Steel bar grating is a crucial component in many industries. It is widely used in industrial, commercial, and architectural applications. Steel grating provides strength, durability, and versatility, making it essential for platforms, walkways, and safety solutions. Factories specialize in producing various materials like carbon steel, stainless steel, aluminum, and fiberglass to meet diverse needs. Each material offers unique advantages, such as corrosion resistance or lightweight properties. Choosing the right steel grating factory ensures high-quality products that can be customized to fit specific project requirements, guaranteeing long-lasting results. GangLong Fiberglass, a top steel grating factory in China, provides high-quality grating products and custom solutions for various applications.

Types of Steel Bar Grating Available in a Steel Grating Factory

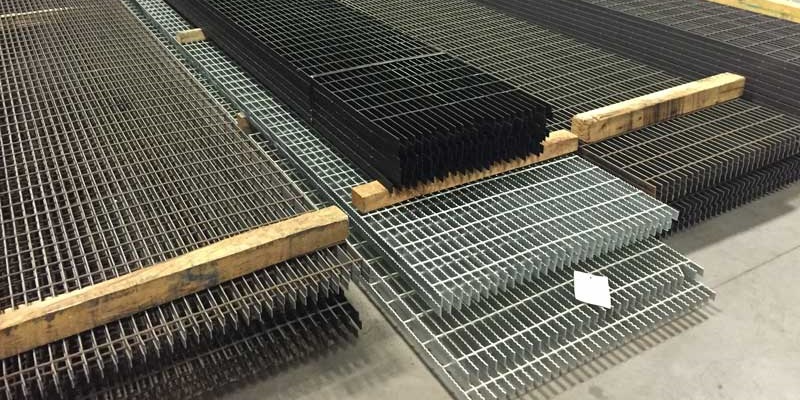

A steel grating factory offers a wide variety of steel bar grating types, each designed for specific applications. From light-duty to heavy-duty, these products cater to diverse industries and needs. Below is a detailed breakdown of the most common types of steel bar grating available.

Light Duty Steel Grating

Light-duty steel grating is ideal for pedestrian traffic and lightweight industrial applications. It’s used in walkways, platforms, and stair treads. This type of grating is known for its balance between strength and flexibility, making it a common choice for urban infrastructure.

Heavy Duty Steel Grating

Heavy-duty steel grating is designed for areas that require higher load-bearing capacities. It is commonly applied in highways, bridge decking, and loading docks. A steel grating factory typically fabricates this type using thicker steel bars to handle heavy vehicular and equipment loads.

Stainless Steel Bar Grating

Stainless steel bar grating is highly resistant to corrosion and is ideal for harsh environments like marine and chemical industries. This grating type is often used in oil and gas platforms, wastewater treatment plants, and food processing facilities where durability and hygiene are critical.

Expanded Metal Grating

Expanded metal grating is a lightweight but strong option produced by stretching a sheet of metal. It provides excellent slip resistance, making it perfect for safety walkways, stair treads, and mezzanine flooring. A steel grating factory offers this product as an economical alternative with versatility in both indoor and outdoor environments.

Aluminum Bar Grating

Aluminum bar grating is chosen for its lightweight nature and corrosion-resistant properties. It is commonly used in environments where weight needs to be minimized, such as in ship decks, offshore platforms, and ventilation grilles. In addition to traditional bar grating, aluminum expanded metal grating is also a popular choice for applications requiring enhanced strength and airflow. Factories specializing in aluminum grating offer custom designs, including both bar grating and expanded metal grating, to meet specific project specifications.

Press-Locked Grating

Press-locked grating involves combining two steel bars through pressure to form a sturdy, aesthetically appealing grid. It is used in architectural applications such as facades, fences, and partitions. A steel grating factory can provide press-locked grating for both functional and decorative purposes.

Custom-Fabricated Grating

For unique project needs, custom-fabricated grating can be designed to specific dimensions and load-bearing requirements. Whether for oil and gas platforms, walkways, or industrial mezzanines, a steel grating factory ensures that custom fabrication meets the exact requirements of the project.

Innovative Uses: Can You Reshape Fiberglass Rods Effectively

How to Choose the Right Steel Grating Factory for Your Project

Selecting the right steel grating factory is crucial to ensure that your project meets quality, safety, and performance standards. Here are the key factors to consider when choosing a factory.

Location Proximity

One of the first considerations when selecting a steel grating factory is its proximity to your project site. A nearby factory reduces shipping costs and ensures faster delivery times. This is especially important for large-scale projects where delays can increase overall costs. Choosing a local factory can also simplify logistics, enabling better communication and coordination throughout the project.

Custom Fabrication Options

Not all projects have the same specifications, and that’s where custom fabrication becomes essential. A reputable steel grating factory should offer a variety of custom fabrication services. This includes tailoring the size, shape, and load capacity of the grating to suit specific project requirements. Whether you need specialized designs for marine applications or customized stair treads for an industrial setting, the ability to fabricate custom grating is key. Companies like GangLong Fiberglass are known for offering customizable fiberglass grating solutions for industries requiring lightweight, corrosion-resistant materials.

Range of Materials and Products Offered

A reliable steel grating factory should provide a wide range of materials and finishes to cater to different applications. Whether your project requires carbon steel, aluminum, stainless steel, or fiberglass, the factory should offer these options along with various finishes such as galvanized or powder-coated. Additionally, a steel grating calculator can help determine the exact specifications for each material type, ensuring the correct weight, load-bearing capacity, and deflection limits are met for your specific needs. Factories like GangLong Fiberglass can supply fiberglass grating for environments requiring high corrosion resistance, and the calculator can assist in verifying that the selected material meets all necessary performance criteria.

Certifications and Technical Support

Certifications are a crucial indicator of a factory’s adherence to industry standards. A steel grating factory should have proper certifications that validate the quality of its products. For example, ISO certifications ensure that the factory meets international quality management standards. In addition to certifications, technical support is another important factor. A reliable factory will offer expert consultation to help you choose the right grating material, design, and installation method for your project. Access to technical guidance ensures that the grating solution will meet all safety and performance requirements.

Choosing the Right Steel Grating Factory for Your Needs

- Selecting the right steel grating factory is crucial to the success of your project. The quality of materials, range of products, and reliability of customer service directly impact the performance and longevity of your grating solutions. Whether you’re working on industrial platforms, commercial walkways, or environmental projects, it’s essential to partner with a factory that offers both expertise and customizable options. Consider the location of the factory, as proximity can reduce costs and lead times, ensuring timely project completion.

- A reputable steel grating factory provides access to high-quality materials such as carbon steel, stainless steel, aluminum, and fiberglass. Additionally, the ability to meet custom fabrication needs and offer specialized products like slip-resistant grating further enhances project safety and functionality. Factories like GangLong Fiberglass is an example of manufacturers offering diverse options, ensuring that your specific requirements are met.

Innovative Solutions and Applications from a Steel Grating Factory

A steel grating factory plays a crucial role in providing high-performance products designed to meet the unique demands of various industries. With an extensive range of offerings, these factories cater to needs ranging from slip-resistant surfaces to corrosion-resistant materials and structural support systems. Below is a detailed look at three key areas of specialization that highlight the versatility and innovation of steel grating factories.

Grip Strut and Heavy-Duty Grip Strut

Grip Strut and Heavy-Duty Grip Strut gratings are engineered specifically to address slip hazards in challenging environments. Featuring serrated surfaces, these gratings provide outstanding traction, making them indispensable for applications where safety is paramount. Typical use cases include industrial walkways, stair treads, and platforms, where exposure to oil, grease, or water could increase the risk of accidents.

For environments with heavy loads or high-impact traffic, Heavy-Duty Grip Strut is the preferred choice. Designed with reinforced strength, this variant is widely used in demanding settings such as loading docks, rail yards, and transportation infrastructure. By minimizing the risk of slips and ensuring long-lasting durability, these products exemplify the essential contributions of steel grating factories to workplace safety.

Fiberglass Grating

Fiberglass grating represents a modern solution for projects requiring lightweight yet highly durable materials. As a product commonly offered by leading steel grating factories such as GangLong Fiberglass, it is ideal for environments where corrosion resistance is critical. Unlike traditional metal gratings, fiberglass grating does not rust and requires minimal maintenance, making it a cost-effective and reliable choice for long-term applications.

This type of grating is particularly suited for industries like wastewater treatment, marine facilities, and chemical processing plants, where harsh environmental conditions demand high-performance materials. Its non-conductive properties also enhance safety in electrical applications, underscoring its versatility and importance.

Applications in Various Industries

Steel grating products manufactured by steel grating factories play an integral role in supporting a wide range of industrial, commercial, and environmental applications. Their unique combination of strength, durability, and versatility ensures they meet the demanding requirements of various sectors. Below is a detailed exploration of the specific applications and benefits of steel grating in different industries.

Industrial Platforms and Walkways

Steel grating is commonly used in industrial platforms and walkways, offering a strong, durable surface capable of supporting heavy machinery, equipment, and frequent foot traffic. These platforms are designed to provide stability and safety, even under demanding conditions such as exposure to oil, chemicals, or other hazardous substances. Typical industries that rely on these applications include:

- Oil and Gas: Platforms on offshore rigs and refineries.

- Power Plants: Walkways and elevated platforms for equipment inspection and maintenance.

- Manufacturing Facilities: Factory floors and assembly lines.

Stair Treads

Stair treads made from steel grating ensure slip resistance and safety in high-risk environments. The open design allows for drainage of liquids and debris, reducing the chance of accidents. These stair treads are often used in:

- Chemical Plants: For safe movement in areas prone to spills.

- Construction Sites: Temporary staircases on scaffolding and structural frameworks.

- Transportation Hubs: Maintenance stairways in rail yards and airports.

Trench Covers and Drainage Solutions

Steel grating is widely employed as trench covers, offering efficient drainage while maintaining structural integrity. The grating prevents clogging while allowing water, oil, or other liquids to pass through freely. Applications include:

- Urban Infrastructure: Trench covers for stormwater drainage in city streets and sidewalks.

- Industrial Facilities: Drainage systems for warehouses and workshops.

- Roadways and Parking Lots: Heavy-duty grating for vehicle load-bearing drainage.

Mezzanines and Elevated Floors

Steel grating is an ideal choice for mezzanines and elevated floors due to its lightweight yet strong design. It allows light and air to pass through, creating a well-ventilated and illuminated environment. Applications include:

- Warehousing and Storage: Elevated shelving and mezzanine floors for increased storage capacity.

- Retail Spaces: Elevated platforms in display areas or back-end storage sections.

- Sports Arenas: Utility platforms for lighting, sound equipment, and other infrastructure.

Bridges and Catwalks

Steel grating is often used in the construction of bridges and catwalks, where durability, low maintenance, and resistance to environmental factors are crucial. Specific applications include:

- Pedestrian Bridges: Lightweight bridges for public access in parks or urban areas.

- Catwalks in Factories: Elevated pathways for equipment maintenance and monitoring.

- Marine Environments: Walkways in ports, harbors, and oil terminals that resist corrosion.

Specialized Industrial Applications

Steel grating also serves in niche applications that require unique designs and capabilities:

- Cooling Tower Grating: Used in power plants to provide a sturdy, non-slip surface.

- Ventilation Screens: Grating used for HVAC systems to facilitate airflow.

- Machinery Guards: Protective grating around rotating or hazardous equipment.

Key Benefits for Diverse Industries

Across all these applications, steel grating offers:

- Durability: Withstanding heavy loads and harsh environments.

- Safety: Slip-resistant surfaces and efficient drainage capabilities.

- Versatility: Customizable designs to suit specific requirements.

- Low Maintenance: Long service life with minimal upkeep needs.

By providing these products, steel grating factories contribute to the safety, efficiency, and sustainability of various industrial and commercial operations, showcasing their indispensable role in modern infrastructure and industry.

Buying from a Steel Grating Factory: What You Need to Know

When purchasing products from a steel grating factory, it’s essential to follow a clear, step-by-step process to ensure you receive exactly what you need. Here is a detailed guide to help you place your order efficiently.

Choosing the Right Material and Construction Type

The first step when ordering from a steel grating factory is to select the appropriate material for your project. Common materials include carbon steel, stainless steel, aluminum, and fiberglass. Each material has distinct advantages depending on the application. For instance, stainless steel is corrosion-resistant, ideal for marine or chemical environments, while aluminum grating is lightweight and works well in industries where weight is a concern. Additionally, for grating work that requires specific load-bearing capacities or non-slip properties, it’s essential to consider the precise needs of your application.

Next, choose the construction type. Factories offer various steel grating designs such as welded, press-locked, or swage-locked. Heavy-duty applications may require thicker bars and welded construction, while lighter projects can benefit from press-locked grating, which offers a sleek, aesthetic finish.

Specifying Product Dimensions, Surface Finish, and Load-Bearing Capacity

Once you’ve chosen the material and construction type, the next step is to define your grating’s dimensions. A steel grating factory will need details about the size, shape, and spacing of the bars. It’s also important to determine the surface finish you require. Common finishes include galvanized steel, powder-coated steel, or bare metal. A galvanized finish is recommended for outdoor or corrosive environments, as it adds an extra layer of protection against rust.

You must consider the load-bearing capacity. Whether the grating will support foot traffic, heavy machinery, or vehicles will influence the thickness and spacing of the bearing bars. Be sure to consult the factory’s load tables or guidelines to ensure the grating meets your structural requirements.

Discussing Custom Requirements with the Factory’s Technical Team

If your project requires unique specifications, discussing custom fabrication options with the factory’s technical team is essential. A reliable steel grating factory will offer custom fabrication services to meet specific project needs, such as non-standard dimensions, additional safety features like toe plates or nosings, and specialized coatings for added durability. Technical teams can also help you navigate complex requirements, ensuring that your order complies with safety standards and fits the application perfectly.

Custom orders may also involve specialized grating for industries like oil and gas, transportation, or marine sectors. By collaborating closely with the factory’s technical experts, you ensure that every detail, from load capacity to corrosion resistance, is addressed.

Key Features of an FRP Cable Threading Pipe Factory Explained

Successful Projects Using Steel Grating from a Steel Grating Factory

Steel grating has been an essential component in numerous successful projects across various industries. Each steel grating factory plays a critical role in delivering high-quality products tailored to specific project needs. Below, we highlight key examples of how steel grating has been effectively used in commercial, industrial, and environmental sectors.

Industrial Platforms

A steel grating factory recently completed a large-scale industrial project involving the construction of platforms for a major oil refinery. McNichols bar grating was used due to its durability and ability to withstand heavy loads and corrosive environments. The grating provided sturdy walkways for workers and easy access to machinery, while its open-grid design allowed for efficient drainage of liquids, essential in oil and gas applications. The custom fabrication ensured the grating fit perfectly, enhancing safety and functionality.

Bridges and Walkways

In the transportation sector, a steel grating factory supplied expanded metal grating for pedestrian bridges and safety walkways across a busy metropolitan area. The grating was chosen for its slip-resistant surface, lightweight design, and strength, making it perfect for high-traffic areas. The expanded metal grating was installed to allow water drainage during rain, reducing the risk of accidents and enhancing public safety. This project demonstrated the versatility of steel grating in both functional and aesthetic applications, as it blended seamlessly into the urban environment.

Environmental Projects

In a recent environmental project, stainless steel grating was used in wastewater treatment plants. A steel grating factory produced corrosion-resistant stainless steel grating for use in platforms and walkways within the facility. The stainless steel grating ensured long-term durability despite constant exposure to moisture and chemicals. Its open design also allowed for proper ventilation and reduced debris buildup, contributing to the efficiency and cleanliness of the plant.

Safety Walkways

Another notable project involved the installation of safety walkways in a large chemical manufacturing plant. A steel grating factory provided steel walkway grating, specifically Grip Strut safety grating, which offered enhanced traction, even in wet or greasy conditions. The plant’s management selected this type of grating to improve worker safety, particularly in high-risk areas. The custom-fabricated safety walkways were fitted to tight spaces around machinery, demonstrating the flexibility and adaptability of steel grating in complex industrial settings.

Top Features of the Best Fiberglass Street Rod Body

Advantages of Steel Grating Produced by a Steel Grating Factory

Steel grating produced by a steel grating factory offers a wide range of benefits, making it indispensable for numerous industries.

Here’s an in-depth explanation of each advantage:

High Strength and Load-Bearing Capacity

Steel grating is constructed with robust materials, such as carbon steel, stainless steel, or aluminum, which provide it with exceptional strength. Its structure is engineered to distribute loads evenly, enabling it to bear heavy weights without bending or deforming. This makes it suitable for high-load areas like bridges, heavy equipment platforms, and transportation infrastructure, ensuring safety and reliability even under extreme pressure.

Excellent Drainage Performance

The open grid design of steel grating allows water, snow, dust, and debris to pass through effortlessly. This prevents accumulation, which could otherwise compromise safety and functionality. For applications like trench covers, roadways, and outdoor platforms, this drainage capability ensures that the surfaces remain clean and dry, reducing maintenance requirements and extending the product’s lifespan.

Ventilation, Lighting, and Heat Dissipation

Steel grating’s perforated design enables air circulation, natural light penetration, and heat dispersion. In industrial environments such as factories, power plants, or boiler rooms, these features improve operational efficiency by maintaining optimal airflow and temperature regulation. Additionally, in outdoor settings, grating enhances visibility and provides a ventilated and illuminated environment.

Explosion-Proof and Anti-Skid Features

Steel grating can be manufactured with anti-skid serrations on its surface, which significantly enhance traction in slippery conditions. This makes it ideal for wet or icy areas, such as outdoor walkways, stair treads, and platforms. The explosion-proof properties of steel grating are essential in environments like oil refineries and chemical plants, where safety is paramount. These features prevent accidents and protect both workers and infrastructure.

Corrosion Resistance and Durability

Steel grating products are often treated with anti-corrosion coatings, such as galvanization or powder coatings, to withstand harsh environmental conditions. This makes them resistant to rust, chemical exposure, and abrasion, ensuring a long service life in corrosive environments like marine docks, wastewater treatment facilities, and industrial plants.

Simple and Aesthetic Design

The clean and uniform design of steel grating enhances the appearance of industrial and commercial spaces. Its functional yet sleek structure can be customized to match the design requirements of modern architecture, infrastructure, and public spaces. This balance between form and function makes it a practical and visually appealing choice.

Lightweight and Easy Installation

Despite its high strength, steel grating is lightweight due to its open structure and efficient design. This makes transportation, installation, and dismantling easier and less labor-intensive. In applications like temporary walkways, construction scaffolding, or mezzanine floors, this advantage reduces time and cost associated with installation.

Weather-Resistant and Safe Performance

Steel grating maintains its integrity in extreme weather conditions, including heavy rain, snow, and high humidity. The combination of anti-skid surfaces and weather-resistant coatings ensures that it performs reliably in adverse environments. This feature is particularly valuable in outdoor settings, such as pedestrian bridges and parking lots, where safety and durability are critical.

By leveraging these advantages, steel grating factories produce solutions that are versatile, reliable, and tailored to the needs of industries, contributing significantly to infrastructure development and workplace safety.

Production Process and Industry Standards in a Steel Grating Factory

The production process of a steel grating factory is a meticulously managed sequence that ensures high-quality products meeting industry standards. From raw material preparation to final inspections, every step is carried out with precision to deliver durable, reliable, and safe steel gratings. Below is an overview of the production process and the key industry regulations that must be adhered to during manufacturing.

Production Process in a Steel Grating Factory

Raw Material Workshop

The process begins in the raw material workshop, where high-quality materials such as carbon steel, stainless steel, or aluminum are carefully selected and prepared. The materials are inspected for compliance with specifications, such as thickness, tensile strength, and corrosion resistance. Any substandard materials are rejected to ensure the quality of the final product. The raw materials are then cut, shaped, and processed into standard sizes suitable for welding.

Key Activities:

- Material selection and quality checks.

- Cutting and shaping materials into required dimensions.

- Preparing materials for welding.

Welding Workshop

The welding workshop is where the core structure of the steel grating is formed. Using advanced welding equipment, the bearing bars and crossbars are joined to create a strong, durable grid structure. Depending on the type of grating being manufactured (e.g., welded grating, press-locked grating), the appropriate welding or locking techniques are applied. Automated welding processes ensure uniformity and precision, while skilled technicians perform quality checks at every stage.

Key Activities:

- Assembling bearing bars and crossbars.

- Performing welding or press-locking based on design specifications.

- Conducting interim inspections for structural integrity.

Product Workshop

In the product workshop, the welded grating undergoes finishing processes to enhance its functionality and appearance. This includes surface treatments such as galvanization, which provides corrosion resistance, or powder coating for aesthetic purposes. The finished gratings are inspected for compliance with dimensional accuracy, load-bearing capacity, and anti-slip properties. Once approved, they are packaged and prepared for shipment.

Key Activities:

- Surface treatments (e.g., galvanization, powder coating).

- Quality assurance inspections.

- Packaging and preparation for delivery.

Industry Regulations for Steel Grating Production

To ensure safety, durability, and environmental compliance, a steel grating factory must adhere to several industry regulations and standards, including:

Material Standards:

- ASTM (American Society for Testing and Materials): Specifies material properties such as tensile strength, corrosion resistance, and dimensional tolerances for steel gratings.

- DIN24537 (German Standard): Regulates the design and construction of locking steel gratings.

Welding Standards:

- AWS D1.1 (American Welding Society): Ensures high-quality welding practices and structural integrity.

- ISO 3834: Governs the quality requirements for welding processes.

Safety and Performance Standards:

- OSHA (Occupational Safety and Health Administration): Requires gratings to meet slip resistance and load-bearing safety standards for workplace environments.

- EN 1433 (European Standard): Regulates the performance of trench covers and drainage gratings for public use.

Environmental and Coating Standards:

- ISO 14001: Ensures that the production process is environmentally sustainable.

- ISO 1461: Governs the quality of galvanization to protect against corrosion.

By following this rigorous production process and adhering to established industry regulations, a steel grating factory ensures that its products meet the highest standards of quality, safety, and functionality, serving a wide range of industrial and commercial applications.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.