- Home

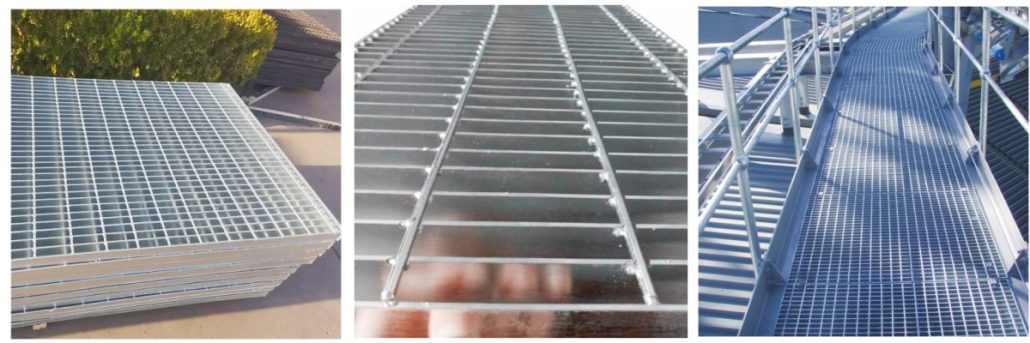

- Steel Walkway Grating

Custom Steel Walkway Grating for Platforms and Stairs

Steel walkway grating is used broadly across many rugged industrial and commercial applications such as walkways, ventilation, trench covers.

Steel Walkway Grating is economical, offering high strength for various industrial and commercial applications. It comes in different materials including stainless steel, aluminum, and primarily galvanized steel, which is noted for its cost-effectiveness and long service life. Steel Walkway Grating is most commonly used in settings requiring durable platforms for pedestrian and light vehicle traffic due to its load-bearing capacity.

Steel Walkway Grating is also available in various bearing bar spacing and thicknesses to suit different applications and load requirements. The standard versions include smooth top or serrated surfaces to enhance slip resistance. This grating is not only used for pedestrian pathways but also for floors, mezzanines, stair treads, and maintenance platforms, providing a stable and secure surface in demanding conditions such as weather extremes and heavy machinery operations. Its open grid design facilitates efficient drainage, reducing the risk of slips and falls in workplaces like warehouses and construction sites.Pultruded grating offers an alternative with the same functional advantages, along with increased corrosion resistance and a lighter weight, making it particularly useful in corrosive or chemical-prone environments.

Simplifying Your Life: Key Functionalities

| Attribute Name | Attribute Value |

|---|---|

| Product Name | Steel Walkway Grating |

| Place of Origin | Hebei, China |

| Brand Name | GangLong Fiberglass |

| Application | Outdoor, Trench, Walkway, Platform, Drainage Cover, Construction (Hotels, Villas, Apartments) |

| Material | Non-Alloy Steel, Alloy Steel, FRP GRP Fiberglass |

| Surface Treatment | Galvanized, Smooth, Gritted, PVC Coated |

| Technique | Pultrusion, Moulding, Centrifugal Casting |

| Features | Durable, Long-Lasting, High Strength, Anti-Fire, Anti-Corrosion, Good Compression Resistance,Easy installation,competitive pricing, expert support |

| Processing Services | Welding, Cutting, Bending, Moulding |

| Customization Options | Shape, Color (Gray, Red, White, Green, Blue, Yellow, etc.), Design Style (Contemporary, Traditional, Modern) |

| Warranty | 5 Years |

| Project Solution Capability | 3D Model Design |

| Certifications | Compliant with industry standards (Chemical composition: C, Mn, P, S, etc.) |

| After-Sale Service | Online technical support |

| Other | Meets regulatory standards, suitable for harsh outdoor environments |

| Packaging Details | Carton or pallet, with wood plate cover |

News

- Exploring the Benefits of Carbon Fiber Apparel

- How to Work with Carbon Fiber Successfully

- Carbon Fiber Suit: The Future of Lightweight Armor

- Is Carbon Fiber Armor the Future of Protection?

- Why White Carbon Fiber is Popular in Automotive Design

- Transparent Carbon Fiber Sheets Two Sided Gloss Twill

- Epoxy-Compatible Chopped Carbon Fiber Mat

- Carbon Fiber EG Hatch: Upgrade Your Civic Today

- The Benefits of Using Structural Carbon Fibre in Engineering

- How Many Layers of Layered Carbon Fiber Are Needed?

Types of Steel Walkway Grating

Bar Grating

- Description: Composed of parallel bars, this grating is known for its strength and durability.

- Applications: Commonly used in industrial settings, walkways, and platforms.

- Types:

- Heavy Duty: Designed for high-load applications.

- Light Duty: Suitable for pedestrian walkways and lighter loads.

Expanded Metal Grating

- Description: Made from a single sheet of metal that has been cut and stretched to form a mesh-like pattern.

- Advantages: Lightweight, slip-resistant, and allows for drainage.

- Applications: Ideal for walkways, catwalks, and security fencing.

Wire Mesh Grating

- Description: Constructed from welded wire, this type provides a flat surface with good visibility.

- Characteristics: Offers good airflow and light penetration.

- Applications: Used in stair treads, platforms, and industrial flooring.

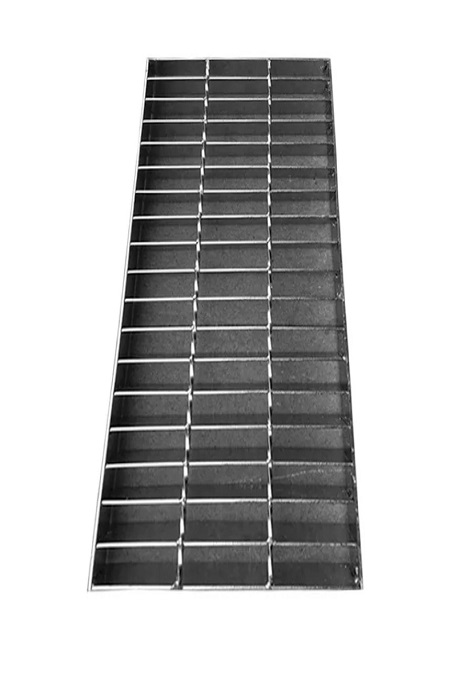

Tread Grating

- Description: Specifically designed for stairways, featuring a surface that enhances traction.

- Features: Often includes a slip-resistant surface and is available in various designs.

- Applications: Commonly used in commercial and industrial staircases.

Plastic Coated Grating

- Description: Steel grating coated with plastic for added protection against corrosion.

- Benefits: Increases longevity and provides a non-slip surface.

- Applications: Suitable for environments with exposure to chemicals or moisture.

Architectural Grating

- Description: Designed for aesthetic appeal while maintaining functionality.

- Features: Available in various patterns and finishes.

- Applications: Used in public spaces, parks, and modern building designs.

Key Considerations:

- Load Requirements: Different types of grating can support varying loads; choose based on application.

- Environment: Consider exposure to chemicals, moisture, and temperature when selecting materials.

- Safety Features: Slip resistance and visibility are critical for walkways.

These types of steel walkway grating offer various benefits and applications, making them suitable for a wide range of environments and uses.

Steel Walkway Grating Common Uses Steel Walkway Grating Common Uses

Here are some common uses of steel walkway grating:

1. Industrial Facilities

- Platforms and Walkways: Provides safe access over machinery and equipment.

- Catwalks: Allows maintenance personnel to move easily above production areas.

2. Stairways

- Stair Treads: Enhances safety with slip-resistant surfaces.

- Access Steps: Durable and weather-resistant for outdoor or indoor settings.

3. Commercial Buildings

- Elevated Walkways: Connects different parts of the facility without obstructing ground-level activity.

- Balconies and Viewing Areas: Offers structural support while maintaining visibility.

4. Parking Structures

- Grated Floors: Provides ventilation and drainage while supporting vehicle loads.

- Walkways: Ensures safe pedestrian movement within multi-level parking areas.

5. Wastewater Treatment Plants

- Access Platforms: Allows for safe access to treatment equipment.

- Grating Covers: Prevents debris from entering tanks while allowing liquids to flow.

6. Marine Applications

- Docks and Piers: Provides non-slip surfaces for pedestrians and equipment.

- Boat Ramps: Facilitates access for vehicles and personnel.

7. Mining and Oil Industries

- Work Platforms: Supports personnel and equipment in extraction sites.

- Trails and Access Roads: Enhances safety in rugged terrain.

8. Agricultural Settings

- Livestock Handling Areas: Offers drainage and cleanliness in animal enclosures.

- Feed Bunks: Provides structural support while minimizing waste.

9. Public Infrastructure

- Bridges and Walkways: Ensures pedestrian safety over roadways and waterways.

- Park Pathways: Durable surfaces for high foot traffic in recreational areas.

10. Chemical and Pharmaceutical Industries

- Access Platforms: Safe access to sensitive equipment and areas.

- Storage Racks: Supports heavy containers while allowing airflow.

These applications highlight the versatility and practicality of steel walkway grating in various settings, ensuring safety, durability, and efficiency.

Steel Walkway Grating Mechanical Properties

Here are the mechanical properties of steel walkway grating:

1. Tensile Strength

- Definition: The maximum amount of tensile (stretching) stress that a material can withstand before failure.

- Typical Values: Generally ranges from 250 MPa to 600 MPa, depending on the grade of steel used.

2. Yield Strength

- Definition: The stress at which a material begins to deform plastically.

- Typical Values: Commonly between 200 MPa and 400 MPa for structural steel.

3. Elastic Modulus (Young’s Modulus)

- Definition: A measure of the stiffness of a material, defined as the ratio of tensile stress to tensile strain.

- Typical Values: Approximately 200 GPa (gigapascals) for carbon steel.

4. Impact Resistance

- Definition: The ability of a material to absorb energy and resist shock loading.

- Considerations: Steel grating is often designed to withstand sudden loads and impacts, essential in industrial applications.

5. Fatigue Strength

- Definition: The strength of a material under repeated loading and unloading cycles.

- Considerations: Important for grating used in dynamic applications, such as catwalks and platforms subjected to foot traffic or machinery.

6. Corrosion Resistance

- Definition: The ability of a material to withstand deterioration caused by environmental factors.

- Considerations: While steel is prone to corrosion, coatings (like galvanization or powder coating) can significantly enhance durability.

7. Weight and Load-Bearing Capacity

- Description: Steel grating is designed to support specific loads based on its configuration and material thickness.

- Considerations: Load capacity varies with grating type (e.g., heavy-duty vs. light-duty) and bar spacing.

8. Ductility

- Definition: The ability of a material to undergo significant plastic deformation before rupture.

- Importance: Steel’s ductility allows it to absorb energy and deform under stress without breaking, making it safer in many applications.

9. Thermal Properties

- Thermal Conductivity: Steel has good thermal conductivity, making it effective for applications requiring heat dissipation.

- Expansion: Steel expands with heat, so considerations must be made for temperature fluctuations in design.

These mechanical properties make steel walkway grating a reliable choice for various applications, ensuring safety and longevity in demanding environments.

Steel Walkway Grating Weight

Factors Affecting Weight

The weight of Steel Walkway Grating is influenced by several key factors, including the thickness of the bars, the type of steel used, and the overall size of the grating. Thicker bars naturally add more weight, which can enhance the grating’s load-bearing capacity but may also require more robust structural support during installation. The material type, such as carbon steel or stainless steel, also plays a role—stainless steel tends to be slightly heavier due to its higher density and corrosion-resistant properties. The size of the grating, particularly its width and length, directly impacts its total weight, with larger panels weighing more.

Standard Weight Ranges

Understanding the weight of Steel Walkway Grating is crucial for planning both the installation process and the structural support needed. Light-duty grating, often used for pedestrian traffic, typically ranges from 15 to 30 pounds per square foot. This type is easier to handle and install but still provides ample strength for standard applications. On the other hand, heavy-duty grating, designed for industrial environments where it may need to support vehicles or heavy machinery, can weigh anywhere from 40 to 80 pounds per square foot or more. These weight ranges help in selecting the appropriate grating for your specific needs, ensuring both safety and efficiency in its application.

Heavy Duty Steel Walkway Grating

Definition and Applications

Heavy Duty Steel Walkway Grating is specifically designed to withstand the most demanding industrial environments. It is characterized by its thicker bars and stronger construction, which allow it to support heavy loads, including vehicles, forklifts, and other industrial machinery. This type of grating is commonly used in applications such as loading docks, industrial flooring, bridge decking, and high-traffic platforms where superior strength and durability are essential. The increased thickness of the bars not only enhances its load-bearing capacity but also ensures long-term performance in environments where regular wear and tear are significant concerns.

Strength and Durability

The strength of Heavy Duty Steel Walkway Grating is one of its most critical attributes. The grating is designed to bear substantial loads without deforming or losing its structural integrity. This makes it an ideal choice for environments where the grating will be subjected to frequent and heavy use. The durability of this grating is further enhanced by the use of high-quality materials, such as galvanized steel, which provides excellent resistance to corrosion, rust, and other forms of environmental degradation. This ensures that the grating remains functional and safe even in harsh conditions, reducing the need for frequent replacements and maintenance.

Safety is a paramount concern in industrial settings, and Heavy Duty Steel Walkway Grating is engineered to meet these demands. One of the key safety features is its slip-resistant surface, which is often serrated or designed with patterns that enhance traction, preventing slips and falls even in wet or oily conditions. This is particularly important in areas with high foot traffic or where machinery is frequently moved. Additionally, the structural integrity of heavy-duty grating ensures that it remains stable under pressure, minimizing the risk of accidents caused by shifting or collapsing surfaces. The combination of strength, durability, and safety features makes Heavy Duty Steel Walkway Grating an essential component in any industrial setting that requires reliable and secure flooring solutions.Safety Features

Thank you for your interest in our products. To receive our pricelist or for any inquiries, please fill out the form below. We will get back to you within 24 hours.

Walkway Grating Plastic

Comparison with Steel Walkway Grating

When comparing plastic walkway grating with Steel Walkway Grating, it’s essential to consider the specific needs of your project. Plastic grating, typically made from fiberglass-reinforced plastic (FRP), is lightweight, corrosion-resistant, and non-conductive, making it an excellent choice for environments where exposure to chemicals, moisture, or electricity is a concern. It is often used in chemical plants, food processing facilities, and areas prone to rust or electrical hazards. On the other hand, Steel Walkway Grating is known for its superior strength, load-bearing capacity, and long-term durability, making it the preferred option for heavy-duty industrial applications, such as factory floors, loading docks, and bridges, where the grating must support heavy equipment or vehicles.

Advantages and Disadvantages

Plastic grating offers several advantages over Steel Walkway Grating. Its lightweight nature makes it easier to handle and install, reducing labor costs and installation time. Additionally, plastic grating is highly resistant to corrosion, making it ideal for environments exposed to harsh chemicals or constant moisture. It also doesn’t require the same level of maintenance as steel, as it won’t rust or corrode over time. However, plastic grating does have its limitations. It lacks the strength and rigidity of steel, which means it is not suitable for applications where heavy loads or high traffic are involved. In scenarios where maximum durability and structural integrity are required, Steel Walkway Grating remains the superior choice due to its ability to withstand extreme conditions and support significant weight. Steel grating also offers better resistance to impact and is generally more versatile for a broader range of industrial applications.

Steel Walkway Grating Manufacturing Process

1. Material Selection

- Steel Grade: Choose appropriate grades of steel, commonly carbon steel, stainless steel, or alloy steel.

- Thickness and Dimensions: Determine specifications based on the intended use and load requirements.

2. Cutting

- Sheet Cutting: Large sheets of steel are cut to size using saws, lasers, or plasma cutting methods.

- Bar Preparation: Steel bars are cut to the required lengths for the grating design.

3. Welding

- Welded Grating: Bars are welded together at predetermined intervals to form a grid pattern.

- Methods:

- Resistance Welding: Commonly used for bar grating, where electrical resistance generates heat to fuse the bars.

- Arc Welding: Used for heavier applications requiring stronger joints.

4. Expansion (for Expanded Metal Grating)

- Metal Sheet Expansion: A sheet of steel is slitted and stretched to create a diamond-shaped mesh pattern.

- Process: The expansion process increases strength while reducing weight.

5. Surface Treatment

- Cleaning: Remove impurities, oils, and rust using methods like sandblasting or chemical cleaning.

- Coating:

- Galvanization: Coating with zinc to prevent corrosion.

- Powder Coating: Applying a polymer-based finish for additional protection and aesthetics.

6. Quality Control

- Inspection: Conduct dimensional checks, weld integrity tests, and surface finish evaluations.

- Testing: Mechanical tests may be performed to ensure the grating meets specified load requirements.

7. Finishing

- Cutting Edges: Ensure all edges are smooth and safe to handle.

- Packaging: Prepare the grating for shipping, often in bundles or pallets, to protect it during transport.

8. Delivery

- Logistics: Coordinate transportation to deliver the finished products to customers or job sites.

This manufacturing process ensures that steel walkway grating is durable, safe, and tailored to meet specific application needs.

Custom Steel Walkway Grating – GangLong Fiberglass

When it comes to steel walkway grating, custom solutions are often required to meet specific project needs. Custom steel grating provides versatility and adaptability for a wide range of applications, whether in industrial, commercial, or specialized environments. At GangLong Fiberglass, we pride ourselves on offering tailored grating solutions that meet our clients’ exact specifications. With an emphasis on both quality and flexibility, we ensure that our custom steel walkway grating serves your exact purpose.

Our service offers several customization options that enhance both the functionality and aesthetic appeal of the grating. We can accommodate almost any size, spacing, shape, and color preferences to ensure a seamless fit with your specific requirements.

Custom Manufacturing Services

We understand that every project has unique demands. That’s why we offer a wide range of manufacturing services to meet the most intricate custom needs. Our team is capable of handling large-scale projects that require significant customization. Here are some of the services we offer:

Cut to Size: We can cut the steel grating to the precise dimensions required for your walkway, ensuring that every piece fits perfectly into your design.

Welding, Banding, Skirting, or Protrusions: If your project calls for additional features such as welded seams, banding around the edges, skirting, or protruding elements, we can integrate these seamlessly into the grating.

Non-Standard Tolerances and Bearing Bar Spacing: For projects that need non-standard tolerances or unique spacing between the bearing bars, we can customize the grating to meet those exact requirements.

Cut-Outs for Penetration: If your walkway grating needs specific cut-outs for cables, pipes, or other utilities, we can provide precise cuts to allow for easy penetration through the grating panels.

Custom Accessories: We also provide custom accessories such as tread plates, lifting handles, and hinges to enhance the usability and efficiency of your walkway grating.

Why Choose Custom Steel Walkway Grating?

Choosing custom steel grating offers several advantages:

Perfect Fit: Customization ensures that the grating fits perfectly within the constraints of your design, eliminating the need for modifications to pre-made products.

Durability: Steel walkway grating is renowned for its durability and ability to withstand harsh environments, making it a perfect choice for industrial and commercial applications.

Enhanced Safety: Custom grating can be designed with specific safety features, such as anti-slip surfaces, to ensure a safer walking experience.

Long-Lasting Performance: With high-quality materials and attention to detail, custom steel walkway grating offers long-term reliability and performance, even in demanding conditions.

At GangLong Fiberglass, we are committed to working closely with our clients to ensure that every custom steel grating project meets their exact specifications. Whether you’re looking for a unique design or specialized functional requirements, we can deliver the custom solutions you need to bring your project to life.

If you’re ready to discuss your custom walkway grating needs, don’t hesitate to reach out and let us help you create the perfect solution for your project.

FAQs about Steel Walkway Grating

What are metal walkways called?

They can also be called platforms or catwalks, depending on their specific design and application.

What is walkway grating?

It provides a strong, durable surface for walking while minimizing slipping hazards.

Walkway grating is often used in industrial settings, pedestrian areas, and on bridges

What is the standard width of steel grating?

Custom widths can also be manufactured depending on specific project requirements.

What material is used for walkway grating?

Steel: This is the most widely used material due to its strength, durability, and load-bearing capacity. It can be made from carbon steel or stainless steel, with surface treatments like galvanization to prevent corrosion.

Aluminum: Used in environments where weight is a concern, aluminum grating is lightweight but still strong enough for many applications.

Fiberglass Reinforced Plastic (FRP): Also known as GRP (Glass Reinforced Plastic), this material is corrosion-resistant, lightweight, and non-conductive, making it ideal for chemical plants and electrical installations.

Ductile Iron: Commonly used in heavy-duty applications, especially in outdoor settings like bridges and roads.

Is GRP grating better than steel grating?

Corrosion Resistance: GRP is highly resistant to corrosion, making it superior in environments exposed to chemicals, saltwater, or other corrosive substances.

Weight: GRP is significantly lighter than steel, which makes it easier to install and reduces the overall load on structures.

Non-Conductivity: GRP is non-conductive, which is essential in electrical installations or environments where electrical hazards are a concern.

Maintenance: GRP requires less maintenance since it doesn’t rust or corrode.

Strength and Load Capacity: Steel grating generally offers higher strength and load-bearing capacity, which is crucial in heavy industrial settings.

In summary, GRP grating is often better for environments that demand corrosion resistance and lightweight materials, while steel is preferred for applications requiring high strength and durability.

What is the best material for a walkway?

Steel: Ideal for industrial environments requiring high load-bearing capacity. Galvanized or stainless steel is often used for outdoor applications due to its durability and resistance to rust.

GRP (Fiberglass): Best for corrosive environments, such as chemical plants or marine settings, due to its corrosion resistance, lightweight nature, and safety features like non-conductivity.

Aluminum: Suitable for walkways where weight is a concern, such as on ships or offshore platforms.

Wood or Composite Materials: Often used in residential or park settings, these materials provide aesthetic appeal but generally lack the durability and strength of metal grating.

What material is used for pedestrian walkways?

Concrete: Commonly used for its durability and ease of maintenance, particularly in urban settings.

Asphalt: Also widely used, especially for outdoor paths, due to its flexibility and ability to handle temperature changes.

GRP Grating: Used in industrial settings where corrosion resistance is important and in places where safety is a concern, such as areas around electrical installations.

Metal Grating (Steel or Aluminum): Used in areas where drainage is necessary, such as pedestrian bridges or platforms.

Pavers or Tiles: Often used for aesthetic purposes in public spaces.

Which type of grating is the best?

Steel Grating: Best for heavy-duty industrial applications requiring high load capacity and durability.

GRP Grating: Best for environments where corrosion resistance, non-conductivity, and low maintenance are critical.

Aluminum Grating: Best for applications where weight reduction is essential, such as on platforms and walkways in marine environments.

Ductile Iron Grating: Best for outdoor heavy-duty applications, such as drainage systems in roads and bridges.

How thick is grating sheet?

Standard Steel Grating: Typically ranges from 1/8 inch to 1/4 inch (3mm to 6mm) for the bearing bars. The overall thickness, including the grating height, can range from about 1 inch to 3 inches (25mm to 76mm).

GRP Grating: Usually ranges from 1 inch to 2 inches (25mm to 51mm) in thickness, with the bearing bars themselves being around 1/8 inch to 1/4 inch (3mm to 6mm) thick.

What is stainless steel grating?

Which material is used for grating?

Carbon Steel: Most common for general industrial use, offering strength and cost-effectiveness.

Stainless Steel: Used in environments requiring high corrosion resistance and hygiene.

Aluminum: Chosen for applications requiring lightweight and corrosion resistance.

GRP (Fiberglass): Ideal for corrosive environments, offering lightweight, non-conductive, and low-maintenance properties.

Ductile Iron: Used in heavy-duty outdoor applications.

What is the standard size of steel grating?

Panel Sizes: Standard panels are often 3 feet by 24 feet (915mm by 7,320mm) or 3 feet by 20 feet (915mm by 6,100mm).

Bearing Bar Spacing: The most common spacing is 19/16 inches (1-3/16 inches or 30mm) center-to-center of the bearing bars, although other spacings such as 15/16 inches (25mm) and 11/16 inches (19mm) are also used.

Cross Bar Spacing: Typically, cross bars are spaced at 4 inches (102mm) on center.

How do you size a grating?

Load Requirements: Determine the load that the grating must support. This includes both uniform loads (e.g., pedestrian traffic) and concentrated loads (e.g., machinery).

Span Length: The distance between supports is critical in sizing. Longer spans require stronger (thicker or deeper) bearing bars.

Bearing Bar Size and Spacing: Choose the size (height and thickness) of the bearing bars based on the load and span. Closer spacing increases the grating’s load capacity.

Deflection Criteria: Consider the maximum allowable deflection under load, which typically should not exceed 1/240th of the span length.

How do l choose a grating?

Load Capacity: Select grating that can handle the expected loads (both static and dynamic). Heavy-duty grating might be necessary for vehicular traffic, while lighter grating suffices for pedestrian use.

Material: Choose based on environmental conditions. Steel (carbon or stainless) is robust but may require coatings to prevent corrosion. GRP is ideal for corrosive environments.

Span and Deflection: Ensure the grating can span the distance between supports without excessive deflection.

Surface Type: Consider serrated or plain surfaces depending on slip resistance requirements.

Open Area: The open area of the grating affects drainage, air circulation, and light penetration. Choose based on the application's needs.

What is the minimum bearing length for grating?

Steel Grating: Generally, the minimum bearing length should be at least 1 inch (25mm) for end-bearing bars. However, 1-1/2 inches (38mm) is preferred for better load distribution.

GRP Grating: Typically requires a minimum bearing length of 1-1/2 inches (38mm) to ensure proper support.

What size mesh for steel grating?

19W4 Mesh: The most common mesh size for industrial flooring, with bearing bars spaced 19/16 inches (1-3/16 inches or 30mm) apart, and cross bars spaced 4 inches (102mm) apart.

Other Mesh Sizes: Can include 15W4, 11W4, and 7W4, where the number refers to the bearing bar spacing in 16ths of an inch (e.g., 15/16 inches, 11/16 inches, etc.).

What is the maximum gap in grating?

Standard Steel Grating: For pedestrian traffic, the maximum gap between bearing bars is typically around 1-3/16 inches (30mm) to prevent foot entrapment.

ADA Compliance: For grating to comply with the Americans with Disabilities Act (ADA), the openings must not allow a sphere greater than 1/2 inch (13mm) to pass through, with the long dimension of the openings perpendicular to the dominant direction of travel.

What is the formula for grating length?

Grating Length Formula:

Grating Length=Number of Bearing Bars×Bearing Bar Spacing+Allowance for Bearing Lengths

The actual length also needs to consider the allowance for any required bearing length at the ends (typically around 1 to 1-1/2 inches per end).

How thick is 19w4 grating?

Bearing Bar Height: Common heights include 1 inch, 1-1/4 inches, 1-1/2 inches, 2 inches, etc.

Bearing Bar Thickness: Typically ranges from 1/8 inch (3mm) to 1/4 inch (6mm).

Example: A 19W4 grating with a 1-1/4 inch bearing bar height and 3/16 inch thickness is a common configuration.

What is the deflection limit for steel grating?

Standard Deflection Limit: Typically, the maximum deflection under load should not exceed 1/240th of the span length. For instance, for a span of 24 feet, the maximum deflection should be 0.1 feet (1.2 inches or about 30mm).

Higher Loads: For applications with heavy loads, a stricter deflection limit (e.g., 1/360th of the span) might be used to ensure minimal movement.

How thick is heavy duty grating?

Bearing Bar Thickness: Heavy-duty gratings often have bearing bars with a thickness of 1/4 inch (6mm) or more.

Bearing Bar Height: Heights typically range from 2 inches (51mm) to 6 inches (152mm) or more, depending on the span and load requirements.

How much does a square meter of steel grating weight?

Standard Weight: A typical steel grating might weigh around 30 to 50 kilograms per square meter (kg/m²) for standard configurations like 19W4 with 1-1/4 inch bearing bars.

Heavy-Duty Grating: Can weigh upwards of 60 to 80 kg/m² or more, depending on the bearing bar thickness and height.

What is mild steel grating?

Characteristics: Mild steel is known for its ductility, malleability, and ease of welding, making it a cost-effective choice for many applications.

Applications: Often used in industrial flooring, walkways, platforms, and stair treads, where high strength and toughness are required but corrosion resistance is not a primary concern.

Surface Treatments: To improve its resistance to corrosion, mild steel grating is often galvanized or coated with other protective layers.

What is metal grating called?

What can l use instead of steel grating?

GRP/FRP Grating (Glass Reinforced Plastic/Fiberglass Reinforced Plastic): Corrosion-resistant, lightweight, and non-conductive, ideal for corrosive environments or areas with electrical hazards.

Aluminum Grating: Lightweight and resistant to corrosion, often used in marine and outdoor applications.

Wood or Composite Materials: For applications where metal grating might not be suitable, such as in residential or decorative environments.

Concrete or Pavers: For solid surfaces that need to bear heavy loads without the need for drainage.

What is the difference between grating and chequered plate?

Chequered Plate (also known as Tread Plate): A solid metal plate with a raised, diamond-shaped pattern for slip resistance. It provides a continuous surface and is used where a solid, non-slip surface is required.

What are the two types of grating?

Bar Grating: Made from metal bars welded, swaged, or locked together to form a grid. Bar grating includes varieties like welded, press-locked, and swaged.

GRP/FRP Grating: Made from fiberglass-reinforced plastic, offering corrosion resistance and non-conductivity, used primarily in corrosive environments.

Why use steel grating?

Strength and Durability: Steel grating can support heavy loads and withstand harsh environments.

Cost-Effective: Compared to other materials, steel offers a good balance of strength and cost.

Versatility: It can be used in a wide range of applications, from industrial flooring to drainage covers.

Customization: Steel grating can be manufactured to various sizes, shapes, and specifications to meet specific needs.

What is the most common grating?

What is galvanized steel grating?

What are the different types of grating in steel structure?

Welded Bar Grating: The most common type, where the cross bars are welded to the bearing bars, creating a strong and durable grid.

Press-Locked Grating: Made by pressing cross bars into bearing bars under high pressure, creating a flush surface without welding.

Swaged Grating: Produced by mechanically locking the cross bars to the bearing bars, often used for aluminum grating.

Heavy-Duty Grating: Designed for high-load applications, featuring thicker and deeper bearing bars.

Serrated Grating: Has serrated bearing bars for additional slip resistance.

What is grating in landscape?

Drainage Grating: Covers for storm drains or channels to allow water to flow through while preventing debris from entering the drainage system.

Tree Grates: Placed around the base of trees to protect roots and provide a walking surface, while allowing water and air to reach the soil.

Walkway Grating: Used for pedestrian pathways, often in parks or outdoor spaces, allowing for drainage and air circulation.

What is the difference between expanded metal and grating?

Grating: Typically made from separate bars welded or locked together to form a grid. Grating is stronger in load-bearing applications and is used in flooring, platforms, and drainage covers.

What is the difference between grating and grid?

Grid: A more general term that refers to any framework of spaced bars or wires. While grating is a type of grid, not all grids are designed for load-bearing applications. Grids can also refer to non-structural frameworks, such as those used in fencing or decorative applications.

What is a serrated grating?

How do you install steel grating?

Prepare the Support Structure: Ensure that the supporting structure is level, secure, and capable of bearing the load that the grating will carry. The structure should be clean and free from debris or any obstacles.

Position the Grating Panels: Place the grating panels on the support structure with the bearing bars oriented in the direction of the span. Ensure that each panel is properly aligned and seated on the supports.

Check for Proper Bearing: Ensure that the grating panels rest on the supports with adequate bearing length (usually at least 1 inch on each side). The grating should not overhang excessively or be unsupported in any areas.

Fasten the Grating: Secure the grating to the supporting structure using appropriate fasteners such as saddle clips, hold-down clips, or welding. Fasteners should be installed at regular intervals, typically at each corner and at intermediate points along the span, to prevent movement and ensure stability.

Align Adjacent Panels: Ensure that adjacent panels are aligned correctly to create a uniform, continuous surface. If necessary, use clips or other connectors to align and secure the panels to each other.

Inspect and Test: After installation, inspect the grating for proper alignment and secure attachment. Perform a load test if required, to ensure that the grating can support the expected loads without excessive deflection or movement.

What is the minimum bearing for steel grating?

Standard Bearing Length: The minimum bearing length is typically 1 inch (25mm) for each end of the grating. However, for heavier loads or larger spans, a bearing length of 1-1/2 inches (38mm) or more may be recommended to ensure proper load distribution and prevent sagging.

How do you fasten steel fascia?

Measure and Cut: Measure the length of the fascia required and cut the steel fascia to size using appropriate cutting tools, such as metal shears or a saw with a metal cutting blade.

Position the Fascia: Place the steel fascia over the edge of the roof or the structure it is intended to cover. Ensure it is aligned properly with the roofline or the structure's edge.

Attach with Screws or Nails: Use self-tapping screws or nails designed for metal to attach the fascia to the underlying structure. Fasten at regular intervals (typically every 12-24 inches) along the top edge where it meets the roof and along the bottom edge.

Overlap Joints: Where two pieces of fascia meet, overlap them slightly and secure them with additional screws or nails to ensure a continuous and secure connection.

Seal Joints: Use sealant or caulking to seal any gaps at the joints or ends to prevent water ingress.

What are the support requirements for grating?

Support Spacing: The spacing of supports (beams or ledges) should match the load-bearing capacity of the grating and minimize deflection. Typically, support spacing ranges from 3 to 4 feet (0.9 to 1.2 meters) for standard industrial grating, depending on the load and grating type.

Bearing Length: Ensure a minimum bearing length of 1 to 1-1/2 inches (25 to 38mm) on each end of the grating.

Alignment: Supports must be level and aligned properly to prevent twisting or uneven load distribution on the grating.

Load Capacity: The support structure must be strong enough to bear the expected loads, including dynamic loads (e.g., vehicles or heavy equipment).

How do you place grating?

Align the Grating: Position the grating panels on the supporting structure with the bearing bars oriented in the direction of the span (the distance between supports).

Ensure Proper Bearing: Ensure that each grating panel rests securely on the supports with adequate bearing length.

Secure the Panels: Use fasteners, such as clips or bolts, to secure the grating to the supports. Fasten at regular intervals to prevent movement.

Check Alignment: Ensure that adjacent grating panels are aligned properly, with no gaps or overlaps that could pose a safety risk or affect load distribution.

Inspect Placement: Verify that the grating is securely fastened, properly aligned, and free from movement or deflection.

How do you secure bar grating?

Use Saddle Clips: Saddle clips are commonly used to fasten grating to the supporting structure. Place the clip over the bearing bar, and secure it with a bolt or screw that attaches to the underlying support.

Use Hold-Down Clips: Hold-down clips can be used to secure grating panels to the supports. These clips fit over the grating bars and are bolted to the structure.

Weld the Grating: For permanent installations, grating can be welded directly to the supporting structure. Weld at the intersections of the bearing bars and supports, typically at the corners and at intermediate points.

Use Bolts: Bolts can be used to secure grating panels to the supports, especially in applications where the grating may need to be removed or adjusted in the future.

What is the clip spacing for grating?

Standard Spacing: Clips should be placed at each corner of the grating panel, as well as at intermediate points along the bearing bars. A common spacing is every 2 to 4 feet (0.6 to 1.2 meters), depending on the load and application.

Heavy-Duty Applications: In areas with heavy traffic or where grating panels are subject to dynamic loads, clip spacing may be reduced to every 1 to 2 feet (0.3 to 0.6 meters) for added security.

How do you align a grating?

Position the Panels: Place the grating panels on the support structure, ensuring the bearing bars are oriented in the direction of the span.

Align Adjacent Panels: Ensure that adjacent panels are flush with each other, with no gaps or overlaps at the edges. Use temporary clamps or clips to hold the panels in place if necessary.

Check for Leveling: Verify that the grating is level across the entire surface. Adjust the support structure or the grating placement if necessary to eliminate any unevenness.

Secure the Grating: Once aligned, secure the grating panels to the supports using clips, bolts, or welds. Ensure that the panels do not shift during fastening.

Final Inspection: After securing, inspect the entire installation to ensure that the grating is properly aligned and securely fastened.

Which way does grating span?

Thank you for your interest in our products. To receive our pricelist or for any inquiries, please fill out the form below. We will get back to you within 24 hours.