When it comes to high-performance materials, the debate between woven fiberglass vs carbon fiber is ongoing across multiple industries, including automotive, sports, and aerospace. Both materials offer unique advantages, but selecting the right one can significantly impact the final product’s performance, cost, durability, and flexibility. For instance, carbon fiber is often favored for its superior strength-to-weight ratio, while woven fiberglass offers a more cost-effective alternative with great durability. The choice between woven fiberglass vs carbon fiber plays a crucial role in products like helmets, hoods, and pickleball paddles. In this article, we’ll explore key factors such as weight, strength, cost, and their specific applications to help guide your material selection process.

Woven Fiberglass vs Carbon Fiber: Weight

Fiberglass Weight

Woven fiberglass is known for being relatively lightweight, but compared to carbon fiber, it tends to be denser. This increased density can result in more bulk when used in certain applications. For example, in products like helmets or automotive components, woven fiberglass may add a noticeable amount of weight, which could influence the design and comfort of the final product. While fiberglass is a good choice for cost-effective solutions, its weight can sometimes be a limiting factor when high performance and minimal mass are critical.

Woven Fiberglass vs Carbon Fiber: Understanding Carbon Fiber Weight and Its Impact

In contrast, carbon fiber is significantly lighter than woven fiberglass, offering a clear advantage in weight-sensitive industries like aerospace, automotive, and high-performance sports. Its lower density allows for greater flexibility in design, enabling manufacturers to create lighter components without sacrificing strength or durability. In sports such as pickleball, carbon fiber’s lighter weight helps produce paddles that offer greater maneuverability and speed, essential for high-level performance. This makes carbon fiber the material of choice when every gram counts, especially in competitive environments.

Impact on Performance

The weight difference between woven fiberglass vs carbon fiber has a profound impact on performance across various industries. In sports, for instance, the lighter weight of carbon fiber in equipment like pickleball paddles leads to better control, faster reaction times, and increased overall performance. On the other hand, in automotive applications, such as hoods, the weight of woven fiberglass can provide a balance between durability and reduced weight, although it may not achieve the extreme lightness offered by carbon fiber. The choice of material influences not only the performance but also the user experience, whether it’s the agility of a sports player or the fuel efficiency of a vehicle.

How to Painting Murals on Fiberglass Reinforced Plastic

Woven Fiberglass vs Carbon Fiber vs Kevlar: Material Comparison

Fiberglass

Fiberglass is often considered a cost-effective material that provides excellent flexibility and impact resistance. It is commonly used in applications such as automotive parts, boats, and industrial equipment where durability is key. Fiberglass is made from woven strands of glass fibers that are embedded in a resin matrix, making it both strong and relatively lightweight. While not as light or strong as carbon fiber, woven fiberglass offers a good balance of performance at a much lower cost. It is particularly valued in scenarios where budget constraints are a factor, but durability and impact resistance are still required.

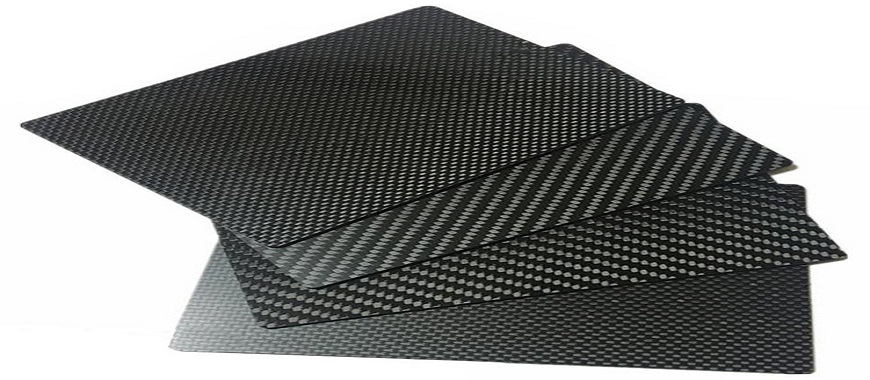

Carbon Fiber

Carbon fiber stands out for its superior strength-to-weight ratio, making it an ideal choice for high-performance applications. Its strength and rigidity are far greater than that of fiberglass, yet it is significantly lighter. This makes carbon fiber highly sought after in industries like aerospace, automotive, and sports, where performance is paramount, and every ounce of weight matters. However, its higher cost compared to woven fiberglass makes it less accessible for all applications. Carbon fiber excels in situations where reducing weight while maintaining strength is crucial, such as in lightweight car hoods, pickleball paddles, and even aircraft components.

Kevlar

Kevlar, like carbon fiber, is renowned for its high strength and impact resistance, but it is primarily used for applications that require superior toughness rather than stiffness or lightweight properties. Kevlar fibers are incredibly strong and flexible, often used in bulletproof vests, ropes, and tires. In comparison to woven fiberglass vs carbon fiber, Kevlar’s major advantage lies in its ability to absorb impact without breaking, making it ideal for protective gear and other high-impact uses. However, it does not offer the same rigidity or lightness as carbon fiber, and it can be more difficult to handle during the manufacturing process. Kevlar is typically chosen for scenarios where impact resistance outweighs the need for lightness or rigidity.

Choosing the Right Material

When deciding between fiberglass and woven carbon fiber vs Kevlar, the choice largely depends on the specific requirements of the application. If budget is a primary concern, woven fiberglass is an excellent choice, as it offers a good balance of impact resistance, flexibility, and durability at a lower cost. If the goal is to achieve the highest strength-to-weight ratio, carbon fiber is the clear winner, offering top-tier performance in both strength and lightness, though it comes at a higher price. On the other hand, if impact resistance is the primary consideration—especially in high-risk scenarios such as protective wear or military applications—Kevlar may be the best option due to its exceptional toughness, despite its lack of carbon fiber’s stiffness and lightness.

| Material | Cost | Strength | Weight | Flexibility | Impact Resistance |

|---|---|---|---|---|---|

| Fiberglass | Low | Moderate | Moderate | High | Good |

| Carbon Fiber | High | Very High | Very Low | Low | Moderate |

| Kevlar | Moderate | High | Moderate | Very High | Excellent |

By assessing the needs of your project—whether you prioritize cost, strength, weight, or impact resistance—you can choose the material that best meets your requirements.

Market Fiberglass Reinforced Plastic: Global Trends and Insights

Woven Fiberglass vs Carbon Fiber in Pickleball Paddles

Woven Fiberglass Paddles

Woven fiberglass paddles are a popular choice for pickleball players due to their affordability, flexibility, and overall good performance. These paddles are designed to offer a balanced mix of power and spin, making them ideal for players who prefer a versatile game. Fiberglass is a slightly more flexible material than carbon fiber, allowing players to generate greater spin on the ball. This feature is beneficial for those who like to add extra movement to their shots.

In terms of cost, woven fiberglass paddles are generally more affordable, making them an excellent option for recreational players or those who are just starting out in the sport. While they may not provide the same level of control or durability as carbon fiber paddles, they offer solid performance and are great for players looking for a budget-friendly option without compromising too much on power.

Advantages of Woven Fiberglass Paddles:

- Cost-effective: Woven fiberglass paddles are more affordable than carbon fiber paddles.

- Spin generation: The flexibility of the material allows for greater spin on the ball.

- Powerful hits: The slightly flexible surface helps generate powerful shots.

- Durable: While not as durable as carbon fiber, fiberglass paddles still offer good longevity.

Carbon Fiber Paddles

Carbon fiber paddles are designed for players who demand top-tier performance, especially in fast-paced games. Carbon fiber’s rigidity and lightweight properties offer superior control and precision, making it an excellent choice for advanced players and those who play in high-speed environments. Carbon fiber paddles are more durable and can withstand the rigors of aggressive play, providing a longer lifespan.

Due to their stiffer surface, carbon fiber paddles provide greater control over ball placement and consistency. This makes them a great option for players who value accuracy and finesse in their shots. However, the higher cost of carbon fiber paddles may be a deterrent for beginners or casual players.

Advantages of Carbon Fiber Paddles:

- Enhanced control: The rigidity of carbon fiber offers superior control and shot placement.

- Durability: Carbon fiber paddles are more durable and resistant to wear and tear.

- Lightweight: The material is lighter than fiberglass, reducing fatigue during long games.

- High-performance: Ideal for advanced players and high-speed gameplay, offering excellent precision and consistency.

Which Material is Better for You?

When choosing between woven fiberglass vs carbon fiber paddles for pickleball, the decision largely depends on your playstyle, skill level, and budget.

- Woven Fiberglass: If you’re a recreational player or someone just starting out, woven fiberglass paddles offer excellent value for money. They are perfect for players who enjoy spinning the ball and generating power without spending a lot on equipment.

- Carbon Fiber: If you’re an advanced player or someone looking to take your game to the next level, carbon fiber paddles provide unmatched control, precision, and durability. These paddles excel in fast-paced, high-intensity games where every shot counts.

| Material | Cost | Control | Durability | Spin | Weight | Ideal for |

|---|---|---|---|---|---|---|

| Woven Fiberglass | Low | Moderate | Moderate | High | Moderate | Recreational players, beginners |

| Carbon Fiber | High | Very High | Very High | Moderate | Low | Advanced players, competitive play |

Ultimately, your choice will depend on how much you’re willing to invest in your paddle and what aspects of the game you prioritize, whether it’s power, spin, control, or durability.

Lows Fiberglass Reinforced Plastic Pannel: Durable and Reliable

Woven Fiberglass vs Carbon Fiber: Cost

Fiberglass Cost

Woven fiberglass is generally more affordable compared to carbon fiber, making it a popular choice for budget-conscious applications. The material itself is less expensive to produce, and the manufacturing process is simpler. Fiberglass paddles, automotive parts, and even construction materials can be made from woven fiberglass at a fraction of the cost of carbon fiber components. This affordability is one of the key reasons fiberglass remains a go-to material for mass-produced items that don’t necessarily require the highest performance standards but still need durability and flexibility.

The relatively low cost of woven fiberglass makes it a suitable option for industries and individuals looking to save money while still benefiting from the material’s strength and versatility. Whether it’s for everyday consumer goods, sporting equipment, or automotive parts, fiberglass provides a good balance between price and functionality, making it a great value in many applications.

Carbon Fiber Cost

Carbon fiber, on the other hand, is significantly more expensive due to its complex manufacturing process and the cost of raw materials. The production of carbon fiber involves high-tech techniques, such as the use of precursor fibers, specialized machinery for weaving, and heat treatments to cure the fibers into a rigid structure. This results in a much higher per-unit cost when compared to woven fiberglass.

The expensive production process and the specialized equipment required to work with carbon fiber contribute to its high price point. As a result, carbon fiber is typically found in premium products and industries where its exceptional properties—such as strength, lightness, and stiffness—are essential. For example, in automotive manufacturing, carbon fiber is used in high-performance vehicles to reduce weight and improve fuel efficiency, even though the material comes at a steep price.

Cost-Effectiveness vs Performance

One of the major debates when considering woven fiberglass vs carbon fiber is whether the increased performance of carbon fiber justifies its higher cost in certain applications. While carbon fiber excels in providing a superior strength-to-weight ratio and enhanced durability, the high price tag can be a barrier for many applications, especially when similar performance can be achieved with less expensive materials like woven fiberglass.

In high-end automotive hoods or racing vehicles, the performance benefits of carbon fiber—such as reduced weight for better handling and fuel efficiency—can justify the investment. Similarly, in sports like cycling or tennis, carbon fiber’s lightness and rigidity allow for better control, faster speeds, and longer-lasting gear, making the cost worthwhile for competitive athletes.

However, for applications where weight and strength are important but not critical, such as in recreational sports gear or mass-produced consumer items, woven fiberglass offers a more cost-effective alternative. While it may not offer the same elite performance, it still provides solid durability, flexibility, and impact resistance at a fraction of the cost.

Choosing between woven fiberglass vs carbon fiber depends on the specific requirements of the application and the budget constraints. If cost is a major concern and performance demands are moderate, woven fiberglass offers a more affordable option without compromising too much on functionality. However, if superior strength, lightness, and durability are essential, and the budget allows for the investment, carbon fiber is the ideal choice.

Ultimately, the decision comes down to the value placed on performance versus cost-effectiveness and the specific demands of the product or application.

Woven Fiberglass vs Carbon Fiber: Strength

Fiberglass Strength

Woven fiberglass is a material known for its impressive strength, especially considering its relatively low cost. It has the ability to withstand substantial forces and stresses, making it ideal for products that require durability and impact resistance. However, one of the key differences between woven fiberglass vs carbon fiber is that fiberglass is more flexible and less stiff. This flexibility allows fiberglass to absorb impacts and distribute stress more evenly, which makes it a great choice for applications where shock absorption and resilience are critical.

Fiberglass is often used in industries where a balance between strength and flexibility is needed, such as in automotive parts, boats, and sports equipment. While it doesn’t have the same level of rigidity as carbon fiber, it offers good overall performance and is particularly effective in scenarios where impact resistance is more important than stiffness.

Carbon Fiber Strength

Carbon fiber is renowned for its superior strength-to-weight ratio. It is much stiffer than woven fiberglass, making it an ideal material for applications that require high rigidity and minimal flexibility. Carbon fiber’s rigidity gives it outstanding strength, allowing it to withstand extreme stresses and forces without bending or flexing. This makes it particularly useful in industries where lightweight materials need to be strong and highly rigid, such as aerospace, high-performance automotive, and competitive sports gear.

The superior strength of carbon fiber, combined with its light weight, makes it the go-to material when both strength and weight reduction are critical. While its lack of flexibility may make it less ideal for certain applications where impact resistance is key, its strength and rigidity are unmatched, especially in environments that demand performance under high stress.

Examples of Application

When comparing the applications of woven fiberglass vs carbon fiber, the differences in strength and flexibility become clear. Here are some common examples where each material excels:

- Automotive Hoods: Carbon fiber is often used in high-performance automotive hoods because of its incredible strength and rigidity. The material provides the necessary structural integrity while reducing the overall weight of the vehicle, improving speed and fuel efficiency. The stiffness of carbon fiber helps maintain the shape of the hood at high speeds, ensuring it can withstand the forces of high-performance driving.

- Helmets: In helmets, both materials offer protection, but their specific strengths cater to different needs. Carbon fiber helmets are preferred for their superior strength and rigidity, offering high protection against impacts and absorbing force efficiently. The stiffness of carbon fiber ensures the helmet maintains its shape and protects the wearer from severe impacts. On the other hand, fiberglass helmets provide excellent resilience and impact resistance, absorbing shock effectively while being more flexible, which can sometimes make them more comfortable in some applications.

Advantages of Woven Fiberglass:

- Flexibility: Ideal for applications that require impact resistance and the ability to absorb shocks.

- Durability: Strong enough for general use in industries like automotive and sports.

- Cost-effective: A good alternative when flexibility and impact resistance are more critical than rigidity.

Advantages of Carbon Fiber:

- Superior strength-to-weight ratio: Offers exceptional strength while being lightweight, making it ideal for high-performance products.

- High rigidity: Provides excellent stiffness, which is crucial in high-stress applications where flexibility is less important.

- Durability: Carbon fiber components tend to last longer and maintain their shape under stress, even in extreme conditions.

The choice between woven fiberglass vs carbon fiber ultimately depends on the specific needs of the application. If strength and rigidity are the highest priorities, carbon fiber is the material of choice. However, if flexibility and impact resistance are needed without compromising too much on strength, woven fiberglass remains a strong, cost-effective alternative.

FAQs about Woven Fiberglass VS Carbon Fiber

When comparing fiberglass and carbon fiber, the answer largely depends on the specific needs of the application. Carbon fiber is generally considered superior in terms of strength-to-weight ratio, rigidity, and durability. It is lighter, stronger, and stiffer than fiberglass, which makes it ideal for high-performance applications such as aerospace, high-end sports equipment, and automotive components. However, carbon fiber comes with a higher price tag due to its complex manufacturing process and specialized properties.

On the other hand, fiberglass is more affordable and offers great impact resistance and flexibility, which makes it suitable for general-purpose applications where flexibility and cost are more important than extreme strength and stiffness. It’s commonly used in boats, construction, and sports gear for recreational use.

Carbon fiber is significantly stiffer than fiberglass, making it the preferred material for applications that require high rigidity and minimal flex. Carbon fiber’s stiffness is one of its most prized characteristics, which allows it to perform exceptionally well in demanding environments. The increased stiffness translates to greater strength and structural integrity, which is crucial for industries like aerospace, automotive, and high-performance sports equipment. Carbon fiber’s rigidity allows it to maintain its shape under high stress, reducing deformation and providing precise performance.

In contrast, fiberglass is more flexible and less stiff compared to carbon fiber. While fiberglass still offers a significant amount of strength, its ability to bend and absorb impact without breaking makes it better suited for applications requiring flexibility and shock absorption. For instance, in boat hulls or sports equipment, fiberglass’s flexibility allows for better shock resistance and impact dissipation, making it more forgiving when subjected to stresses.

While carbon fiber is known for its superior strength-to-weight ratio, it is not the ultimate material in all scenarios. There are materials that may be better in certain aspects or provide specific advantages depending on the needs of the application. For example:

Graphene: Often considered a contender for being better than carbon fiber in terms of strength and flexibility. Graphene is a single layer of carbon atoms arranged in a two-dimensional lattice. It has been shown to have an unprecedented combination of strength, lightness, and electrical conductivity. However, it is still not as widely used as carbon fiber due to its high production cost.

Titanium: Titanium alloys are known for their corrosion resistance, strength, and durability, making them ideal for aerospace and medical implants. While titanium may not be as light as carbon fiber, its resilience and strength in certain environments make it an excellent alternative for specific uses.

Kevlar: While not as strong or rigid as carbon fiber, Kevlar is renowned for its impact resistance and tensile strength, making it an excellent material for bulletproof vests and protective gear. Kevlar is superior in energy absorption but doesn’t offer the same level of stiffness or weight-saving capabilities as carbon fiber.

When choosing between carbon fiber and fiberglass for pickleball paddles, both materials offer distinct advantages based on your playstyle and priorities.

Carbon fiber paddles are preferred by advanced players and those looking for high-performance gear. Carbon fiber offers an exceptional strength-to-weight ratio, making the paddle lighter and more responsive. This rigidity and stiffness allow for precise shot control, consistent ball placement, and powerful shots. Carbon fiber paddles are also more durable and long-lasting, withstanding the wear and tear of frequent use. However, they come at a higher cost, making them more suitable for players who are serious about the sport.

Fiberglass paddles, on the other hand, are generally more affordable and are often preferred by recreational players or those just starting with the game. The flexibility of fiberglass allows for better spin generation, making it easier to add spin to your shots. While not as stiff as carbon fiber, the added flexibility offers a more forgiving feel, helping players who need a bit more power without sacrificing comfort.

Which material is better for pickleball really depends on your budget and playstyle. If you are looking for high performance, control, and durability, carbon fiber is the way to go. However, if you’re looking for a more budget-friendly option with a focus on spin and versatility, fiberglass paddles are a great choice.

As the editor of GangLong Fiberglass, I have years of experience and in-depth research, focusing on cable tray products, fiberglass solutions, and grille systems. I incorporate years of industry insights and practical experience into every content, committed to promoting the progress of the industry. At GangLong Fiberglass, my commitment is reflected in every product, from innovative cable trays to durable fiberglass solutions and sturdy grille systems. As an authoritative voice in the industry, my goal is to provide valuable information to professionals and businesses and promote forward-looking solutions.