- Home

- Pultrusion Equipment

Supply New Pultrusion Equipment | Systems | Technology

GangLong Fiberglass has over two decades of experience in manufacturing Pultrusion Equipment, offering both Thermoplastic and Thermoset pultrusion solutions. GangLong Fiberglass is a manufacturer of high quality, durable, reliability and performance pultrusion equipment and systems. These machines are engineered using advanced technology, designed to exceed customer expectations in both functionality and efficiency.

GangLong Fiberglass’s commitment to innovation is evident in their use of servo motor and drive technology to control pulling and clamping forces, providing precise feedback to the operating system. This technological advancement ensures enhanced production speed and consistency, crucial for meeting the high standards required in various industries, including construction and aerospace.

Our company not only manufactures a broad range of high-quality pultruded structural products but also designs and builds pultrusion mold and the equipment needed to produce them. This allows GangLong Fiberglass to continuously upgrade and expand its offerings in Pultrusion Equipment technology. Our line of Pultrusion Equipment is tailored to meet diverse needs, from entry-level and value-minded customers to the most complex systems required by large-scale pultruders.

News

- Exploring the Benefits of Carbon Fiber Apparel

- How to Work with Carbon Fiber Successfully

- Carbon Fiber Suit: The Future of Lightweight Armor

- Is Carbon Fiber Armor the Future of Protection?

- Why White Carbon Fiber is Popular in Automotive Design

- Transparent Carbon Fiber Sheets: Strength Meets Clarity in Design

- Chopped Carbon Fiber Mat for Lightweight Reinforcement

- Carbon Fiber EG Hatch: Upgrade Your Civic Today

- The Benefits of Using Structural Carbon Fibre in Engineering

- How Many Layers of Layered Carbon Fiber Are Needed?

Simplifying Your Life: Key Functionalities

| Attribute | Description |

|---|---|

| Product Name | FRP Pultrusion Machine / Pultrusion Equipment |

| Brand Name | GangLong Fiberglass |

| Place of Origin | Hebei, China |

| Warranty | 2 Year |

| Control System | PLC (Programmable Logic Controller) |

| Core Components | PLC, Gearbox, Motor |

| Material | Q235 (for main structure) |

| Color Options | Blue, Orange, or Customized |

| Application | Production of pipes, tanks, fiberglass rebar, building materials |

| Processing Services | Cutting, Bending, Decoiling, Moulding, Welding, Punching |

| Surface Treatment | Smooth |

| Customizable Features | Shape, Length, Size |

| Certifications | ISO9001 |

| After-Sales Service | Technicians available for guidance via overseas visits or video |

| OEM | Yes |

| Support Service | Custom Service |

| Inspection Reports | Provided (up to standard) |

| Product Features | High Strength, Light Weight, Customizable Sizes and Shapes, Advanced Equipment, High Automation, Easy to Operate |

Thank you for your interest in our products. To receive our pricelist or for any inquiries, please fill out the form below. We will get back to you within 24 hours.

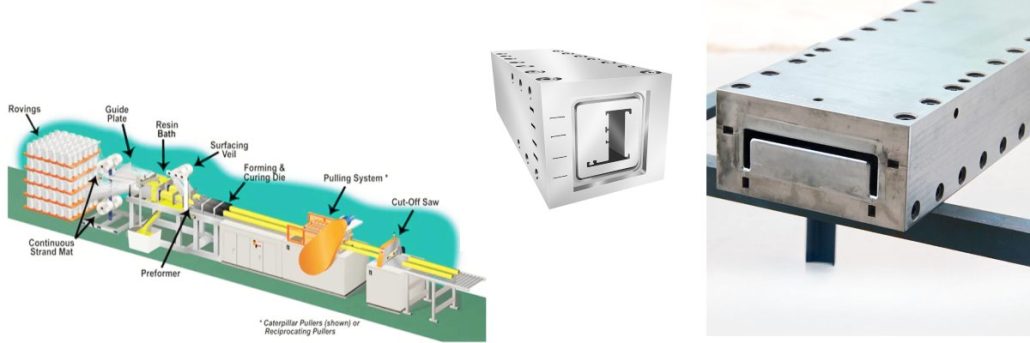

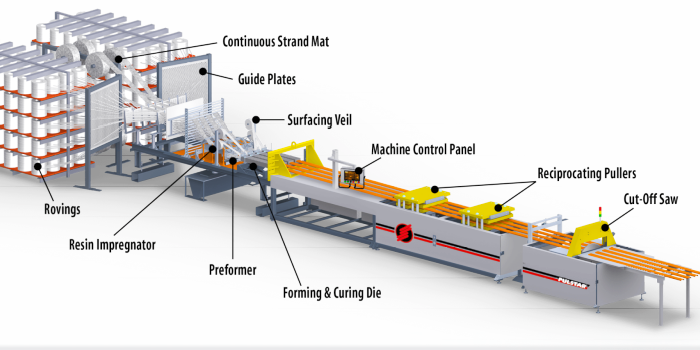

Types of Pultrusion Equipment

Pultrusion is a manufacturing process used to produce continuous lengths of reinforced polymer profiles with a constant cross-section. The equipment required for pultrusion is specifically designed to support the process efficiently and precisely. Here is a detailed description of the various types of pultrusion equipment:

Resin Impregnation Systems

- Function: These systems saturate the reinforcing fibers (such as fiberglass, carbon fiber, or aramid) with resin.

- Components:

- Resin Bath: A trough or tank filled with resin where fibers are passed through to ensure complete impregnation.

- Injection Boxes: Used for closed resin impregnation methods to reduce wastage and control resin-to-fiber ratio.

- Features:

- Temperature control for consistent resin viscosity.

- Adjustable resin bath depth and tensioning devices for uniform saturation.

Fiber Delivery Systems

Function: Ensure continuous and consistent feeding of reinforcing fibers to the resin impregnation stage.

Components:

- Creels: Racks that hold spools of fiber rovings or mats.

- Tensioners: Devices that maintain constant tension in the fibers to prevent sagging or snapping.

Features:

- Easy loading and unloading of fiber spools.

- Adjustable tension controls to accommodate different fiber types.

Heated Die Systems

Function: Shape and cure the resin-impregnated fibers into the desired profile.

Components:

- Pultrusion Die: A steel mold with the desired cross-sectional shape.

- Heating Elements: Electric or oil-based heaters embedded in the die for curing.

Features:

- Precise temperature control to ensure consistent curing.

- Adjustable die length for different production speeds and profile complexities.

Pulling Systems

Function: Pull the composite material through the die and out of the system at a consistent speed.

Types:

- Caterpillar Pullers: Use belt-like systems to grip and pull the material.

- Clamp and Grab Systems: Alternate gripping and pulling actions to move the material.

Features:

- Variable speed control to match production requirements.

- Durable gripping surfaces to avoid damage to the cured profile.

Cutting Systems

Function: Cut the pultruded profile into specified lengths.

Types:

- Manual Cutters: Operated by hand for small-scale production.

- Automatic Cutters: Equipped with servo motors for precision cutting during continuous production.

Features:

- Programmable cutting lengths.

- Dust and debris collection systems for cleaner operations.

Control Systems

Function: Oversee and coordinate all aspects of the pultrusion process.

Components:

- PLC (Programmable Logic Controllers): Manage temperature, speed, and synchronization.

- HMI (Human-Machine Interface): Touchscreen displays for operator control and monitoring.

Features:

- Real-time data logging and fault detection.

- Remote monitoring and adjustment capabilities.

Auxiliary Equipment

- Preheaters: Heat the resin or fibers before they enter the die to improve curing efficiency.

- Cooling Systems: Cools the finished profile to stabilize its shape and properties.

- Material Handling Systems: Conveyors or rollers for smooth profile transportation.

Applications of Different Pultrusion Equipment

The choice of pultrusion equipment depends on the type of profile being manufactured (e.g., rods, beams, tubes) and the materials used. Advanced systems are often employed for high-performance applications in industries like aerospace, construction, and renewable energy.

Pultrusion equipment continues to evolve with advancements in automation, materials, and design, enabling higher efficiency, lower costs, and enhanced product quality.

Size of Pultrusion Equipment

The size of pultrusion equipment varies significantly depending on the scale of production, the complexity of the profile, and the materials being processed. Below is a detailed overview of the sizing considerations for key components of pultrusion equipment:

Resin Impregnation Systems

Resin Bath/Injection Box Size:

Small-Scale Systems: Typically 0.5–1 meter (length) to accommodate smaller profiles and limited fiber volumes.

Large-Scale Systems: Can extend up to 2 meters or more for higher throughput and large profiles.

Volume Capacity:

Small resin baths hold approximately 5–15 liters.

Industrial systems can hold over 100 liters for continuous production.

Fiber Delivery Systems

Creel Rack Dimensions:

Small Creels: Approximately 1–2 meters wide, capable of holding 10–50 spools.

Large Creels: Up to 10 meters wide, designed to hold 100–500 spools for high-volume production.

Space Requirements:

Compact systems may fit within a 10–20 square meter area.

Industrial setups can require 50–100 square meters, depending on the number of fibers and complexity.

Heated Die Systems

Die Length:

Short Dies: 0.5–1 meter for thin or simple profiles.

Long Dies: 1.5–3 meters for thick, complex profiles requiring extended curing times.

Die Width:

Varies with profile dimensions. Commonly ranges from 10–150 cm to accommodate small rods to wide panels.

Pulling Systems

Puller Dimensions:

Compact Pullers: 1–1.5 meters in length for light-duty operations.

Heavy-Duty Pullers: 2–3 meters long, designed to handle high pulling forces for large, reinforced profiles.

Force Capacity:

Light Pullers: Up to 2 tons of pulling force.

Heavy-Duty Systems: 5–20 tons for large-scale industrial applications.

Cutting Systems

Cutter Size:

Manual Cutters: Small and portable, around 0.5–1 meter in length.

Automatic Cutters: Larger units, typically 2–3 meters in size, integrated into production lines.

Blade Size:

Diameters range from 10–50 cm, depending on the profile’s cross-section.

Control Systems

Control Cabinet Size:

Small Units: 1–2 meters tall, 0.5–1 meter wide.

Large Industrial Panels: Up to 3 meters tall and 2 meters wide, depending on the complexity of automation.

Overall Pultrusion Line Size

Compact Lines:

Designed for research, prototyping, or small-scale production.

Typical Dimensions: 10–20 meters in length, 2–3 meters wide.

Industrial Lines:

For high-volume, continuous production of large profiles.

Typical Dimensions: 30–50 meters in length, 5–10 meters wide, with additional space for material handling and storage.

Height:

Usually 2–3 meters to accommodate fiber racks and overhead systems.

Auxiliary Equipment

Preheaters: Typically 1–2 meters long and 0.5–1 meter wide.

Cooling Systems: Can span 2–5 meters in length for adequate cooling of large profiles.

Conveyors:

Compact Lines: 2–5 meters in length.

Industrial Lines: 10–20 meters, depending on the length of the profiles being produced.

Factors Affecting Size

Profile Dimensions:

Larger profiles require wider dies, more extensive pulling systems, and larger cutting tools.

Production Speed:

High-speed systems need longer equipment to allow for curing and cooling.

Material Type:

Carbon fiber or heavy reinforcement profiles may need more robust equipment, increasing size.

Example Dimensions of an Industrial Pultrusion Line

- Total Length: 30–40 meters.

- Width: 5–10 meters.

- Height: 3 meters (average, can be taller with additional material racks).

This scale ensures continuous production while meeting industrial standards for strength, precision, and throughput.

Pultrusion Equipment Systems Technology

Pultrusion equipment is designed to automate and streamline the process of producing continuous fiber-reinforced polymer profiles. The technology focuses on precise material handling, efficient curing, and achieving high-strength, lightweight composite structures. Below is a detailed explanation of the core technologies that underpin pultrusion equipment systems.

Resin Impregnation Technology

Open Bath Systems:

Fibers are passed through an open tank filled with resin (e.g., polyester, epoxy, or vinyl ester).

Simple and cost-effective for general applications.

Closed Injection Systems:

Use an injection box to impregnate fibers with resin under controlled pressure.

Benefits:

- Reduced resin waste.

- Better control of fiber-to-resin ratios.

- Lower emissions of volatile organic compounds (VOCs).

Automation:

Sensors to monitor resin levels and adjust flow rates.

Temperature control for maintaining resin viscosity.

Fiber Delivery Technology

Creel Systems:

Advanced designs allow for tension-free or constant-tension delivery.

Features:

- Multi-axis racks for optimizing fiber alignment.

- Automated spool changeover to minimize downtime.

Alignment Guides:

Roller-based or guide-bar systems to ensure uniform distribution of fibers before resin impregnation.

Heated Die Technology

Precision Dies:

- Machined from high-grade steel to ensure uniform heat distribution and durability.

- Coatings (e.g., Teflon) are often applied to reduce resin sticking.

Temperature Control:

- Electric heating elements or oil circulation systems embedded within the die.

- Multiple heating zones allow fine-tuned temperature control.

- Real-time sensors provide feedback to maintain consistent curing.

Design Innovations:

- Modular dies for easier profile shape changes.

- Adjustable dies for handling profiles of varying thickness.

Pulling System Technology

Mechanisms:

- Caterpillar Pullers: Use belts or tracks to grip and pull profiles.

- Clamp-and-Grab Systems: Operate by alternately gripping and releasing the profile.

Features:

- Servo-controlled motors for precise pulling speed adjustments.

- Variable force settings to handle profiles of different weights and strengths.

- Anti-slip mechanisms to prevent damage to the cured product.

Digital Control:

- Integration with control systems to synchronize pulling speed with resin curing and die throughput.

Cutting and Finishing Technology

Cutting Systems:

- High-precision saws or water-jet cutters for clean and accurate cuts.

- Servo-controlled positioning to adjust cutting length automatically.

Edge Finishing:

- Optional sanding or grinding units for smooth edges.

- Inline inspection systems to detect defects and ensure quality.

Dust Control:

- Enclosed cutting stations with vacuum systems to minimize airborne particulates.

Cooling and Post-Curing Systems

Cooling Zones:

- Water baths or air-cooled systems to rapidly stabilize profiles after they exit the die.

- Length and cooling intensity depend on the material type and profile thickness.

Post-Curing:

- Infrared or UV systems for secondary curing, ensuring full polymerization of resins.

- Often used for profiles requiring high mechanical or thermal performance.

Automation and Control Systems

Programmable Logic Controllers (PLCs):

- Centralized control of pulling speed, die temperature, resin flow, and cutting length.

Human-Machine Interfaces (HMIs):

- Touchscreen displays for real-time monitoring and manual adjustments.

- User-friendly interfaces for quick setup and troubleshooting.

Sensors and Feedback Systems:

- Load cells to monitor pulling force.

- Fiber breakage sensors to detect interruptions in the fiber feed.

- Temperature and viscosity sensors in the resin bath.

Data Logging and Remote Monitoring:

- Advanced systems log production parameters for quality assurance.

- Remote access capabilities for maintenance and troubleshooting.

Material Optimization Technology

Fiber Handling:

Technologies like pre-tensioning or preheating fibers to improve adhesion with resin.

Resin Blending:

Inline mixers to ensure consistent resin properties during production.

Hybrid Materials:

Equipment designed to handle multiple fiber types (e.g., glass and carbon) for hybrid composites.

Sustainability Features

Low VOC Systems:

- Closed resin systems minimize emissions.

- Use of bio-based or recyclable resin options.

Energy Efficiency:

- Optimized heating and pulling systems reduce power consumption.

Recyclable Components:

- Equipment built with modular parts for easy replacement and recycling.

Applications of Pultrusion Systems Technology

- Construction: Beams, panels, and gratings for high-strength structures.

- Transportation: Lightweight components for automotive, rail, and aerospace.

- Energy: Wind turbine blades, utility poles, and cable trays.

- Marine: Corrosion-resistant profiles for docks and offshore structures.

Modern pultrusion technology emphasizes automation, precision, and efficiency, ensuring that manufacturers can produce high-performance composite profiles at competitive costs with minimal environmental impact.

Supply Pultrusion Equipment

GangLong Fiberglass, with over 10 years of experience in pultrusion profile production, is committed to providing customers with high-quality, efficient, and reliable pultrusion equipment and products. Whether you need thermoplastic or thermosetting pultrusion solutions, we are here to meet your needs. Our pultrusion machinery is built with the most advanced technology, and our design philosophy is always centered on exceeding customer expectations.

Key Features of Our Pultrusion Machines:

High Automation: Equipped with a PLC control system, our machines achieve automated operation, reducing manual intervention and significantly improving production efficiency.

Powerful Traction: The track traction system provides stable pulling force, making it ideal for pultruding large or hollow profiles.

Flexible Speed Control: The traction system features variable frequency speed control, allowing flexible adjustment of speed according to production needs for energy-efficient operation.

Integrated Design: Combining creel, resin impregnation, preforming, mold curing, continuous pultrusion, traction, and automatic cutting into one complete production line.

Production Flexibility: Adjustable process parameters for different raw materials and product specifications, suitable for producing a wide range of composite products.

High-Precision Cutting: Equipped with an automatic cutting machine to ensure precise cutting of profiles according to set dimensions.

User-Friendly Operation: An intuitive human-machine interface allows operators to easily master the equipment.

Choose GangLong Fiberglass for efficient, reliable, and flexible pultrusion solutions that will take your production to the next level!

New Equipment

New pultrusion equipment encompasses a range of advanced machines designed to enhance the efficiency and precision of the pultrusion process. These machines include features such as automated pulling systems, integrated heating elements, and advanced control panels that ensure consistent quality and high production rates. New models often come with customizable options to fit specific manufacturing needs, such as varying sizes of profile windows or specialized die designs. The latest equipment typically offers improved energy efficiency, enhanced safety features, and greater ease of operation, making them ideal for both high-volume production and specialized applications.

Used Equipment

The market for used pultrusion equipment presents an opportunity for cost-effective investment in manufacturing machinery. Used machines can offer significant savings compared to new equipment, but potential buyers should be cautious. It’s essential to assess the condition, age, and maintenance history of used pultrusion machines before purchase. Benefits of buying used equipment include lower upfront costs and the possibility of acquiring high-quality machines at a fraction of the new price. However, risks include potential wear and tear, limited warranty options, and the need for possible refurbishments. Examples of available used pultrusion machines often include models from reputable brands, which can be found through specialized equipment dealers and online marketplaces.

Pultrusion Equipment Pricing

Pultrusion Equipment Price

The price of pultrusion equipment varies based on several factors, including machine size, features, and materials used. Larger machines with wider profile windows and higher pulling capacities generally come with a higher price tag. Advanced features, such as automated control systems, integrated heating elements, and customizable die designs, also contribute to increased costs. The quality of materials used in the construction of the equipment, such as stainless steel or high-grade alloys, can further influence the price. For example, the use of stainless steel cable tray in the design not only enhances durability but also contributes to a more robust and efficient system. This choice of materials is crucial in determining the overall cost and longevity of the equipment, ensuring that it meets the demands of various applications. Additionally, the complexity of the machine’s design, including specialized functions and adaptability for different types of profiles, plays a significant role in determining the overall cost.

Pultrusion equipment pricing varies widely based on several factors, including the equipment’s specifications, production capacity, level of automation, and additional features. Below is a detailed breakdown of aspects influencing the cost of pultrusion machinery:

Type of Pultrusion Equipment

- Basic Manual Machines: These are the most affordable, typically suitable for small-scale production or R&D purposes. Pricing can start from $50,000 to $100,000.

- Semi-Automatic Machines: These offer partial automation for higher efficiency, with pricing ranging from $100,000 to $250,000, depending on production speed and capabilities.

- Fully Automatic Machines: High-speed, fully automated systems with advanced controls and monitoring systems. These can cost $250,000 to $1,000,000 or more, tailored to industrial-scale production.

Production Capacity

- Low-capacity Machines: Suitable for small-scale operations, priced on the lower end of the spectrum.

- High-capacity Machines: Designed for mass production with multiple pulling systems, often priced significantly higher due to enhanced throughput.

Customization Options

- Many manufacturers offer customized pultrusion equipment tailored to specific profiles, materials, or end-use applications. Customization can add 10-50% to the base cost, depending on complexity.

Automation and Software Integration

- Basic Control Systems: Machines with standard PLC (Programmable Logic Controller) systems are more affordable.

- Advanced Systems: Equipment with high-end SCADA (Supervisory Control and Data Acquisition) systems or IoT (Internet of Things) integration for remote monitoring and diagnostics can significantly increase the price.

Additional Features

- Heating Systems: Equipment with advanced heating options (e.g., infrared or induction heating) can be more expensive.

- Multi-resin Compatibility: Machines designed to handle various resins (e.g., polyester, vinyl ester, epoxy) may cost more.

- Profile Variety: Equipment capable of producing diverse profiles (tubes, rods, custom shapes) can also add to the cost.

Brand and Manufacturer

- Renowned brands with proven track records often charge a premium due to reliability, after-sales support, and service warranties.

- Less-known or local manufacturers may offer competitive pricing, but with potential trade-offs in terms of support and longevity.

Geographic Location

- Domestic vs. Imported Machines: Importing equipment may involve additional costs for shipping, customs, and taxes.

- Local Suppliers: Buying locally may reduce transportation and importation fees but could limit access to advanced options.

Maintenance and Warranty

- Extended warranties or bundled maintenance services can add 5-10% to the total price but offer peace of mind and reduced downtime costs.

Market Trends

- Global demand for lightweight and durable materials, particularly in industries like construction, automotive, and aerospace, can influence pricing as manufacturers scale production to meet demand.

If you’re considering purchasing pultrusion equipment, it’s essential to evaluate your specific production requirements and budget. Most manufacturers will provide detailed quotations and allow some negotiation based on bulk orders or long-term partnerships.

Pultrusion Machine Operators

Role and Responsibilities

Pultrusion machine operators play a crucial role in ensuring the efficient and effective operation of pultrusion equipment. Their primary responsibilities include setting up and adjusting the pultrusion machines, monitoring the production process, and maintaining the quality of the output. Operators are tasked with loading raw materials into the machine, configuring the machine settings according to the product specifications, and overseeing the entire pultrusion process to ensure consistent profile production. They must also conduct routine inspections, perform minor repairs, and troubleshoot any issues that arise during operation. A strong understanding of the pultrusion process, as well as the ability to read technical blueprints and machine manuals, is essential for ensuring that the equipment operates smoothly and produces high-quality fiber-reinforced composites.

Skills and Qualifications Required

To effectively operate pultrusion equipment, individuals need a combination of technical skills and hands-on experience. Key skills include a solid understanding of machinery operation, mechanical aptitude, and familiarity with safety protocols. Operators should possess problem-solving abilities to address and resolve operational challenges. Qualifications may include a high school diploma or equivalent, with additional vocational training or experience in manufacturing or machinery operation preferred. Knowledge of composite materials and pultrusion techniques is also beneficial for optimizing machine performance and product quality.

Training and Certification

Training programs for pultrusion machine operators often include both theoretical instruction and practical hands-on experience. These programs cover topics such as machine operation, maintenance procedures, safety standards, and troubleshooting techniques. Certification can further validate an operator’s expertise and enhance their job prospects. Certified operators are generally recognized for their proficiency in handling pultrusion equipment and adhering to industry standards. Having a certified operator for your pultrusion equipment ensures that the machines are operated efficiently, which can lead to improved production quality and reduced downtime. Certification may also be a requirement for certain job positions or industries, highlighting the importance of formal training in the field.

The Pultrusion Process

The pultrusion process is a continuous manufacturing technique used to produce strong, lightweight, and uniform composite profiles with constant cross-sections. It is widely used in industries such as construction, automotive, aerospace, and infrastructure. Below is a detailed explanation of the process:

Raw Materials Preparation

Reinforcements, such as continuous fibers (glass, carbon, or aramid), are the primary materials. These fibers are typically supplied as rovings, mats, or woven fabrics. Thermosetting resins like polyester, vinyl ester, epoxy, or phenolic act as the matrix material. Additives like pigments, UV stabilizers, and flame retardants may also be included in the resin.

Resin Impregnation

The reinforcing fibers are pulled through a resin bath or impregnator where they are thoroughly saturated with resin. This wetting process ensures that the fibers are fully coated, creating a strong bond between the reinforcement and resin matrix.

Pre-Forming

After resin impregnation, the wet fibers pass through a pre-forming guide or a series of rollers to align them into the desired shape. This step ensures uniform distribution of fibers and prepares the material for final shaping in the die.

Heated Die

The wetted and pre-formed fibers are pulled through a heated die, which shapes the material into the final profile, such as rods, tubes, channels, or other custom forms. Heat in the die activates the resin curing process (polymerization), solidifying the composite into a rigid shape.

Pulling Mechanism

A pulling system continuously draws the cured composite through the die. Common pulling systems include caterpillar pullers and clamping pullers. The pulling speed determines the production rate and is optimized based on material properties and product specifications.

Cutting and Finishing

The continuous profile exits the die and is cooled to maintain its shape. The material is then cut to the desired length using an automated saw or cutting mechanism. Additional finishing processes, such as sanding, painting, or drilling, may follow, depending on the application.

Advantages of Pultrusion

- Continuous production enables high-volume manufacturing with consistent quality.

- Optimized use of materials minimizes waste.

- The process produces lightweight yet durable composites with a high strength-to-weight ratio.

- Suitable for complex cross-sectional profiles.

- Offers excellent corrosion resistance, making it ideal for challenging environments.

- Cost-effective compared to other composite manufacturing methods.

The pultrusion process is highly efficient and versatile, making it a cornerstone of modern composite manufacturing.

Purchasing and Maintaining Pultrusion Equipment

Buying Tips

When purchasing pultrusion equipment, it’s essential to consider several factors to ensure you invest in the right machinery for your needs. Start by evaluating the reliability and reputation of the supplier. Choose a supplier known for high-quality products and strong customer support. Review warranty options thoroughly, as a robust warranty can provide peace of mind and protect your investment. Additionally, consider the specific requirements of your production process, including the types of profiles you need to produce and the volume of production. This will help you select equipment that meets your technical and capacity needs.

Maintenance Best Practices

Proper maintenance is crucial for the longevity and optimal performance of pultrusion equipment. Regularly inspect and clean the machinery to prevent the buildup of resin or debris, which can affect performance. Follow the manufacturer’s maintenance schedule, including lubrication of moving parts and checking for wear and tear. Ensure that heating elements, such as those in the die, are functioning correctly and calibrate temperature controls regularly. Additionally, train your operators on routine maintenance tasks and the importance of early detection of potential issues. Implementing a proactive maintenance plan can prevent costly downtime and extend the equipment’s lifespan.

Service and Support

Good service and support from manufacturers and suppliers are vital for keeping your pultrusion equipment in top condition. Many manufacturers offer technical support, including troubleshooting assistance and parts replacement services. Check if the supplier provides training for your operators to help them understand the equipment better. Also, inquire about the availability of spare parts and the ease of ordering them. Having access to prompt and reliable support can minimize downtime and ensure that any issues with your pultrusion equipment are resolved quickly, allowing your production process to continue smoothly.

FAQs about Pultrusion Equipment

What are the disadvantages of pultrusion?

What is the process of epoxy pultrusion?

What are the examples of pultruded parts?

How can you tell the difference between forging and extrusion?

What products are made from pultrusion?

What are the uses of pultrusion?

What is the difference between pultrusion and filament winding?

What other everyday products are made from using the extrusion process?

What is the principle of pultrusion?

What is pultrusion?

What is carbon fiber pultrusion?

Which are the elements of a pultrusion machine?

Creel: Holds the spools of reinforcing fibers.

Resin bath: Coats the fibers with resin.

Heated die: Shapes and cures the impregnated fibers into the desired profile.

Pulling system: Continuously pulls the fibers through the machine.

Cutting system: Cuts the pultruded profile to the desired length once it exits the die. Each element works in coordination to ensure the continuous production of composite profiles with consistent quality.

What are the advantages and disadvantages of pultrusion process?

Strength and Lightweight: Pultruded products are strong, durable, and lightweight due to the fiber reinforcement.

Corrosion Resistance: Pultruded composites are resistant to environmental factors such as moisture, chemicals, and UV light, making them ideal for outdoor applications.

Efficiency: The continuous nature of pultrusion allows for long production runs with consistent quality.

Design Flexibility: Pultrusion can produce complex cross-sectional profiles with tight tolerances.

Disadvantages:

Limited to Constant Cross-Sections: Pultrusion can only produce profiles with a consistent cross-section along their length, making it unsuitable for parts that require varying shapes.

Initial Setup Costs: The equipment and molds used for pultrusion can be costly to set up, making it less economical for short production runs.

High Maintenance: Pultrusion machinery requires regular maintenance to ensure optimal performance and product quality.

What are the defects of pultrusion?

Voids and Air Bubbles: Improper impregnation of fibers with resin can lead to voids or air bubbles, weakening the structure.

Surface Roughness: Poor control of the resin flow or curing process can result in a rough or uneven surface finish.

Fiber Misalignment: If the fibers are not properly aligned during the pulling process, the final product may lack the desired strength and mechanical properties.

Resin Rich or Resin Starved Areas: Uneven distribution of resin can lead to regions with excess resin (resin rich) or insufficient resin (resin starved), affecting the product’s structural integrity.

What is the difference between pultrusion and pulforming?

Which are the elements of pultrusion machine?

Creel: A frame that holds the fiber spools.

Resin bath: Where the fibers are impregnated with resin.

Heated die: Shapes and cures the resin-impregnated fibers into a solid composite profile.

Pulling system: Mechanically pulls the fibers through the machine.

Cutting system: Cuts the cured product to the desired length. Each element plays a critical role in ensuring the continuous, consistent production of high-quality composite profiles.

What is a pultrusion machine?

What is an example of a pultrusion?

What are the disadvantages of pultrusion process?

Limited Shapes: Pultrusion is ideal for producing parts with a constant cross-section but cannot create complex shapes or varying thicknesses along the profile.

High Initial Costs: The setup and tooling costs for pultrusion can be high, making it less economical for low-volume production.

Maintenance Requirements: Pultrusion machines require regular maintenance to avoid defects in the final product, such as voids or fiber misalignment.

Surface Finish Issues: Without careful control of the resin flow, the surface of the final product can sometimes have a rough finish, which may require post-processing.

What are the applications of pultrusion?

Construction: Beams, channels, handrails, and grating.

Electrical and Telecommunications: Cable trays, ladder rails, and enclosures.

Transportation: Lightweight panels, automotive parts, and rail interiors.

Energy: Wind turbine blades and solar panel frames.

Marine and Offshore: Corrosion-resistant walkways, ladders, and handrails used in harsh environments like oil rigs and ship decks.

What does pultruded mean?

What is the pulforming process?

Which of the following polymer materials is commonly used in pultrusion?

What is pultrusion in injection Moulding?

What products are made from pultrusion process?

What is the continuous pultrusion process?

What are the components of pultrusion?

Fibers: Usually glass, carbon, or aramid fibers that provide strength to the composite.

Resin: A thermosetting polymer, typically polyester, vinyl ester, or epoxy, which bonds with the fibers and cures to form the final solid structure.

Resin Bath: Where fibers are impregnated with the resin.

Heated Die: Shapes and cures the fibers into the desired profile.

Pulling Mechanism: Continuously pulls the fibers through the resin bath and die.

Cutting System: Cuts the finished product to the desired length once it exits the die.

What is the pultrusion process of carbon fiber?

What materials are used in pultrusion?

Reinforcing fibers: Typically glass fibers (fiberglass), carbon fibers, aramid fibers (Kevlar), or basalt fibers. These fibers provide strength and stiffness to the composite material.

Resins: Common thermosetting resins include polyester, vinyl ester, epoxy, and phenolic. The resin binds the fibers together and provides environmental resistance, such as corrosion and moisture protection. Other materials such as pigments, fillers, and fire retardants may be added to improve the performance of the final product.

What are the pros and cons of pultrusion?

High strength-to-weight ratio: Pultruded products are lightweight yet strong, making them ideal for structural applications.

Corrosion resistance: Pultruded materials are highly resistant to corrosion from chemicals, water, and UV exposure.

Cost efficiency: Once set up, the pultrusion process is highly automated, producing large quantities of materials at a low cost.

Durability: Pultruded composites are highly durable and have long service lives.

Cons:

Limited design flexibility: Pultrusion is limited to producing profiles with a constant cross-section, making it unsuitable for complex shapes.

Initial tooling costs: The setup and tooling for the pultrusion process can be expensive, making it less cost-effective for short production runs.

Surface finish quality: Pultruded products may require additional finishing for aesthetic applications if surface smoothness is crucial.

What is the pultrusion process?

Fibers: Continuous fibers (e.g., glass or carbon) are pulled from spools.

Resin bath: The fibers are pulled through a resin bath, where they are impregnated with a thermosetting resin.

Heated die: The resin-impregnated fibers are pulled through a heated die that shapes and cures the material, forming a rigid composite profile.

Pulling system: A mechanical system continuously pulls the fibers through the die.

Cutting system: The cured composite profile is cut to the desired length. The result is a strong, lightweight, corrosion-resistant profile with a constant cross-section.