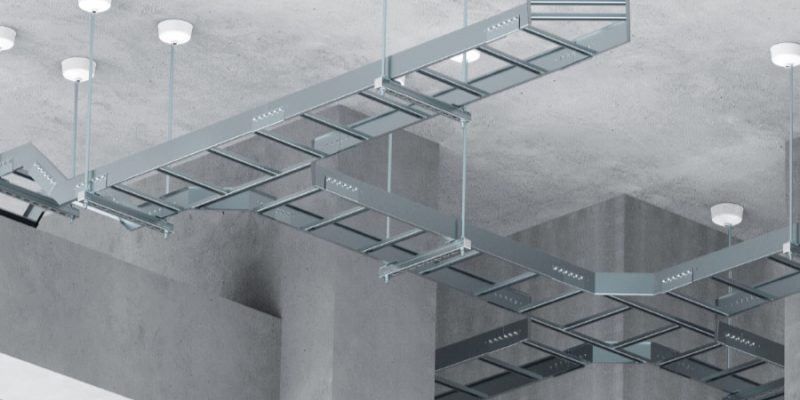

Effective cable management is essential in modern electrical installations to ensure safety, optimal performance, and simplified maintenance. Cable tray systems provide secure, accessible pathways that prevent damage, reduce clutter, and ease troubleshooting. Available in ladder, channel, and wire mesh styles, they cater to diverse environments and load requirements. Whalebone cable trays stand out with their wave-like structural design, offering enhanced strength, load distribution, and airflow—ideal for high-density settings like data centers, industrial plants, and commercial buildings. Whalebone cable tray installation for organized cable management—durable, flexible & ideal for industrial desktop tidying. Their unique form factor maximizes space efficiency, supports heavy loads, and delivers long-term durability under demanding conditions.

What is a Whalebone Cable Tray?

Definition and Overview

A whalebone cable tray is a modern, innovative cable management solution that incorporates a unique “whalebone” or “wavebone” design. This design combines strength, flexibility, and lightweight construction to provide superior support for cables in various environments. Inspired by the shape of a whale’s ribcage, the tray structure features wave-like, ribbed patterns that enhance stability without increasing the weight of the system. This makes it a popular choice for larger commercial or industrial applications. For residential spaces, a more streamlined solution, like a residential cable tray, might be more appropriate. These trays are specifically designed to meet the needs of home environments, providing a balance between functionality and aesthetics. Whether for residential or larger-scale projects, cable trays like the whalebone ensure efficient and organized cable management.

- Unique Structure: The tray’s distinct wave-like design offers both flexibility and durability.

- Enhanced Support: The design enables the tray to bear heavier cable loads compared to traditional systems.

- Lightweight: Despite its strength, the whalebone tray remains relatively lightweight, making it easier to install and handle.

- Better Airflow: The ribbed structure facilitates optimal airflow around cables, helping to reduce heat buildup.

- Flexible Design: The unique shape allows for easy modification of tray paths, adapting to evolving infrastructure needs.

How Whalebone Cable Trays Work

Whalebone cable trays work by utilizing their distinctive ribbed, wave-like construction to distribute weight and maintain cable organization. The design maximizes strength and stability, even over long spans, while minimizing the need for additional materials. This helps to prevent sagging, which can compromise cable integrity and accessibility.

- Optimal Load Distribution: The wave-like structure ensures that weight is evenly distributed, preventing uneven strain on the tray.

- Support for High-Density Cables: The design allows for effective management of high-density cable installations, particularly in industries such as data centers, telecommunications, and manufacturing.

- Easy Modifications: The flexibility of the whalebone tray allows quick adjustments to accommodate changes in the layout, making it an excellent choice for growing or dynamic systems.

- Efficient Heat Dissipation: The open, ribbed design aids in cooling cables, reducing the risk of overheating and potential system failures.

- Durable and Long-Lasting: The materials and design provide a high level of durability, ensuring long-term reliability in demanding environments.

This innovative cable management solution is especially beneficial for environments where space is limited, cables need to be supported over long spans, and future modifications are anticipated. The whalebone cable tray, with its modern design, offers a balance between performance, flexibility, and efficiency. As a new style cable tray, it adapts to various installation needs, allowing for quick adjustments and easy integration into evolving systems. Its unique structure ensures that cables remain securely supported while leaving room for future expansions or changes in layout.

CE Certification Cable Tray System: What You Need to Know

Key Features of Whalebone Cable Trays

Durability and Strength

The whalebone cable tray is engineered for durability and strength, making it well-suited for heavy-duty applications and challenging environments. Constructed from a range of materials including steel, aluminum, and fiberglass, these trays provide exceptional load-bearing capacity, ensuring that even the heaviest cables can be supported over long spans. The backbone cable tray maintains its structural integrity even under stress, providing long-term reliability.

- Material Options: Available in steel, aluminum, and fiberglass, offering versatility for different environments.

- Heavy-Duty Support: Designed to withstand substantial cable loads without compromising strength.

- Environmental Resistance: Suitable for indoor and outdoor use, enduring harsh conditions such as high humidity or extreme temperatures.

- Aesthetic Appeal: The robust materials also maintain their form and finish, ensuring the tray remains visually appealing.

Ventilation and Heat Dissipation

One of the key advantages of the whalebone cable tray is its superior ventilation properties, a crucial feature for ensuring safe and efficient cable management. The wave-like design promotes natural airflow around the cables, which is especially important in high-density installations where heat build-up can be a significant issue. This ventilation capability helps to maintain optimal operating temperatures, preventing overheating that could potentially damage cables or lead to system failures. Compared to a flat cable tray, the whalebone cable tray offers better airflow due to its unique design, making it a more effective solution for environments that require enhanced cooling and cable protection.

- Wave-Like Design: The unique structure allows air to flow freely, preventing heat accumulation.

- Prevents Overheating: Essential for high-voltage, power, and data cables, which generate significant heat.

- Ideal for Critical Environments: Perfect for power plants, data centers, telecommunications facilities, and other high-density cabling areas.

- Reduces Fire Risk: Proper heat dissipation minimizes the risk of cable fires caused by excess heat.

Customizability

The versatility of the whalebone cable tray design allows for extensive customization to meet specific project requirements. The tray can be adapted to different sizes, materials, and load-bearing capacities, making it suitable for a wide range of applications. Whether for a small-scale commercial building or a large industrial facility, the whalebone cable tray can be tailored to fit the exact needs of any installation. Additionally, the tray is compatible with various accessories such as covers, dividers, and supports, offering further flexibility for adapting to unique environmental conditions or organizational requirements.

- Flexible Sizing: Customizable lengths, widths, and depths to accommodate specific project dimensions.

- Material Choices: Adaptable for use with different materials, including galvanized steel, stainless steel, or fiberglass, to suit the environment.

- Accessory Compatibility: Can be integrated with a range of accessories to meet specific cable management needs.

- Future Proof: The modular design makes it easy to adjust or expand the system as your needs evolve.

Corrosion Resistance

Another standout feature of the whalebone cable tray is its ability to withstand corrosive environments, ensuring long-term performance even in challenging conditions. Constructed from corrosion-resistant materials like galvanized steel, stainless steel, or fiberglass, the whalebone cable tray is well-suited for installations in areas exposed to moisture, chemicals, or saltwater. These trays are ideal for use in industries such as chemical processing, marine environments, and other locations where corrosive elements are prevalent.

- Corrosion-Resistant Materials: Options include galvanized steel, stainless steel, and fiberglass, ensuring longevity in harsh conditions.

- Suitable for Harsh Environments: Ideal for chemical plants, coastal locations, and outdoor installations.

- Low Maintenance: The corrosion-resistant properties reduce the need for frequent replacements or repairs.

- Long-Term Durability: Helps to extend the life of the cable management system, providing reliable service even in extreme environments.

Choosing the Right Cable Tray Cross Section Size

Benefits of Using Whalebone Cable Trays

Efficient Cable Organization

The whalebone cable tray is designed to provide an organized, efficient pathway for cables, significantly improving cable management in any installation. The tray’s unique ribbed, wave-like structure holds cables securely in place, preventing them from becoming tangled or misrouted. This organized layout is particularly beneficial when managing large volumes of cables, such as in industrial environments or data centers. It minimizes the risk of disorganization and facilitates easy access for future maintenance, upgrades, or modifications. By keeping cables neatly separated, the tray also ensures that cables remain clearly identifiable, making troubleshooting and system expansions simpler. Whether in new installations or retrofitting existing systems, the whalebone cable tray provides an effective and flexible solution for maintaining an organized and scalable cable network.

- Prevents Cable Tangling: The ribbed structure ensures that cables stay in place and are organized without the risk of tangling.

- Easy Access for Modifications: Future upgrades or changes can be made effortlessly, improving the system’s flexibility.

- Clutter Reduction: A clean and organized tray reduces the clutter of cables, making the space more manageable and visually appealing.

Enhanced Safety

Safety is a critical consideration in electrical installations, and the whalebone cable tray excels at promoting a safer environment. The tray’s design ensures that cables are securely held in place, preventing them from being accidentally damaged or subjected to external physical stresses, which can lead to electrical faults. The tray’s wave-like structure also improves airflow, helping to regulate cable temperature and prevent overheating, a common cause of fire hazards in poorly ventilated cable systems. By reducing the risk of heat build-up, the whalebone cable tray enhances the safety of electrical installations, especially in high-density environments such as data centers or industrial facilities.

- Prevents Cable Damage: The tray secures cables, protecting them from accidental impacts, bending, or physical damage.

- Improved Ventilation: The wave design promotes airflow, reducing the risk of overheating and associated fire hazards.

- Reduced Fire Risks: Proper airflow and cable management significantly decrease the likelihood of cable failures caused by excessive heat.

Cost-Effectiveness

While the initial cost of installing a whalebone cable tray may be higher compared to traditional cable tray systems, its long-term cost-saving benefits make it an excellent investment. The tray’s durable materials, such as galvanized steel, stainless steel, or fiberglass, are designed to withstand harsh environments and resist corrosion, reducing the need for frequent repairs or replacements. This increased durability lowers maintenance costs over time, ensuring that the tray remains in service for years without significant degradation. For projects requiring more rigid, pre-formed components, precast cable trays can also offer an alternative, providing quick installation and consistent quality. Moreover, the tray’s ability to handle heavier cable loads without the need for additional supports reduces installation costs, making it an efficient choice for large-scale cable management projects.

- Long-Term Durability: The high-quality materials ensure that the tray lasts longer, reducing the frequency of replacements.

- Corrosion Resistance: Materials like galvanized steel or fiberglass prevent rust and corrosion, especially in challenging environments.

- Reduced Installation Costs: The tray’s strong, ribbed design allows it to support heavy cables without additional support structures, saving on labor and materials.

Applications of Whalebone Cable Trays

Industrial Applications

The whalebone cable tray is a preferred solution for industrial environments where durability, strength, and flexibility are essential for handling large volumes of heavy cables. It is widely used in factories, power plants, manufacturing facilities, and refineries to manage the electrical and control wiring that powers and monitors industrial operations. The tray’s robust design allows it to support high-voltage cables, power lines, and heavy-duty cables that are commonly found in these settings. Due to its wave-like structure, the whalebone cable tray efficiently distributes the load across its length, preventing sagging or instability, even under substantial cable weight. Additionally, the ability to withstand harsh conditions such as high temperatures, chemicals, or moisture makes it a reliable choice for demanding industrial environments.

- Heavy-Duty Support: Ideal for power distribution and high-voltage wiring in industrial facilities.

- Adaptability: Provides flexibility for various types of cable management in factories and plants.

- Robust Performance: Designed to resist wear and tear in environments subject to heavy use and exposure to harsh elements.

Commercial Buildings

In commercial buildings, the whalebone cable tray provides both an aesthetic and practical solution for organizing electrical, telecommunication, and data cables. Its sleek and modern design allows it to blend seamlessly with the building’s interior architecture, especially in office spaces, retail environments, and malls, where appearance is crucial. The tray’s structural design allows for easy installation and future expansions, making it suitable for both new builds and retrofitting projects. Whalebone cable trays also enable efficient cable management in crowded spaces, offering quick access for maintenance, upgrades, or repairs. Their flexibility ensures that installations can be easily adapted to accommodate changing cable loads or layouts, which is essential in dynamic commercial settings.

- Aesthetic Integration: A sleek, modern design that fits well with commercial interior aesthetics.

- Ease of Maintenance: Allows quick access to cables for routine inspections, repairs, or upgrades.

- Scalability: Can be adapted for changing requirements, making it ideal for growing commercial spaces.

Data Centers and Telecommunications

Data centers and telecommunications facilities have some of the highest cable management demands due to the need for high-density, organized, and secure wiring systems. The whalebone cable tray is well-suited for these environments, providing support for large volumes of power, data, and networking cables while promoting airflow and cooling. This is especially important for preventing overheating in high-density installations. For added protection and organization, a box type cable tray may be used in tandem with whalebone trays, offering a more enclosed structure for sensitive cables. Additionally, the flexibility of the whalebone cable tray makes it ideal for scalable systems that require frequent updates or reconfigurations. As data centers and telecommunication facilities grow, the need for adaptable and durable cable management solutions becomes even more important, and the whalebone cable tray excels in providing a long-lasting and efficient solution.

- High-Density Cable Management: Supports numerous cables, ensuring they are securely organized and easily accessible.

- Thermal Management: Helps maintain proper airflow and prevents overheating, reducing the risk of cable damage.

- Scalability and Flexibility: Suitable for expanding data or telecom networks, allowing quick adjustments as needs change.

Planning and Designing Effective Cable Tray Runs for Safety

Installation Considerations for Whalebone Cable Tray

In modern electrical systems, effective cable management relies on clear guidelines, efficient cable tray function, a robust center spine design, and precise installation. Together with stringent safety measures and regular maintenance, these elements ensure that whalebone cable trays deliver long-term reliability, optimal performance, and easy scalability in any high-density environment.

Center Spine

The central “spine” of a whalebone cable tray is a wave-like structural rib that provides enhanced strength and even load distribution. Select the spine material—steel, aluminum, or fiberglass—based on environmental factors and load demands. Calculate rib spacing to prevent sagging and ensure balanced support. Its unique form allows better airflow around cables, improving heat dissipation and accommodating future expansions without compromising rigidity.

Installation Guidelines

Begin by selecting the tray material (steel, aluminum, or fiberglass) and all necessary accessories—fasteners, brackets, supports, covers, and dividers—based on load requirements and environmental conditions. Calculate proper section spacing to prevent sagging and ensure balanced load distribution. Allow sufficient clearance for airflow around cables and future expansions. Align each tray section accurately and secure it firmly to maintain structural integrity throughout its service life.

Safety Considerations

Anchor trays to structural elements with certified mounting hardware to prevent shifting or collapse. Never exceed the tray’s rated cable capacity—overloading risks deformation and damage. Ensure installers are trained, use proper PPE, and de-energize circuits before work. Maintain clear work areas to avoid trip hazards and exercise caution around any live conductors.

Maintenance Tips

Perform scheduled inspections to confirm cables remain secure and trays are free from dust, debris, or corrosion. Clean trays regularly—especially in harsh or dusty environments—to maintain airflow. Check for signs of wear or structural fatigue, particularly at joins and supports. Promptly repair or replace any compromised sections to preserve system performance and extend service life.

FAQs about Whalebone Cable Tray

The best type of cable tray largely depends on the specific requirements of the project, including the type of cables, installation environment, and load demands. Generally, four types of cable trays are most commonly used: ladder, channel, wire mesh, and solid bottom trays.

Ladder Trays: Ideal for heavy-duty applications, especially where ventilation is crucial. Their open design allows for maximum airflow, making them suitable for high-density power cables and data cables.

Channel Trays: Perfect for smaller, lighter installations. These trays are more enclosed and are often used for telecommunications or instrumentation cables.

Wire Mesh Trays: Known for their flexibility and ease of installation. Wire mesh trays are lighter and easier to modify, making them a good choice for low-density applications.

Solid Bottom Trays: Best for installations that require complete protection of the cables from dust, debris, or other environmental factors. They are often used in harsh environments like chemical plants.

Ultimately, the best cable tray is one that suits the specific needs of your installation, considering factors like cable type, weight, environmental conditions, and required ventilation.

Both cable ladders and cable trays serve the same primary function—supporting and organizing cables—but their design and applications differ.

Cable Ladders: These are open-frame structures that resemble a ladder, with two side rails connected by rungs. This design allows for excellent ventilation, making cable ladders ideal for high-density applications like data centers and industrial facilities where heat dissipation is important. The open design also provides flexibility, allowing cables to enter or exit at any point along the span. Cable ladders are typically used for larger, heavier cables and where long spans are required between supports.

Cable Trays: Cable trays, on the other hand, can be solid or have a perforated design. They are generally used for lighter, smaller cable management. The tray design provides better protection for cables compared to the ladder, especially in environments where dust, debris, or mechanical impacts are a concern. Some trays have a solid bottom, while others may feature slots for ventilation but are less open than ladders.

The main difference lies in their design and suitability: cable ladders are preferred for heavy-duty, high-ventilation applications, while cable trays are better for environments that require more protection for the cables.

A fish plate in a cable tray system is a metal plate used to join two sections of the tray together. The term “fish plate” is derived from the shape of the plate, which resembles a fish, and it is typically used for connecting straight lengths of trays or providing extra stability in large installations.

Fish plates are essential components in cable tray systems, particularly when long spans of tray are required. They help ensure that the tray sections are securely attached to one another, preventing any misalignment or sagging that could compromise the integrity of the cable management system. These plates are usually fastened with bolts and are made from materials like steel or aluminum, depending on the environmental conditions.

Fish plates are used in both horizontal and vertical configurations, particularly in industrial or large-scale commercial installations. They help distribute the weight load more evenly across the system, providing additional support, and reducing the potential for structural failure. When selecting fish plates, it’s essential to choose those that match the material and weight requirements of the tray system.

Both cable trays and cable trenches are used to support and protect cables, but they are quite different in design, function, and application.

Cable Tray: A cable tray is an open or enclosed structure that supports electrical cables, typically mounted above the ground or along walls or ceilings. Cable trays are primarily used for organizing, supporting, and securing cables in place while offering easy access for maintenance, modifications, or future cable additions. They are commonly found in commercial, industrial, and data center environments. Depending on the needs, trays can be open (ladder trays), partially enclosed (channel trays), or completely enclosed (solid-bottom trays).

Cable Trench: A cable trench is an underground or floor-based system used to house and protect cables, often in more permanent installations. The trench is typically a narrow, long channel dug into the ground or floor, and it’s often covered with a solid lid to protect the cables from damage and environmental factors. Cable trenches are commonly used in outdoor settings, large industrial facilities, or areas where overhead cable systems are not feasible. Unlike trays, cable trenches are not easily accessible and do not provide the same ease of modification or maintenance once installed.

The key difference between the two lies in their location and accessibility. Cable trays are typically installed above ground and provide easy access to cables, while cable trenches are buried underground or within floors, offering more permanent cable protection but less accessibility for maintenance or changes.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.