- Home

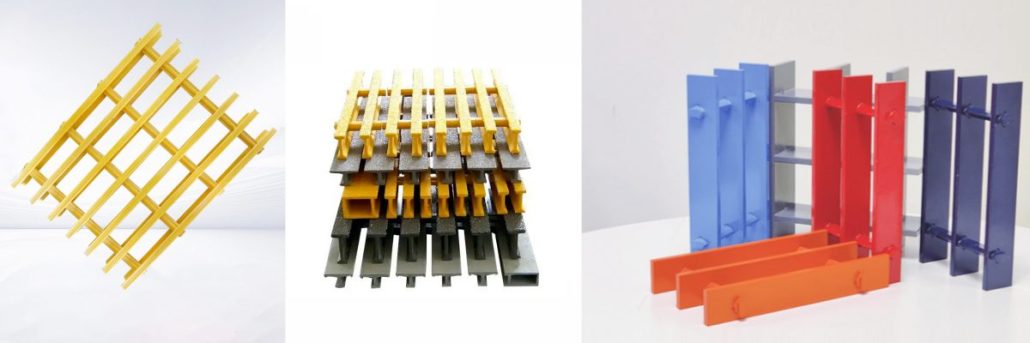

- Pultruded Grating

Standard Structural Fiberglass Pultruded Grating Manufacturer

GangLong Fiberglass‘s Pultruded Grating is distinguished by its high glass content within the laminates, enhancing its strength, rigidity, and load-bearing capacity. Pultruded Grating with ratio of 70% glass to 30% resin offers strength and high load capacity, allowing it to span greater distances.This type of grating is crafted through a meticulous process where fiberglass rovings and mats are pulled through guides and a resin bath, then wrapped with a surfacing veil. The material is finally pulled through a heated die to form bars in shapes like I-Bars and T-Bars. These bars are drilled for crossrods, assembled at spaced intervals, and bonded with epoxy to secure their placement, ensuring robust structural integrity.

Pultruded Grating is especially suited for commercial and industrial applications such as floor systems, walkways, work platforms, stairs, ramps, trench covers, and catwalks. It surpasses steel bar grating in durability due to its resistance to corrosion, moisture, and fire, making it a superior choice compared to traditional steel walkway grating for various applications. It is also non-conductive, thermally insulating, and offers dimensional stability, making it lighter and easier to install and maintain than traditional steel grating. These properties make Pultruded Grating a cost-effective solution by minimizing the operational costs associated with maintenance.

This product is available in different resin types like Isophthalic Polyester and Vinyl Ester, catering to various environmental needs. The distinctions between pultruded and molded grating also offer choices based on specific project requirements, highlighting the versatility and adaptability of Pultruded Grating in diverse settings.

Simplifying Your Life: Key Functionalities

| Attribute | Details |

|---|---|

| Product Name | Pultruded Grating |

| Materials Used | Fiberglass Reinforced Plastic (FRP), Composite Materials, E-glass, C-glass, Vinyl Ester Resin (ORT), Phenolic Resin |

| Technique | Pultrusion Process |

| Brand | GangLong Fiberglass |

| Place of Origin | Hebei, China |

| Application | - Walkway protection and platforms |

| - Sewage treatment plants, breeding industry, car wash facilities | |

| - Trench covers, stair steps, warehouse flooring | |

| Surface Treatment | - Gritted, Smooth, Grooved, Covered (varies by model) |

| Panel Size | Customizable panel sizes |

| Thickness Options | 20mm - 50mm, Customized Thickness |

| Fiberglass Content | 24% - 30% |

| Resin Options | ORT, ISO, Vinyl, Phenolic |

| Fiberglass Types | E-glass, C-glass |

| After-Sale Service | - Online technical support |

| - Project solution capability: Graphic design, 3D models, total project solutions, and Cross Categories Consolidation | |

| Certificates | ISO9001, ABS, DNV |

| Processing Services | - Cutting, Moulding, Punching, Custom shaping |

| Features | - Durable and slip-resistant |

| - Aging-resistant and long-lasting | |

| - Resistant to extreme temperatures and chemicals | |

| - Lightweight but sturdy, easy to install | |

| MOQ (Minimum Order Quantity) | From 50kgs to 1000kg |

| OEM Acceptance | OEM accepted |

| Delivery Time | 7 to 15 days |

News

- Exploring the Benefits of Carbon Fiber Apparel

- How to Work with Carbon Fiber Successfully

- Carbon Fiber Suit: The Future of Lightweight Armor

- Is Carbon Fiber Armor the Future of Protection?

- Why White Carbon Fiber is Popular in Automotive Design

- Transparent Carbon Fiber Sheets: Strength Meets Clarity in Design

- Chopped Carbon Fiber Mat for Lightweight Reinforcement

- Carbon Fiber EG Hatch: Upgrade Your Civic Today

- The Benefits of Using Structural Carbon Fibre in Engineering

- How Many Layers of Layered Carbon Fiber Are Needed?

What is FRP Pultruded Grating?

FRP Pultruded Grating is a specialized type of fiberglass reinforced plastic grating, renowned for its high strength and durability. Unlike molded grating, which is cast in a mold, pultruded grating is produced through a continuous process known as pultrusion. In this process, continuous strands of fiberglass are pulled through a resin bath, impregnated with either Isophthalic Polyester Resin or Vinyl Ester Resin, and then drawn through a heated die to form strong, consistent profiles like I-bars or T-bars.

The key characteristics of Pultruded Grating include unidirectional strength, which makes it exceptionally strong along the length of the bars, lightweight properties that make it easy to handle and install, and excellent corrosion resistance, which ensures long-term performance in harsh environments. These features make Pultruded Grating a preferred choice for applications that require long spans, heavy loads, and exposure to corrosive elements, such as in chemical processing plants, marine environments, and industrial flooring.

Pultruded Grating Standard Structural

Pultruded grating in a standard structural configuration refers to a specialized fiberglass-reinforced plastic (FRP) grating that is manufactured with standardized profiles, sizes, and specifications to provide consistent structural performance across various applications. These grating structures are typically used in industrial, marine, chemical, and public access areas due to their strength, corrosion resistance, and durability. Here’s a detailed description of its components, structural properties, and key performance characteristics:

Structural Components of Pultruded Grating

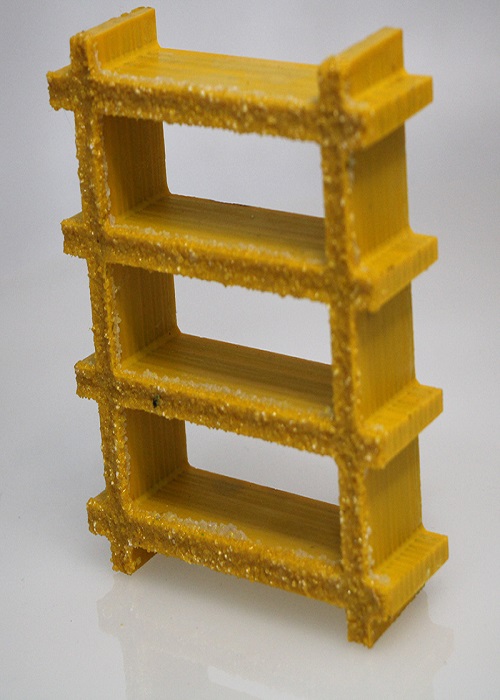

- Bearing Bars: The main load-bearing components of the grating, usually aligned in the lengthwise (span) direction. They are made from continuous glass rovings that run the full length of the panel, providing structural integrity and load-bearing strength.

- Cross Rods: Positioned at regular intervals (typically every 6 inches) across the width of the grating, these are connected to the bearing bars to enhance the panel’s stability and distribute loads evenly.

- Matting and Coating Options: Surface coatings, such as resin finishes, add UV protection, chemical resistance, and abrasion resistance. Grating can also include grit for slip resistance, crucial for safety in industrial environments.

Standard Structural Profiles

Pultruded grating comes in standardized profiles that meet the needs of most structural applications:

- I-Bar Profile: Offers high strength-to-weight ratio with a reduced material profile. These profiles allow efficient load distribution without excessive weight, making them ideal for structural floors and platforms.

- T-Bar Profile: Provides a wider bearing surface for better footing, typically used in areas with pedestrian traffic where a flat, stable surface is necessary.

- Rectangular Bar Profile: Uniform thickness across the bar maximizes load-carrying capacity, suitable for applications with heavy load demands.

These profiles are available in standard panel sizes (e.g., 3′ x 10′ or 4′ x 12′) with a typical thickness range of 1 inch to 2 inches, although custom options may be available based on application requirements.

Material Composition and Resin Options

Standard structural pultruded grating is made from fiberglass-reinforced plastic (FRP) using various resin systems to cater to different application environments:

- Polyester Resin: Suitable for general-purpose applications with moderate corrosion resistance.

- Vinyl Ester Resin: Used in highly corrosive environments (e.g., chemical plants) due to its superior chemical resistance.

- Phenolic Resin: Provides exceptional fire and smoke resistance, commonly used in areas with strict fire safety requirements.

Load-Bearing and Structural Strength

Pultruded grating is designed to meet specific load and deflection criteria, providing reliable structural support for various industrial applications:

- Uniform Load Capacity: Load tables are typically provided to guide maximum load-bearing capacities across different spans and bar sizes.

- Deflection Control: Standard deflection limits (e.g., 0.25 inches under load) are used to ensure safety and performance consistency.

- High Strength-to-Weight Ratio: Pultruded grating is around one-third the weight of steel, providing similar load-bearing strength but with easier handling and installation.

Environmental and Chemical Resistance

Pultruded grating in standard structural configurations is suitable for both indoor and outdoor use, especially in harsh environments:

- Corrosion Resistance: Excellent resistance to moisture, chemicals, and saltwater makes it suitable for applications in water treatment facilities, marine environments, and chemical processing plants.

- UV Stability: UV inhibitors and coatings protect against sun exposure and degradation in outdoor applications.

- Temperature Tolerance: Can withstand a wide temperature range, typically up to 200°F (93°C) for most resin types, with certain types (e.g., phenolic resin) tolerating even higher temperatures.

Standard structural pultruded grating is a reliable, versatile solution for demanding environments where durability, safety, and low maintenance are essential. Its standardized structural specifications make it adaptable to various designs while ensuring that it meets the rigorous demands of industrial, marine, and public applications.

Fiberglass Pultruded Grating Specifications

Material Composition

- Fiberglass Reinforcements: Continuous glass fibers provide tensile strength and load-bearing capacity. These fibers are aligned to provide optimal strength in the longitudinal (pultrusion) direction.

- Resin Systems:

- Polyester Resin: Used for general-purpose applications with good corrosion resistance.

- Vinyl Ester Resin: Enhanced chemical resistance, suitable for highly corrosive environments.

- Phenolic Resin: Excellent fire resistance, commonly used where flame retardancy is essential.

- UV Inhibitors: Optional UV-stabilized resins or surface coatings to reduce UV degradation for outdoor applications.

- Fire Retardant Additives: Often included to meet specific fire safety ratings, such as ASTM E-84.

Load-Bearing and Strength Properties

- Load Capacity: Pultruded grating panels are designed to support loads up to specified limits, with load tables provided based on span, thickness, and deflection criteria.

- Deflection Limits: Commonly designed for a maximum deflection of 0.25″ under normal loading conditions.

- Tensile Strength: Typically in the range of 30,000 to 40,000 psi, depending on resin and reinforcement configuration.

- Modulus of Elasticity: Ranges from 2.5 to 4.0 million psi, offering significant rigidity and structural performance.

- Shear Strength: Around 4,000 psi, which provides adequate shear resistance for heavy-duty applications.

Weight Specifications

- Lightweight Nature: Typically weighs about one-third of steel grating of the same load capacity. Weight can vary by profile, resin, and bar type, usually ranging from 2 to 3 lbs/ft².

5. Slip Resistance

- Surface Options: Available with an integrally bonded grit surface for slip resistance, especially in wet or oily environments. Grit can be fine or coarse, depending on the application.

- Smooth Surface: Available for applications where a smoother finish is needed, but less slip resistance is required.

Chemical and Environmental Resistance

- Corrosion Resistance: Suitable for exposure to chemicals, saltwater, and other corrosive substances, particularly when vinyl ester or phenolic resin is used.

- Temperature Tolerance: Can withstand a wide temperature range, typically up to 200°F (93°C) for continuous use, with some phenolic options able to endure higher temperatures.

- UV Stability: UV inhibitors are often added to protect against degradation from prolonged sunlight exposure.

Fire Resistance

- Fire-retardant ratings can comply with ASTM E-84 requirements for flame spread.

- Specific resin choices (like phenolic) improve fire retardancy and meet stricter fire codes for certain industries, such as transportation and oil & gas.

Certifications and Standards

- ASTM Standards: ASTM D635 (Burning Rate), ASTM D638 (Tensile Properties), ASTM E84 (Surface Burning Characteristics).

- OSHA and ANSI Compliance: Pultruded grating is often manufactured to meet the standards and requirements set by OSHA and ANSI for industrial and commercial safety.

- ISO Standards: Pultruded grating may also conform to ISO specifications for manufacturing and performance consistency.

Installation Accessories

- Hold-Down Clips: Stainless steel or FRP clips to secure panels, ensuring stability in high-traffic or heavy-load areas.

- Fasteners: Corrosion-resistant fasteners compatible with FRP materials, designed for both structural integrity and ease of installation.

These specifications help ensure that fiberglass pultruded grating meets structural requirements, safety standards, and durability needs across various demanding applications.

Pultruded Grating Price

Factors Affecting Pultruded Grating Price

The price of Pultruded Grating can vary significantly depending on several key factors. One of the primary factors is the cost of materials, particularly the types of resin used and the fiberglass content. High-performance resins like Vinyl Ester Resin typically increase the cost due to their superior resistance to chemicals and high temperatures, making them ideal for demanding environments. The fiberglass content also plays a crucial role; a higher concentration of fiberglass generally enhances the strength and durability of the grating, but it also raises the price.

Manufacturing process complexities and customization options further influence the price of Pultruded Grating. Custom grating that requires specific sizes, shapes, or additional features like special coatings will naturally be more expensive due to the additional labor and materials involved. The load-bearing capacity and span requirements are also critical considerations. Gratings designed to support heavy loads or cover longer spans require more robust materials and precise engineering, which can drive up costs.

A comparison of prices between standard and heavy-duty Pultruded Grating reveals that heavy-duty options are generally more expensive due to their enhanced strength and ability to withstand extreme conditions, making them suitable for industrial flooring, bridges, and other high-load applications.

The price of pultruded grating is influenced by several factors, each contributing to the overall cost based on material, manufacturing requirements, and specific application needs. Here’s an in-depth look at the primary factors affecting the price of pultruded grating:

1. Material Composition

- Fiberglass Content: The amount and quality of fiberglass used in the pultrusion process directly affect the grating’s strength and price. High-strength gratings require more fiberglass content, which increases material costs.

- Resin Type: Different resins, such as polyester, vinyl ester, and phenolic, offer various levels of chemical resistance, fire resistance, and durability. Higher-performance resins, like vinyl ester and phenolic, cost more than standard polyester due to their enhanced properties, such as improved resistance to chemicals, UV radiation, and fire.

- Additives and Coatings: Certain applications require specialized additives, like UV inhibitors, fire retardants, or anti-slip coatings, which raise material costs. These additives enhance the durability and safety of the grating but also contribute to the overall price.

2. Grating Thickness and Size

- Bar Thickness: Thicker bars provide more strength and load-bearing capacity, making them suitable for heavy-duty applications. However, increased thickness requires more raw material, leading to higher costs.

- Panel Size and Configuration: Larger grating panels or custom-sized panels increase the production and material requirements, impacting the overall cost. Some applications may require custom shapes or configurations, which adds to both material and production expenses.

3. Load-Bearing Requirements

- Strength and Load Ratings: Gratings intended for heavy-duty or high-load applications, such as vehicular traffic areas or industrial flooring, must have enhanced strength. These gratings are typically more robust and use additional fiberglass, increasing the price compared to standard pedestrian gratings.

- Span Length: Long-span grating that spans greater distances without support requires additional material strength and stability, often leading to a thicker, reinforced product. This results in higher material and manufacturing costs.

4. Customization and Special Features

- Custom Designs and Colors: Custom colors, patterns, or surface finishes may be necessary for specific architectural or aesthetic projects. These customizations require additional processing steps, which increase production time and material costs.

- Surface Treatments: Specialty surface treatments, such as anti-slip coatings or extra grit for slip resistance, improve safety in high-traffic or wet environments. These treatments typically increase the product’s cost due to the extra materials and labor required.

- Precision Requirements: Some applications require tight tolerances or precise configurations for accurate fitting, especially in high-tech or specialized industrial environments. This level of precision can raise manufacturing costs due to the additional time and equipment needed.

5. Environmental and Regulatory Compliance

- Fire, Chemical, and UV Resistance: Gratings for use in environments with exposure to chemicals, high temperatures, or sunlight require special resins or coatings. Compliance with specific industry standards for fire resistance (such as ASTM or NFPA ratings) or chemical resistance increases material costs.

- Safety Standards and Certifications: Certain applications require compliance with safety standards and regulations, which may necessitate additional testing, quality assurance, and certification processes, thereby increasing costs.

6. Production Volume and Lead Time

- Order Volume: Bulk purchases generally result in lower unit costs due to economies of scale, as larger orders spread production setup costs over a greater number of units. Conversely, small or one-time orders may incur higher costs per unit.

- Lead Time: Orders requiring short lead times may incur additional costs, as manufacturers need to expedite production, potentially adjusting schedules or sourcing materials more quickly. Custom orders with short deadlines often result in increased labor and handling charges.

7. Shipping and Installation Costs

- Shipping Distance and Weight: Pultruded grating is lightweight compared to metal options, but large orders or heavy-duty grating can still incur significant shipping costs, especially if transported long distances. Shipping costs vary based on weight, distance, and the logistical complexity of the order.

- Installation Complexity: The ease of installation can impact the overall project cost, though not always directly affecting the grating price. Gratings designed for easy installation may reduce labor costs, while more complex configurations may require specialized installation techniques, adding to the overall project budget.

TThe price of pultruded grating depends on a range of factors, including material choice, strength requirements, customization, compliance needs, order volume, and logistical considerations. Each of these elements contributes to the cost, and balancing the specific needs of an application with budget constraints is crucial for selecting the appropriate grating solution.

Market Trends and Pricing Insights

Market trends also play a significant role in determining the price of Pultruded Grating. As demand for durable, lightweight, and corrosion-resistant materials increases in sectors like construction, marine, and industrial manufacturing, prices may rise. Advances in manufacturing technology and the introduction of new materials can also affect pricing, either by reducing production costs or by introducing premium products with enhanced features.

Regional pricing variations are another important factor, influenced by local manufacturing capabilities, availability of raw materials, and shipping costs. For instance, Pultruded Grating may be more expensive in regions where the materials need to be imported or where manufacturing infrastructure is limited. Additionally, global economic conditions, such as fluctuations in resin prices or transportation costs, can lead to price adjustments.

GangLong Fiberglass Fiberglass Pultruded Grating Supply

GangLong Fiberglass Pultruded Grating Supply offers a high-quality solution for various industrial and commercial applications, focusing on strength, durability, and safety. Made from fiberglass-reinforced polyester (FRP), this pultruded grating is designed to meet the demanding requirements of industrial environments while providing excellent resistance to corrosion, heavy loads, and extreme weather conditions.

Key Features of GangLong Fiberglass Pultruded Grating

Corrosion Resistance: The fiberglass pultruded grating from GangLong is resistant to corrosion, making it ideal for use in harsh environments, including chemical plants, offshore platforms, and water treatment facilities. It can withstand exposure to corrosive substances like acids, alkalis, and salts without losing its strength or structural integrity.

Lightweight and Strong: Despite its lightweight nature, this type of grating offers excellent load-bearing capacity. Its pultrusion manufacturing process ensures a uniform, continuous structure, maximizing its strength-to-weight ratio. This makes it easier to handle, install, and maintain while offering the necessary durability for high-traffic areas.

Slip Resistance: The grating is designed with a slip-resistant surface that enhances safety in areas where wet or oily conditions are common. The open-grid design ensures a firm grip for both foot traffic and equipment, reducing the risk of slips and falls, which is crucial for industrial safety.

Ventilation and Drainage: One of the standout features of fiberglass pultruded grating is its open design. This allows for effective ventilation and drainage, preventing the accumulation of water, oil, or debris. This is particularly beneficial in environments where moisture or chemical runoff needs to be managed efficiently.

Low Maintenance: Fiberglass grating requires minimal maintenance compared to traditional steel grating. It does not rust or degrade over time, which means less frequent replacements and reduced maintenance costs. Additionally, it is resistant to UV degradation, ensuring a long lifespan even when exposed to sunlight.

Benefits of Choosing GangLong Fiberglass Pultruded Grating

Cost-Effective: Although the initial investment may be higher than traditional materials like steel, the long-term benefits of fiberglass pultruded grating make it a cost-effective choice. Its durability, low maintenance, and resistance to corrosion contribute to significant savings over time.

Environmental Sustainability: Fiberglass is a more environmentally friendly option compared to metal alternatives. It’s made from sustainable materials and is fully recyclable, contributing to eco-friendly construction practices.

Customization: GangLong offers a range of customization options for their fiberglass pultruded grating. Clients can select from different sizes, colors, and surface textures to meet specific project requirements. Whether the need is for enhanced slip resistance or aesthetic considerations, the company provides tailored solutions.

GangLong Fiberglass Pultruded Grating Supply is a trusted choice for those seeking a strong, durable, and versatile grating solution for industrial, commercial, and marine applications. With ours impressive load-bearing capacity, resistance to corrosion, slip-resistant surface, and low maintenance requirements, we ensures both safety and functionality. Whether for walkways, stair treads, or platforms, this fiberglass grating offers the perfect combination of performance and durability for challenging environments.

Pultruded Grating Bearing Bar Types

Pultruded grating bearing bars come in a variety of types, each designed to offer specific performance characteristics depending on the application. Here’s an overview of the main types:

1. I-Bar

- Description: Shaped like the letter “I” in cross-section, this bar type is one of the most common for pultruded grating.

- Characteristics:

- Offers a good balance of strength and weight reduction.

- Provides efficient load distribution with reduced material usage.

- Applications: Ideal for applications requiring high load capacity with minimal weight, such as industrial platforms and walkways.

2. T-Bar

- Description: Shaped like the letter “T” in cross-section, this type offers a flatter, more stable surface than the I-bar.

- Characteristics:

- Provides a wider surface area for more secure footing.

- Has good load-bearing capabilities while offering a more stable surface for walking.

- Applications: Common in pedestrian walkways, platforms, and areas where stability is key for safety.

3. Rectangular Bar

- Description: Rectangular in cross-section, this bar type has a simple, solid shape.

- Characteristics:

- Delivers maximum load-carrying capacity due to its uniform thickness.

- Offers high stiffness, making it suitable for heavy-duty applications.

- Applications: Best for applications requiring high strength and rigidity, such as industrial flooring, bridges, and platforms that bear heavy loads.

4. Double-Web or “Box” Bar

- Description: Features a box-like structure with two webs for added stability and strength.

- Characteristics:

- Combines the strength of the rectangular bar with some weight reduction.

- Provides enhanced rigidity and resistance to deflection.

- Applications: Often used in heavy-duty applications, such as equipment platforms and high-traffic industrial walkways.

5. Round or Circular Bar

- Description: Cylindrical in shape, though less common in pultruded grating compared to other types.

- Characteristics:

- Lightweight and easy to handle.

- Generally not as strong as I-bar or T-bar but can offer specific benefits in certain designs.

- Applications: Occasionally used for decorative grating or in applications where a non-slip grip is essential, though primarily used in non-load-bearing designs.

6. Wide-Flange Bar

- Description: Features a wide top flange for increased surface area and strength.

- Characteristics:

- Provides more support and stiffness compared to standard I-bars.

- Often has a higher load-bearing capacity than other bar types.

- Applications: Suitable for areas with heavy pedestrian or equipment traffic, and where a wider surface area is needed for load distribution.

Each bearing bar type is chosen based on specific load requirements, environmental conditions, and desired safety and stability features. By selecting the appropriate bearing bar type, pultruded grating can meet a wide range of structural, industrial, and commercial needs.

Thank you for your interest in our products. To receive our pricelist or for any inquiries, please fill out the form below. We will get back to you within 24 hours.

Types of Pultruded Grating

Pedestrian Pultruded Grating

Pedestrian Pultruded Grating is specifically designed to provide a safe, durable surface for areas where foot traffic is prevalent. This type of pultruded grating is commonly used in public access areas such as walkways, parks, and pedestrian bridges. It is engineered to offer a comfortable walking surface, often with added slip resistance to prevent accidents, especially in wet or slippery conditions. The lightweight nature of Pultruded Grating makes it easy to install, reducing labor costs and time. Additionally, its corrosion-resistant properties ensure longevity even in outdoor environments exposed to the elements. Pedestrian Pultruded Grating is an ideal choice for municipalities and property owners looking to enhance safety and accessibility in public spaces.

Pedestrian Pultruded Grating is designed specifically for areas with significant foot traffic, where a safe, durable surface is needed. This type of grating is commonly found in public access locations such as walkways, parks, pedestrian bridges, boardwalks, and observation decks. Its design prioritizes comfort, safety, and durability, with features that address the specific needs of pedestrian areas:

Slip Resistance: Pedestrian grating often includes a grit or textured surface, providing extra grip to reduce the risk of slips and falls, especially in wet or rainy conditions. This is essential for walkways and boardwalks exposed to weather changes, as it helps prevent accidents. Drainage and Ventilation: With its open-grid structure, pedestrian pultruded grating facilitates efficient water drainage, minimizing puddling and maintaining a dry, secure walking surface. This drainage is particularly beneficial in outdoor environments like parks or nature trails, where water accumulation can lead to slippery surfaces or muddy paths. Lightweight and Easy Installation: Pultruded grating is significantly lighter than metal alternatives, making it easier and faster to install. This advantage helps reduce installation time, labor costs, and transportation expenses, particularly valuable for large projects like public parks or municipal facilities. Corrosion Resistance and Longevity: Constructed from corrosion-resistant materials, this grating withstands outdoor elements like sun exposure, rain, and saltwater. This property ensures a long-lasting solution that minimizes maintenance and replacement costs over time, ideal for municipal or commercial properties looking for sustainable infrastructure. Aesthetic Compatibility: Pedestrian pultruded grating is available in various colors and finishes, allowing it to blend seamlessly with natural landscapes or urban settings without sacrificing functionality. For projects with aesthetic requirements, such as scenic overlooks or historical sites, pedestrian grating provides a subtle, practical solution. Heavy-Duty Pultruded Grating is designed for applications that require superior strength and the ability to withstand heavy loads, such as vehicular traffic. This type of grating is often used in industrial flooring, bridge decking, and other high-stress environments where durability and performance are critical. Compared to standard Pultruded Grating, heavy-duty versions feature thicker bars and a denser configuration, providing enhanced load-bearing capacity and resistance to impact. The continuous fiberglass strands in the pultrusion process give these gratings unidirectional strength, making them particularly effective for long-span applications. Heavy-Duty Pultruded Grating is essential for industries that demand reliable and robust infrastructure solutions. Heavy-Duty Pultruded Grating is engineered for demanding environments that require strong, load-bearing surfaces, capable of supporting heavy vehicles or industrial machinery. This type of grating is a staple in industrial facilities, bridge decking, loading docks, and other high-stress settings due to its robust structure and unique benefits: Enhanced Load-Bearing Capacity: Heavy-duty grating features thicker bars and a more compact grid structure, providing significantly greater load-bearing strength compared to standard pedestrian grating. This strength is crucial in applications such as industrial floors or areas where forklifts, trucks, or other heavy vehicles are frequently in use. Unidirectional Fiberglass Strength: The manufacturing process, known as pultrusion, pulls continuous strands of fiberglass through a resin matrix. This method creates a grating with unidirectional strength, making it particularly suitable for long-span installations that need to maintain rigidity under heavy loads, such as bridge decks or large platform surfaces. Impact and Abrasion Resistance: Heavy-duty pultruded grating is resistant to impact and abrasion, making it ideal for high-traffic areas exposed to potential wear and tear. For example, in industrial environments with heavy machinery, this grating maintains structural integrity despite repeated pressure and physical impact. Corrosion and Chemical Resistance: Heavy-duty grating is crafted with specialized resins to enhance resistance to corrosion and chemicals, making it suitable for environments where exposure to oils, chemicals, or moisture is common, such as chemical plants or wastewater treatment facilities. Low Maintenance and Cost-Efficiency: Although heavy-duty, this grating requires minimal upkeep and lasts significantly longer than traditional materials, such as metal, which can corrode or degrade over time. Its durability and low maintenance make it a cost-effective choice for high-stress applications. Specialty Pultruded Grating offers custom solutions tailored to meet specific customer requirements, making it a versatile option for unique or challenging applications. This type of grating is used in specialized environments, such as offshore platforms, where the material must withstand harsh marine conditions, or in chemical processing facilities where resistance to corrosive substances is paramount. Specialty Pultruded Grating can be customized in terms of bar thickness, resin type, and surface finish to ensure optimal performance for the intended application. Whether it’s for a niche industrial project or a bespoke architectural feature, specialty Pultruded Grating provides the flexibility and reliability needed to meet diverse needs. Specialty Pultruded Grating is a highly customizable solution that can be designed to meet specific needs for unique or challenging applications. This type of grating is particularly valuable in specialized environments where standard options might not provide adequate performance, such as marine platforms, chemical processing plants, and architectural projects. Specialty grating can be tailored with various options to suit specific environments: Customization Options: Specialty grating can be customized for bar thickness, grid pattern, resin type, and surface finish, allowing it to meet precise functional and aesthetic requirements. For example, architectural projects may require a certain color or finish to match the surrounding design, while industrial applications may demand specific thicknesses for maximum strength. Marine and Offshore Use: In marine environments, such as offshore platforms or docks, specialty pultruded grating is crafted from materials that withstand harsh saltwater exposure and marine humidity. These gratings often use special marine-grade resins that provide extra corrosion resistance to prevent degradation and ensure longevity. Chemical Resistance for Industrial Use: For environments where the grating may come into contact with corrosive chemicals or high-temperature liquids, specialty gratings are often designed with resins that resist chemical reactions, ensuring safety and durability. Applications such as oil refineries, chemical plants, and laboratories benefit from these properties. Special Properties for Safety and Performance: Specialty gratings can also be manufactured with additional fire-resistant resins or UV inhibitors, making them suitable for high-heat environments or outdoor areas with prolonged sun exposure. Electrical conductivity can also be managed with specific resin types, providing an additional safety feature in environments where static electricity could pose a risk. Architectural Applications: In architectural and design applications, specialty pultruded grating offers a unique aesthetic with functional benefits. These gratings can be used in high-end construction projects as structural components, facade elements, or even decorative features, providing both visual appeal and practical functionality. Each type of pultruded grating offers distinct advantages, tailored to meet the demands of its specific environment. Whether for public access, industrial strength, or custom applications, pultruded grating is an adaptable, durable solution that balances performance, longevity, and low maintenance across diverse settings.Heavy-Duty Pultruded Grating

Specialty Pultruded Grating

Molded vs Pultruded Grating

Key Differences Between Molded and Pultruded Grating

When selecting the appropriate FRP grating for your project, it is essential to understand the key differences between Molded Grating and Pultruded Grating. These two types of grating are manufactured using distinct processes that result in different structural properties and performance characteristics.

Manufacturing Processes:

Molded grating is produced by placing layers of continuous glass fibers in a mold, followed by the addition of liquid resin. This mixture is then cured to form a solid, integral panel with a square or rectangular mesh pattern. The process results in bi-directional strength, making molded grating suitable for applications where load distribution in multiple directions is necessary.

On the other hand, Pultruded Grating is manufactured through a continuous process known as pultrusion. Fiberglass strands are pulled through a resin bath, which impregnates them with resin, and then passed through a heated die that shapes them into long, consistent profiles like I-bars or T-bars. The result is a grating with unidirectional strength, making Pultruded Grating particularly effective for applications requiring high strength along the length of the bars.

While both types of grating offer excellent strength and durability, Pultruded Grating typically provides higher load capacity along its length, making it ideal for applications requiring long spans or heavy loads, such as in bridge decking or industrial flooring. Molded grating, with its bi-directional strength, is better suited for applications where the load is more evenly distributed, such as in walkways or platforms. Pultruded Grating offers more design flexibility due to its ability to be produced in custom shapes, sizes, and configurations. This flexibility makes it suitable for projects with specific requirements, such as unique load-bearing needs or complex architectural designs. Molded grating, while available in various sizes and thicknesses, is more limited in customization options due to the constraints of the molding process. Selecting the right type of grating depends on several factors, including load requirements, environmental exposure, and budget. If your project demands high strength, long spans, or exposure to corrosive environments, Pultruded Grating is often the superior choice due to its higher load capacity and corrosion resistance. It is particularly advantageous in industrial settings where reliability and durability are critical. Conversely, if your project involves applications where load distribution is key, such as in platforms or pedestrian walkways, Molded Grating may be more appropriate. Molded grating is also generally more cost-effective for standard applications, making it an excellent choice for projects with tighter budgets.Strength and Load Capacity:

Design Flexibility:

Choosing the Right Grating for Your Project

GangLong Fiberglass Pultruded Grating Manufacturer

GangLong Fiberglass is a leading manufacturer of fiberglass-reinforced plastic (FRP) products, specializing in pultruded grating and other industrial solutions designed to meet the needs of facilities, safety, and manufacturing professionals. Our fiberglass products offer innovative solutions for various applications, including industrial platforms, mezzanines, walkways, fixed ladders, handrails, guardrails, stairs, and bridges, providing nearly limitless configuration possibilities to fit specific project requirements.

Key Benefits of GangLong Fiberglass Pultruded Grating

Corrosion Resistance: GangLong’s pultruded fiberglass grating is highly resistant to corrosion, making it ideal for use in harsh environments like chemical processing plants, offshore platforms, and water treatment facilities. Unlike metal grating, fiberglass will not rust or degrade when exposed to corrosive chemicals or moisture.

Slip Resistance: The grating comes with a built-in slip-resistant surface, which significantly reduces the risk of slips and falls, ensuring the safety of workers in demanding environments. This feature is particularly valuable in industries that require workers to operate in wet or oily conditions.

Fire Retardant: GangLong’s FRP products are designed to meet fire safety standards. The material has excellent flame-retardant properties, making it suitable for environments where fire safety is critical, such as in manufacturing plants and power plants.

High Strength-to-Weight Ratio: Despite being lightweight, GangLong fiberglass grating has a high strength-to-weight ratio, making it durable enough to handle heavy loads while remaining easy to install and transport. The grating’s rigidity and strength make it an ideal solution for long support spans without the need for frequent maintenance.

Non-Conductive: Being electrically non-conductive, FRP grating reduces the risk of electrical hazards, making it the preferred choice for environments where electrical safety is a concern, such as power plants and refineries.

Low Installation Costs: The lightweight nature of fiberglass grating reduces the installation costs significantly. It can be easily fabricated and installed using standard tools, lowering both labor and material costs during the installation process.

Long Service Life: With its durable and corrosion-resistant properties, GangLong fiberglass grating offers a long service life with minimal maintenance. This makes it a cost-effective solution for long-term projects, reducing the need for frequent replacements or repairs.

Applications of GangLong Pultruded Grating

GangLong Fiberglass pultruded grating is used in a variety of industrial settings where safety, durability, and low maintenance are essential. Some common applications include:

Industrial Platforms and Mezzanines: The grating can be used to create stable, strong platforms and mezzanines that are capable of withstanding heavy traffic and exposure to harsh conditions.

Walkways: The slip-resistant surface of the grating makes it an ideal choice for creating safe walkways in factories, warehouses, and outdoor industrial environments.

Fixed Ladders and Handrails: Fiberglass grating is used to create fixed ladders and handrails that offer both strength and durability, as well as the ability to withstand exposure to chemicals and weathering.

Guardrails and Stairs: For additional safety and structure, fiberglass grating can be used in the construction of guardrails and stairs, ensuring worker safety while minimizing the need for maintenance.

Bridges: Lightweight yet strong, fiberglass grating is suitable for constructing durable bridges in various industrial environments, from chemical plants to oil rigs and wastewater treatment facilities.

Why Choose GangLong Fiberglass Pultruded Grating?

Durability: The high fiberglass content and specialized manufacturing process used by GangLong ensure that their grating is incredibly durable, resistant to harsh chemicals, moisture, and environmental stress.

Customizable Options: GangLong Fiberglass offers flexibility in customization, producing grating panels that are tailored to specific dimensions and requirements. This reduces material waste and ensures that the grating fits precisely within the intended area of installation.

Environmental Impact: By offering customizable sizes, GangLong minimizes waste during the manufacturing process, contributing to sustainability efforts in industries that rely on large-scale installations of grating.

Cost-Effective: With reduced maintenance needs, long service life, and lower installation costs, GangLong fiberglass pultruded grating offers a more cost-effective solution over the lifecycle of the product compared to traditional metal grating.

Ergonomics and Safety: Designed with worker safety in mind, GangLong’s grating features ergonomic design and safety-enhancing qualities, ensuring that workers are protected while navigating industrial settings.

GangLong Fiberglass is a reliable manufacturer of high-quality fiberglass pultruded grating that offers superior performance in industrial applications. With its corrosion resistance, slip resistance, fire retardant properties, and ease of installation, GangLong’s fiberglass grating is the ideal solution for a wide range of industries. Whether you are looking to install durable platforms, walkways, ladders, or bridges, GangLong Fiberglass provides a cost-effective, low-maintenance, and safe alternative to traditional metal grating.

FAQs about Pultruded Grating and FRP

What is the pultruded FRP process?

After shaping, the material passes through a heated die, where it undergoes curing, a process that solidifies the resin and bonds the fibers together to form a rigid, durable composite. The cured material is then cut to the required lengths to create grating panels or other structural components. The pultruded FRP process is highly efficient, allowing for the production of long, continuous profiles that are strong, corrosion-resistant, and suitable for various industrial applications. This process is ideal for producing grating, handrails, structural beams, and other components that require high strength-to-weight ratios.

How long does fiberglass grating last?

Does fiberglass crack over time?

What is the best way to cut fiberglass grating?

How bendable is fiberglass?

What is pultruded grating?

What is the pultruded technique?

What is the difference between extrusion and pultrusion?

Extrusion involves pushing material (typically metal or plastic) through a shaped die to form a continuous profile. It is commonly used for metals and thermoplastics.

Pultrusion involves pulling continuous fibers (like glass or carbon) through a resin and then through a die to create reinforced polymer composites. Pultrusion is mainly used for creating fiber-reinforced products such as FRP and GRP.

What are pultruded products?

What is the difference between FRP and GRP grating?

What is the pultruded carbon fiber process?

How is pultruded fiberglass made?

What is the pultrusion process?

What is ball proof grating?

What is the purpose of floor grating?

What is the grating and what does it do?

What is the difference between pultruded FRP and Moulded FRP?

Pultruded FRP is produced by pulling continuous fibers (such as glass or carbon) through a resin bath and a heated die, creating a material with unidirectional fiber alignment, which gives it high strength in the direction of the fibers. Pultruded FRP has a higher strength-to-weight ratio and is used for load-bearing applications.

Moulded FRP is created by layering fibers in a mold and saturating them with resin before curing. This method results in a grid-like structure with bidirectional strength (strength in two directions), but it generally has lower strength than pultruded FRP. Moulded FRP is often used for non-load-bearing applications such as flooring and walkways.

What are the disadvantages of FRP in construction?

Higher initial cost: FRP materials are often more expensive than traditional materials like steel or wood.

Limited thermal resistance: FRP can degrade or lose strength at high temperatures, limiting its use in environments exposed to fire or extreme heat.

UV sensitivity: Prolonged exposure to sunlight without proper UV protection can degrade the material over time.

Complex repairs: Repairing FRP structures is more challenging and expensive compared to traditional materials.

Limited material stiffness: While FRP is strong, it may have lower stiffness (modulus of elasticity) compared to steel, making it less suitable for applications requiring rigid support structures.

Which is better FRP or PVC?

FRP (Fiber Reinforced Polymer) is stronger, more durable, and more resistant to corrosion, making it ideal for structural applications and harsh environments. FRP has a high strength-to-weight ratio and can be used in load-bearing applications.

PVC (Polyvinyl Chloride) is a cost-effective plastic commonly used for pipes, conduits, and non-structural components. It is less expensive and easier to install than FRP but lacks the strength and durability needed for heavy-duty applications.

Overall, FRP is better for structural and long-term durability, while PVC is preferable for low-cost, lightweight, non-structural uses.

Is FRP better than fiberglass?

Is FRP stronger than wood?

What is the difference between FRP and Pp?

FRP is a composite material made by reinforcing a polymer matrix with fibers like glass or carbon. It has high strength, durability, and resistance to corrosion and is used in structural and industrial applications.

PP is a thermoplastic polymer that is lightweight, chemical-resistant, and commonly used in packaging, pipes, and non-load-bearing components. While PP is cheaper and easier to manufacture, it is not as strong or durable as FRP and is generally unsuitable for structural applications.

Why is FRP better than steel?

Corrosion resistance: FRP does not rust or corrode, even when exposed to harsh chemicals, moisture, or saltwater environments, unlike steel which can corrode.

Lightweight: FRP is much lighter than steel, making it easier to transport and install, reducing labor and handling costs.

Non-conductive: FRP is non-conductive, making it ideal for electrical applications and environments where electrical insulation is required.

Low maintenance: FRP requires minimal maintenance compared to steel, which needs regular painting, coating, or treatment to prevent rust.

Design flexibility: FRP can be molded into various shapes and sizes, offering more flexibility for complex structures.

However, steel is still preferred in applications that require very high stiffness or fire resistance.

What are the types of FRP grating?

Pultruded FRP grating: Made using the pultrusion process, offering high strength and rigidity, particularly in load-bearing applications. The bars are aligned in one direction, providing high strength along that axis.

Moulded FRP grating: Produced using a mold, with a bidirectional grid structure that is more flexible but lower in strength compared to pultruded grating. It is often used for flooring, walkways, and areas requiring slip resistance.

Covered FRP grating: This type includes a solid cover over the open mesh grating, providing a smooth, closed surface for areas where spills or small objects passing through are a concern.

Mini-mesh FRP grating: Features smaller openings than standard grating, providing better slip resistance and preventing small objects from falling through.

Is FRP the same as HDPE?

FRP is a composite material made by reinforcing a polymer matrix (often thermosetting resin) with fibers (usually glass or carbon). It is used in structural applications where high strength and durability are needed.

HDPE is a thermoplastic polymer that is commonly used in piping, containers, and non-structural components. It is lightweight, chemical-resistant, and easy to mold, but lacks the high strength and stiffness of FRP.

HDPE is generally used in less demanding applications compared to FRP.

What is the pultruded FRP process?

What does pultruded mean?

What is the difference between extruded and pultruded?

Extrusion involves pushing a material (typically metal or plastic) through a shaped die to form a continuous profile. It is used for metals and thermoplastics and creates solid or hollow profiles.

Pultrusion involves pulling continuous fibers (such as glass or carbon) through a resin and then through a heated die. Pultrusion produces fiber-reinforced polymer composites, providing higher strength and rigidity than extrusion, which focuses more on shaping rather than reinforcing materials.

What are the advantages and disadvantages of pultrusion process?

High strength-to-weight ratio: Pultruded products are lightweight but have excellent mechanical strength due to continuous fiber reinforcement.

Corrosion resistance: Pultruded FRP is highly resistant to corrosion, making it ideal for use in harsh environments, such as chemical plants, marine applications, and wastewater treatment.

Consistency: The process produces uniform profiles with consistent cross-sectional dimensions.

Low maintenance: Pultruded products require little maintenance compared to traditional materials like steel or wood.

Customizable: Various fiber and resin combinations can be used to achieve specific mechanical properties.

Disadvantages:

Limited shapes: Pultrusion can only produce constant cross-sectional profiles, which limits design flexibility for complex shapes.

Higher initial cost: Pultruded products can be more expensive than traditional materials, though they offer cost savings in the long term.

Lower impact resistance: Pultruded products may have lower impact resistance compared to metals.

What are the 4 main types of FRP?

Glass Fiber Reinforced Polymer (GFRP): Uses glass fibers as the reinforcement, commonly used in construction, industrial equipment, and transportation due to its durability and cost-effectiveness.

Carbon Fiber Reinforced Polymer (CFRP): Uses carbon fibers, offering high strength and stiffness with low weight, often used in aerospace, automotive, and sporting goods.

Aramid Fiber Reinforced Polymer (AFRP): Uses aramid fibers (e.g., Kevlar) known for their high impact and abrasion resistance, typically used in protective gear and high-performance applications.

Basalt Fiber Reinforced Polymer (BFRP): Uses basalt fibers, providing good thermal and chemical resistance, used in construction and environmental applications.

What is the difference between HDPE and FRP?

HDPE is a thermoplastic polymer known for its chemical resistance, flexibility, and low cost. It is often used in non-structural applications like piping, containers, and packaging. HDPE is lightweight but lacks the strength needed for heavy-duty applications.

FRP is a composite material made from a polymer matrix reinforced with fibers (typically glass or carbon). FRP is much stronger, more rigid, and more durable than HDPE, making it suitable for structural applications in industries like construction, transportation, and chemical processing.

What is an example of a pultrusion?

What is pultruded structural FRp profiles?

How does FRP fail?

Brittle failure: FRP is generally strong but can be brittle, meaning it can crack or shatter under high impact or overload.

Delamination: Layers of fibers can separate from the resin matrix under stress, causing a loss of structural integrity.

Creep: Under prolonged load, FRP can experience slow deformation, especially at elevated temperatures.

UV degradation: Without proper protection, prolonged exposure to ultraviolet light can degrade the surface of FRP, weakening its structural properties.

Environmental stress cracking: Exposure to harsh chemicals or extreme environmental conditions can lead to microcracking or corrosion of the polymer matrix.

What are the methods of FRP strengthening?

FRP wrapping: Applying FRP sheets or wraps to the surface of columns, beams, or other structural elements to increase their load-bearing capacity or resistance to seismic forces.

FRP laminates: Bonding FRP plates or strips to concrete or steel surfaces using adhesives to improve the flexural or shear strength of structural members.

FRP bars: Replacing or supplementing traditional steel reinforcement in concrete structures with FRP bars to improve corrosion resistance and reduce weight.

NSM (Near-Surface Mounting): Embedding FRP bars or strips into grooves cut into concrete surfaces, then securing them with an adhesive, enhancing structural capacity without significantly altering the original structure.

What is FRP grating used for?

Walkways and platforms in chemical plants, wastewater treatment facilities, oil rigs, and marine environments.

Flooring in areas exposed to moisture, chemicals, or extreme weather conditions.

Safety applications such as stair treads, ramps, and non-slip surfaces.

Ventilation systems where airflow is necessary, and grating is required to prevent debris or people from falling through.

Does FRP crack easily?

What is the lifespan of FRP grating?

Is FRP better than steel?

Corrosion resistance: FRP does not rust or corrode like steel, making it ideal for use in corrosive environments (e.g., chemical plants, marine settings).

Lightweight: FRP is significantly lighter than steel, which makes it easier to transport, handle, and install.

Non-conductive: FRP is electrically non-conductive, which is important in applications where electrical insulation is required.

Low maintenance: FRP requires less maintenance compared to steel, which can rust or need protective coatings.

However, steel may still be preferred for applications requiring very high stiffness, extreme loads, or resistance to fire.

Why is FRP so expensive?

What is the best thing to cut FRp with?

Circular saws or angle grinders equipped with these blades are commonly used to cut large sections of FRP.

For finer or more precise cuts, jigsaws or oscillating multi-tools with the appropriate blade can be used. Always use proper dust collection and personal protective equipment (PPE) when cutting FRP, as the dust can be harmful if inhaled.

Is FRP still used?

Is FRP better than carbon fiber?

FRP (typically reinforced with glass fibers) is more affordable and offers good durability, chemical resistance, and strength, making it suitable for industrial applications.

Carbon fiber is much stronger and lighter than standard FRP but also significantly more expensive. Carbon fiber is often used in high-performance applications, such as aerospace, automotive racing, and sporting goods, where weight reduction and high strength are critical.

For most industrial and construction purposes, FRP is more practical due to its cost-effectiveness, while carbon fiber is chosen for its superior mechanical properties in specialized fields.

What can l use instead of FRP?

Steel: Offers higher stiffness and fire resistance but is susceptible to corrosion and requires more maintenance.

Aluminum: Lightweight and corrosion-resistant, but it can be more expensive and not as strong as steel or FRP in some applications.

HDPE (High-Density Polyethylene): Lightweight and chemical-resistant but not as strong or durable as FRP for structural uses.

Wood: A natural alternative that is cost-effective but prone to rot, decay, and termite damage in harsh environments.

The choice of material depends on the specific requirements of the project, such as cost, weight, environmental exposure, and load-bearing capacity.

What is FRP good for?

Industrial walkways, platforms, and stairways.

Water treatment facilities and chemical plants.

Bridges and infrastructure where lightweight, durable materials are needed.

Marine environments (docks, piers) where corrosion resistance is essential.

Electrical enclosures and panels where non-conductive materials are required.

How to install FRP grating?

Preparation: Ensure that the supporting structure is strong enough to hold the FRP grating. Measure and cut the grating to the desired size using appropriate cutting tools.

Fastening: Place the FRP grating on the supporting structure and secure it using appropriate hold-down clips or fasteners. The clips should be spaced evenly to prevent movement or lifting.

Alignment: Ensure the grating is properly aligned and level. Use leveling shims if necessary to create a stable surface.

Final Inspection: Check all fastenings and ensure that the grating is securely attached and will not move under load.

Proper installation is essential to maximize the safety and longevity of FRP grating.

Thank you for your interest in our products. To receive our pricelist or for any inquiries, please fill out the form below. We will get back to you within 24 hours.