Vinyl backed fiberglass insulation is a fiberglass sheet versatile insulation material made by combining traditional fiberglass with a layer of vinyl backing. This backing adds durability and moisture resistance, making it ideal for environments where humidity is a concern, such as basements or metal buildings. Vinyl backed fiberglass insulation is commonly used in both residential and commercial settings, providing excellent thermal resistance while protecting the insulation from moisture damage. The vinyl layer acts as a protective barrier, preventing water vapor from penetrating the insulation and helping to extend its lifespan. It is a practical choice for areas that require both insulation and moisture control. Vinyl backed fiberglass insulation offers thermal protection, moisture control, and durability, making it ideal for metal buildings and improving indoor comfort.

What is Vinyl Backed Fiberglass Insulation?

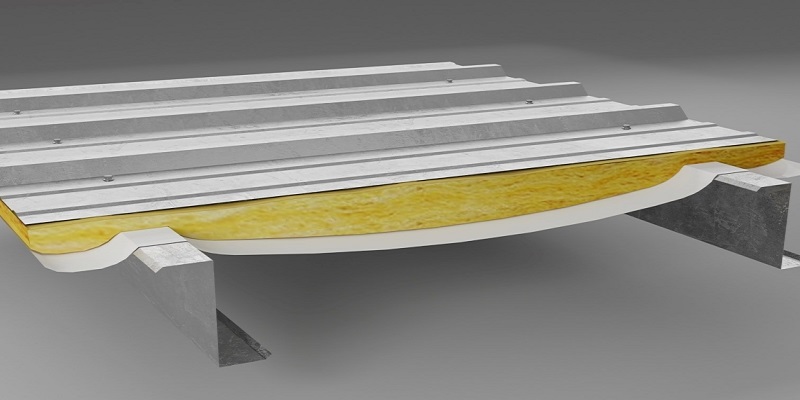

Vinyl-backed fiberglass insulation consists of fiberglass material covered by a layer of vinyl, which adds strength, moisture resistance, and ease of handling. The fiberglass itself is made from fine strands of glass that trap air, making it an excellent insulator. This insulation material is known for its ability to resist heat flow, which helps regulate indoor temperatures, reduces energy consumption, and improves overall comfort within buildings. Additionally, cover fiberglass insulation is a great option for areas requiring extra protection, as it provides a protective layer that further enhances the insulation’s durability and resistance to external elements.

The addition of the vinyl facing makes this insulation especially suited for areas where moisture control is essential, such as basements, crawl spaces, and metal buildings. The vinyl backing helps to prevent moisture from seeping into the insulation, thereby reducing the risk of mold growth, rust, and other moisture-related damage. GangLong Fiberglass offers a wide range of vinyl backed fiberglass insulation products in different thicknesses and R-values, allowing builders to choose the right insulation for their specific project.

Composition and Structure

- Fiberglass Core: The core of this insulation consists of fine strands of glass woven into a fibrous material. These fibers trap air, creating an effective barrier against heat transfer.

- Vinyl Facing: A durable layer of vinyl is adhered to one side of the fiberglass, enhancing the material’s strength, moisture resistance, and ease of handling.

- Benefit: The vinyl backing not only protects the fiberglass but also simplifies installation, providing a clean and professional finish.

Thermal Efficiency

- Heat Resistance: The fiberglass component of this insulation is highly effective at resisting heat flow, which helps maintain consistent indoor temperatures.

- Energy Savings: By reducing heat loss in winter and heat gain in summer, vinyl backed fiberglass insulation lowers energy consumption and enhances comfort in buildings.

Moisture Control

- Vapor Barrier: The vinyl facing acts as a vapor barrier, preventing moisture from penetrating the insulation.

- Mold and Rust Prevention: By keeping the fiberglass dry, the vinyl layer reduces the risk of mold growth, rust, and other moisture-related damage.

- Ideal Applications: This makes it particularly suitable for basements, crawl spaces, and metal buildings, where humidity and condensation are common.

Durability

- Reinforced Backing: The vinyl layer adds durability to the insulation, making it more resistant to wear and tear during installation and use.

- Long-Lasting Protection: This durability ensures that the insulation remains effective over time, even in challenging environments.

Versatility and Application

- Wide Range of Uses: Vinyl backed fiberglass insulation is suitable for residential homes, commercial buildings, and industrial facilities, including warehouses and manufacturing plants.

- Customizable Options: Available in various thicknesses and R-values, it allows builders to select the right insulation for their specific needs.

- GangLong Fiberglass: Manufacturers like GangLong Fiberglass offer a diverse range of products tailored to unique project requirements, ensuring compatibility with different building designs.

Additional Benefits

- Noise Reduction: The fiberglass core also provides sound-dampening properties, reducing noise levels in the insulated space.

- Fire Resistance: Fiberglass is inherently fire-resistant, and the vinyl layer can be enhanced with fire-retardant additives for added safety.

- Aesthetic Appeal: The vinyl facing provides a clean, finished look, eliminating the need for additional coverings.

Vinyl backed fiberglass insulation is a durable, efficient, and versatile insulation solution that combines the benefits of thermal protection, moisture control, and enhanced durability. With its ability to regulate indoor temperatures, prevent moisture damage, and improve energy efficiency, it is a preferred choice for a variety of applications, from residential renovations to large-scale industrial projects. By selecting the appropriate product, such as those offered by GangLong Fiberglass, builders can ensure long-lasting and effective insulation for any environment.

Vinyl Backed Fiberglass Insulation Price

Vinyl backed fiberglass insulation is a versatile material widely used in construction for its durability, thermal efficiency, and moisture control. When determining the cost of vinyl backed fiberglass insulation, several factors play a key role. The price can vary based on the insulation’s thickness, R-value, and the specific requirements of the project. GangLong Fiberglass offers a variety of vinyl backed fiberglass insulation products, ensuring builders and homeowners have access to high-quality materials that meet their needs while fitting within a budget.

The price of vinyl backed fiberglass insulation can vary depending on several factors, including the thickness, R-value, and size of the insulation. Thicker insulation with higher R-values, such as R19 or R30, tends to be more expensive due to the increased material costs and the higher level of thermal protection it provides. However, investing in higher R-value insulation can result in significant energy savings over time, making it a cost-effective option for projects that prioritize energy efficiency.

GangLong Fiberglass offers a range of vinyl backed fiberglass insulation products at competitive prices, ensuring that customers have access to high-quality insulation without exceeding their budget. The company also provides bulk purchasing options, which can further reduce costs for large construction projects.

Vinyl backed fiberglass insulation is an investment in the long-term efficiency and durability of a building, offering benefits that far outweigh the initial costs. By choosing the right insulation for your project, you can ensure that your building remains energy-efficient, comfortable, and protected from moisture and fire hazards for years to come.

Average Price Ranges for Different Thicknesses and R-Values

- Thinner Insulation (Lower R-Values):

Vinyl backed fiberglass insulation with lower R-values, such as R11 or R13, typically costs between $0.50 and $1.00 per square foot. This insulation is suitable for mild climates or projects requiring minimal thermal resistance. - Thicker Insulation (Higher R-Values):

For insulation with higher R-values, such as R19 or R30, prices range from $1.50 to $2.50 per square foot. These options are ideal for colder climates or applications demanding greater energy efficiency, like metal buildings or attics. - Special Features and Aesthetic Options:

Insulation with specialized vinyl backing, such as white vinyl for enhanced moisture resistance and a clean appearance, may cost slightly more. The added benefits of durability and aesthetics make it a preferred choice for exposed areas like basements or crawl spaces.

Factors That Influence the Price of Vinyl Backed Fiberglass Insulation

Thickness and Material Requirements:

Thicker insulation requires more fiberglass material and backing, increasing production costs. Projects prioritizing high energy efficiency often opt for thicker insulation.

R-Value:

Higher R-values mean better thermal resistance but also a higher price. For example, R30 insulation is more expensive than R13 due to its superior insulating capabilities.

Project Scale and Scope:

Large projects, such as warehouses or industrial facilities, require more insulation, driving up total costs. Bulk discounts can help offset these expenses.

Vinyl Backing Type:

The type of vinyl backing, such as reinforced or mold-resistant vinyl, affects the cost. Premium vinyl options offer additional protection and durability, justifying the higher price.

Installation and Labor Costs:

The complexity of the installation process and labor requirements can add to the overall cost, especially for custom or large-scale applications.

Vinyl backed fiberglass insulation is a durable and efficient choice for a wide range of applications, offering excellent thermal performance and moisture control. Its price varies depending on thickness, R-value, and project needs. While higher-quality insulation may cost more upfront, the long-term benefits of energy savings and durability make it a worthwhile investment. By considering the factors influencing price and exploring options like those offered by GangLong Fiberglass, you can find cost-effective insulation solutions tailored to your project’s requirements.

Overview of Purchasing Options from GangLong Fiberglass

GangLong Fiberglass offers a range of vinyl backed fiberglass insulation products that are suitable for a variety of applications, from residential homes to large industrial facilities. Purchasing options include insulation rolls, which are convenient for covering large areas quickly, as well as precut panels for more precise installations.

For those seeking insulation with a specific R-value, GangLong Fiberglass provides products that cater to different performance needs. For example, R19 vinyl backed fiberglass insulation is an excellent option for energy-efficient construction projects, while R13 insulation may be suitable for areas with less stringent insulation requirements. The company ensures that each product is manufactured to the highest standards, ensuring durability, fire resistance, and moisture control.

GangLong Fiberglass also offers competitive pricing on all of their vinyl backed fiberglass insulation products, with bulk discounts available for larger orders. This makes it easier for contractors and builders to stay within budget while ensuring that their projects meet both energy efficiency and fire safety standards. Customers can also take advantage of customization options, where insulation thickness and vinyl backing type can be adjusted to meet specific project needs.

Additionally, GangLong Fiberglass provides detailed product information to help customers make informed decisions about which type of insulation is best suited for their project. Whether you are insulating a metal building, a commercial warehouse, or a residential home, GangLong Fiberglass has the right solution at a competitive price.

White Vinyl Faced Insulation

White vinyl faced insulation is a versatile insulation product that combines thermal efficiency, moisture resistance, and aesthetic appeal. It is specifically designed for areas where the insulation will be visible, such as basements, garages, utility rooms, or commercial spaces, offering both functional benefits and a clean, professional appearance. This insulation features a fiberglass core for excellent thermal performance, covered by a durable white vinyl facing that enhances both its durability and visual appeal. Below, we explore what white vinyl faced insulation is, its key advantages, and its common applications.

What is White Vinyl Faced Insulation?

White vinyl faced insulation consists of fiberglass insulation bonded with a white vinyl facing. The fiberglass core provides high thermal resistance (R-value) and sound-dampening properties, while the vinyl facing acts as a vapor barrier and adds strength and durability.

- Fiberglass Core: Traps air to minimize heat transfer, improving energy efficiency.

- White Vinyl Facing: Enhances the insulation’s moisture resistance and provides a polished, finished look for exposed installations.

This type of insulation is typically available in rolls, making it easy to install in walls, ceilings, and floors.

Advantages of White Vinyl Faced Insulation

Aesthetic Appeal

- The white vinyl facing provides a clean, polished appearance, making it ideal for visible installations in basements, garages, and utility rooms.

- Eliminates the need for additional coverings, reducing costs while improving the space’s visual appeal.

Thermal and Moisture Protection

- The fiberglass core delivers excellent thermal resistance, reducing energy loss and maintaining indoor comfort.

- The vinyl facing acts as a vapor barrier, preventing moisture intrusion and protecting against mold, rust, and water damage.

Durability and Maintenance

- The reinforced vinyl layer resists tears, dust, and debris, ensuring long-term performance in challenging environments.

- Easy to clean, making it suitable for spaces prone to wear and tear.

Versatility

- Available in various thicknesses and R-values, white vinyl faced insulation meets the needs of diverse projects, from residential renovations to large commercial installations.

Applications of White Vinyl Faced Insulation

Residential Applications

- Used in basements, crawl spaces, and utility rooms for areas where insulation remains exposed.

- Improves energy efficiency in homes while providing a clean, finished look.

Commercial Applications

- Ideal for garages, warehouses, and industrial buildings, offering both thermal performance and a professional appearance.

- Commonly installed in metal buildings where moisture control is critical.

Versatile Installation Areas

- Effective in walls, ceilings, and floors, making it a practical solution for a wide range of building projects.

- Can be used to reduce noise levels in shared spaces, such as multi-family housing or commercial offices.

White vinyl faced insulation is an exceptional choice for projects that require both high-performance insulation and a polished appearance. By combining the thermal and moisture-resistant properties of fiberglass with the clean, durable finish of white vinyl, this insulation offers a practical and aesthetically pleasing solution for residential, commercial, and industrial spaces. Its ease of installation, maintenance, and versatility make it a preferred option for exposed applications, ensuring energy efficiency and durability in any project.

R19 Vinyl Faced Insulation

One of the most popular options within the vinyl backed fiberglass insulation range is R19 vinyl faced insulation. This particular type of insulation provides an R-value of 19, which means it offers high resistance to heat flow. The higher the R-value, the better the insulation performs in keeping buildings warm in the winter and cool in the summer. R19 insulation is ideal for spaces that require enhanced thermal efficiency, such as attics, walls, and ceilings.

GangLong Fiberglass R19 vinyl-faced insulation and unfaced fiberglass insulation both come in a variety of sizes to suit different installation needs. For example, the vinyl-faced version can be purchased in large rolls for easy installation in expansive areas like warehouses or commercial buildings, while unfaced fiberglass insulation is an excellent option for areas that don’t require a moisture-resistant facing. The vinyl facing on the R19 insulation ensures it remains durable and resistant to wear and tear, even in environments where humidity or moisture is a concern. In contrast, unfaced fiberglass insulation is often preferred in dry environments where additional moisture resistance is unnecessary. Both types, whether faced or unfaced, provide excellent thermal performance, making them top choices for projects that prioritize both energy efficiency and long-lasting durability.

In addition to its thermal properties, R19 vinyl faced insulation also provides soundproofing benefits, making it an excellent option for spaces where noise reduction is important. Whether used in a home or a commercial setting, this insulation can help create a quieter and more comfortable indoor environment.

Common Uses for R19 Insulation in Areas That Require High Energy Efficiency

R19 vinyl faced insulation is commonly used in areas that require a high level of energy efficiency, such as attics, exterior walls, and floors. These are the parts of a building where heat loss or gain is most likely to occur, and by installing R19 insulation, property owners can reduce their energy consumption and save on heating and cooling costs.

In residential buildings, R19 vinyl-faced insulation is often installed in attics to prevent heat from escaping during the winter months and to keep homes cooler in the summer. It is also frequently used in exterior walls to improve the thermal envelope of the home, reducing drafts and maintaining a consistent indoor temperature. Additionally, fiberglass insulation for crawl spaces is also an effective solution to prevent heat loss and moisture buildup in these often-overlooked areas. This type of R19 vinyl-faced insulation is also beneficial in floors, where it helps to keep basements or crawl spaces insulated from the rest of the house, further enhancing energy efficiency.

In commercial and industrial settings, R19 vinyl faced insulation is ideal for large metal buildings or warehouses. These structures often experience significant temperature fluctuations due to the metal exterior, but installing vinyl backed fiberglass insulation can help regulate indoor temperatures, reduce energy costs, and provide a more comfortable working environment.

R19 Vinyl Faced Insulation for High-Efficiency Projects

R19 vinyl faced insulation is a popular choice for projects that require high levels of thermal resistance. The R19 rating indicates that the insulation provides excellent heat flow resistance, making it ideal for use in walls, ceilings, and floors where energy efficiency is a top priority.

R19 vinyl faced insulation is commonly used in residential and commercial buildings to improve energy efficiency and reduce heating and cooling costs. The vinyl facing adds a layer of moisture protection, ensuring that the insulation remains effective even in damp environments. This combination of thermal resistance and moisture control makes R19 vinyl faced insulation a reliable choice for projects where both energy efficiency and durability are essential.

In addition to its energy-saving benefits, R19 vinyl faced insulation also contributes to improved indoor comfort. By reducing heat transfer, it helps maintain consistent indoor temperatures, making living and working spaces more comfortable year-round.

Vinyl Backed Fiberglass Insulation for Metal Buildings

Metal buildings face unique challenges, such as condensation, temperature regulation, and noise control. Vinyl backed fiberglass insulation is specifically designed to address these issues by combining thermal efficiency, moisture resistance, and durability. Below is a detailed and organized description of its features, benefits, and applications.

Key Features of Vinyl Backed Fiberglass Insulation

Vinyl backed fiberglass insulation is uniquely designed to meet the demands of metal buildings. It integrates advanced material properties to provide thermal protection, moisture resistance, and long-lasting durability. These features make it one of the most effective insulation options for both industrial and commercial metal structures.

- Fiberglass Core: The fiberglass layer provides excellent thermal insulation by reducing heat transfer, stabilizing indoor temperatures, and enhancing energy efficiency.

- Vinyl Backing: Acts as a vapor barrier, preventing moisture from penetrating the insulation and protecting the building from condensation-related issues, such as rust or mold growth.

- Customization: Available in various thicknesses and R-values to suit different climates and project requirements.

- Ease of Installation: Comes in rolls, making it easy to install in large metal buildings and customize for specific spaces.

Benefits of Vinyl Backed Fiberglass Insulation for Metal Buildings

Vinyl backed fiberglass insulation offers multiple benefits, from controlling temperature and moisture to reducing noise and enhancing durability. These advantages make it an ideal choice for metal buildings that require reliable, long-term insulation solutions.

Thermal Efficiency

- Insulation reduces heat transfer through the metal walls and roofs, helping maintain stable indoor temperatures.

- Prevents excessive heating in summer and heat loss in winter, reducing energy consumption and utility costs.

Moisture Protection

- The vinyl backing acts as a vapor barrier, preventing condensation inside the insulation.

- Moisture resistance helps protect the metal structure from corrosion and the insulation from mold and degradation.

Durability and Longevity

- The vinyl facing adds an extra layer of protection, making the insulation resistant to wear and tear.

- Ensures long-term performance, even in environments with fluctuating temperatures and high humidity.

Noise Reduction

- Fiberglass absorbs sound, reducing noise levels inside the building.

- Beneficial for industrial spaces with loud machinery or for reducing noise caused by rain or hail hitting the metal roof.

Applications of Vinyl Backed Fiberglass Insulation in Metal Buildings

Vinyl backed fiberglass insulation is a versatile solution that can be used across a wide range of applications. Its adaptability makes it suitable for industrial, agricultural, and commercial metal buildings.

Industrial Buildings

- Warehouses, factories, and manufacturing facilities benefit from the insulation’s ability to control temperature and reduce energy costs.

- Helps protect stored goods and equipment from damage caused by temperature extremes or moisture.

Agricultural Buildings

- Ideal for barns, storage facilities, and animal shelters where moisture control is crucial to protect feed, equipment, and livestock.

- Ensures a stable environment, reducing the risk of moisture-related damage.

Commercial Buildings

- Retail spaces and commercial offices in metal buildings use insulation to improve energy efficiency and indoor comfort.

- Enhances the building’s overall sustainability by reducing heating and cooling demands.

Installation Benefits

Vinyl backed fiberglass insulation is designed to simplify the installation process while providing maximum performance. These benefits make it an efficient choice for large-scale projects or spaces with specific needs.

- Large Coverage: Rolls of vinyl backed fiberglass insulation are designed to cover large areas efficiently, reducing installation time.

- Flexibility: The insulation can be easily cut to fit irregular spaces or challenging areas, ensuring a seamless installation.

- Durable Finish: The vinyl facing provides a clean, professional look, making it suitable for exposed installations in industrial or commercial settings.

Energy Efficiency and Cost Savings

Vinyl backed fiberglass insulation is a cost-effective solution that enhances energy efficiency and reduces long-term expenses. It offers both immediate and ongoing benefits for building owners.

- By improving thermal performance, vinyl backed fiberglass insulation reduces heating and cooling costs, especially in large metal buildings with significant energy demands.

- The insulation’s durability minimizes maintenance and replacement costs over time, making it a cost-effective solution.

Noise Control

Metal buildings are particularly prone to noise from external elements and internal operations. Vinyl backed fiberglass insulation addresses this challenge effectively.

- Metal buildings are prone to noise, especially during rain or hailstorms.

- Fiberglass insulation absorbs sound, creating a quieter and more comfortable indoor environment for occupants.

Products and Customization

GangLong Fiberglass offers a range of vinyl backed fiberglass insulation products tailored to various needs. These customizable options ensure optimal performance for every project.

- Variety of R-Values: Available in R-values ranging from R11 to R30, ensuring compatibility with different climates and energy requirements.

- Customization Options: Products from manufacturers like GangLong Fiberglass are tailored to specific project needs, including thickness, size, and moisture-resistant features.

In fact, fiberglass insulation with vapor barrier is an ideal choice for such applications, as it enhances the overall protection against moisture, ensuring long-term durability of both the insulation and the building structure.Vinyl backed fiberglass insulation is an essential solution for metal buildings, addressing thermal regulation, moisture control, and noise reduction while enhancing energy efficiency and durability. With its customizable options, ease of installation, and long-term cost savings, it is a practical and effective choice for industrial, agricultural, and commercial metal structures. By choosing high-quality products like those from GangLong Fiberglass, building owners can ensure optimal performance and protection for their projects.

Vinyl Faced Insulation Rolls

Vinyl faced insulation rolls provide a practical and versatile option for insulating large areas in various construction projects. These rolls, which come in different widths and lengths, are designed to be quick and easy to install, offering an efficient way to cover expansive spaces such as walls, ceilings, and floors. The vinyl facing adds both a functional and aesthetic layer of protection, making it a preferred choice for environments where moisture control and durability are essential. Below is a detailed breakdown of the key features, benefits, and applications of vinyl faced insulation rolls.

Key Features of Vinyl Faced Insulation Rolls

Vinyl faced insulation rolls combine the thermal benefits of fiberglass with the moisture resistance of a vinyl barrier. These rolls are designed to provide high-performance insulation in various environments, ensuring both energy efficiency and protection against moisture damage.

Easy Installation and Flexibility

Vinyl faced insulation rolls are designed for quick and efficient installation. The flexible nature of the rolls makes them suitable for covering large, continuous areas such as walls, ceilings, and floors. This ease of installation reduces labor costs and project timelines, making them ideal for both residential and commercial applications. The rolls can be easily cut and adjusted to fit irregular spaces, ensuring seamless coverage without gaps or overlaps.

Moisture and Vapor Barrier

The vinyl facing on the insulation serves as a vapor barrier, preventing moisture from penetrating the insulation material. This feature is especially important in areas prone to humidity or condensation, such as basements, crawl spaces, or metal buildings. By protecting the insulation from moisture, vinyl faced rolls help to reduce the risk of mold, mildew, and water damage.

Benefits of Vinyl Faced Insulation Rolls

Vinyl faced insulation rolls offer numerous advantages that make them a popular choice for large-scale projects. These benefits include energy efficiency, durability, and moisture protection, all of which contribute to creating a comfortable and sustainable indoor environment.

Enhanced Thermal Performance

One of the primary benefits of vinyl faced insulation rolls is their ability to provide superior thermal insulation. The fiberglass core effectively traps air, reducing heat transfer and improving energy efficiency. By maintaining stable indoor temperatures, these insulation rolls help reduce heating and cooling costs, making them an energy-efficient option for any building.

Durability and Long-Term Effectiveness

The combination of fiberglass insulation and vinyl facing creates a durable and long-lasting insulation solution. The vinyl barrier adds an extra layer of protection, ensuring that the insulation maintains its effectiveness over time. This durability is particularly beneficial in environments where the insulation may be exposed to wear and tear, such as in garages, warehouses, and utility rooms.

Moisture Control and Protection

The vinyl facing serves as a reliable vapor barrier, providing critical protection against moisture. This moisture control feature is essential in preventing water damage and ensuring the longevity of both the insulation and the building structure. In spaces like basements, metal buildings, or areas with high humidity, vinyl faced insulation rolls offer a practical solution for reducing the risk of mold, mildew, and rust.

Applications of Vinyl Faced Insulation Rolls

Vinyl faced insulation rolls are versatile and can be used in a wide range of applications across residential, commercial, and industrial sectors. Their ability to be customized and their ease of installation make them suitable for various building types.

Residential Applications

In residential buildings, vinyl faced insulation rolls are commonly used in areas such as attics, basements, crawl spaces, and garages. These spaces often require insulation that provides both thermal protection and moisture resistance, and vinyl faced rolls excel at fulfilling these needs. The vinyl facing also offers a clean, polished look for areas where the insulation might be exposed, such as in unfinished basements or utility rooms.

Commercial and Industrial Applications

Vinyl faced insulation rolls are widely used in commercial and industrial settings, including warehouses, manufacturing plants, and agricultural buildings. These environments often experience significant temperature fluctuations and require insulation that can handle both moisture and thermal challenges. Vinyl faced insulation rolls provide an effective solution for maintaining temperature control and preventing moisture-related damage, such as rust or mold growth. The insulation is easy to install, making it an efficient choice for large-scale projects.

Metal Buildings

Metal buildings, particularly those in industrial settings, benefit from the moisture and temperature regulation provided by vinyl faced insulation rolls. The vinyl backing serves as a vapor barrier, reducing the risk of condensation, which can lead to rust, mold, and mildew. These rolls help maintain a stable indoor climate while providing a durable and long-lasting insulation solution.

Efficiency in Large-Scale Projects

Vinyl faced insulation rolls are particularly well-suited for large-scale construction projects due to their size and ease of installation. The roll format allows for continuous coverage, which is ideal for large areas such as commercial warehouses or expansive residential spaces.

Speed and Cost Efficiency

One of the major advantages of vinyl faced insulation rolls is the speed with which they can be installed. Since the rolls cover large areas quickly and with minimal cutting or adjustments, they reduce labor costs and project timelines. This makes them an excellent choice for large-scale projects that require fast and efficient insulation.

Seamless Coverage

The flexibility of vinyl faced insulation rolls ensures that they can be applied without gaps or overlaps, resulting in consistent and seamless coverage. This helps to maximize the thermal efficiency of the insulation and minimizes the risk of energy loss or moisture intrusion, which can occur if the insulation is improperly installed.

Aesthetic Benefits of Vinyl Faced Insulation Rolls

In addition to their functional benefits, vinyl faced insulation rolls offer aesthetic advantages, particularly when the insulation will be visible. The clean, polished look of the vinyl facing provides a finished appearance, making it suitable for exposed applications.

Clean and Professional Appearance

The vinyl facing provides a neat and tidy finish, making it ideal for spaces where insulation may be left exposed, such as in unfinished basements, garages, or utility rooms. The white or light-colored vinyl surface enhances the overall appearance of the space, giving it a professional, well-maintained look.

Customization and Versatility

Vinyl faced insulation rolls are available in a range of sizes and thicknesses, allowing them to be tailored to specific project requirements. Whether for a residential remodel or a large industrial building, there is a vinyl faced insulation roll to suit every need.

Size and Thickness Options

GangLong Fiberglass offers a variety of insulation roll sizes and thicknesses, making it easy to select the right product based on the climate and thermal needs of the space. Higher R-values are ideal for areas requiring enhanced insulation, while lower R-values may be suitable for less demanding environments.

Easy to Cut and Fit

The rolls are flexible and easy to cut, allowing them to be installed in irregularly shaped areas. This adaptability makes them an excellent choice for both standard and non-standard applications, ensuring that insulation is provided wherever it is needed.

Vinyl faced insulation rolls offer a convenient and effective solution for a wide range of construction projects. Whether used in residential, commercial, or industrial spaces, these rolls provide excellent thermal and moisture protection while being easy to install and customize. Their durability, flexibility, and aesthetic benefits make them a preferred choice for large-scale projects and exposed installations. With various sizes and thicknesses available, vinyl faced insulation rolls from GangLong Fiberglass are designed to meet the specific needs of any building.

Benefits of Vinyl Backed Fiberglass Insulation

Vinyl backed fiberglass insulation offers a range of benefits that make it a highly effective choice for various construction applications. By combining the superior thermal properties of fiberglass with the added protection of a vinyl backing, this insulation material addresses multiple concerns, including moisture control, durability, energy efficiency, and ease of installation. Whether for residential, commercial, or industrial applications, vinyl backed fiberglass insulation is versatile and reliable. Below, we break down the key benefits of this insulation solution.

Moisture Resistance and Mold Prevention

One of the primary advantages of vinyl backed fiberglass insulation is its ability to resist moisture. The vinyl facing acts as an effective vapor barrier, preventing moisture from entering the insulation and causing potential problems like mold growth, wood rot, and metal corrosion.

Protection Against Moisture Damage

In areas prone to high humidity or frequent moisture exposure—such as basements, crawl spaces, and metal buildings—the vinyl backing helps ensure that the insulation remains dry. Moisture can degrade insulation over time, but with the vinyl barrier in place, the insulation stays intact and functional, protecting the building’s structure and improving its longevity.

Mold and Mildew Prevention

By stopping moisture from infiltrating the insulation, vinyl backed fiberglass helps prevent the growth of mold and mildew. Mold can lead to serious health issues, as well as compromise the integrity of a building. This moisture control makes vinyl backed fiberglass insulation particularly beneficial in environments with fluctuating temperatures or excessive moisture.

Durability and Longevity

Vinyl backed fiberglass insulation is known for its robustness and long-lasting performance. The vinyl facing not only serves as a moisture barrier but also adds an extra layer of protection against physical damage.

Increased Durability

The vinyl layer shields the fiberglass insulation from wear and tear, reducing the likelihood of punctures or tears during installation and throughout its lifespan. This makes it an ideal choice for high-traffic or high-use areas, such as utility rooms, garages, or industrial environments.

Longevity in Challenging Environments

The added durability of vinyl backed fiberglass insulation extends its service life, particularly in harsh conditions where other insulation types may degrade. Whether exposed to the elements in a metal building or subject to temperature fluctuations in industrial settings, the insulation remains effective and protective for years.

Thermal Efficiency and Energy Savings

Vinyl backed fiberglass insulation is an excellent thermal insulator, helping to maintain consistent indoor temperatures and reducing the need for excessive heating or cooling. This results in significant energy savings, making it a valuable choice for both residential and commercial applications.

Effective Heat and Cold Resistance

The fiberglass core of the insulation resists heat flow, making it ideal for keeping indoor spaces warm during the winter and cool in the summer. By reducing the demand for heating and cooling systems, vinyl backed fiberglass insulation helps lower energy bills and improves the overall energy efficiency of the building.

Improved Indoor Comfort

By preventing temperature fluctuations, vinyl backed fiberglass insulation helps create a more comfortable indoor environment. Whether in homes, offices, or industrial buildings, it ensures that spaces remain comfortable year-round, regardless of external weather conditions.

Ease of Installation

Vinyl backed fiberglass insulation is easy to install, particularly when offered in roll form. This makes it a convenient solution for covering large areas quickly and efficiently, reducing installation time and labor costs.

Quick and Efficient Installation

The roll format simplifies the process, allowing for fast and seamless coverage across expansive areas such as walls, ceilings, and floors. This makes it an excellent choice for large-scale construction projects, where speed and efficiency are crucial.

Customizable Fit for Irregular Spaces

The flexibility of vinyl backed fiberglass insulation rolls allows them to be easily cut to fit irregularly shaped spaces. Whether insulating around pipes, corners, or other non-standard structures, the insulation can be tailored to meet specific needs, ensuring complete coverage without gaps.

Acoustic Benefits

In addition to its thermal and moisture resistance properties, vinyl backed fiberglass insulation offers acoustic advantages. The fiberglass material naturally absorbs sound, helping to reduce noise transmission within buildings.

Noise Reduction

In commercial or industrial buildings, where noise levels can be high due to machinery or equipment, vinyl backed fiberglass insulation helps reduce noise pollution. It acts as a sound barrier, minimizing the amount of noise that travels between rooms or floors. This can create a quieter, more comfortable environment for employees, visitors, or residents.

Improved Soundproofing for Residential Spaces

In residential settings, vinyl backed fiberglass insulation is often used to soundproof walls and ceilings, improving indoor comfort and privacy. This makes it a popular choice for homes, especially in multi-story buildings or apartments, where noise between units can be a concern.

Cost Efficiency in Large-Scale Projects

Vinyl backed fiberglass insulation offers substantial cost benefits, especially for large-scale construction projects. Its ease of installation and long-term performance help to reduce both upfront and ongoing costs.

Reduced Labor Costs

Because vinyl backed fiberglass insulation is easy to install, it can help reduce labor costs during construction or renovation projects. The roll format allows for quicker coverage, and its flexibility means less time is spent cutting and fitting the material. This is particularly valuable in commercial or industrial settings, where minimizing downtime and labor expenses is crucial.

Long-Term Savings on Energy Bills

The thermal efficiency provided by vinyl backed fiberglass insulation leads to long-term energy savings. By improving the building’s energy performance, it helps reduce the overall cost of heating and cooling throughout its lifespan. This makes it a cost-effective choice for property owners looking to improve energy efficiency and reduce utility expenses.

Versatility in Various Applications

Vinyl backed fiberglass insulation is highly versatile, making it suitable for a wide range of applications across different types of buildings.

Residential Applications

In homes, vinyl backed fiberglass insulation is commonly used in attics, basements, and crawl spaces, where moisture control and energy efficiency are top priorities. Its ability to resist moisture while maintaining thermal performance ensures that residential spaces stay comfortable and dry.

Commercial and Industrial Applications

For commercial and industrial buildings, vinyl backed fiberglass insulation is used in walls, ceilings, and floors to maintain temperature stability, reduce energy costs, and protect against moisture-related issues. It is particularly effective in large metal buildings, warehouses, or manufacturing facilities, where temperature fluctuations and moisture control are critical concerns.

Vinyl backed fiberglass insulation is an exceptional solution for construction projects that require a combination of thermal efficiency, moisture resistance, durability, and ease of installation. Its ability to protect against moisture and mold, along with its superior insulating properties, makes it an ideal choice for a wide range of applications, from residential homes to large industrial buildings. By offering both immediate and long-term benefits—such as energy savings, improved comfort, and reduced maintenance—vinyl backed fiberglass insulation proves to be a cost-effective, sustainable solution for building owners and contractors alike.

How about Vinyl Backed Fiberglass Insulation R-Value

The R-value of insulation is a crucial factor in determining how well it resists heat flow and maintains indoor temperatures. Vinyl backed fiberglass insulation is available in a range of R-values, allowing builders and homeowners to select the optimal level of thermal protection based on their specific needs. The higher the R-value, the more effective the insulation is at preventing heat transfer, which can lead to energy savings and increased comfort. Below, we break down the details of vinyl backed fiberglass insulation R-values, including how R-values are measured, their impact on building performance, and the factors influencing R-value selection.

What is R-Value and Why Does It Matter?

R-value is a measure of an insulation material’s resistance to heat flow. It indicates how effectively the material will prevent heat from passing through it. The higher the R-value, the better the insulation performs in terms of thermal resistance. Understanding the R-value is essential for choosing the right insulation to ensure energy efficiency and comfort in various climate conditions.

R-Value Explained

The R-value is calculated based on the thickness and type of insulation material. It is typically represented as a numerical value (e.g., R-11, R-30), with higher numbers corresponding to better insulation performance. In colder climates, higher R-values are necessary to keep buildings warm, while in hotter climates, higher R-values help maintain cooler indoor environments.

Importance of R-Value

Choosing the correct R-value helps control energy consumption and reduces heating and cooling costs. Inadequate insulation can lead to energy loss, making heating and cooling systems work harder and increasing utility bills. The appropriate R-value ensures that a building remains comfortable throughout the year, regardless of outside weather conditions.

Available R-Values for Vinyl Backed Fiberglass Insulation

Vinyl backed fiberglass insulation is available in various R-values, offering flexibility for different insulation needs. The selection of R-value depends on factors such as climate, building type, and specific areas of application.

Common R-Value Ranges

- R-11 to R-13: These lower R-values are commonly used for interior walls and less exposed areas where thermal performance is still important but not as critical. These are typical choices for standard interior applications in mild climates.

- R-19 to R-21: These mid-range R-values are often used in exterior walls and ceilings, where thermal resistance plays a larger role in maintaining comfortable indoor temperatures.

- R-30 to R-38: These higher R-values are commonly chosen for attics, roofs, and exterior walls, especially in colder climates where extreme temperatures are common. These areas require thicker insulation to prevent heat loss.

R-Value Selection by Area

- Attics: Higher R-values (R-30 to R-38) are recommended for attic insulation as heat rises and is more likely to escape through the roof. A higher R-value ensures that the attic remains well-insulated.

- Exterior Walls: For exterior walls, R-19 to R-21 is typically sufficient, but in extremely cold areas, higher R-values like R-23 or R-30 may be necessary.

- Interior Walls: Lower R-values like R-11 or R-13 are appropriate for interior walls, as these areas do not require as much thermal resistance.

Thickness and Its Impact on R-Value

The thickness of vinyl backed fiberglass insulation is directly related to its R-value. The thicker the insulation, the higher the R-value, which improves thermal resistance. However, the required thickness depends on the specific needs of the building.

Thickness and R-Value Relationship

Vinyl backed fiberglass insulation can range in thickness, typically from 3 inches (R-11) to 10 inches (R-30). Thicker insulation provides greater thermal resistance, which is essential for climates with extreme temperatures. However, thicker insulation also requires more space for installation, which can be a consideration when dealing with smaller or more confined areas.

Multiple Layers for Higher R-Values

In some cases, multiple layers of insulation may be used to achieve a higher R-value. For instance, in a climate requiring a higher level of thermal resistance, contractors may choose to stack two layers of R-13 insulation to reach an effective R-26 rating. This flexibility allows for customized insulation solutions based on specific building needs.

How to Choose the Right R-Value

Selecting the appropriate R-value for vinyl backed fiberglass insulation depends on several factors, including local climate, energy efficiency goals, and the specific application within the building.

Climate Considerations

- Cold Climates: In colder regions, higher R-values (R-19 to R-30) are necessary for exterior walls, attics, and ceilings to reduce heat loss and maintain indoor warmth.

- Warm Climates: In warmer climates, a lower R-value (R-11 to R-19) may suffice, especially for areas like interior walls and ceilings. However, ensuring sufficient insulation can still help with cooling costs by preventing heat from entering the building.

Building Use and Design

The purpose of the building plays a role in determining the required R-value. For example, commercial buildings and industrial spaces may require higher R-values in specific areas to meet energy codes or improve comfort. Additionally, multi-story buildings may need higher R-values in walls to reduce heat transfer between floors.

Energy Efficiency Goals

If reducing energy consumption is a priority, opting for a higher R-value in key areas (like attics and exterior walls) will significantly improve a building’s energy efficiency. This is particularly important in areas with extreme temperature fluctuations, where maintaining a consistent indoor temperature is crucial for comfort.

Benefits of Higher R-Values

Choosing higher R-value insulation provides several benefits beyond just improved thermal resistance. These advantages help ensure energy efficiency, comfort, and long-term performance.

Improved Energy Efficiency

The higher the R-value, the better the insulation will perform in reducing energy loss. In the long run, investing in higher R-values can lead to significant savings on heating and cooling costs. This is especially true in regions where winters are harsh or summers are extremely hot.

Increased Comfort

Higher R-value insulation helps maintain consistent indoor temperatures by preventing heat from escaping in the winter and entering during the summer. This results in a more comfortable living or working environment, regardless of the outside weather conditions.

Reduced Strain on HVAC Systems

With better thermal resistance, the need for HVAC systems to constantly work to maintain a comfortable temperature is reduced. This can extend the lifespan of HVAC units and reduce maintenance costs.

The R-value of vinyl backed fiberglass insulation is a crucial factor to consider when selecting the right insulation for a construction project. By choosing the appropriate R-value, you can significantly enhance the thermal performance of a building, leading to increased energy efficiency, reduced utility costs, and improved comfort. Whether you’re insulating attics, exterior walls, or ceilings, understanding the relationship between thickness, R-value, and application requirements will ensure that you choose the best insulation for your specific needs. With a range of R-values available, vinyl backed fiberglass insulation offers a versatile and effective solution for various climates and building types.

Key Fiberglass Insulation Manufacturers Leading the Market

Vinyl Backed Fiberglass Insulation and Application

Vinyl backed fiberglass insulation combines the thermal efficiency of fiberglass with the added benefits of a vinyl facing. This combination makes it a highly effective and versatile insulation solution for a range of residential, commercial, and industrial applications. The fiberglass core provides excellent thermal resistance, while the vinyl backing offers added protection against moisture and enhances the durability of the insulation. Below, we break down the key applications and benefits of vinyl backed fiberglass insulation, as well as the specific environments where it excels.

Reasons Why Vinyl Backed Fiberglass Insulation is Widely Used

Vinyl backed fiberglass insulation delivers a unique set of advantages that make it ideal for many building projects. The combination of fiberglass’s thermal resistance and vinyl’s moisture control properties ensures that this insulation performs effectively in a variety of settings.

Enhanced Moisture Resistance

One of the standout features of vinyl backed fiberglass insulation is its moisture resistance. The vinyl facing acts as a barrier, preventing moisture from penetrating the fiberglass insulation. This is particularly beneficial in areas that are prone to high humidity or water exposure, such as basements, crawl spaces, and metal buildings. By preventing moisture infiltration, vinyl backed insulation helps to extend the lifespan of the insulation, reduces the risk of mold and mildew growth, and maintains the material’s effectiveness over time.

Superior Thermal Performance

Fiberglass insulation, including vinyl backed versions, is known for its excellent thermal resistance. The material helps to maintain comfortable indoor temperatures by reducing heat transfer. This is particularly important for energy efficiency, as it reduces the need for heating and cooling systems to work as hard, ultimately lowering utility bills.

Durability and Longevity

The vinyl backing not only provides moisture resistance but also enhances the overall durability of the insulation. The additional layer protects the fiberglass from physical damage during installation and over time, ensuring that the insulation continues to perform effectively throughout its lifespan.

Non-Combustibility and Fire Resistance

Fiberglass is a non-combustible material, which means that vinyl backed fiberglass insulation contributes to a building’s fire resistance. This makes it a safe option for areas where fire safety is a concern, such as in attics, ceilings, and walls.

Common Applications of Vinyl Backed Fiberglass Insulation

Vinyl backed fiberglass insulation is suitable for a wide variety of applications, particularly in areas where moisture and temperature control are important. Below are some of the most common applications where this type of insulation excels.

Basements and Crawl Spaces

Basements and crawl spaces are typically areas of a building that experience high levels of moisture and humidity. Vinyl backed fiberglass insulation is an ideal choice for these spaces, as it helps to control moisture levels, prevent water damage, and maintain the insulation’s thermal performance. The vinyl layer acts as a protective barrier, preventing mold and mildew from developing, which is a common problem in damp environments.

Metal Buildings and Warehouses

Metal buildings, such as warehouses and industrial facilities, are highly susceptible to temperature fluctuations and condensation, which can affect energy efficiency and contribute to moisture-related issues. Vinyl backed fiberglass insulation provides an excellent solution for these buildings, as it offers both thermal resistance and moisture control. The vinyl layer protects the insulation from condensation and humidity, preventing it from becoming less effective over time.

Residential Attics and Exterior Walls

In residential construction, vinyl backed fiberglass insulation is often used in attics and exterior walls to help regulate temperature and improve energy efficiency. In attics, where heat rises and can escape through the roof, higher R-value insulation is needed to prevent energy loss. The vinyl facing in these applications helps to improve the insulation’s durability, particularly in spaces where exposure to moisture may be a concern.

Commercial and Industrial Insulation

Vinyl backed fiberglass insulation is frequently used in commercial and industrial applications to meet strict building codes and improve energy efficiency. These buildings require large-scale insulation solutions to maintain a comfortable working environment while reducing energy consumption. Vinyl backed fiberglass is easy to install and provides long-term thermal protection and moisture control, making it ideal for large commercial spaces and industrial facilities.

Installation of Vinyl Backed Fiberglass Insulation

The installation process of vinyl backed fiberglass insulation is straightforward and efficient, especially in large areas where quick installation is a priority. The flexibility and roll format of this insulation make it easy to cut and fit into place, allowing contractors to cover large surface areas in a short amount of time.

Quick and Efficient Installation

Vinyl backed fiberglass insulation typically comes in rolls, which makes it easier to handle and install compared to sheet or batt insulation. The rolls can be unrolled and cut to fit specific spaces, reducing the risk of gaps or areas of incomplete coverage. This quick installation process not only saves time but also reduces labor costs for large-scale projects.

Fitting into Irregular Spaces

Another advantage of vinyl backed fiberglass insulation is its flexibility. It can be easily cut and shaped to fit irregular spaces, such as around ducts, pipes, or electrical wires. This adaptability ensures that there is consistent coverage, even in challenging or hard-to-reach areas.

Benefits for Energy Efficiency and Comfort

One of the most important reasons to use vinyl backed fiberglass insulation is its contribution to energy efficiency. By reducing heat transfer and controlling moisture, vinyl backed fiberglass insulation helps maintain stable indoor temperatures and lower energy costs.

Temperature Regulation

The thermal resistance of vinyl backed fiberglass insulation helps to keep indoor temperatures consistent throughout the year. In winter, it keeps warm air inside, and in summer, it prevents hot air from entering. This reduces the workload of heating and cooling systems, leading to more energy-efficient operation.

Lower Utility Costs

The enhanced thermal performance of vinyl backed fiberglass insulation translates into lower heating and cooling bills. Because this insulation helps to maintain stable indoor temperatures, buildings can operate with less reliance on HVAC systems, resulting in long-term savings.

Vinyl backed fiberglass insulation is a versatile and effective solution for a wide range of building applications. Its combination of thermal resistance and moisture protection makes it ideal for environments that are prone to dampness or temperature fluctuations. From residential basements to industrial warehouses, this type of insulation ensures energy efficiency, durability, and improved comfort. Whether you’re working on a new construction project or a renovation, vinyl backed fiberglass insulation provides a reliable and long-lasting solution for maintaining temperature control and preventing moisture-related issues.

Why Choose Fiberglass Insulation for Ductwork: Key Advantages

How Vinyl Backed Fiberglass Insulation Contributes to Energy Efficiency

Vinyl backed fiberglass insulation plays a crucial role in improving the energy efficiency of buildings by reducing heat transfer. This type of insulation helps maintain stable indoor temperatures, minimizing the need for heating and cooling systems to operate constantly. In turn, this can lead to significant savings on energy bills, a reduction in greenhouse gas emissions, and a more comfortable living or working environment. Below, we break down the key ways vinyl backed fiberglass insulation contributes to energy efficiency in buildings.

Reducing Heat Transfer for Better Temperature Control

One of the main ways vinyl backed fiberglass insulation contributes to energy efficiency is by significantly reducing heat transfer through walls, ceilings, and floors. By creating a thermal barrier, this insulation slows down the movement of heat, helping to regulate the indoor climate.

Winter Heat Retention

During colder months, vinyl backed fiberglass insulation helps prevent warm air from escaping the building. The insulation traps the heat inside, reducing the need for additional heating and maintaining a comfortable indoor temperature. This helps to reduce the workload on heating systems, leading to energy savings.

Summer Heat Prevention

In warmer months, vinyl backed fiberglass insulation prevents hot outdoor air from entering the building. By keeping heat out, the insulation reduces the demand on air conditioning systems, helping to keep indoor spaces cooler. This minimizes the use of cooling systems, lowering energy consumption.

Long-Term Energy Savings and Reduced Utility Bills

By improving the efficiency of a building’s insulation, vinyl backed fiberglass helps reduce the strain on HVAC (heating, ventilation, and air conditioning) systems. This results in long-term energy savings and lower utility bills.

Reduced Heating and Cooling Demand

Because the insulation slows down the movement of heat, buildings require less energy to maintain a consistent temperature. This is especially beneficial in regions with extreme climates, where buildings are subjected to significant temperature fluctuations. By reducing the need for constant heating in the winter and cooling in the summer, vinyl backed fiberglass insulation helps keep utility costs down year-round.

Less Wear on HVAC Systems

With less demand on heating and cooling systems, HVAC units experience less wear and tear, which can extend their lifespan and reduce maintenance costs. This makes vinyl backed fiberglass insulation a cost-effective choice over the long term.

Environmental Benefits and Reduced Carbon Footprint

Vinyl backed fiberglass insulation is not only beneficial for energy efficiency but also for the environment. By reducing energy consumption, this type of insulation plays a role in decreasing the carbon footprint of a building.

Lower Greenhouse Gas Emissions

Energy-efficient buildings consume less energy, and as a result, they produce fewer greenhouse gas emissions. Vinyl backed fiberglass insulation helps achieve this by lowering the energy needed for heating and cooling. As buildings use less energy from nonrenewable sources, they contribute to a cleaner and more sustainable environment.

Support for Green Building Certifications

Many commercial and residential projects seek to meet sustainability standards such as LEED (Leadership in Energy and Environmental Design) or other green building certifications. Vinyl backed fiberglass insulation is an effective component in achieving these certifications, as it enhances a building’s energy performance, contributing to the overall sustainability goals of the project.

Increased Market Value and Appeal of Energy-Efficient Buildings

Buildings that prioritize energy efficiency are not only more comfortable and environmentally friendly but also tend to have higher market value and greater appeal to potential buyers or tenants.

Higher Property Value

Energy-efficient buildings, which offer lower operational costs, are increasingly sought after in the real estate market. By installing vinyl backed fiberglass insulation, property owners can increase the value of their building, making it more attractive to buyers who are looking for long-term savings and reduced utility bills.

Appeal to Sustainability-Conscious Buyers

As sustainability becomes a higher priority for many buyers and renters, properties with energy-efficient features such as vinyl backed fiberglass insulation are seen as more desirable. These buildings are perceived as more comfortable and cheaper to maintain, which adds to their marketability.

Vinyl backed fiberglass insulation is an effective and efficient solution for improving a building’s energy performance. By reducing heat transfer, lowering heating and cooling demands, and contributing to environmental sustainability, it provides long-term benefits that extend beyond just energy savings. Whether in residential, commercial, or industrial applications, this insulation contributes to reduced utility costs, a smaller carbon footprint, and an overall more comfortable indoor environment. Additionally, it increases the market value of a property, making it an appealing choice for both builders and homeowners.

Maintaining R-Value in Compressed Fiberglass Insulation

FAQs about Vinyl Backed Fiberglass Insulation

Fiberglass insulation is widely used for its affordability, fire resistance, and thermal efficiency, but it may not be the best choice in all situations. One of the primary concerns with fiberglass insulation is its vulnerability to moisture. When fiberglass gets wet, it can lose its insulating properties, and moisture buildup can lead to mold growth. Additionally, fiberglass particles can be irritating to the skin, eyes, and respiratory system during installation, so proper protective gear is required. In some cases, other insulation materials may be preferred for their ease of installation, moisture resistance, or better performance in specific environments, such as spray foam or mineral wool.

Vinyl on its own is not typically used as an insulating material, but when combined with fiberglass insulation, it adds important benefits. Vinyl serves as a vapor barrier, helping to control moisture and prevent condensation from affecting the performance of the insulation. In areas prone to humidity or water exposure, vinyl backed insulation is particularly useful because the vinyl layer protects the fiberglass from becoming damp, which could otherwise reduce its effectiveness. While vinyl does not provide insulation by itself, its role in protecting the insulation material and enhancing durability makes it a valuable addition to fiberglass insulation products.

The R-value of vinyl backed insulation refers to its ability to resist heat flow, which is an important factor when choosing insulation. The R-value depends on the thickness and density of the fiberglass material used in the insulation. Generally, vinyl backed fiberglass insulation offers R-values ranging from R-11 to R-30, depending on the specific product and its application. For example, R-19 insulation is commonly used in walls, ceilings, and floors where higher thermal resistance is needed. The vinyl layer itself does not contribute significantly to the R-value but adds moisture protection, making the insulation more effective in humid environments.

Vinyl backed insulation is a type of fiberglass insulation with a layer of vinyl material adhered to one side. This vinyl facing acts as a vapor barrier, preventing moisture from penetrating the fiberglass and potentially reducing the risk of mold or mildew growth. It is commonly used in applications like metal buildings, garages, and basements where added moisture control is necessary.

Vinyl backed insulation not only provides thermal insulation but also enhances durability and aesthetic appeal, as the vinyl facing offers a clean and finished appearance. It is available in different R-values, which measure its thermal resistance, making it versatile for a range of applications. Its vapor barrier functionality helps maintain indoor air quality and energy efficiency by controlling condensation. However, proper installation is crucial to ensure its effectiveness, particularly in high-humidity areas where incorrect placement can lead to trapped moisture.

The biggest problem with fiberglass insulation is its susceptibility to moisture. If fiberglass insulation becomes wet, its thermal performance (R-value) decreases significantly, and it may create an environment conducive to mold growth. This issue is especially relevant in applications where a vapor barrier, like the vinyl backing in vinyl backed insulation, is not used or improperly installed.

Another concern is its potential to release tiny fibers into the air if not properly covered or sealed, which can cause skin irritation or respiratory issues during handling. Vinyl backing can mitigate this by encapsulating the fiberglass, reducing fiber release and making the material easier to handle and install. While fiberglass insulation is effective and widely used, addressing these challenges through proper installation and the use of vinyl backing can enhance its performance and safety.

Exposed fiberglass insulation is generally not recommended because of health and safety concerns. The tiny glass fibers can become airborne, causing skin irritation, eye discomfort, and respiratory issues if inhaled. Exposed insulation can also degrade over time, leading to a loss of effectiveness in thermal performance.

Vinyl backed fiberglass insulation addresses this issue by covering the fiberglass with a durable vinyl layer, preventing fiber release and improving safety. The vinyl facing also provides a more finished appearance and acts as a vapor barrier to protect the insulation from moisture. In areas like basements or garages, using vinyl backed insulation is a safer and more practical choice than leaving fiberglass exposed. Properly covering fiberglass insulation ensures it remains effective while minimizing health risks.

Yes, it is possible to over-insulate a house, although it is rare. Over-insulating can lead to reduced airflow and improper ventilation, which may trap moisture and lead to mold growth or structural issues. In well-sealed spaces, over-insulation can also result in overheating during warmer months, reducing indoor comfort and energy efficiency.

Vinyl backed fiberglass insulation helps balance insulation needs by providing effective thermal resistance while managing moisture with its vapor barrier. Proper planning and adhering to recommended R-values for your climate and building design are essential. Adding insulation beyond the point of diminishing returns will not significantly improve energy savings and may create unintended issues. It is best to consult energy efficiency guidelines and professionals to determine the optimal amount of insulation for your specific needs.

The difference between R13 and R19 lies in their R-value, which measures thermal resistance. R19 insulation has a higher R-value than R13, meaning it provides better resistance to heat transfer and is more effective at maintaining indoor temperatures. R13 is typically used for walls in mild climates, while R19 is better suited for exterior walls, attics, or colder climates where greater insulation is required.

Vinyl backed fiberglass insulation is available in both R13 and R19 options, offering a choice depending on application needs. In areas prone to higher moisture levels, the vinyl backing adds an extra layer of protection, improving overall performance. Selecting the appropriate R-value ensures optimal energy efficiency and comfort, with R19 being ideal for spaces requiring higher thermal resistance.

The thinnest insulation with the highest R-value is typically aerogel insulation. Aerogel panels offer an R-value of up to R10 per inch, making them far more efficient than traditional fiberglass insulation. However, aerogel is significantly more expensive and less common in residential construction.

For more accessible and cost-effective options, vinyl backed fiberglass insulation provides a balance of good R-values with moderate thickness. For example, R13 insulation can fit into 3.5-inch wall cavities, and R19 into 6-inch spaces, making them suitable for standard construction while maintaining high thermal performance. While aerogels are ideal for space-constrained or high-performance applications, fiberglass insulation remains a practical choice for most homeowners due to its affordability and ease of installation.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.