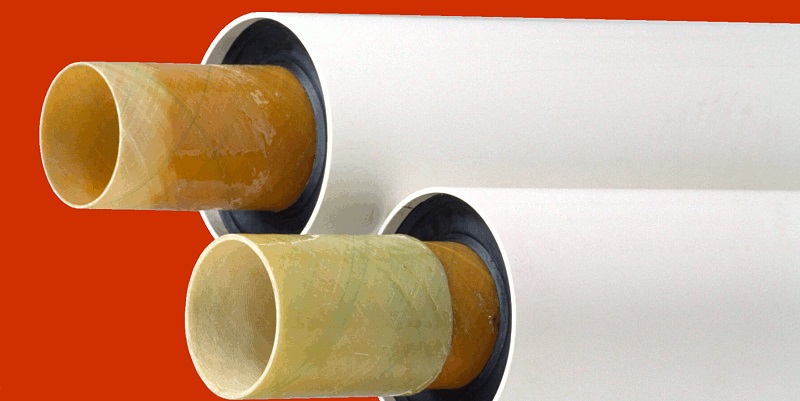

Pre insulated FRP pipe is a specialized piping solution designed to offer both thermal efficiency and durability. It is constructed with a fiberglass reinforced plastic (FRP) outer jacket and insulation material, typically made of polyisocyanurate (PIR) or polyurethane foam. The insulation helps maintain the temperature of fluids being transported, while the FRP outer layer provides protection against environmental factors such as moisture, corrosion, and physical impact. Pre insulated FRP pipe is widely used in industrial applications, including district heating and cooling, water distribution, and oil and gas systems, where maintaining fluid temperature and long-term durability are essential for efficient operations. Pre insulated FRP pipe features a fiberglass reinforced jacket and polyisocyanurate foam insulation, ideal for durable, non-corrosive piping in various applications.

Simplifying Your Life: Key Functionalities

| Attributes | Details |

|---|---|

| Place of Origin | Hebei, China |

| Brand Name | GangLong Fiberglass |

| Product Name | Pre Insulated FRP Pipe |

| Application | Construction, Industry, Housing |

| Technology | Pultrusion |

| Surface Treatment | Smooth |

| Processing Services | Forming, Welding, Punching, Cutting |

| Material | Fiberglass |

| Features | Durable, Lightweight, High Strength, Flame Retardant, Corrosion Resistant, UV Resistant |

| Tensile Strength | >550 MPa |

| Certificate | ISO9001 |

| Shape | Custom Shape |

| Color | Custom Color |

| Size | Custom Size |

| Thickness | Custom Thickness |

| Diameter | Custom Diameter |

| Minimum Order Quantity | 1 Piece |

| Supply Capacity | 20,000 Meters/Month |

What is Pre Insulated FRP Pipe?

Pre insulated FRP pipe refers to fiber-reinforced plastic (FRP) piping that is equipped with insulation to provide thermal protection in various industrial applications. This combination of insulation and FRP offers multiple advantages, including corrosion resistance, durability, and improved thermal retention. The insulation layer ensures that the pipe maintains the temperature of fluids flowing through it, preventing heat loss and maintaining energy efficiency in systems such as oil and gas pipelines, district energy systems, and chemical processing facilities.

The core of pre insulated FRP pipe is built from high-quality fiberglass reinforced with resin, creating a strong and lightweight pipe that can handle high pressures and withstand harsh environments. The insulation, typically made from polyurethane foam or other high-performance insulating materials, is applied over the FRP pipe to provide superior thermal protection. The result is a pipe that not only resists corrosion and mechanical damage but also maintains the desired temperature of the fluids being transported.

GangLong Fiberglass specializes in the production of pre insulated FRP pipe, ensuring that each pipe is designed to meet the specific needs of its intended application. The insulation process is tailored to provide optimal thermal efficiency while maintaining the structural integrity of the FRP pipe.

The Key of Pre Insulated FRP Pipe Composition

Pre insulated FRP pipe is composed of three main layers, each contributing to the pipe’s overall performance. The innermost layer is the FRP pipe itself, constructed from a combination of fiberglass and resin. This layer provides mechanical strength, flexibility, and resistance to corrosion, making it ideal for use in demanding industrial environments. Depending on the specific application, the resin used may be polyester, vinyl ester, or epoxy, each offering different levels of chemical and thermal resistance.

The middle layer is the insulation, which is typically made from polyurethane foam. This insulation provides excellent thermal retention, ensuring that the pipe maintains the temperature of the fluid being transported. In applications where maintaining fluid temperature is critical, such as district heating or cooling systems, this insulation layer can significantly improve energy efficiency by reducing heat loss.

The outermost layer, sometimes referred to as the protective jacket, is designed to shield the insulation from external elements. This jacket is often made from materials such as polyethylene or aluminum, providing additional protection against moisture, UV radiation, and physical damage. The combined structure of these three layers ensures that pre insulated FRP pipe delivers reliable performance, even in the harshest environments.

How about Pre Insulated FRP Pipe Applications?

Pre insulated FRP pipe is widely used in industries where maintaining the temperature of transported fluids is critical. The thermal insulation properties, combined with the corrosion resistance and durability of FRP, make this type of piping an excellent choice for many demanding applications.

Oil and Gas Industry

In the oil and gas sector, pre insulated FRP pipe is often used for transporting fluids over long distances. The insulation helps maintain the temperature of the transported oil or gas, preventing issues such as solidification or condensation that could disrupt the flow of materials. Additionally, the corrosion-resistant nature of FRP makes these pipes ideal for use in environments where they may be exposed to moisture, saltwater, or harsh chemicals commonly found in oil and gas fields.

District Energy Systems

District energy systems, which provide heating and cooling to multiple buildings through a centralized network, rely heavily on pre insulated FRP pipe to maintain the temperature of the fluid circulating through the system. The insulation layer ensures that minimal heat is lost as the fluid travels through the network, improving overall energy efficiency and reducing operational costs. Pre insulated FRP pipe can be customized to meet the specific needs of district energy systems, allowing for precise control over temperature retention.

Chemical Processing

In chemical processing facilities, pre insulated FRP pipe is used to transport various chemicals at specific temperatures. Maintaining consistent temperatures is essential for ensuring product quality and process efficiency. The insulation in pre insulated FRP pipe prevents temperature fluctuations that could compromise the chemical reactions or the stability of the materials being transported. Additionally, the FRP layer provides resistance to the corrosive chemicals commonly encountered in these environments.

Marine and Offshore Applications

Pre insulated FRP pipe is also widely used in marine and offshore applications, where it is exposed to harsh environmental conditions such as saltwater and UV radiation. The insulation in these pipes helps to protect against temperature changes, while the FRP core provides corrosion resistance and durability. These characteristics make pre insulated FRP pipe ideal for use in offshore oil rigs, ships, and other marine structures.

What are the Joint Methods for Pre Insulated FRP Pipe?

Properly joining pre insulated FRP pipe sections is essential for maintaining the integrity of the system. Several joint methods can be used depending on the application and project requirements. These joint methods ensure that the pipe sections are securely connected, while also preserving the thermal insulation properties.

Adhesive Bonding

One of the most common methods for joining pre insulated FRP pipe is adhesive bonding. In this process, a specialized adhesive is applied to the ends of the pipe sections, which are then pressed together, including the use of an FRP pipe end cap for a secure fit. The adhesive forms a strong bond between the FRP layers, ensuring that the pipe sections remain securely connected. Adhesive bonding also helps maintain the insulation layer’s continuity, ensuring that there is no heat loss at the joint.

Flanged Connections

Flanged connections are another common method for joining pre insulated FRP pipe sections. In this method, each pipe section is equipped with a flange, which allows the sections to be bolted together. Flanged connections are particularly useful in applications where the pipe sections may need to be disassembled for maintenance or repair. The insulation layer is typically protected during the assembly of the flanges to ensure that the thermal properties of the pipe are preserved.

Bell and Spigot Joints

Bell and spigot joints are commonly used in pre insulated FRP pipe installations where flexibility and ease of assembly are essential. This method involves inserting the spigot end of one pipe section into the bell end of another, creating a secure, leak-proof connection, especially when using bell and spigot FRP pipe configurations. Gaskets or adhesive may be used to seal the joint and maintain the thermal insulation properties of the system.

The Idea of Pre Insulated FRP Pipe Installation

Pre insulated FRP pipe is relatively easy to install, thanks to its lightweight construction and flexibility. However, proper installation practices must be followed to ensure that the pipe delivers optimal performance over its service life.

Before installation, it is important to inspect the pre insulated FRP pipe for any damage that may have occurred during transport. If any damage is found, the affected sections should be repaired or replaced before installation begins. This will help prevent issues such as leaks or reduced thermal efficiency once the pipe is in service.

During installation, care should be taken to ensure that the joints are properly aligned and securely connected. Depending on the joint method used, additional steps such as curing adhesive or tightening flanges may be necessary. Ensuring that the insulation layer is continuous across the entire system is critical for maintaining thermal efficiency.

Pre insulated FRP pipe can be installed in various environments, including above ground, underground, and underwater. Each installation environment presents its own challenges, but the lightweight and flexible nature of pre insulated FRP pipe makes it adaptable to a wide range of conditions.

What are the Advantages of Pre Insulated FRP Pipe?

Pre insulated FRP pipe offers numerous advantages that make it a preferred choice in many industries. These advantages include:

Corrosion Resistance

One of the most significant advantages of pre insulated FRP pipe is its resistance to corrosion. The fiberglass and resin composition of the pipe ensures that it remains unaffected by moisture, chemicals, and other corrosive elements commonly encountered in industrial environments. This makes it an ideal solution for applications where metal pipes would corrode and fail over time.

Thermal Retention

The insulation layer in pre insulated FRP pipe is designed to maintain the temperature of the fluid being transported. This reduces energy losses and helps maintain the efficiency of the system. In applications such as district energy systems or chemical processing plants, maintaining fluid temperature is critical for both performance and cost savings.

Lightweight and Easy to Install

Pre insulated FRP pipe is much lighter than traditional materials such as metal or concrete. This makes it easier to handle and install, reducing labor costs and installation time. The pipe’s flexibility also allows it to be installed in a variety of configurations, making it adaptable to different environments.

Long Service Life

Pre insulated FRP pipe is designed for durability, with the combination of corrosion resistance, mechanical strength, and thermal insulation ensuring that the pipe can provide reliable performance for many years. This long service life reduces the need for frequent replacements, making pre insulated FRP pipe a cost-effective solution in the long run.

GangLong Fiberglass offers a wide range of pre insulated FRP pipe solutions, each tailored to meet the specific needs of various industries. By choosing GangLong Fiberglass products, businesses can benefit from high-quality, long-lasting pipes designed for optimal performance in even the most demanding environments.

How About Pre-Insulated Pipe 15mm for Specialized Applications

Pre insulated FRP pipe with a 15mm diameter is commonly used in smaller, more compact systems where space is limited, such as in residential or light industrial applications. These systems often require precise thermal control, and the insulation within pre insulated FRP pipe helps achieve that by preventing heat loss or temperature fluctuations. In environments where maintaining consistent temperatures is critical, such as in small-scale heating or cooling systems, 15mm pre insulated FRP pipe provides an ideal solution. Additionally, its compact size allows for easy installation in tight spaces while still offering the durability and protection of a larger FRP system.

Pre Insulated Pipe for Underground Installations

Underground piping systems face specific challenges such as soil pressure, moisture, and temperature changes. Pre insulated FRP pipe is especially suited for underground installations due to its protective outer layer and thermal insulation. The FRP outer jacket shields the pipe from environmental damage, including corrosion and moisture intrusion, while the insulation maintains the temperature of the fluids transported through the system. This combination makes pre insulated FRP pipe an excellent choice for underground heating and cooling systems, as well as for water distribution networks. Pre insulated FRP pipe’s resistance to environmental factors helps ensure long-term reliability, reducing the need for frequent maintenance or pipe replacement.

The Key of Pre Insulated FRP Pipe in District Energy Systems

District energy systems, including district heating and cooling, are highly reliant on the efficient transfer of thermal energy over long distances. Pre insulated FRP pipe plays a vital role in maintaining thermal efficiency within these systems. The insulation layer prevents significant heat loss, ensuring that the energy generated at the central plant is efficiently delivered to the end user. The FRP outer jacket adds durability, making pre insulated FRP pipe suitable for installation in various environments, including both underground and exposed areas. This durability helps protect the system from external stressors, such as mechanical impacts and temperature variations, ensuring a long-lasting, efficient operation of district energy systems.

Pre Insulated Pipe 28mm for Industrial Use

In larger industrial applications, such as in oil and gas or district energy systems, the 28mm pre insulated FRP pipe is commonly used due to its ability to handle higher flow volumes while maintaining the necessary insulation properties. The increased diameter allows for more efficient transportation of fluids, while the insulation layer helps maintain the temperature throughout the system. This type of pre insulated FRP pipe is also resistant to external environmental factors such as corrosion, UV radiation, and physical damage. The combination of these features makes it ideal for use in harsh industrial environments where temperature control and long-term durability are crucial to operational efficiency.

Pre Insulated FRP Pipe for Heating Applications

Pre insulated FRP pipe is particularly valuable in heating applications, where energy efficiency and temperature consistency are vital. The insulation in these pipes ensures that heat loss is minimized as fluids are transported through the system. This is particularly important in district heating systems, where thermal energy must travel long distances from a central plant to multiple locations. Pre insulated FRP pipe not only maintains the desired temperature but also helps reduce the overall energy consumption of the system. Additionally, the FRP outer jacket provides protection from external factors, ensuring that the pipe remains in good condition even in exposed or harsh environments. For residential or industrial heating systems, pre insulated FRP pipe offers a reliable solution that enhances performance and reduces energy waste.

Customization Options for Pre Insulated FRP Pipe

One of the main advantages of pre insulated FRP pipe is the ability to customize it for specific project needs. Various sizes, insulation thicknesses, and outer jacket specifications can be tailored to meet the requirements of different industries and applications. Whether a system requires higher temperature resistance, thicker insulation, or enhanced protection from external factors, pre insulated FRP pipe can be designed accordingly. This flexibility makes it an ideal choice for complex or unique installations that require specialized solutions. Customization also ensures that each system operates at peak efficiency, providing the exact level of thermal insulation and durability required for the specific application.

HDPE vs FRP Pipe: Which is Best for Your Project?

Pre Insulated Water Pipe for Consistent Water Temperature

Pre insulated FRP pipe is also widely used in water distribution systems, both for hot and cold water applications. The insulation in these pipes helps maintain a consistent water temperature, ensuring that cold water stays cool and hot water retains its heat over long distances. This is particularly important in large buildings or industrial facilities where water may need to travel through extensive piping networks before reaching its destination. The FRP outer layer adds an extra level of protection, preventing damage from environmental factors like corrosion or temperature changes. Pre insulated FRP pipe ensures that water systems operate efficiently and consistently, minimizing energy loss and maintaining the quality of the water being delivered.

Durability and Longevity of Pre Insulated FRP Pipe

Pre insulated FRP pipe is designed to withstand the demands of harsh environments, providing long-term durability and reliability. The fiberglass reinforced plastic outer jacket protects the pipe from mechanical damage, UV exposure, and chemical corrosion, while the insulation ensures thermal efficiency over time. This combination of strength and insulation makes pre insulated FRP pipe an ideal solution for systems that need to operate continuously without the risk of breakdowns or frequent maintenance. Industries that require piping systems to function reliably over long periods, such as oil and gas, water distribution, or district heating, benefit from the longevity that pre insulated FRP pipe offers.

Environmental Benefits of Pre Insulated FRP Pipe

The use of pre insulated FRP pipe in industrial and residential systems provides several environmental benefits. Its ability to maintain fluid temperatures reduces the energy needed for heating or cooling, thereby lowering overall energy consumption. Additionally, the long lifespan of pre insulated FRP pipe means that fewer resources are needed for repairs or replacements, contributing to a reduction in material waste. The durability of the FRP outer layer also minimizes the risk of leaks or environmental contamination, helping industries meet sustainability goals while maintaining efficient operations. Pre insulated FRP pipe supports energy conservation and resource efficiency, making it an environmentally friendly choice for modern infrastructure systems.

Installation and Maintenance of Pre Insulated FRP Pipe

Pre insulated FRP pipe is relatively easy to install due to its lightweight nature and flexible design. The ease of handling during installation reduces labor costs and time, making it a cost-effective solution for both new projects and upgrades. Additionally, pre insulated FRP pipe requires minimal maintenance once installed, thanks to its durable construction. The FRP outer jacket and internal insulation are designed to withstand environmental stressors, meaning that regular inspections and repairs are seldom needed. This low-maintenance aspect is especially beneficial in industries that require uninterrupted operation, such as district heating and water distribution systems, where downtime can be costly.

Pre Insulated FRP Pipe and Its Role in Sustainable Infrastructure

As industries and municipalities move toward more sustainable infrastructure solutions, pre insulated FRP pipe is playing a key role in reducing energy consumption and environmental impact. Its thermal efficiency helps systems operate with minimal energy waste, while its durable construction ensures that infrastructure investments last longer, reducing the need for frequent replacements. Pre insulated FRP pipe also supports efforts to minimize environmental risks, such as leaks or corrosion, which can harm surrounding ecosystems. As a result, industries looking to build or upgrade infrastructure systems in a way that supports sustainability and energy efficiency are increasingly turning to pre insulated FRP pipe as a preferred solution.

The Future of Pre Insulated FRP Pipe Technology

As technology advances, pre insulated FRP pipe continues to evolve to meet the changing needs of modern infrastructure. Innovations in materials science are leading to even better insulation performance and stronger FRP outer jackets, making these pipes suitable for an even wider range of applications. Additionally, advancements in manufacturing processes are enabling more customization options, allowing industries to create tailored piping solutions that meet the specific needs of their systems. As industries become more focused on energy efficiency, durability, and environmental impact, the demand for pre insulated FRP pipe will continue to grow, positioning it as a key component in future infrastructure projects.

Consider When Determining FRP Pipe Pressure Rating

How about Pre Insulated FRP Pipe?

Pre insulated FRP pipe is an advanced piping solution that combines the strength and corrosion resistance of fiber-reinforced plastic (FRP) with a layer of thermal insulation to create a highly efficient and durable system for transporting fluids. This type of pipe is particularly well-suited for industrial applications where maintaining fluid temperature is critical, such as in district heating and cooling systems, chemical processing plants, and oil and gas industries. The pre insulated FRP pipe is constructed with a high-performance insulation layer that ensures minimal heat loss or gain, thus improving energy efficiency.

The core of pre insulated FRP pipe is made from high-strength fiberglass, reinforced with a resin matrix to provide durability, flexibility, and resistance to corrosion. The insulation, often made from materials like polyurethane foam, is applied over the FRP pipe and acts as a barrier to temperature changes, ensuring that the fluids being transported maintain their desired temperature. GangLong Fiberglass, a leading manufacturer of these products, customizes each pipe to meet specific project needs, ensuring long-lasting performance in various environmental conditions.

How about Pre Insulated FRP Pipe Construction?

The construction of pre insulated FRP pipe involves multiple layers, each serving a crucial purpose in the performance of the pipe. The innermost layer is the FRP pipe itself, composed of fiberglass and resin. This layer is designed to withstand high pressures, resist corrosion, and provide the mechanical strength needed for long-term use in industrial settings.

The insulation layer, typically polyurethane foam, is applied over the FRP pipe. This insulation is essential for maintaining the temperature of the fluids inside the pipe, whether they are hot or cold. It prevents heat loss in heating systems or heat gain in cooling systems, making the pipe highly energy-efficient. The thickness of the insulation can be customized based on the specific temperature requirements of the system.

On the exterior, a protective jacket, often made from materials like polyethylene or aluminum, is applied over the insulation. This outer jacket shields the insulation from environmental factors such as moisture, UV radiation, and mechanical damage. The combination of these layers ensures that pre insulated FRP pipe offers excellent thermal performance, durability, and long service life, even in the most challenging conditions.

The Key of Pre Insulated FRP Pipe in Underground Installations

Pre insulated FRP pipe is particularly well-suited for underground installations, where it offers protection against soil pressure, moisture, and temperature fluctuations. The outer jacket of the pipe plays a crucial role in shielding the insulation from environmental elements that could compromise its thermal performance. In underground applications, the pipe must withstand the pressure exerted by the surrounding soil, as well as resist water infiltration that could damage the insulation. The strength of the FRP core and the protective qualities of the outer jacket make pre insulated FRP pipe an ideal choice for these conditions.

In district heating and cooling systems, pre insulated FRP pipe is often buried underground to transport hot or cold water over long distances. The insulation ensures that the temperature of the water remains consistent, minimizing energy losses and improving the efficiency of the system. Additionally, the corrosion-resistant nature of the FRP core means that the pipe can last for decades without needing replacement, even in harsh underground environments.

The customization options available for pre insulated FRP pipe also make it a versatile solution for underground installations. The thickness of the insulation can be tailored to meet the specific thermal requirements of the system, and the outer jacket can be reinforced to provide additional protection against soil movement or other environmental factors.

What are the Joint Methods for Pre Insulated FRP Pipe?

Joining pre insulated FRP pipe sections is a critical aspect of ensuring the integrity and performance of the system. Several joint methods can be used depending on the specific application and the needs of the project. Each method is designed to maintain the continuity of the insulation layer while providing a secure and leak-proof connection between the pipe sections.

Adhesive Bonding

Adhesive bonding is a common method for joining pre insulated FRP pipe sections. A specialized adhesive is applied to the ends of the pipe sections, which are then pressed together and allowed to cure. This method creates a strong, durable bond between the FRP layers, ensuring that the pipe sections remain securely connected. Adhesive bonding is often used in applications where high pressure or temperature fluctuations are expected, as it provides a reliable seal that can withstand these conditions.

Bell and Spigot Joints

Bell and spigot joints involve fitting the spigot end of one pipe section into the bell end of another. A gasket is typically used to seal the joint, ensuring a leak-proof connection. This method is particularly useful in underground installations, where slight movements of the soil could cause misalignment in other types of joints. The bell and spigot joint allows for some flexibility, accommodating these movements without compromising the integrity of the system.

Key Factors Determining FRP Pipe Temperature Limits in Industry

How Pre-Insulated FRP Pipe Works

Pre-insulated FRP pipe is a composite piping system designed to transport fluids while maintaining temperature, reducing energy loss, and offering high resistance to environmental conditions. It is commonly used in district heating, cooling systems, chemical processing, and other industrial applications where fluid temperature must be maintained over long distances.

Components and Materials

Pre-insulated FRP pipe is made of two main components:

- Fiberglass Reinforced Plastic (FRP): The outer jacket is constructed from fiberglass reinforced plastic, offering high mechanical strength, corrosion resistance, and durability. The fiberglass reinforcement provides the pipe with superior resistance to pressure and mechanical stress, while the resin matrix ensures that it is chemically resistant and lightweight.

- Polyisocyanurate (PIR) or Polyurethane Foam Insulation: The insulating layer is made of either polyisocyanurate (PIR) foam or polyurethane foam, both of which offer excellent thermal insulation properties. The foam insulation is applied to the core of the pipe, minimizing heat loss or gain and maintaining the desired temperature of the fluid inside.

How It Works

Pre-insulated FRP pipes function by combining the insulating properties of foam with the structural integrity of fiberglass.

- Thermal Retention: The foam insulation minimizes thermal losses by preventing heat from escaping or being absorbed by the environment, keeping the fluid inside at a consistent temperature. This is critical for systems where energy efficiency is important, such as in heating or cooling networks. The thermal insulation ensures that the fluid remains within a desired temperature range, whether for hot water, steam, or chilled liquids.

- Fluid Transport: The pipe is designed to carry fluids, such as hot or cold water, steam, or chemicals, through a network with minimal temperature fluctuations. The thermal retention allows for long-distance transportation of fluids while reducing energy costs associated with temperature regulation.

- Corrosion Resistance: The fiberglass exterior ensures that the pipe is highly resistant to corrosion from chemicals, moisture, and other environmental factors. This makes it ideal for use in industries like chemical processing or wastewater treatment where metal pipes would corrode over time.

Performance and Efficiency

- Thermal Efficiency: The insulation layer plays a key role in reducing energy consumption by keeping the temperature of the fluid stable. In applications such as district heating, the pre-insulated FRP pipe reduces the need for constant reheating of the fluid, leading to significant energy savings.

- Mechanical Strength: The fiberglass reinforcement ensures that the pipe can withstand high pressures and mechanical stress without failure. It also ensures that the pipe remains flexible enough for installation in various configurations, both underground and above-ground.

- Corrosion Resistance: The fiberglass and resin composition prevents the pipe from degrading due to exposure to harsh chemicals, moisture, or changing weather conditions, giving it a longer lifespan compared to metal pipes.

Safety and Maintenance

- Safety Features: Pre-insulated FRP pipes are non-flammable, making them safer for use in environments where fire risk is a concern. The fiberglass outer layer also protects the pipe from physical damage, which can reduce the risk of leaks or system failures.

- Maintenance Requirements: While pre-insulated FRP pipes are designed for low maintenance due to their resistance to corrosion and environmental degradation, periodic inspection may be required to ensure the insulation remains intact and there are no signs of damage to the pipe. Regular cleaning of any external debris can also help maintain optimal performance.

Installation and Setup

- Ease of Installation: One of the major benefits of pre-insulated FRP pipes is their lightweight nature, which makes them easier to transport and install compared to traditional metal or concrete pipes. The flexibility of the material allows it to be installed in various configurations, both above-ground and underground, without requiring significant modifications.

- Minimal Modification: The pre-insulated pipes come in ready-to-install sections, reducing the need for additional insulation or protective layers during installation. This cuts down on labor costs and installation time, making it a more efficient solution for large-scale projects.

Materials or Energy Usage

- Input Requirements: Pre-insulated FRP pipes do not require additional energy to maintain their insulating properties. However, the fluid being transported, whether hot or cold, must meet the necessary input requirements for the system, such as heating or chilling at the source.

- Output or Results: The result of using pre-insulated FRP pipes is a highly efficient, energy-saving fluid transport system that maintains the temperature of the fluid while offering durability and resistance to corrosion over time.

Lifespan and Durability

- Longevity: The combination of fiberglass and foam insulation ensures that pre-insulated FRP pipes have a long service life. The material is highly resistant to environmental degradation, reducing the need for frequent replacements. Depending on the installation environment, these pipes can last for decades with minimal maintenance.

- Durability: Pre-insulated FRP pipes are designed to withstand extreme temperatures and high pressure, ensuring reliable performance even under challenging conditions.

Environmental Impact

- Sustainability: Pre-insulated FRP pipes are made from materials that are relatively environmentally friendly. The foam insulation is highly effective in reducing energy consumption, which can lower the carbon footprint of the system. Additionally, the longevity of the pipes reduces the need for frequent replacements, contributing to less waste.

- Disposal: At the end of their life cycle, FRP pipes can be recycled, making them a more sustainable choice compared to traditional metal or plastic pipes.

Cost and Value

- Price: While pre-insulated FRP pipes may have a higher upfront cost than traditional pipes, the long-term savings in energy and maintenance costs make them a cost-effective solution in the long run. Their durability and efficiency lead to reduced operating costs and fewer replacements over time.

- Cost vs. Benefits: The benefits of pre-insulated FRP pipes far outweigh the initial investment. They provide superior thermal efficiency, durability, and corrosion resistance, all of which result in long-term cost savings and a reliable, high-performance piping system.

In summary, pre-insulated FRP pipes combine the advantages of fiberglass’s strength and insulation with a durable outer layer to provide a cost-effective, energy-efficient solution for fluid transport systems in a variety of industrial and commercial applications. Their resistance to corrosion, ability to maintain fluid temperature, and ease of installation make them a superior choice in demanding environments.

FAQs about Pre Insulated Frp Pipe

FRP stands for Fiberglass Reinforced Plastic in the context of piping. This type of pipe is made by reinforcing a plastic matrix with fiberglass filaments, which significantly increases the pipe’s strength and durability. FRP pipe is widely used in industries that require materials capable of withstanding corrosive environments, high temperatures, and mechanical stress. Industries such as chemical processing, water treatment, and oil and gas commonly utilize FRP pipes because of their exceptional corrosion resistance, lightweight nature, and long-term durability. The combination of fiberglass and plastic allows FRP pipes to outperform traditional metal pipes in environments where corrosion or chemical reactions would quickly degrade other materials. FRP is often favored for its low maintenance requirements and ability to last for decades, reducing overall operational costs for industries that require robust piping systems.

FRP pipe and PVC pipe are both widely used in various industries, but they serve different purposes and are made from different materials. FRP pipe, or Fiberglass Reinforced Plastic pipe, is made from a composite of fiberglass and resin, making it highly durable, strong, and resistant to corrosion, high temperatures, and harsh chemicals. It is commonly used in chemical processing, oil and gas, and water treatment industries due to its ability to withstand demanding environments.

PVC pipe, or Polyvinyl Chloride pipe, is made from a type of plastic and is more commonly used in residential plumbing, irrigation systems, and other low-pressure applications. PVC pipes are affordable, easy to install, and work well in less aggressive environments where extreme temperatures or corrosive substances are not present. However, PVC is not suitable for high-pressure or industrial applications like FRP pipe. The main difference between the two lies in their performance capabilities—FRP pipe is designed for heavy-duty industrial use, while PVC pipe is better suited for lightweight and residential applications.

A pre-insulated pipe is a pipe system that comes with factory-applied insulation around the core pipe, designed to maintain the temperature of the fluids being transported. These pipes are commonly used in heating and cooling applications, such as district heating, refrigeration, or in industrial settings where temperature control is critical. The insulation is typically made from materials like polyurethane foam or mineral wool and is often encased in a protective outer layer, such as a polyethylene jacket, to protect against environmental factors like moisture, UV exposure, and mechanical damage.

The primary benefit of pre-insulated pipes is their ability to minimize heat loss or gain, making systems more energy-efficient. Pre-insulated pipes also reduce the need for on-site insulation, making installation faster and more cost-effective. In addition, they protect the core pipe from external temperature changes, ensuring the transported fluid maintains its desired temperature over long distances. Pre-insulated pipe systems are essential in industries that require precise temperature control, such as food processing, pharmaceuticals, and chemical manufacturing.

FRP stands for Fiberglass Reinforced Plastic, a composite material made by embedding glass fibers in a plastic matrix (usually epoxy, polyester, or vinyl ester). FRP is widely used for its strength-to-weight ratio, corrosion resistance, and durability. The fiberglass reinforcement provides the material with exceptional tensile strength, while the plastic matrix offers chemical resistance and flexibility. FRP is commonly used in industries such as construction, transportation, marine, and chemical processing. In the context of pipes, FRP is used for manufacturing lightweight, strong, and corrosion-resistant pipes, including pre-insulated FRP pipes, which combine insulation and protection for fluid transport systems. FRP pipes are ideal for environments where traditional metal pipes may corrode or deteriorate due to exposure to harsh chemicals or extreme weather conditions.

FRP and fiberglass are closely related but differ in terms of their composition and applications. Fiberglass is simply the glass fiber material itself, which is often used as a reinforcing component in various composite products. On the other hand, FRP (Fiberglass Reinforced Plastic) is a composite material made by combining fiberglass with a plastic resin (such as epoxy, polyester, or vinyl ester). The addition of the resin gives FRP greater versatility and durability compared to fiberglass alone. In the context of piping, FRP pipes offer enhanced resistance to corrosion, chemical exposure, and weathering compared to traditional fiberglass-based pipes. FRP also offers superior mechanical strength, making it more suitable for demanding industrial applications. Overall, FRP is considered an improvement over raw fiberglass when used in piping, as it combines the benefits of fiberglass reinforcement with the durability and chemical resistance of plastic resins.

In the context of piping, FRP stands for Fiberglass Reinforced Plastic. This refers to a type of composite material used to make durable, lightweight pipes that offer excellent resistance to corrosion, chemicals, and weathering. FRP pipes are commonly used in industries such as water treatment, chemical processing, oil and gas, and sewage systems. These pipes are made by combining glass fibers with a resin matrix, which provides structural strength and chemical resistance. FRP piping is an excellent choice for systems that require non-corrosive solutions for fluid transportation. Additionally, pre-insulated FRP pipes combine the strength and chemical resistance of FRP with thermal insulation, making them ideal for transporting heated fluids or gases while minimizing energy loss and maintaining temperature stability.

A pre-insulated pipe is a piping system that is already equipped with an insulating layer before installation. This type of pipe is used to transport fluids or gases that need to be maintained at a specific temperature. The insulating layer reduces heat loss or gain, ensuring that the fluid temperature remains stable during transport. Pre-insulated pipes are commonly used in heating and cooling systems, industrial applications, and oil and gas pipelines. The insulation is typically made of materials like polyurethane foam, which is applied to the exterior of the pipe, providing thermal protection. In the case of pre-insulated FRP pipes, the fiberglass reinforced plastic pipe is combined with an insulating layer to enhance both temperature control and durability. These pipes are especially beneficial for outdoor or underground installations, where maintaining temperature is critical.

An FRP pipe is a type of Fiberglass Reinforced Plastic pipe, a composite material made by embedding glass fibers into a plastic resin, usually polyester, epoxy, or vinyl ester. The combination of fiberglass and resin gives FRP pipes exceptional strength, durability, and resistance to corrosion, making them ideal for use in aggressive environments where traditional metal pipes would degrade over time. FRP pipes are commonly used in industries such as chemical processing, water treatment, and oil and gas. They are particularly effective in handling corrosive fluids, high temperatures, and extreme weather conditions. When combined with an insulating layer, pre-insulated FRP pipes offer enhanced thermal efficiency, making them suitable for transporting hot or cold fluids with minimal heat loss. These pipes are lightweight, easy to install, and provide a long-lasting, cost-effective solution for many industrial piping needs.

The primary difference between FRP (Fiberglass Reinforced Plastic) pipes and GRP (Glass Reinforced Plastic) pipes lies in the terminology and materials used, though both terms refer to essentially the same type of composite material. FRP is the general term used to describe any composite material made by reinforcing plastic with glass fibers, whereas GRP specifically refers to the use of glass fiber (or glass rovings) as the reinforcement in the plastic matrix. In practical terms, FRP and GRP pipes are virtually identical, as both consist of fiberglass embedded in a resin, and both offer similar benefits, including high strength, resistance to corrosion, and suitability for harsh environments. However, GRP pipes are more commonly used in the UK and Europe, while FRP pipes are more widely used in other parts of the world. The differences in terminology do not impact the overall performance of the pipes in most applications.

FRP stands for Fiberglass Reinforced Plastic, a composite material made by embedding glass fibers in a plastic matrix (usually epoxy, polyester, or vinyl ester). FRP is widely used for its strength-to-weight ratio, corrosion resistance, and durability. The fiberglass reinforcement provides the material with exceptional tensile strength, while the plastic matrix offers chemical resistance and flexibility. FRP is commonly used in industries such as construction, transportation, marine, and chemical processing. In the context of pipes, FRP is used for manufacturing lightweight, strong, and corrosion-resistant pipes, including pre-insulated FRP pipes, which combine insulation and protection for fluid transport systems. FRP pipes are ideal for environments where traditional metal pipes may corrode or deteriorate due to exposure to harsh chemicals or extreme weather conditions.

FRP and fiberglass are closely related but differ in terms of their composition and applications. Fiberglass is simply the glass fiber material itself, which is often used as a reinforcing component in various composite products. On the other hand, FRP (Fiberglass Reinforced Plastic) is a composite material made by combining fiberglass with a plastic resin (such as epoxy, polyester, or vinyl ester). The addition of the resin gives FRP greater versatility and durability compared to fiberglass alone. In the context of piping, FRP pipes offer enhanced resistance to corrosion, chemical exposure, and weathering compared to traditional fiberglass-based pipes. FRP also offers superior mechanical strength, making it more suitable for demanding industrial applications. Overall, FRP is considered an improvement over raw fiberglass when used in piping, as it combines the benefits of fiberglass reinforcement with the durability and chemical resistance of plastic resins.

In the context of piping, FRP stands for Fiberglass Reinforced Plastic. This refers to a type of composite material used to make durable, lightweight pipes that offer excellent resistance to corrosion, chemicals, and weathering. FRP pipes are commonly used in industries such as water treatment, chemical processing, oil and gas, and sewage systems. These pipes are made by combining glass fibers with a resin matrix, which provides structural strength and chemical resistance. FRP piping is an excellent choice for systems that require non-corrosive solutions for fluid transportation. Additionally, pre-insulated FRP pipes combine the strength and chemical resistance of FRP with thermal insulation, making them ideal for transporting heated fluids or gases while minimizing energy loss and maintaining temperature stability.

A pre-insulated pipe is a piping system that is already equipped with an insulating layer before installation. This type of pipe is used to transport fluids or gases that need to be maintained at a specific temperature. The insulating layer reduces heat loss or gain, ensuring that the fluid temperature remains stable during transport. Pre-insulated pipes are commonly used in heating and cooling systems, industrial applications, and oil and gas pipelines. The insulation is typically made of materials like polyurethane foam, which is applied to the exterior of the pipe, providing thermal protection. In the case of pre-insulated FRP pipes, the fiberglass reinforced plastic pipe is combined with an insulating layer to enhance both temperature control and durability. These pipes are especially beneficial for outdoor or underground installations, where maintaining temperature is critical.

An FRP pipe is a type of Fiberglass Reinforced Plastic pipe, a composite material made by embedding glass fibers into a plastic resin, usually polyester, epoxy, or vinyl ester. The combination of fiberglass and resin gives FRP pipes exceptional strength, durability, and resistance to corrosion, making them ideal for use in aggressive environments where traditional metal pipes would degrade over time. FRP pipes are commonly used in industries such as chemical processing, water treatment, and oil and gas. They are particularly effective in handling corrosive fluids, high temperatures, and extreme weather conditions. When combined with an insulating layer, pre-insulated FRP pipes offer enhanced thermal efficiency, making them suitable for transporting hot or cold fluids with minimal heat loss. These pipes are lightweight, easy to install, and provide a long-lasting, cost-effective solution for many industrial piping needs.

The primary difference between FRP (Fiberglass Reinforced Plastic) pipes and GRP (Glass Reinforced Plastic) pipes lies in the terminology and materials used, though both terms refer to essentially the same type of composite material. FRP is the general term used to describe any composite material made by reinforcing plastic with glass fibers, whereas GRP specifically refers to the use of glass fiber (or glass rovings) as the reinforcement in the plastic matrix. In practical terms, FRP and GRP pipes are virtually identical, as both consist of fiberglass embedded in a resin, and both offer similar benefits, including high strength, resistance to corrosion, and suitability for harsh environments. However, GRP pipes are more commonly used in the UK and Europe, while FRP pipes are more widely used in other parts of the world. The differences in terminology do not impact the overall performance of the pipes in most applications.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.