Prevention of Falling Through

The most compelling practical reason for the round shape of manhole covers is safety. A round manhole cover cannot fall through its corresponding circular hole, no matter how it is rotated. This is because the diameter of the cover is the same at every point. In contrast, a square or rectangular cover could potentially fall through if it is oriented at the wrong angle. This risk is eliminated with a round cover, ensuring that it remains securely in place and prevents accidents or injuries, whether it’s during installation, maintenance, or when in use.

Example: If a square cover were placed at a 45-degree angle, its diagonal would be longer than the side of the opening, making it possible for the cover to slip through. A round cover, however, always has a consistent diameter, making it impossible to drop into the hole.

Practicality: Ease of Handling and Installation

Another reason for the round design is ease of handling and installation. Unlike square or rectangular covers, which must be aligned at specific angles to fit into place, a round cover can be rolled into position. This ability to “roll” the cover significantly simplifies the installation and maintenance process.

- Rolling: A round manhole cover is easier to maneuver and position since it can be rolled to the installation site, reducing labor time and minimizing the physical effort required to move heavy covers.

- Alignment: A round cover does not require any alignment of edges or corners, reducing installation errors and making it faster and more efficient to replace or access the manhole.

Engineering Advantage: Even Load Distribution

From an engineering standpoint, the circular shape of manhole covers offers significant advantages, especially in load-bearing applications. A round manhole cover distributes the pressure or load applied to it evenly across its entire surface, which reduces the risk of deformation and ensures the cover can withstand heavy loads without warping.

- Stress Distribution: Unlike square or rectangular covers, which can experience stress concentrations at the corners, a round shape provides a more uniform distribution of weight and pressure across the entire surface. This prevents localized stress points that could lead to cracks or failure, extending the lifespan of the cover.

- Durability: By avoiding weak points, such as corners, round manhole covers are less likely to be damaged under the pressure of heavy vehicles, machinery, or environmental conditions.

Structural Efficiency and Material Optimization

The circular shape is structurally efficient in terms of material strength and weight. Engineering studies have shown that circles offer the best strength-to-weight ratio for a given diameter. For manhole covers, this means they can be both strong and relatively lightweight.

- Material Usage: Round covers require less material to achieve the same strength as a square or rectangular cover. The absence of corners means that no additional reinforcements are needed in these areas, optimizing the use of material and making the covers more cost-effective.

- Weight: The optimal use of material also makes round manhole covers lighter than their square or rectangular counterparts of the same size, which makes them easier to handle during installation or replacement.

Cost-Effectiveness

Round manhole covers are generally more cost-effective to produce than other shapes. Since circles are the most efficient shape to manufacture and require less material for the same strength, the overall production cost is lower.

- Manufacturing Process: The round design can be more easily formed and molded compared to complex shapes with corners, reducing manufacturing time and labor costs.

- Standardization: Because round covers are the industry standard, manufacturers can streamline production, which leads to reduced costs for both suppliers and end users.

Aesthetic and Space Efficiency

While this reason might not be as critical as the others, the round shape can also be more aesthetic and space-efficient in urban environments. Circular shapes often blend better with the surrounding area and can be designed with features that complement the aesthetic goals of a city or neighborhood. Additionally, round covers can fit into circular openings with better precision and are less likely to be misaligned than other shapes.

The round shape of manhole covers is a result of careful consideration of safety, practicality, engineering, and cost-effectiveness. The inability of round covers to fall through their openings, their ease of installation, and their ability to handle heavy loads without deformations make them the optimal choice for urban infrastructure. Moreover, the material efficiency and cost savings associated with round covers contribute to their widespread use in cities and industrial areas worldwide.

By combining practicality with engineering precision, the round design of manhole covers provides a safe, durable, and cost-effective solution for accessing underground utilities.

Manhole Cover Sizes

Manhole covers come in various sizes to accommodate different infrastructure needs. The correct size is crucial for ensuring both safety and functionality, as it ensures that the cover can handle expected traffic loads while providing adequate access to the underground systems. Below, we explore 3-5 standard sizes for manhole covers, followed by an explanation of custom sizes and the benefits they offer.

18-Inch Manhole Covers

Use: Typically used in residential or light-traffic areas, the 18-inch manhole cover is one of the smallest standard sizes. These covers are commonly found in pedestrian pathways, parks, and smaller residential streets where the load demands are minimal.

Benefits: The smaller size allows for easy access to underground utilities such as water lines or communication cables. Its lightweight nature makes it easier to handle during installation or maintenance, but it still provides a secure cover to prevent accidents or unauthorized access.

Applications: Used in low-traffic areas or places with limited access requirements.

24-Inch Manhole Covers

Use: The 24-inch manhole cover is a common size for both residential and light commercial applications. This size provides a good balance between strength and accessibility, making it suitable for streets, parking lots, and smaller industrial zones.

Benefits: Provides a larger opening for access to larger pipes or utilities. While still easy to handle, the 24-inch cover is more robust, able to withstand moderate vehicle or foot traffic.

Applications: Widely used in urban settings, municipal roads, and utility maintenance areas where more frequent access is required but without heavy load-bearing demands.

30-Inch Manhole Covers

Use: A 30-inch manhole cover is more commonly used in areas with heavier traffic, such as minor highways, larger parking lots, and busier commercial zones. This size can accommodate larger utility vaults and provide more room for access.

Benefits: The 30-inch size can support moderate vehicular traffic, making it ideal for areas with higher volumes of cars and trucks. It offers a good level of durability and accessibility for larger infrastructure systems.

Applications: Used in commercial or industrial zones, municipal roads with moderate traffic, and areas with larger utility lines that require more frequent inspection or maintenance.

36-Inch Manhole Covers

Use: The 36-inch manhole cover is considered a standard size for heavy-duty applications, such as busy highways, industrial zones, and other areas with high vehicle traffic. This size is typically used to cover larger openings and provide access to extensive underground systems like sewer systems, power lines, or storm drains.

Benefits: The larger size allows for more robust access and can handle higher traffic loads, including trucks, heavy machinery, and other large vehicles. It is designed for long-lasting durability under demanding conditions.

Applications: Essential in high-traffic zones like highways, industrial plants, and large commercial areas where high stress is placed on the cover.

48-Inch Manhole Covers (and larger)

Use: The 48-inch manhole cover is an example of an extra-large size typically used in specialized or high-capacity infrastructure. Larger covers may be required for utilities, maintenance shafts, or access points in large-scale industrial facilities.

Benefits: Extra-large covers provide expansive access to large vaults, tunnels, or systems. They can withstand extremely heavy loads and are used for installations where significant utility infrastructure is present.

Applications: Used in large-scale industrial applications, underground tunnels, or utility access points that require significant space for equipment or high-capacity systems.

Custom Manhole Covers: Tailored Solutions for Unique Applications

While standard manhole cover sizes meet the needs of most common installations, custom manhole covers provide solutions for unique or non-standard requirements. Whether the project involves specific design constraints or the need to cover irregularly shaped or unusually sized openings, custom covers offer flexibility and reliability.

Benefits of Custom Manhole Covers

- Perfect Fit: Custom manhole covers are tailored to the exact dimensions of a project, ensuring a secure and precise fit. This eliminates issues such as covers that don’t align properly or leave gaps that could compromise safety and functionality.

- Specialized Designs: Custom covers can be designed to meet specific design criteria, such as aesthetic preferences, non-slip surfaces, or locking mechanisms for added security.

- Unique Material Needs: Customization also extends to material selection, which is important for specialized environments where certain materials (e.g., corrosion-resistant alloys, composite materials) are needed to ensure durability and longevity.

- Adaptable to Special Projects: For unusual infrastructure projects, custom manhole covers allow for flexibility in design to meet specific engineering, weight-bearing, or safety requirements.

Selecting the Right Custom Size

To ensure the right custom-sized manhole cover, accurate measurements of the manhole opening are essential. This involves measuring both the diameter and depth of the opening, as well as accounting for any additional design features or functional needs, such as ventilation holes, reinforced edges, or special coatings. Working closely with a manufacturer will help ensure the cover meets all required specifications.

GangLong Fiberglass Manhole Covers: Supporting Custom Sizes

GangLong Fiberglass understands that infrastructure needs are diverse and unique. That’s why we offer customized manhole covers to meet the specific requirements of your project. Whether you’re dealing with unusual dimensions, specialized materials, or unique design features, we can produce fiberglass manhole covers tailored to your needs. Our fiberglass manhole covers offer the added benefits of corrosion resistance, lighter weight, and exceptional durability, making them ideal for demanding applications.

For more information on custom manhole covers and how GangLong Fiberglass can support your project, feel free to reach out to us directly.

Manhole Covers by GangLong Fiberglass Manufacturer

Manhole covers play a crucial role in infrastructure, ensuring safety and accessibility for utilities and maintenance. As a trusted manufacturer, GangLong Fiberglass specializes in producing high-quality manhole covers and providing customization services tailored to meet diverse requirements. Whether purchasing standard options or designing custom covers, understanding the key aspects of selection and customization is essential to ensure optimal performance and satisfaction. Below, we outline important considerations to guide users in making informed decisions when buying or customizing manhole covers.

Factors to Consider When Customizing Manhole Covers

Customization allows users to design manhole covers that fit specific needs. However, several factors must be considered to ensure a successful outcome.

Key Considerations for Customization:

- Material Selection: The choice of material affects durability, load-bearing capacity, and resistance to environmental conditions. GangLong Fiberglass offers expert guidance to help users select the best material for their requirements.

- Size and Dimensions: Accurate measurements are essential to ensure a proper fit. Customized covers should be designed with precise dimensions to match the access point.

- Load Capacity: Depending on the application, manhole covers must withstand specific weight loads. For example, residential areas may require lighter covers, while industrial zones need heavy-duty options.

- Design Features: Users can request unique features such as anti-slip surfaces, custom logos, or locking mechanisms for added safety and functionality.

- Compliance with Standards: Custom covers should meet local and international standards to ensure safety, performance, and legal compliance.

Important Tips for Purchasing Manhole Covers

When buying manhole covers, whether standard or custom, there are several important factors to consider to ensure satisfaction and long-term performance.

Tips for Purchasing Manhole Covers:

- Understand the Application: Clearly define the intended use of the manhole cover to select an appropriate type and design.

- Consider Environmental Conditions: Choose materials and coatings that can withstand the specific conditions of the installation site, such as extreme temperatures or chemical exposure.

- Assess Maintenance Needs: Opt for designs that are easy to clean, repair, and maintain over time.

- Evaluate Cost vs. Quality: While budget constraints are important, investing in higher-quality materials can reduce long-term replacement and maintenance costs.

How GangLong Fiberglass Supports Your Manhole Cover Needs

GangLong Fiberglass not only provides a wide range of manhole cover options but also offers personalized guidance for customers. As an experienced manufacturer, GangLong Fiberglass ensures every client receives expert advice to choose or customize manhole covers that meet their exact needs. From material recommendations to design optimization, we are here to assist at every step.

For customers interested in customization, GangLong Fiberglass offers tailored services that allow for unique designs and specific features. To start your customization journey or receive expert suggestions, you can contact us directly. Send your requirements or inquiries via email, and we’ll work closely with you to deliver a solution that exceeds expectations.

By keeping these considerations in mind and partnering with a trusted manufacturer like GangLong Fiberglass, users can confidently choose or customize manhole covers that align perfectly with their needs.

FAQs about Manhole Covers

What is the new name for a manhole cover?

Can we still say manhole?

Why is there a manhole cover in my garden?

Are manhole covers a standard size?

What is the best shape for a manhole cover?

How many types of manhole covers are there?

Solid Top: Provides a solid cover, usually for sewage or stormwater systems.

Grated: Used for drainage systems to allow water to flow through.

Recessed Covers: Designed to hold paving materials, allowing the cover to blend into the surrounding surface.

Hinged Covers: Have hinges for easy access and to prevent theft or unauthorized opening.

What is underneath manhole covers?

Sewage systems for waste removal.

Stormwater drains for managing rainfall.

Electrical cables or telecommunication lines.

Gas or water pipes that require maintenance.

What are 4 different uses for a manhole cover?

Sewer access: For inspection and maintenance of wastewater and sewage systems.

Electrical systems: Covering access to underground electrical wiring.

Telecommunications: Access to cables and equipment for phone and internet services.

Drainage systems: Covering stormwater drains to manage rainwater flow.

Why are all manhole covers round?

Safety: A round cover cannot fall through its own opening, reducing accidents.

Ease of handling: Round covers can be rolled easily, making them simpler to move.

Uniform pressure distribution: The round shape distributes weight evenly, reducing the risk of damage or breakage.

Cost-efficiency: Round covers require less material than square covers of the same width because circles have the smallest perimeter-to-area ratio.

What are manhole covers used for?

Is it illegal to cover a manhole?

Why are manhole covers in the street?

Should manhole covers be sealed?

Is it safe to walk on a manhole cover?

What can happen if manholes are not covered securely?

Accidents: Pedestrians or vehicles could fall into the open manhole, leading to injuries or damages.

Unauthorized access: People may access dangerous underground utilities, leading to theft, sabotage, or injury.

System contamination: Debris or contaminants could enter and damage the utility system.

Structural damage: Water ingress or blockages can occur, causing disruptions to the utility system.

What is the alternative name for a manhole cover?

Where should manholes be located?

Streets and sidewalks for easy maintenance without disturbing private property.

Near intersections for centralized access to multiple utility lines.

Industrial areas where utilities are clustered, such as drainage or wastewater systems.

On private properties, if utility access is needed for sewage or water systems.

What manhole cover do l need?

Light-duty covers for pedestrian areas, such as walkways or gardens.

Medium-duty covers for areas with light vehicular traffic, such as parking lots.

Heavy-duty covers for roads with heavy traffic or industrial areas where they must withstand high loads.

Additionally, you may need a vented, hinged, or solid top cover depending on the utility and safety requirements.

What happens if you cover a manhole?

What is the modern term for manhole?

What is the difference between a sewer and a manhole?

What is underneath a manhole?

Sewer lines for waste management.

Stormwater drains to handle runoff.

Electrical or communication conduits for power and data cables.

Water or gas pipelines that may require maintenance or inspection.

What is the difference between a hole and a manhole?

Why are manhole covers so heavy?

Withstand high loads: They need to support the weight of vehicles, especially on roads and highways.

Prevent unauthorized removal: The weight deters theft or unauthorized access to underground systems.

Ensure safety: A heavy cover stays securely in place and prevents it from shifting under pressure from traffic or environmental forces.