Carbon fiber has gained significant traction across various industries due to its impressive combination of strength, lightweight properties, and versatility. Originally used in aerospace and high-performance automotive applications, real carbon fibers has now expanded into diverse sectors, including sports equipment, medical devices, and consumer goods. As its popularity grows, so does the demand for understanding the differences between real carbon fibers and its counterfeit counterparts, along with its practical applications. In this article, we’ll explore the advantages of using real carbon fibers over fake alternatives, the factors influencing real carbon fiber price, and how this material is revolutionizing car parts, such as real carbon fibers hoods and real carbon fibers spoilers. We will also discuss the rising trend of real carbon fibers wraps and their benefits for automotive enthusiasts.

What is Real Carbon Fiber?

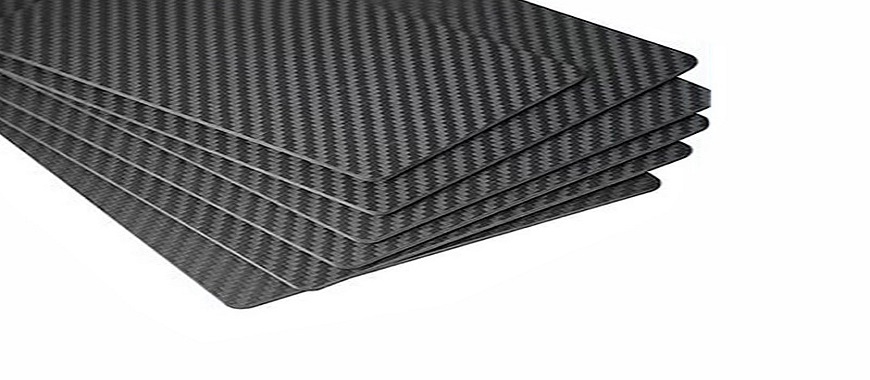

Real carbon fibers is a high-performance composite material that is widely known for its strength-to-weight ratio and versatility. It is composed of carbon filaments that are tightly woven into fabric-like sheets, which are then bonded together with epoxy resins to create a rigid, durable structure. Unlike other materials, real carbon fibers combines the lightweight properties of fibers with the strength and resilience needed to withstand demanding conditions.

Manufacturing Process

The production of real carbon fibers begins with the extraction of carbon filaments, which are made from materials like polyacrylonitrile (PAN). These filaments are then carefully woven into a cloth-like structure, which is known as carbon fiber fabric. This fabric is impregnated with epoxy resin to form a solid bond, which gives the material its strength and rigidity. The next step is the curing process, where heat is applied to harden the resin, permanently setting the carbon fibers in place. This process not only enhances the mechanical properties of real carbon fibers, but also ensures that it is optimized for various applications, including in high-performance automotive parts, aerospace structures, and sports equipment.

Key Characteristics

Lightweight: One of the most notable features of real carbon fibers is its exceptional lightness. Compared to metals like steel or aluminum, carbon fiber is significantly lighter while maintaining similar strength and durability. This makes it ideal for applications where weight reduction is crucial, such as in racing cars or aerospace components.

Strong: Despite its light weight, real carbon fibers is incredibly strong and can bear significant loads without breaking or deforming. The carbon fibers are tightly interwoven and provide excellent tensile strength, making the material perfect for high-stress environments like structural reinforcements or impact-resistant surfaces.

Durable: Real carbon fibers is also highly durable, offering long-lasting performance even in extreme conditions. It resists wear and tear better than many metals and composites, making it an excellent choice for products that require prolonged use.

Corrosion-resistant: Unlike metals, real carbon fibers does not rust or corrode when exposed to moisture or harsh environments. This makes it a preferred material in marine, automotive, and industrial applications, where exposure to water and chemicals can deteriorate other materials.

These remarkable characteristics of real carbon fibre have made it a go-to choice in various industries, setting it apart from other materials that may not offer the same combination of lightness, strength, and resilience.

Is Aerocanard Fiberglass or Carbon Fiber? A Comprehensive Comparison

Real Carbon Fiber vs Fake Carbon Fiber

When comparing real carbon fibers to its imitation counterparts, the differences in performance, appearance, and cost are substantial. While both materials are designed to resemble carbon fiber, the true material offers unique properties that fake versions cannot replicate. Understanding these differences is key when choosing the right material for your application.

Definition of Fake Carbon Fiber

Fake carbon fiber typically refers to materials that are made to look like carbon fiber but are composed of plastic, vinyl, or other synthetic substances. These fake versions are often marketed as “carbon fiber look” or “carbon fiber pattern,” but they do not possess the same strength, durability, or structural properties as real carbon fibers. They are typically used in decorative or non-structural applications where the primary goal is aesthetic appearance rather than functional performance.

Comparison: Real Carbon Fiber vs Fake Carbon Fiber

Strength & Durability

| Property | Real Carbon Fiber | Fake Carbon Fiber |

|---|---|---|

| Strength | Extremely strong and rigid. Able to withstand high stress and pressure. | Weak, less durable; cracks or dents easily under stress. |

| Durability | Long-lasting, resistant to wear and tear. | Prone to fading, scratching, and other types of damage over time. |

Real carbon fibers is known for its exceptional tensile strength and durability. It is capable of withstanding extreme stress without losing its shape or integrity. In contrast, fake carbon fiber made from plastic or vinyl lacks the same structural strength and is more likely to crack or deform when exposed to high pressure or rough use.

Weight

One of the standout features of real carbon fibers is its lightweight nature. Despite its strength, it is much lighter than materials like steel or aluminum, making it ideal for industries such as aerospace or automotive engineering. Fake carbon fiber, however, is often heavier due to the materials used in its production, such as plastic or vinyl.

Appearance

| Property | Real Carbon Fiber | Fake Carbon Fiber |

|---|---|---|

| Weave Pattern | Distinctive and consistent weave, visible throughout the material. | Often glossy or shiny, with inconsistent or artificial-looking patterns. |

| Texture | Authentic, textured surface that you can feel. | Smooth or flat surface with no tactile feedback. |

When it comes to appearance, real carbon fibers sheets boasts a distinctive woven texture that gives it a unique, high-quality look. This texture is consistent and visible throughout the material, which is a telltale sign of genuine carbon fiber. On the other hand, fake carbon fiber often looks shiny or glossy and may feature irregular patterns or designs that don’t resemble the genuine weave. The texture is often smooth, making it easy to distinguish from the real material.

Price

Real carbon fibers is significantly more expensive than its imitation counterparts due to the complex and labor-intensive manufacturing process. The raw materials and technology involved in creating real carbon fibers contribute to its premium cost. In contrast, fake carbon fiber is made from cheaper materials and is often mass-produced, making it far more affordable.

How to Spot Real Carbon Fiber

- Look for a Uniform, Consistent Weave Pattern: Real carbon fibers has a consistent, visible weave pattern throughout the material. If the pattern appears uneven or poorly aligned, it’s likely a fake version.

- Check the Price: Genuine real carbon fibers comes at a premium price due to the extensive manufacturing process and high-quality materials. If the price seems too good to be true, it probably isn’t real carbon fibers.

By paying attention to these key factors—strength, weight, appearance, and cost—you can easily differentiate between real carbon fibers and fake carbon fiber, ensuring that you choose the material that best suits your needs.

Feather Carbon Fiberglass: The Future of Racing Components

Real Carbon Fiber Pricing

When considering the price of real carbon fibers, it is important to recognize that various factors contribute to its cost. These factors include the quality of the material, the manufacturing process, and the type of product being produced. Understanding these elements will help you make an informed decision when purchasing real carbon fibers for a particular application.

Factors Influencing the Price

The cost of real carbon fibers can vary significantly depending on several key factors:

- Material Quality: The quality of the carbon fibers plays a major role in determining the price. Aerospace-grade carbon fibers, which are designed to withstand extreme stresses and environmental conditions, are significantly more expensive than lower-grade fibers used for non-structural applications. High-strength fibers that offer superior performance in critical industries, like automotive and aerospace, command a premium price.

- Manufacturing Process: The method used to create real carbon fibers products can also impact the price. Hand-laid carbon fiber, where each layer of fiber is carefully placed by hand, requires more labor and precision, making it more expensive. Conversely, mass-produced carbon fiber products made using automated processes are generally less costly. Precision-engineered carbon fiber that requires exacting control over the material’s properties adds to the cost due to the advanced techniques involved.

- Product Type: The type of real carbon fibers product you are purchasing can significantly affect its cost. Finished products such as car parts (e.g., hoods, spoilers, and body panels), accessories, and specialized equipment often carry a higher price tag because of the additional labor, craftsmanship, and design work required. Raw materials or simple sheets of carbon fiber will generally be less expensive than custom-engineered products designed for specific applications.

Additional factors influencing the price include:

- Size and Dimensions: Larger or custom-sized sheets or components naturally cost more than standard-sized products due to increased material requirements and labor.

- Surface Finish and Coating: Products with specialized finishes, such as glossy or matte coatings, often require additional processing, raising the overall cost.

- Quantity and Volume: Buying real carbon fibers in bulk or for large-scale production may reduce the unit price, but smaller orders or one-off custom items tend to be more expensive due to the small production runs.

Typical Price Ranges

When it comes to real carbon fibers products, prices can vary widely based on the factors mentioned above. For example:

- Raw Carbon Fiber Sheets or Fabrics: These typically range from $15 to $50 per yard, depending on the type of weave, quality, and strength of the fibers.

- Car Parts: Products like carbon fiber hoods, spoilers, and bumpers can range anywhere from $300 to $2,500 or more, depending on the design, size, and customization options. Custom-made or high-performance parts used in racing or high-end cars may push the price into the higher range.

- Accessories: Smaller carbon fiber accessories such as phone cases, watch bands, or laptop covers typically cost between $50 to $500, depending on the complexity of the design and the finishing process.

- Industrial or Aerospace Components: Custom components for industrial and aerospace applications made from real carbon fibers can range from several thousand dollars to tens of thousands of dollars, depending on the specifications and the amount of labor involved.

The price of real carbon fibers is highly dependent on the quality of the material, the complexity of the manufacturing process, and the specific product or application. For those seeking high-performance or aesthetically advanced carbon fiber products, it’s important to consider these pricing factors to ensure you get the best value for your investment.

Does 30T Carbon Fiber Have in Fiberglass in It? Key Insights

Real Carbon Fiber in Automotive Applications

Real carbon fibers has become a popular material in the automotive industry due to its remarkable properties, including lightweight strength, durability, and sleek aesthetics. As car manufacturers and aftermarket tuners look for ways to improve performance, reduce weight, and enhance the visual appeal of their vehicles, real carbon fibers has become an essential component for various automotive parts.

Carbon Fiber Hoods

One of the most common automotive applications for real carbon fibers is in the creation of car hoods. Car enthusiasts and performance-focused vehicles frequently use carbon fiber to construct hoods, as the material provides several distinct advantages.

Why Carbon Fiber is Used for Car Hoods

- Lightweight: The primary reason real carbon fibers is used for car hoods is its low weight. Compared to traditional steel or aluminum hoods, carbon fiber is significantly lighter, which directly translates into a reduced overall vehicle weight. This weight reduction plays a crucial role in improving acceleration and handling, making it a popular choice for high-performance vehicles.

- Strength-to-Weight Ratio: While real carbon fibers is lightweight, it maintains an exceptional strength-to-weight ratio. This means that carbon fiber hoods offer superior strength compared to metal alternatives while still being lighter, providing structural integrity without adding excess weight. The enhanced durability of real carbon fibers also helps improve safety, as the material can withstand high-impact situations better than many other materials.

- Aesthetics: The woven pattern of real carbon fibers is visually striking, giving cars a high-tech, sporty appearance. Whether used in premium performance vehicles or aftermarket modifications, the distinctive texture of carbon fiber adds a sleek, modern look that appeals to car enthusiasts.

Benefits

- Reduced Vehicle Weight: By replacing metal hoods with carbon fiber, the overall weight of the vehicle is reduced. This reduction in weight leads to improved handling, quicker acceleration, and enhanced braking performance.

- Improved Performance: The lower weight, combined with the high strength of real carbon fibers, enhances the vehicle’s overall performance. This is particularly important in racing and sports cars, where every ounce counts in terms of handling and speed.

- Better Fuel Efficiency: Reducing the weight of a vehicle with carbon fiber components, such as hoods, directly improves fuel efficiency. Lighter vehicles require less energy to move, which translates into better miles per gallon (MPG) ratings.

Price Range

The cost of real carbon fibers hoods can vary widely depending on several factors, such as the design, the brand, and whether the product is OEM (original equipment manufacturer) or aftermarket. Typically, you can expect:

- Starting Prices: The base price for a carbon fiber hood starts around $400 for more basic designs. These hoods are typically produced for common makes and models, using simpler manufacturing techniques.

- Premium Designs: For more advanced or custom carbon fiber hoods, the price can easily exceed $1,500 or more. Premium designs feature intricate weave patterns, advanced UV protection coatings, and other specialized finishes to enhance both the aesthetic appeal and durability of the product.

Example Products

Several popular automotive brands and models are known for their use of real carbon fibers hoods, either as part of their standard offering or as an upgrade option:

- BMW M Series: Models like the BMW M3 and M4 often come with the option for carbon fiber hoods, contributing to reduced weight and improved performance.

- Ford Mustang GT: The Ford Mustang GT offers carbon fiber hoods as part of its high-performance package, adding to the car’s aggressive styling and performance capabilities.

- Chevrolet Corvette: The Corvette is another iconic car that frequently uses real carbon fibers for both aesthetic appeal and performance enhancement, including carbon fiber hoods that reduce weight and improve speed.

Real carbon fibers has established itself as a high-performance material in the automotive industry, particularly for components like hoods. Its combination of lightweight properties, strength-to-weight ratio, and aesthetic appeal make it an ideal choice for car enthusiasts and performance vehicles alike. Whether for aftermarket tuning or factory production, carbon fiber hoods offer significant benefits in terms of performance, efficiency, and style.

Is Carbon Fiber Dust More Harmful Than Fiberglass Dust?

Real Carbon Fiber Spoilers

Real carbon fiber is a highly valued material in the automotive world, especially when it comes to enhancing the performance and appearance of sports cars and high-performance vehicles. Carbon fiber spoilers are an essential component in achieving better aerodynamics, reducing drag, and boosting the vehicle’s overall efficiency. These spoilers not only offer functional benefits but also add a dynamic and aggressive look to cars, making them a popular choice for car enthusiasts and racers alike.

Functionality and Aesthetics of Carbon Fiber Spoilers

Aerodynamic Benefits

The primary function of real carbon fibers spoilers in sports cars and performance vehicles is to improve aerodynamic performance. A properly designed spoiler creates downforce, which pushes the car downward toward the road, increasing the tire’s grip and providing better handling at high speeds. This is particularly important for high-performance and race cars, where maintaining stability at high speeds is crucial.

- Reduced Lift: Real carbon fibers spoilers help reduce lift, a force that tries to push the vehicle upwards at high speeds. By using carbon fiber in the construction, the spoiler becomes much more efficient in generating downforce without adding unnecessary weight.

- Increased Stability: The added downforce from the spoiler improves vehicle stability during cornering and at high speeds. This is especially noticeable when driving on tracks or in conditions where high-speed handling is essential.

- Reduced Drag: While spoilers are designed to generate downforce, real carbon fibers is an excellent material for this purpose due to its lightness and strength. This allows the spoiler to generate the necessary aerodynamic effect without significantly increasing the vehicle’s drag. The result is improved fuel efficiency and faster acceleration.

Aesthetic Appeal

Beyond its functional properties, a real carbon fibers spoiler also enhances the aesthetics of the vehicle. The unique texture and finish of carbon fiber add a sleek, sporty, and modern appearance to any car, particularly in performance and sports car models. The characteristic woven pattern of real carbon fibers gives the vehicle an aggressive, high-tech look, often signaling to others that the car is built for speed.

- High-Performance Look: The use of real carbon fibers spoilers provides a high-performance visual upgrade. Car enthusiasts often use carbon fiber spoilers to differentiate their vehicles and give them a more race-inspired appearance.

- Customizable Finishes: Many manufacturers offer carbon fiber spoilers with different finishes, such as matte, gloss, or clear-coated options, allowing vehicle owners to choose the one that best matches their personal style.

Price Range of Real Carbon Fiber Spoilers

The cost of real carbon fibers spoilers can vary significantly depending on several factors, such as size, design, and brand. In general, you can expect the following price ranges:

- Entry-Level Spoilers: Basic carbon fiber spoilers typically start around $200. These are usually smaller, simple designs that are mass-produced for popular vehicle models.

- Mid-Range Spoilers: Mid-range spoilers with more complex designs or larger sizes can range from $400 to $600. These often feature additional aerodynamic enhancements, such as integrated lip spoilers or adjustable components to fine-tune performance.

- Premium Spoilers: For premium, custom-designed carbon fiber spoilers that offer advanced aerodynamics, the price can go as high as $800 or more. These spoilers are often made for specific high-performance models or racing applications, where precision engineering and premium quality materials are required.

Factors Affecting the Price

The price of real carbon fibers spoilers can also be influenced by:

- Size and Design: Larger spoilers or those with more intricate designs require more carbon fiber and additional manufacturing time, which can raise the cost.

- Brand and Quality: Well-known performance brands and manufacturers with a reputation for high-quality products tend to charge more for their real carbon fibers spoilers. Additionally, aerospace-grade carbon fiber used in the construction can also increase the price.

- Custom Features: Some spoilers come with customizable features, such as adjustable angles or integrated LED lights, which can add to the overall cost.

Real carbon fiber spoilers are an essential component for enhancing both the functionality and the aesthetics of sports and performance vehicles. By improving aerodynamics, reducing drag, and adding visual appeal, carbon fiber spoilers offer significant benefits for car enthusiasts looking to upgrade their ride. With a wide range of prices, there’s a carbon fiber spoiler suitable for nearly every budget and vehicle. The variation in cost is similar to carbon fiber canoe price, where factors like material quality, design, and manufacturing processes influence the final expense. Whether you’re looking for a basic upgrade or a premium, high-performance spoiler, real carbon fiber provides the perfect solution for improving both speed and style.

FAQs about Real Carbon Fiber

Determining whether carbon fiber is real can be tricky, especially when you’re dealing with items that might be made from imitation or plastic composites designed to mimic carbon fiber’s appearance. However, there are several ways you can distinguish real carbon fibers from fake versions.

Check the Weave Pattern: Real carbon fibers features a consistent, uniform weave pattern that can be clearly seen when you look closely. Fake carbon fiber, on the other hand, may have inconsistent patterns or look overly glossy without the characteristic weave.

Feel the Texture: Real carbon fibers has a distinctive texture that feels somewhat rough or textured due to its woven structure. Fake carbon fiber products, often made from plastic or vinyl, may feel smoother or less substantial.

Weight: Real carbon fibers is incredibly lightweight, which is one of its key characteristics. If the item feels heavier than expected for its size, it could be an imitation material.

Price: Genuine real carbon fibers comes at a premium price due to its manufacturing process and material properties. If the product is unusually cheap, it might not be made from real carbon fiber.

Conductivity: Real carbon fibers is electrically conductive. Using a multimeter, you can test for conductivity; if the material conducts electricity, it is likely real carbon fibers.

By observing these characteristics, you can get a clearer idea of whether the carbon fiber you’re dealing with is genuine or not.

When people refer to “simply carbon fiber,” they may be referring to materials made from carbon fiber composites, which could be either real or fake. The term real carbon fibers is reserved for materials that are genuinely made from carbon filaments combined with a resin, resulting in a composite material with high strength, lightweight, and durability. Simply using the term “carbon fiber” without clarification can sometimes be misleading, especially when used to describe products that mimic the appearance of real carbon fibers but are made from cheaper plastic or vinyl.

To determine if a product is made from real carbon fibers, you need to examine the material closely, checking for the telltale signs of genuine carbon fiber, such as its weave pattern, texture, weight, and overall quality. As mentioned earlier, real carbon fibers has a distinctive appearance and feel, which helps distinguish it from fake carbon fiber that only mimics the look of the material.

In short, not all items labeled as “carbon fiber” are made from real carbon fibers. Always look for the proper certification or ask for confirmation from the manufacturer to ensure you’re getting a genuine product.

While real carbon fibers is an incredibly strong and durable material, it is not typically designed to stop a bullet on its own. Carbon fiber is used in various applications requiring high strength-to-weight ratios, such as in aerospace, automotive, and sports equipment. It can absorb and dissipate significant amounts of energy, but its performance when it comes to stopping bullets depends on several factors.

Thickness and Layering: To stop a bullet, a material must have enough mass and structural integrity to absorb the energy and prevent penetration. Bulletproof materials like Kevlar and advanced composite armor often combine multiple layers of materials like Kevlar, ceramic plates, and sometimes real carbon fibers to increase effectiveness. Alone, a single layer of real carbon fibers would not be sufficient to stop most bullets.

Bullet Type: The type and speed of the bullet also play a crucial role in determining whether a material can stop it. High-velocity rounds, such as those fired from rifles, would likely penetrate real carbon fibers, while low-velocity bullets might be stopped, depending on the material’s construction.

Yes, real carbon fibers can be quite expensive, and there are several reasons for its high cost. First and foremost, carbon fiber is a complex and labor-intensive material to produce. The process involves creating carbon filaments from a precursor material like polyacrylonitrile (PAN) or pitch, which is then heated to high temperatures to turn into the fibers. This manufacturing process requires precise equipment, time, and energy, driving up costs.

Additionally, the quality of the carbon fiber plays a significant role in its price. Aerospace-grade carbon fiber, which is used in high-performance applications like aircraft and Formula 1 cars, is often the most expensive because of its higher strength and structural integrity. Lower-grade carbon fiber used in consumer products, such as automotive parts, is less expensive but still pricier than many other materials due to the unique properties it provides.

Another factor influencing the price is the method of production. Hand-laying carbon fiber, as seen in custom or high-end products, is more expensive than mass-producing carbon fiber items using automated machines. As a result, real carbon fibers products, such as car parts, bicycle frames, and high-end accessories, can be significantly more costly compared to items made from cheaper materials or fake carbon fiber.

Despite the price, the durability, lightweight nature, and performance-enhancing benefits of real carbon fibers make it a worthwhile investment for many applications.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.